Patents

Literature

189 results about "Venturo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Venturo or Venturo House is a prefabricated house designed by Finnish architect Matti Suuronen in 1971. It is composed of fiberglass-reinforced polyester plastic, polyester-polyurethane, and acrylic glass. In the late 1960s Suuronen became known for his round-shaped Futuro House and now wanted to create a new "weekend cottage". Venturo House was a part of Suuronen's Casa Finlandia series, known as the model CF-45. Other models were CF-100/200 (1969) and CF-10 (1970), number indicating the floor area in square meters.

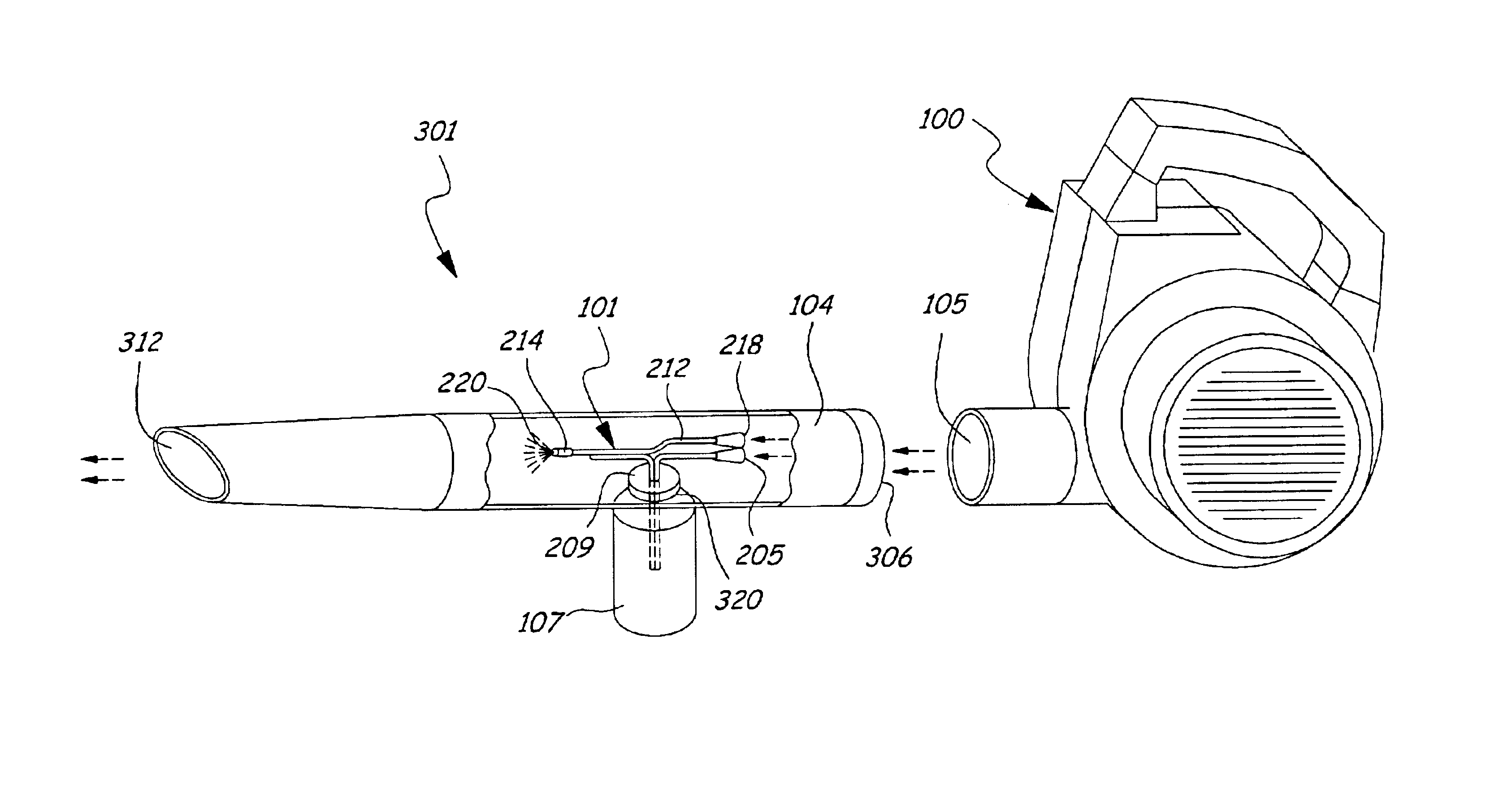

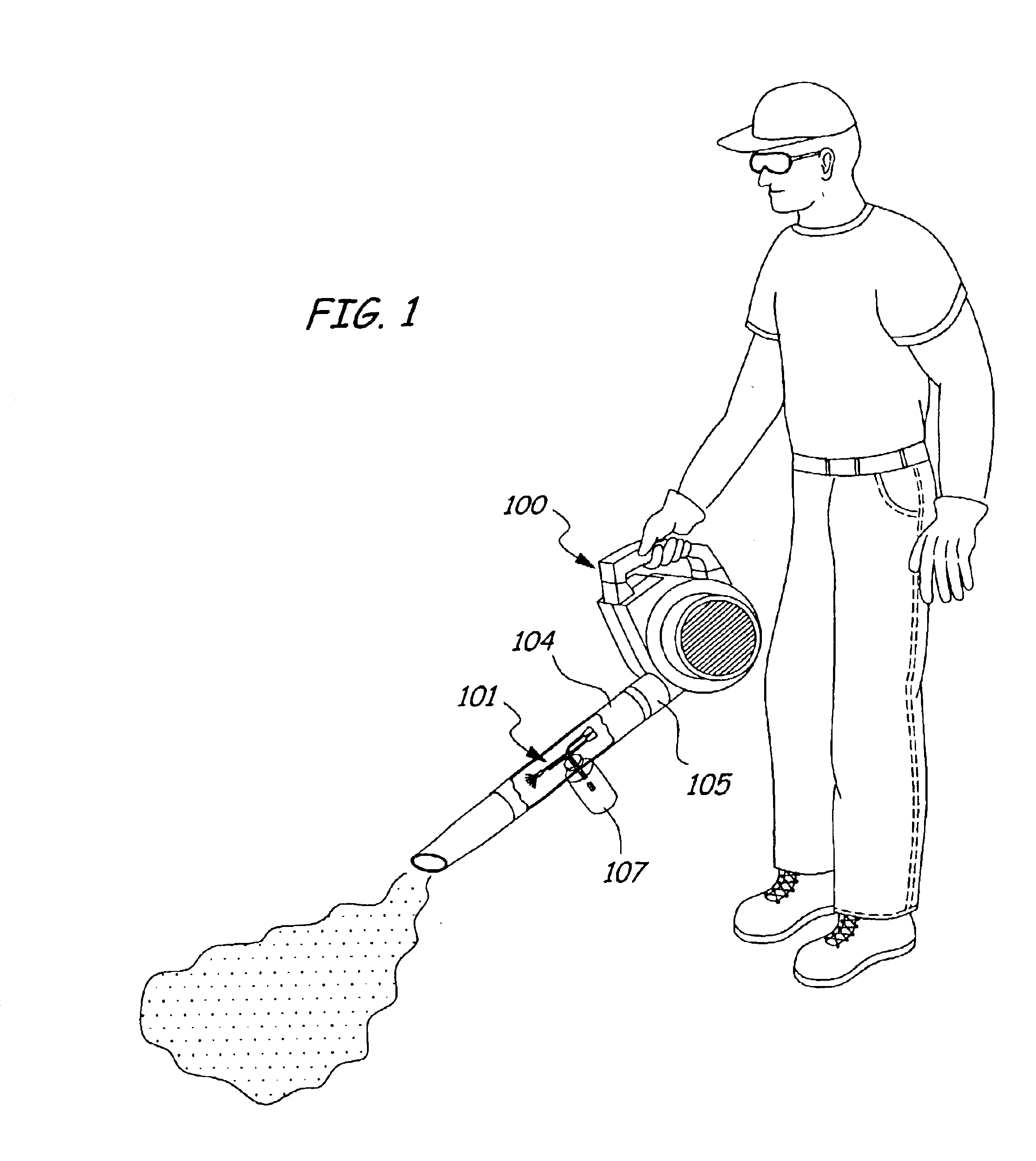

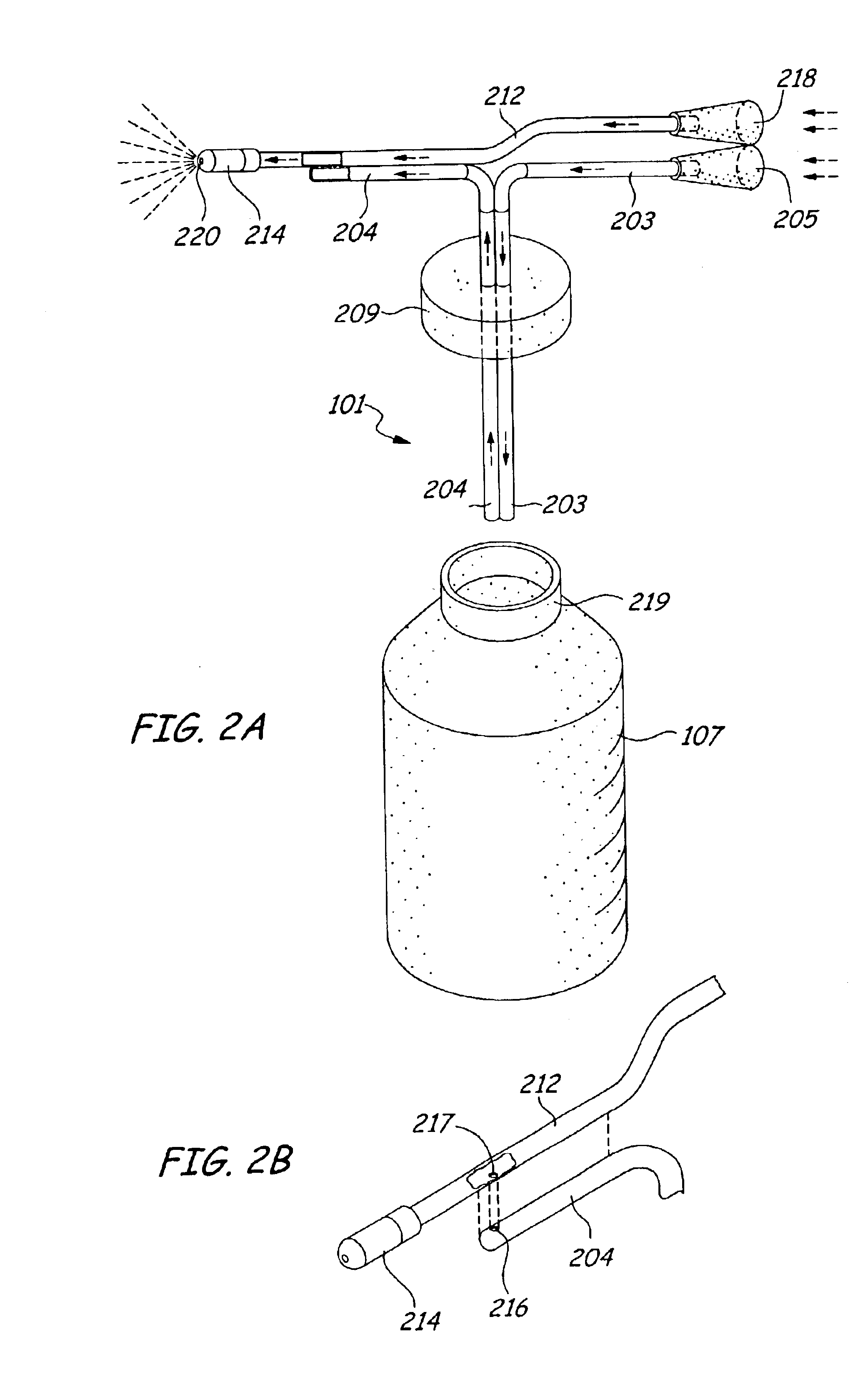

Apparatus for adapting air blower to perform liquid dispersal and related method

An apparatus for adapting a blower system to the dispersing of liquid material is partially housed within an extension tube of a portable blower and includes a pressurizing tub with an inlet for accepting airflow discharged by the blower. The pressurizing tube discharges into a liquid container thus increasing pressure within the container. An extraction tube exits the container and meets a Venturi tube that also accepts airflow discharge by the blower. A vacuum is created in the extraction tube through first and second apertures that allow fluid communication between the Venturi tube and the extraction tube. The vacuum created in the extraction tube extracts liquid from the liquid container and the liquid is drawn out of the extraction tube through the Venturi hole into the Venturi tube mixing with air flowing there through and discharging into airflow by-passing the spray adapter apparatus.

