Display substrate, manufacture method thereof, display panel and mask plate

By introducing an auxiliary electrode in parallel with the cathode layer in the organic light-emitting diode display panel and optimizing the deposition position of the cathode layer, the problem of resistance voltage drop of the cathode layer is solved and the picture quality is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

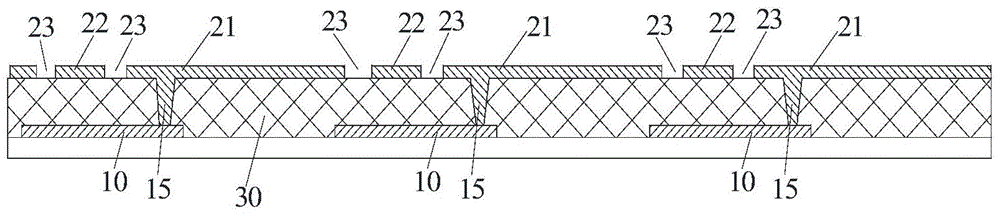

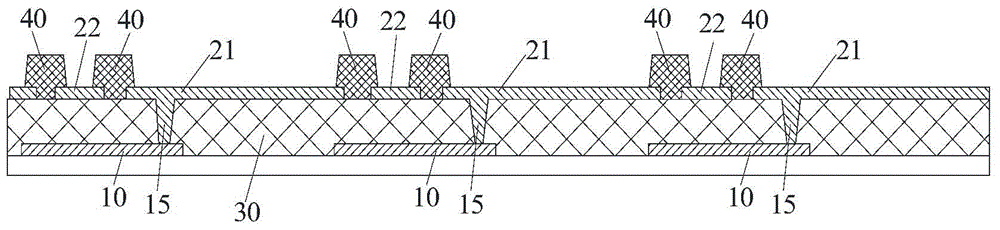

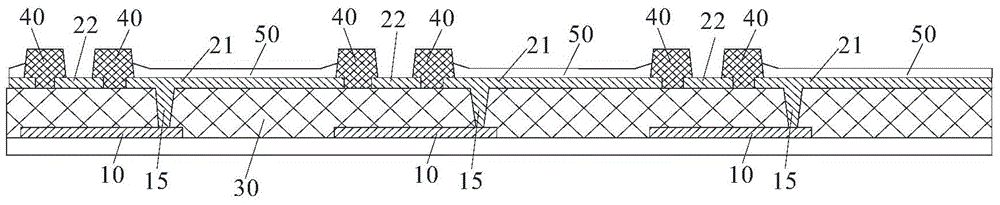

[0073] As a preferred embodiment of the present invention, the display substrate may further include a spacer 40 that insulates and separates the auxiliary electrode 22 from the anode 21 . The spacer 40 can ensure that the auxiliary electrode 22 is reliably insulated from the anode 21 . In the present invention, the specific shape of the spacer 40 is not specifically limited, as long as it can insulate and space the auxiliary electrode 22 from the anode 21 . Specifically, an insulating space 23 is respectively formed on both sides of each auxiliary electrode 22, and a spacer 40 is arranged in each of the insulating space 23, and a part of the spacer 40 is set in the corresponding insulating space 23, and the other part It protrudes from the anode layer to insulate the auxiliary electrode 22 from the adjacent anode 21 .

[0074] As mentioned above, the auxiliary electrode 22 should be arranged at a position that does not affect the normal light emission of the display panel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com