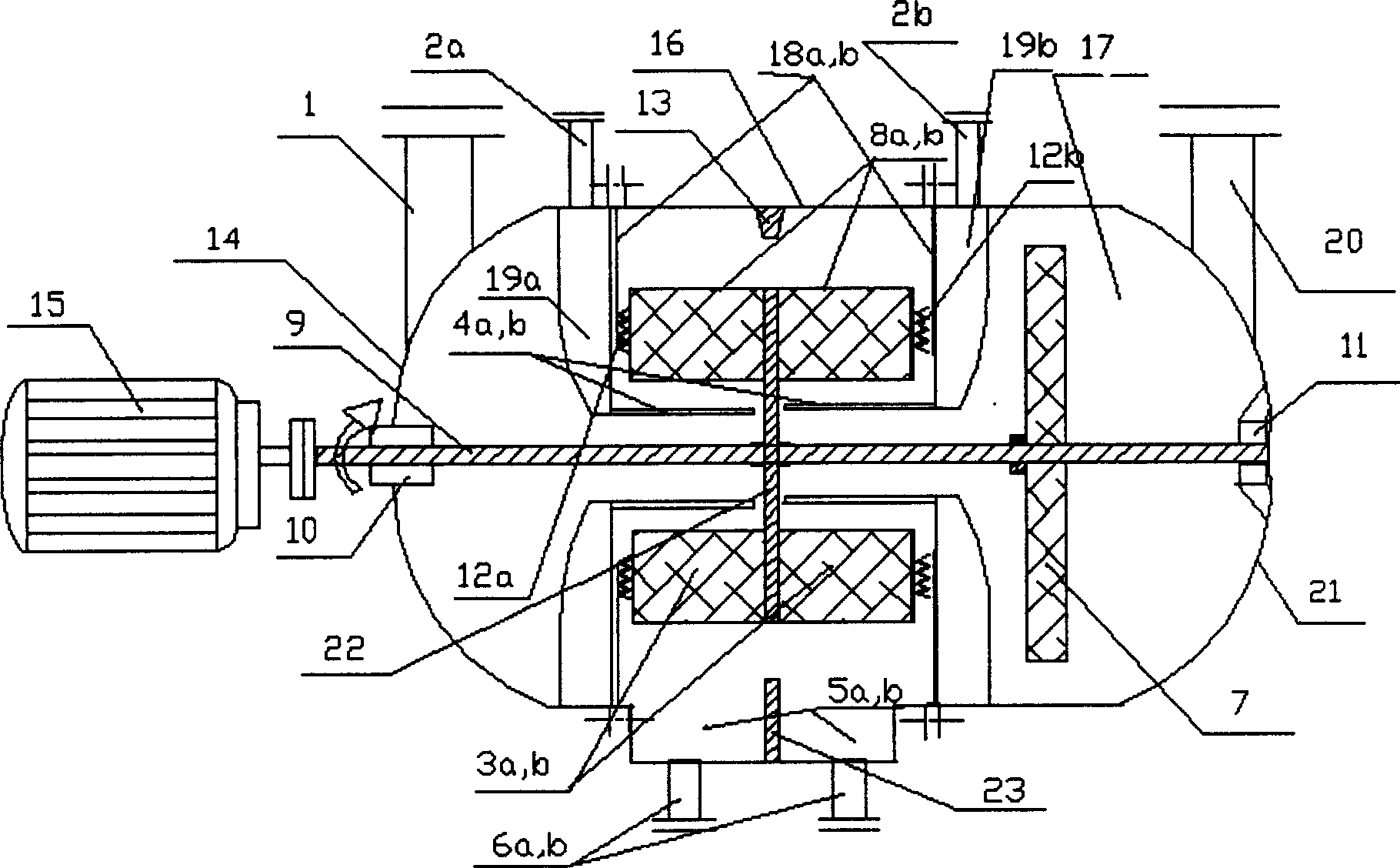

Ultragravity field rotary bed mass transfer and conversion unit

A technology of reaction equipment and supergravity field, applied in chemical/physical/physical chemical mobile reactors, fractionation, chemical instruments and methods, etc., to reduce equipment size, reduce equipment investment, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

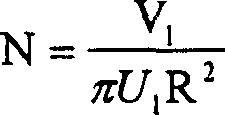

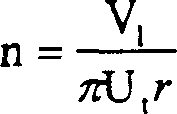

Method used

Image

Examples

Embodiment 1

[0037] The supergravity field rotating bed mass transfer and reaction equipment of the present invention is applied to the absorption of sulfur dioxide in the tail gas of a sulfuric acid plant by using ammonium sulfite. The principle is ammonium sulfite and SO 2 After the reaction, ammonium bisulfite is generated. Ammonium bisulfite is a good reducing agent. When the ammonium bisulfite reaches a certain concentration, it leaves the system as a product. The process flow of the prior art is a two-stage method, which adopts two operating towers to complete, and the SO2 in the raw material gas of the one-stage tower is 2 The absorbing liquid is high-concentration ammonium-containing liquid, which is equivalent to the concentration tower, the raw material gas of the second-stage tower is the outlet gas of the first-stage tower, and the absorbing liquid is the lower-concentration ammonium-containing liquid, which is equivalent to the purification tower, and the outlet gas is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com