Owner:CLARK LACEY BOOTH

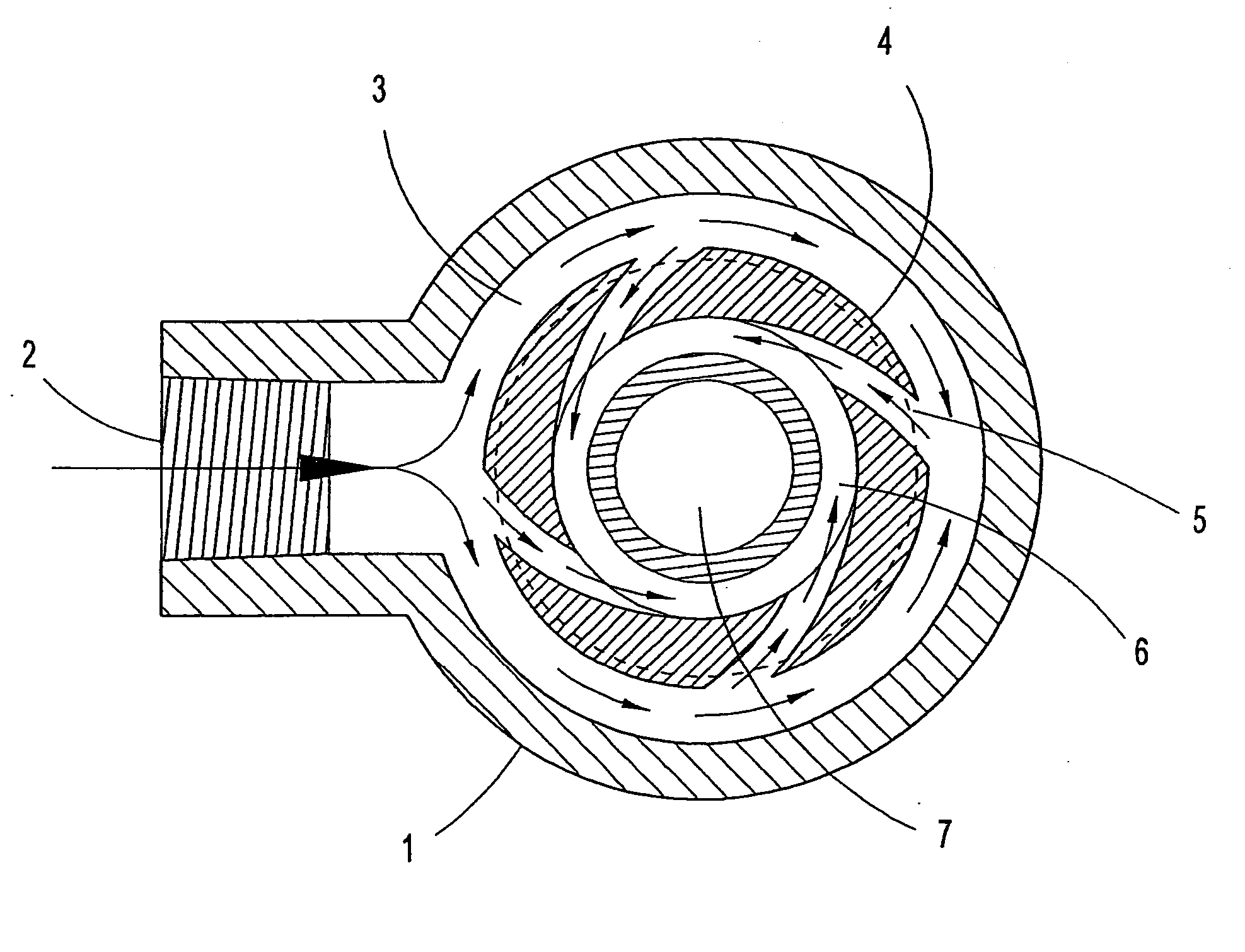

