Canal evaporator

An evaporator and steam technology, applied in the direction of evaporator/condenser, heat exchanger type, indirect heat exchanger, etc., can solve the problems of weakening the effect of surface strengthening measures, drying up inside the tube, and small proportion, so as to reduce energy consumption The effect of conversion and utilization efficiency, enhanced heat transfer, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

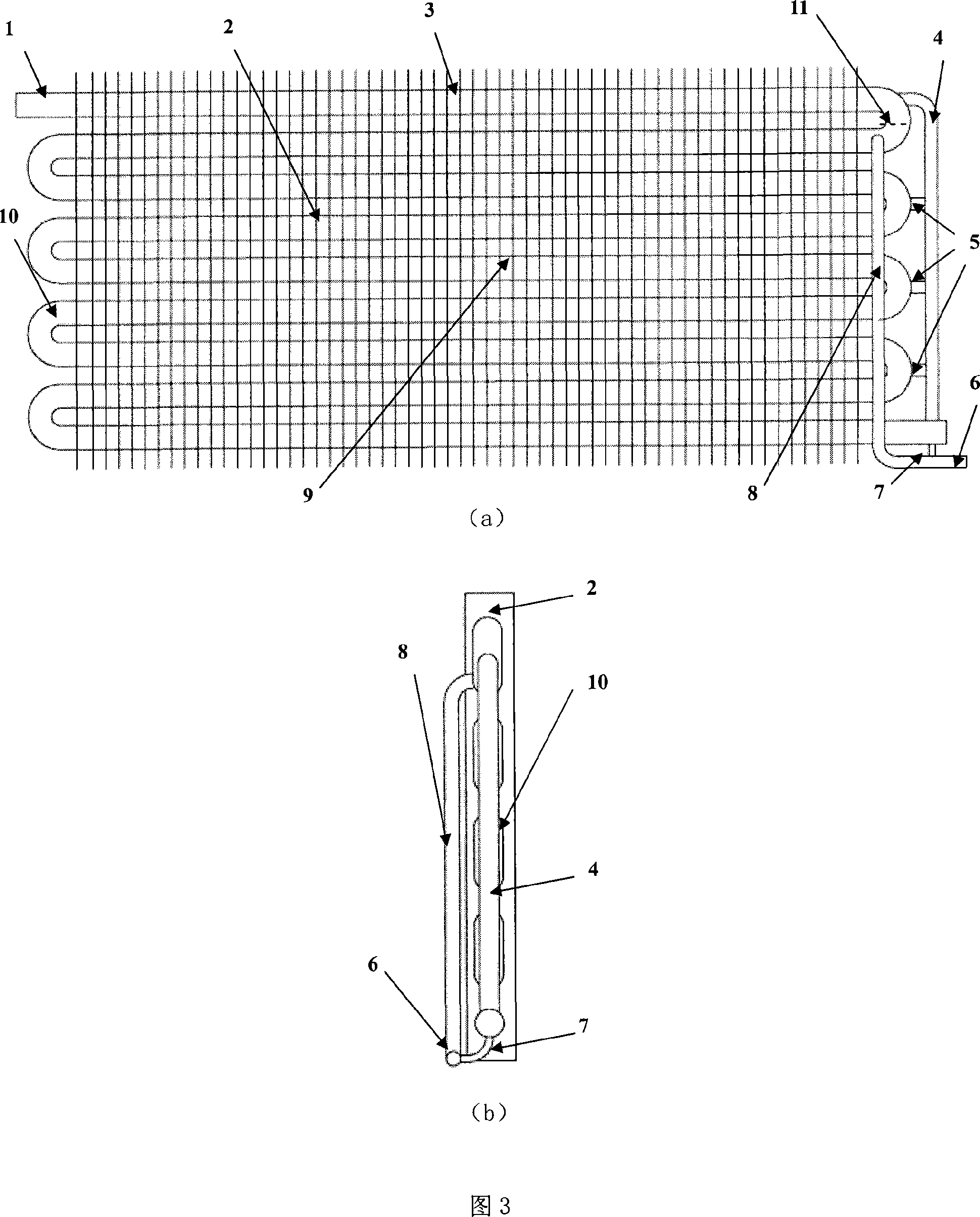

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

