Preparation method of heat exchanger with efficient heat exchange and corrosion resistance and provided with graphene protective membrane

A graphene and anti-corrosion technology, applied in the direction of graphene, single-layer graphene, damage protection, etc., can solve the problems of complex preparation, affecting life and use effect, insufficient adhesion, etc., and achieve simple and convenient preparation and excellent mechanical properties , Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the patent of the present invention will be further described.

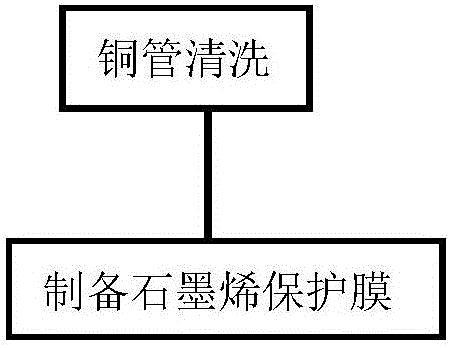

[0019] Such as figure 1 Shown, the preparation method of the heat exchanger with graphene protective film with high heat exchange efficiency and anti-corrosion of the present invention The specific preparation method is as follows:

[0020] First, clean the copper tube: put it in acetone and boil it for 10 minutes, then put it in ethanol and boil it for 10 minutes, then clean it with deionized water, then soak it in glacial acetic acid for 10 minutes, then clean it with deionized water. The final step is to blow dry with nitrogen, which is to remove impurities such as organic matter and copper oxide that may be attached to the copper tube.

[0021] Next, graphene is grown on the surface of the copper tube, the growth temperature is set to 1000°C, a protective gas is introduced into the reaction chamber, and the temperature is rapidly raised to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com