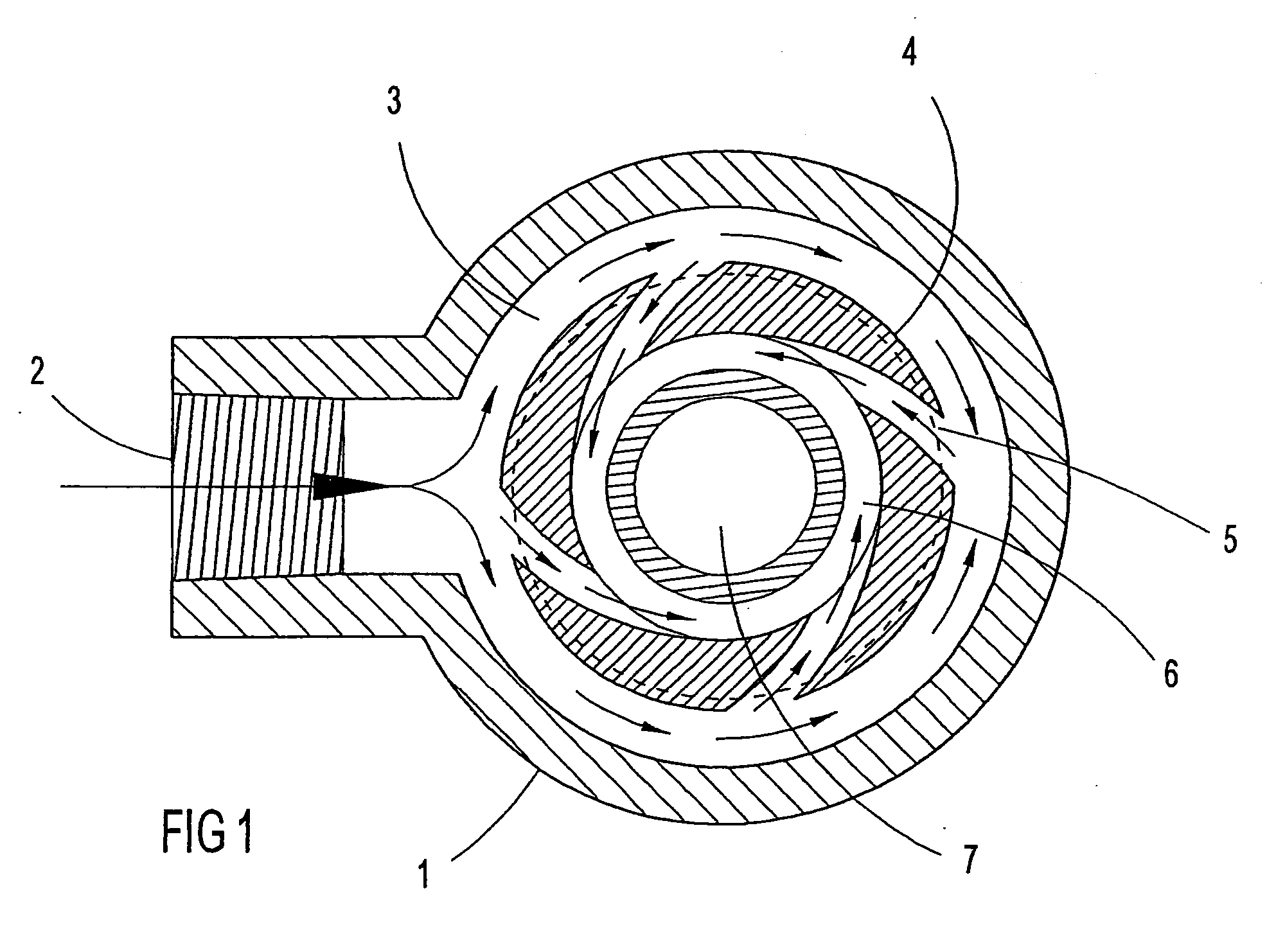

