Microbubble generation device and use thereof

A device for generating micro-bubbles, applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of complex structure and high cost of bubble generation methods, and achieve small pressure drop of equipment, simple structure and good foaming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

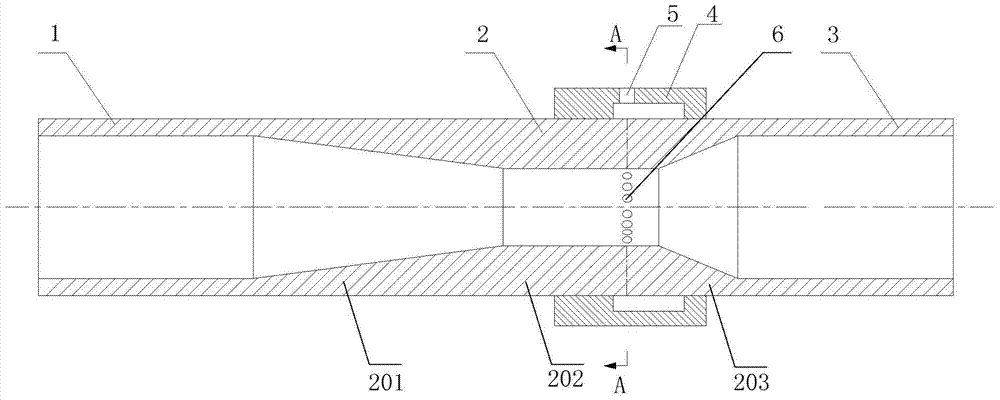

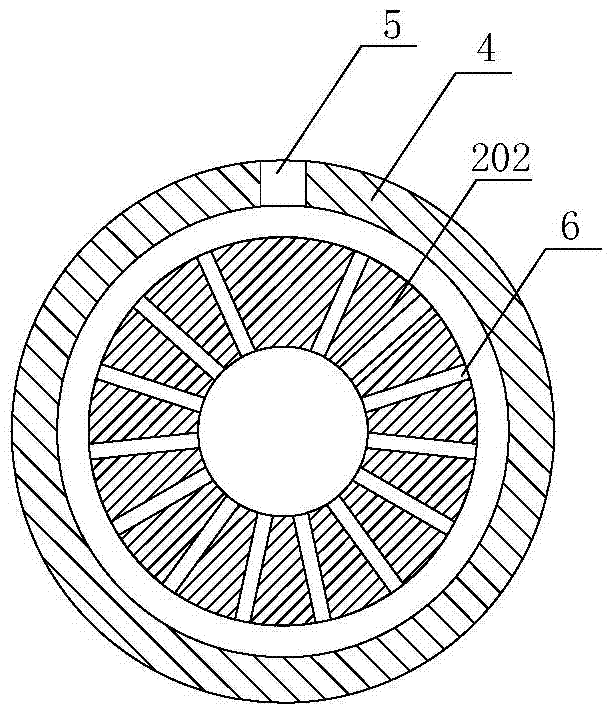

[0033] Such as figure 1 with figure 2 As shown, the microbubble generating device provided in this embodiment includes an input pipeline 1, a venturi tube 2 and an output pipeline 3 connected in sequence; the input pipeline 1, the venturi tube 2 and the output pipeline 3 are on the same straight line; Venturi tube 2 comprises a constriction section 201, a throat section 202 and an expansion section 203 connected in sequence, the input pipeline 1 communicates with the constriction section 201, and the expansion section 203 communicates with the output pipeline 3; the input pipeline 1 and the output pipeline 3 All are equal-diameter straight pipes, the inner diameter of the input pipe 1, the inner diameter of the entrance of the contraction section 201, the inner diameter of the outlet of the expansion section 203 and the inner diameter of the output pipe 3 are the same, and are larger than the inner diameter of the throat section 202. The upper ring of the outer pipe wall of ...

Embodiment 2

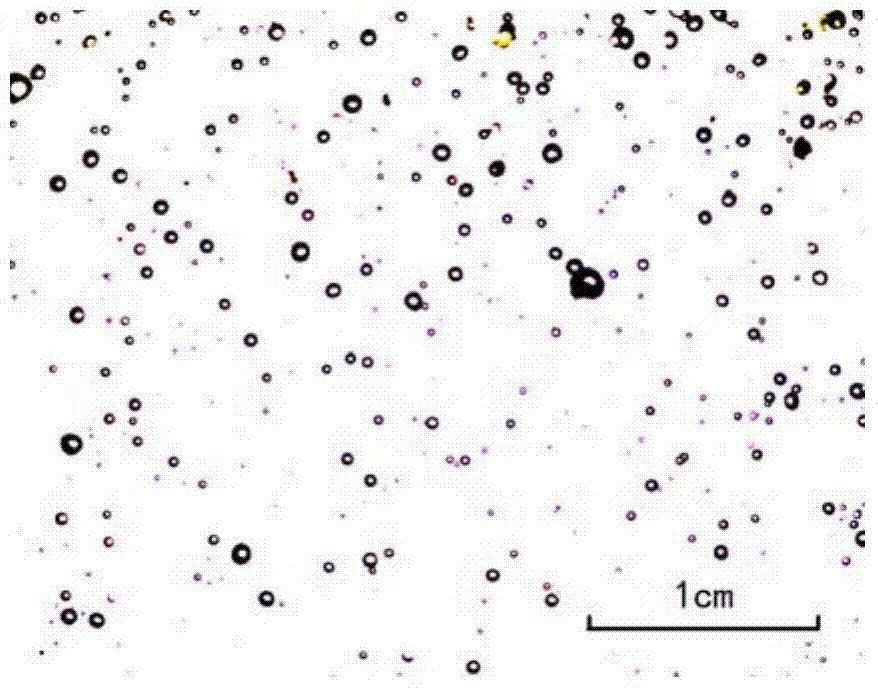

[0038] In this embodiment, the microbubble generating device provided in Example 1 is used to prepare microbubbles in liquid molten salt, wherein the inner diameters of the molten salt delivery pipeline, the input pipeline 1 and the output pipeline 3 of the microbubble generating device are both 50 mm, and the liquid molten salt The flow rate is 20m 3 / h, the number of air holes 6 is 10, the diameter of the air holes 6 is 1mm, the volume percentage of the microbubbles formed in the liquid molten salt is 1% to 5%, and the normal distribution in the liquid molten salt can be obtained Microbubbles with an average diameter of 0.5mm to 3mm, such as image 3 As shown, microbubbles with a diameter of 0.5 mm to 3 mm accounted for more than 80% of the total number of microbubbles.

Embodiment 3

[0040] In this embodiment, the microbubble generating device provided in Example 1 is used to prepare microbubbles in liquid molten salt, wherein the inner diameters of the molten salt delivery pipeline, the input pipeline 1 and the output pipeline 3 of the microbubble generating device are both 50 mm, and the liquid molten salt The flow rate is 20m 3 / h, the number of ventilation holes 6 is 8, the diameter of the ventilation holes 6 is 1mm, and the volume percentage of microbubbles formed in the liquid molten salt is 0.2% to 2%, which can obtain a normal distribution in the liquid molten salt Microbubbles with an average diameter of 0.1mm to 1mm, such as Figure 4 As shown, microbubbles with a diameter of 0.1 mm to 1 mm accounted for more than 90% of the total number of microbubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com