Display panel and display device

A display panel and display device technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of uneven brightness, lower impedance, and insufficient driving current of the display device 1, so as to improve uneven brightness and reduce voltage. The effect of reducing, reducing complexity and its cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

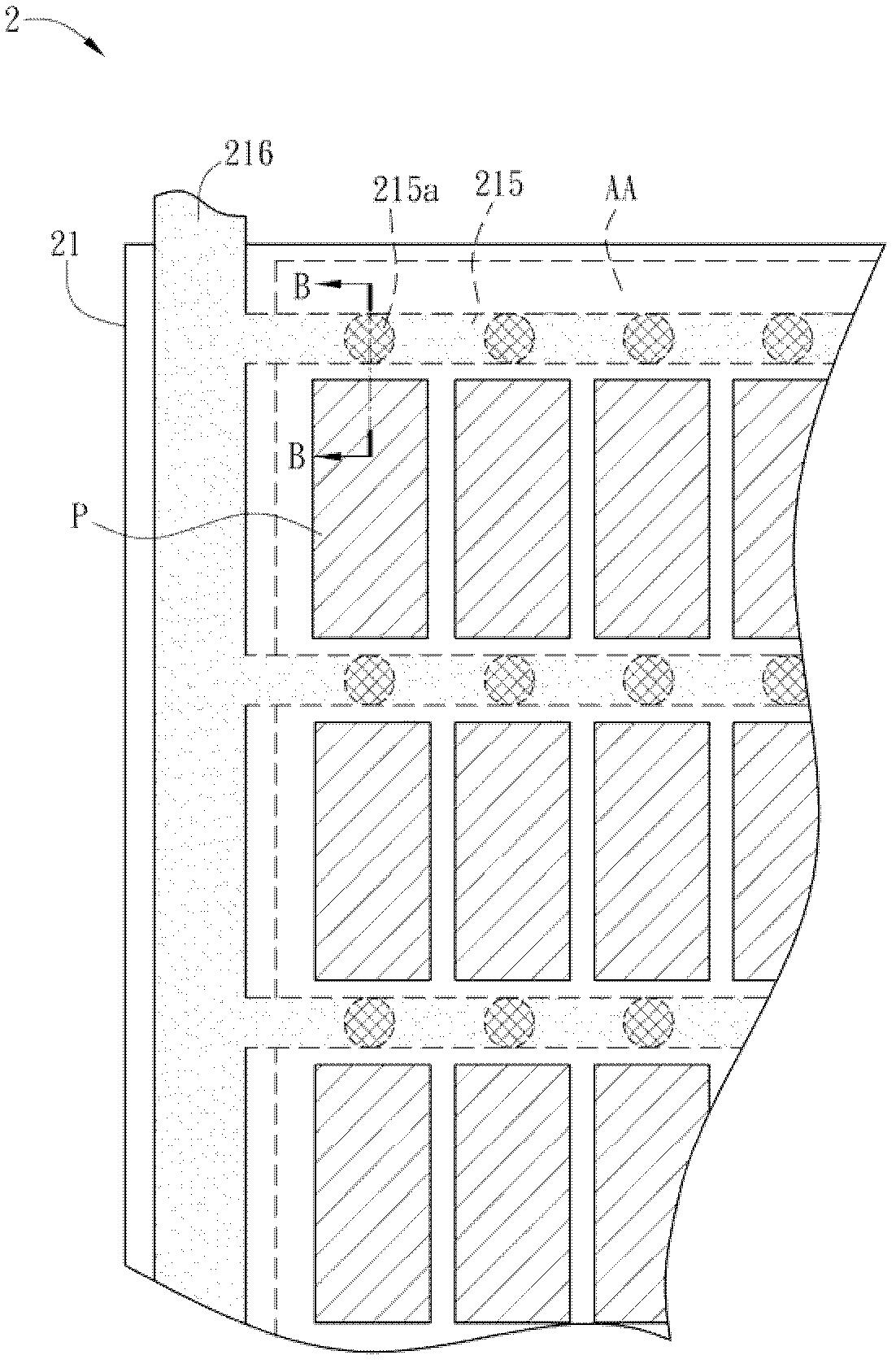

[0060] Please refer to Figure 2A and Figure 2B As shown, among them, Figure 2A is a partial schematic diagram of an organic light emitting display device 2, and Figure 2B for Figure 2A , the schematic cross-sectional view of the line B-B. Herein, an organic light emitting display device emitting upward light is taken as an example.

[0061] The display device 2 includes a display panel 21 , and the display panel 21 may have a display area AA for displaying image frames. In addition, the display panel 21 may include a plurality of pixels P disposed on a substrate N, and each pixel P may have an organic light emitting element E respectively. Such as Figure 2B As shown, the organic light emitting element E includes a pixel electrode layer 213 , an organic light emitting layer 212 and a common electrode layer 211 . The organic light emitting layer 212 is sandwiched between the pixel electrode layer 213 and the common electrode layer 211 to define the area size of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com