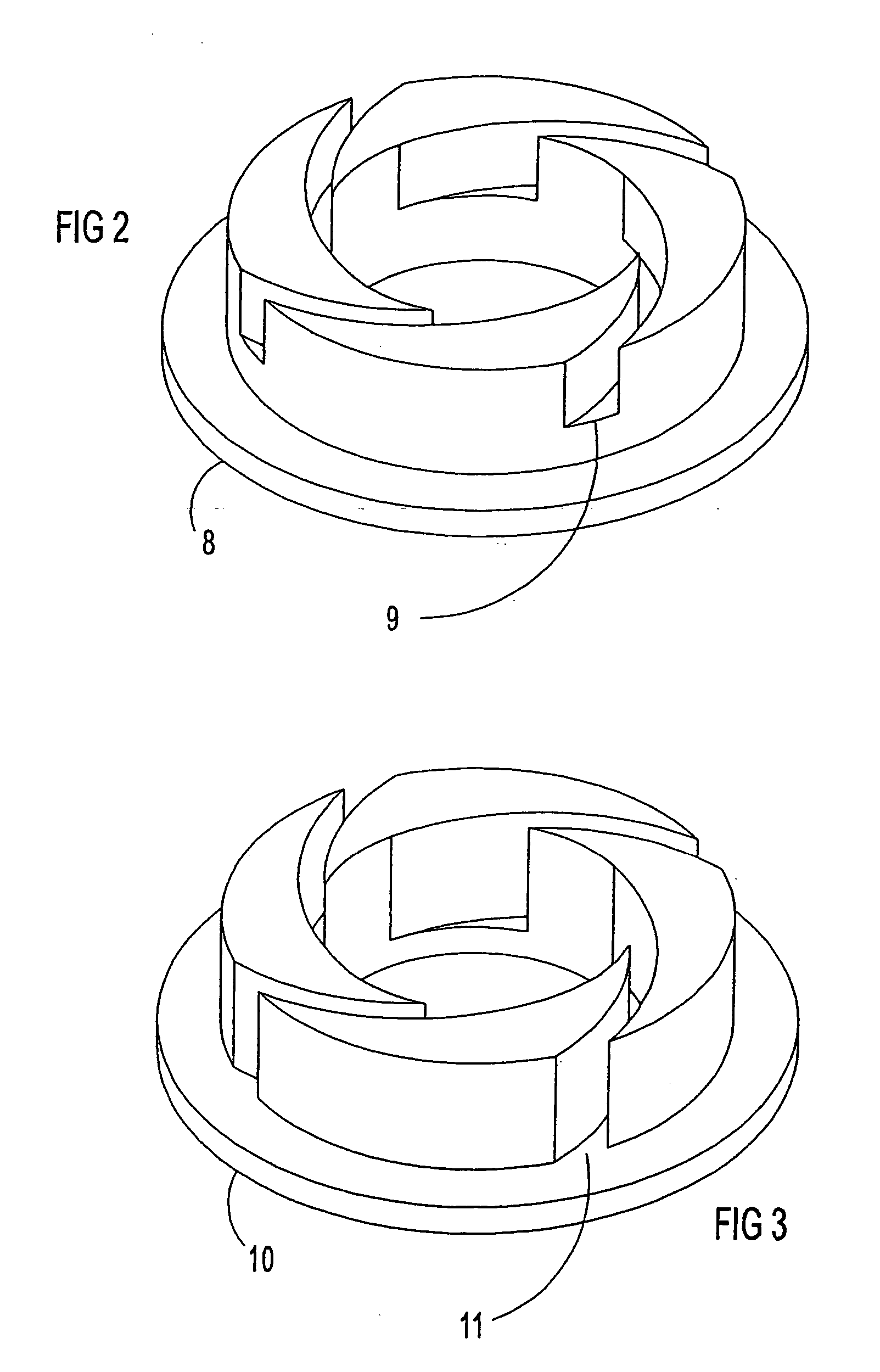