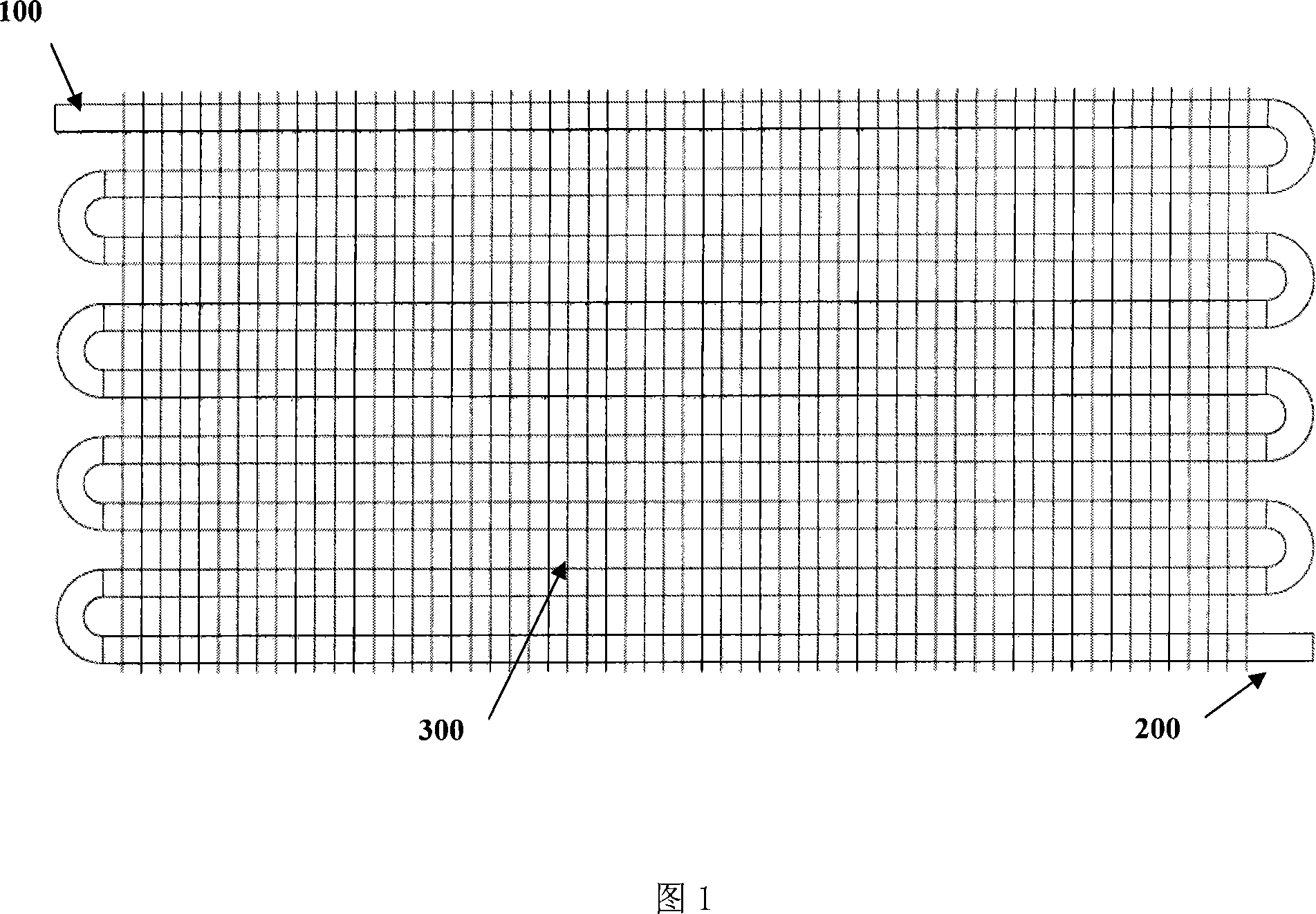

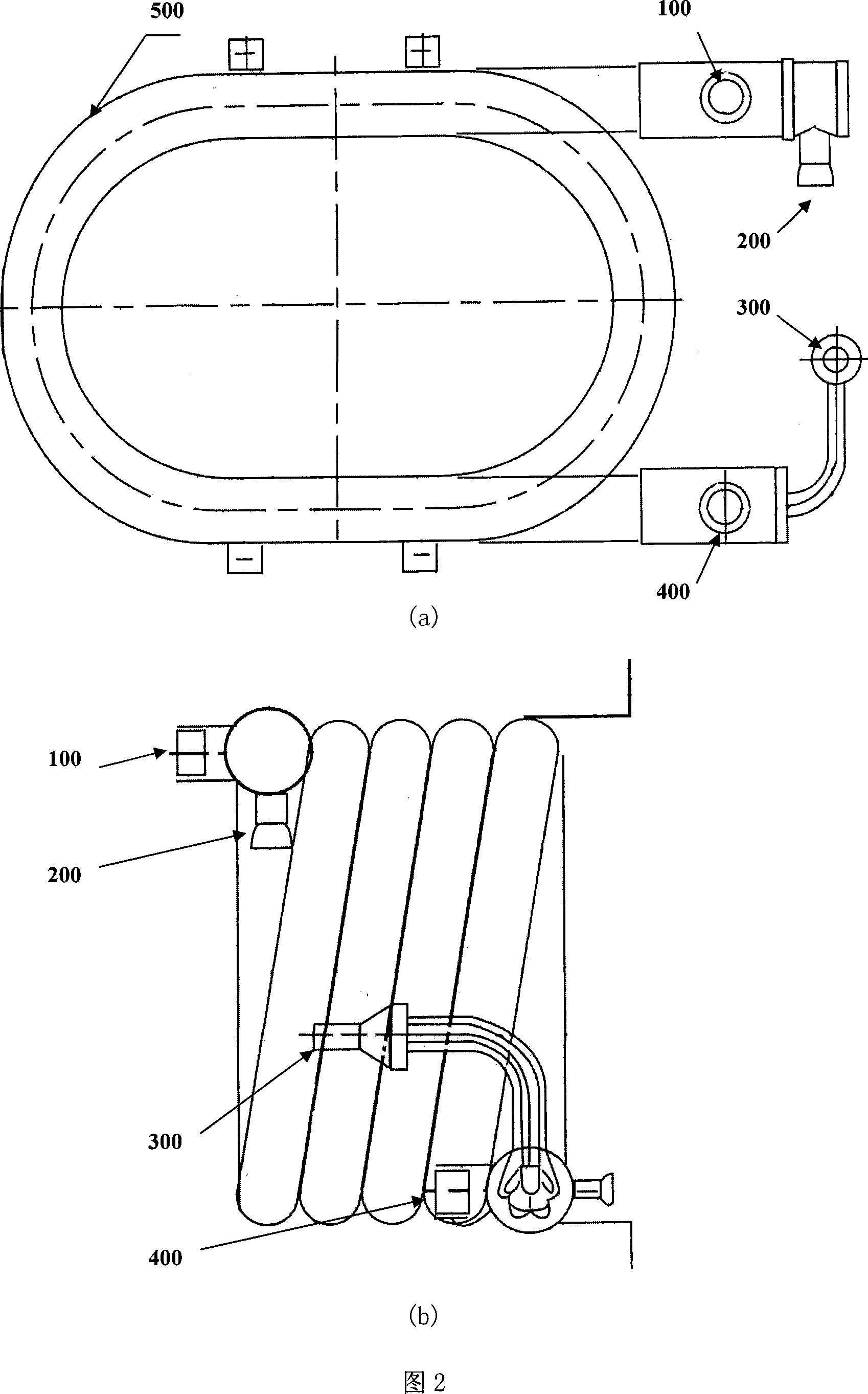

[0026] Fig. 3 is a schematic diagram of a novel high-efficiency air heating (or cooling air) evaporator of the present invention. Including 1. Evaporated liquid (or refrigerant, the same below.) Steam outlet, 2. Fins, 3. Superheating section, 4. Gas collection and exhaust pipe, 5. Gas collection and exhaust port, 6. Evaporated liquid inlet , 7. Residual evaporated liquid liquid phase circulation return pipe, 8. Evaporated liquid inlet pipe, 9. Serpentine heat exchange section, 10. Serpentine heat exchange tube, 11. Separation device. A new type of high-efficiency air-heated evaporator, the heat exchange part of the integral serpentine heat exchange tube (10) is divided into a serpentine heat exchange section (9) and a superheating section (3) by a partition device (11), and the uppermost part is the evaporated liquid vapor Outlet (1), the other end is sealed. The external expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com