Liquid cooling heat management device for power battery pack of vehicle

A power battery pack and management device technology, applied in battery/fuel cell control devices, secondary batteries, transportation and packaging, etc., can solve problems such as low cooling efficiency, small heat transfer coefficient, and reduced efficiency and reliability of battery packs , to achieve the effect of improving compactness and enhancing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

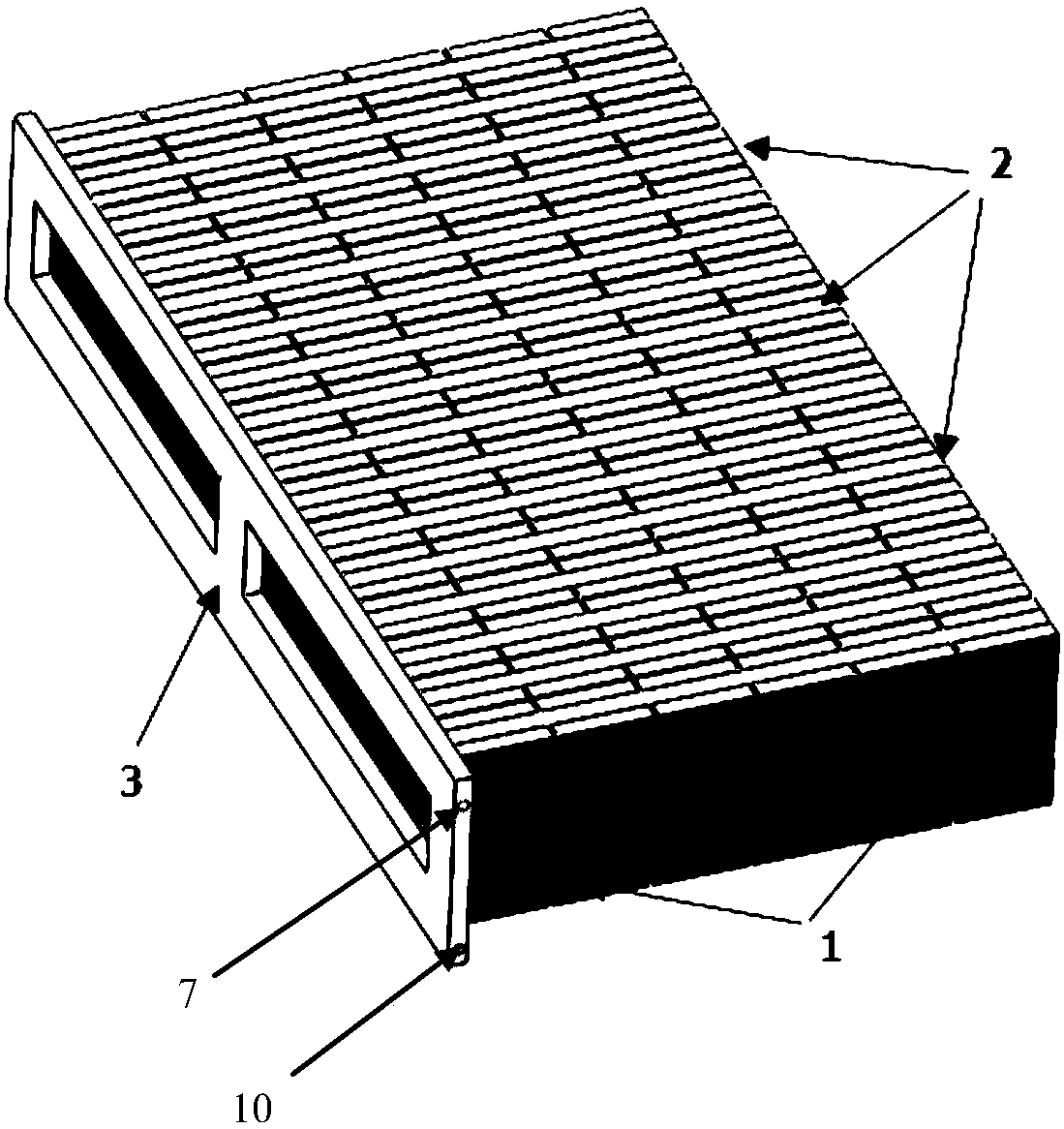

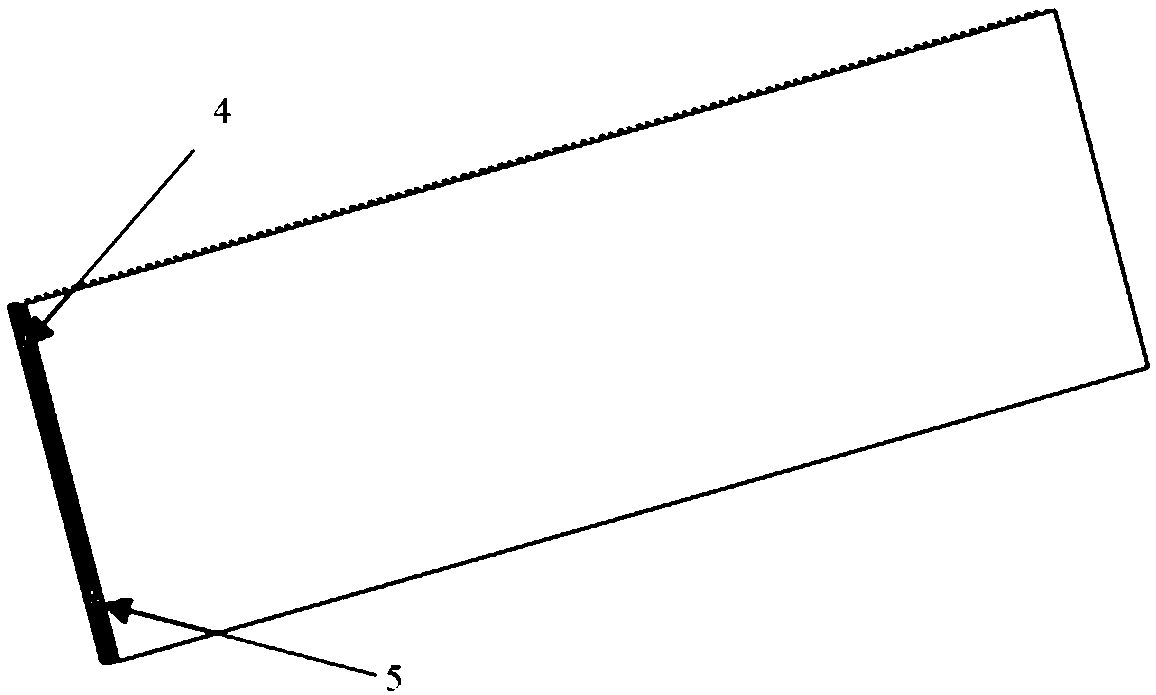

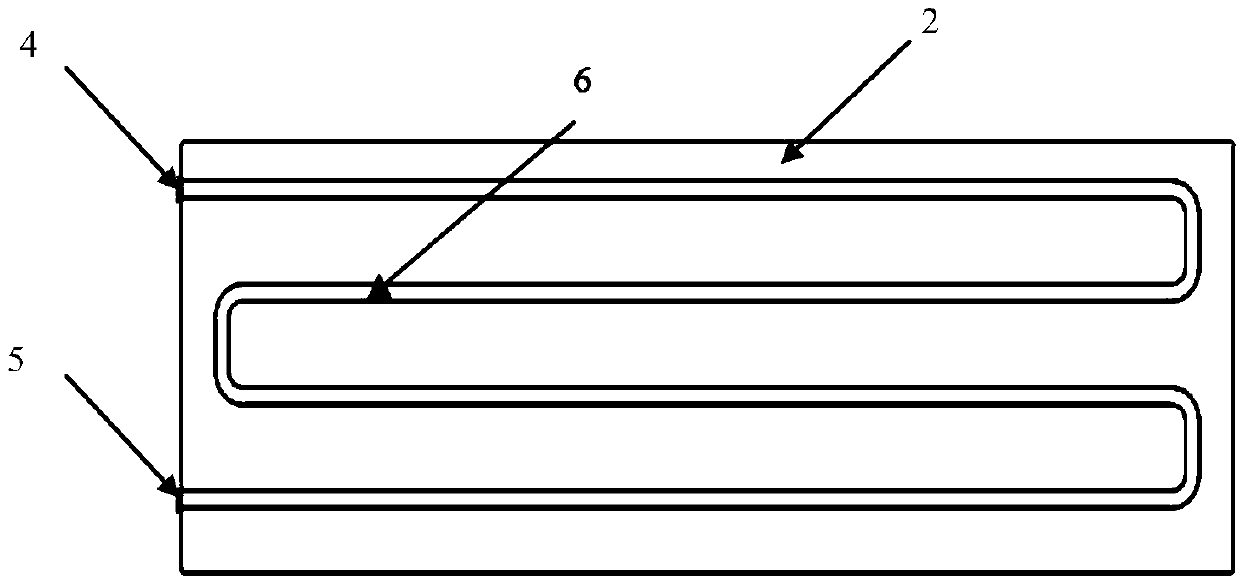

[0018] see Figure 1 to Figure 5 As shown, the present invention discloses a liquid-cooled thermal management device for a vehicle power battery pack, which includes a plate-shaped coolant distributor 3, several liquid-cooled plates 2, and a battery pack 1; one end surface of the liquid-cooled plate 2 A liquid inlet 4 and a liquid outlet 5 are provided, and a channel 6 is provided inside the liquid cooling plate, and one end of the channel 6 is connected to the liquid inlet 4 and the other end is connected to the liquid outlet 5; The channel 6 is selected from one of rectangular straight channel, rectangular S channel, circular channel, Z-shaped channel, mosaic channel and double-layer channel. A more complicated channel 6 can make the coolant in the channel 6 flow through more areas and absorb more heat.

[0019] The upper part of the inner surface of the coolant distributor is provided with a row of coolant distribution outlets 8, and the lower part of the inner surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com