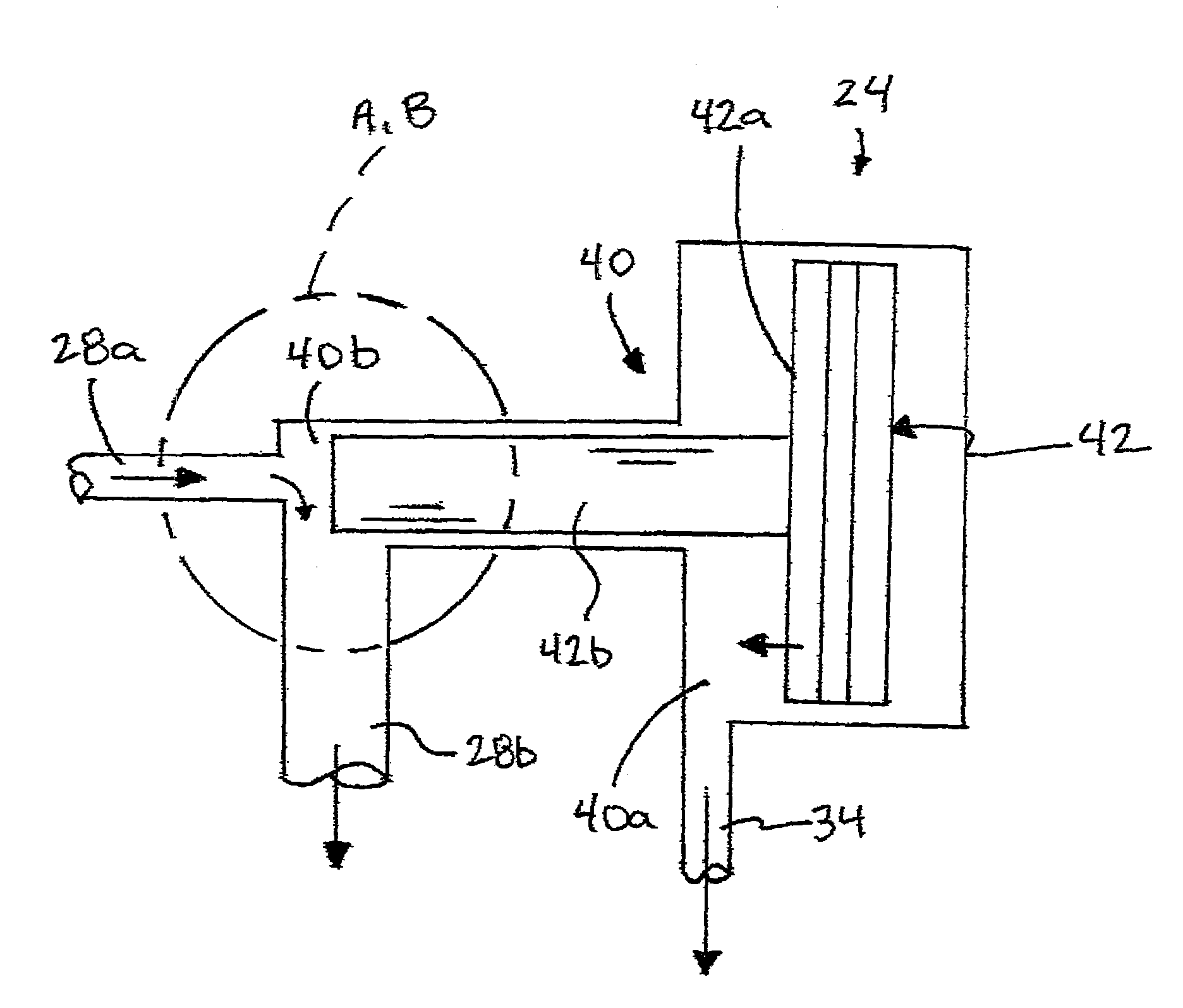

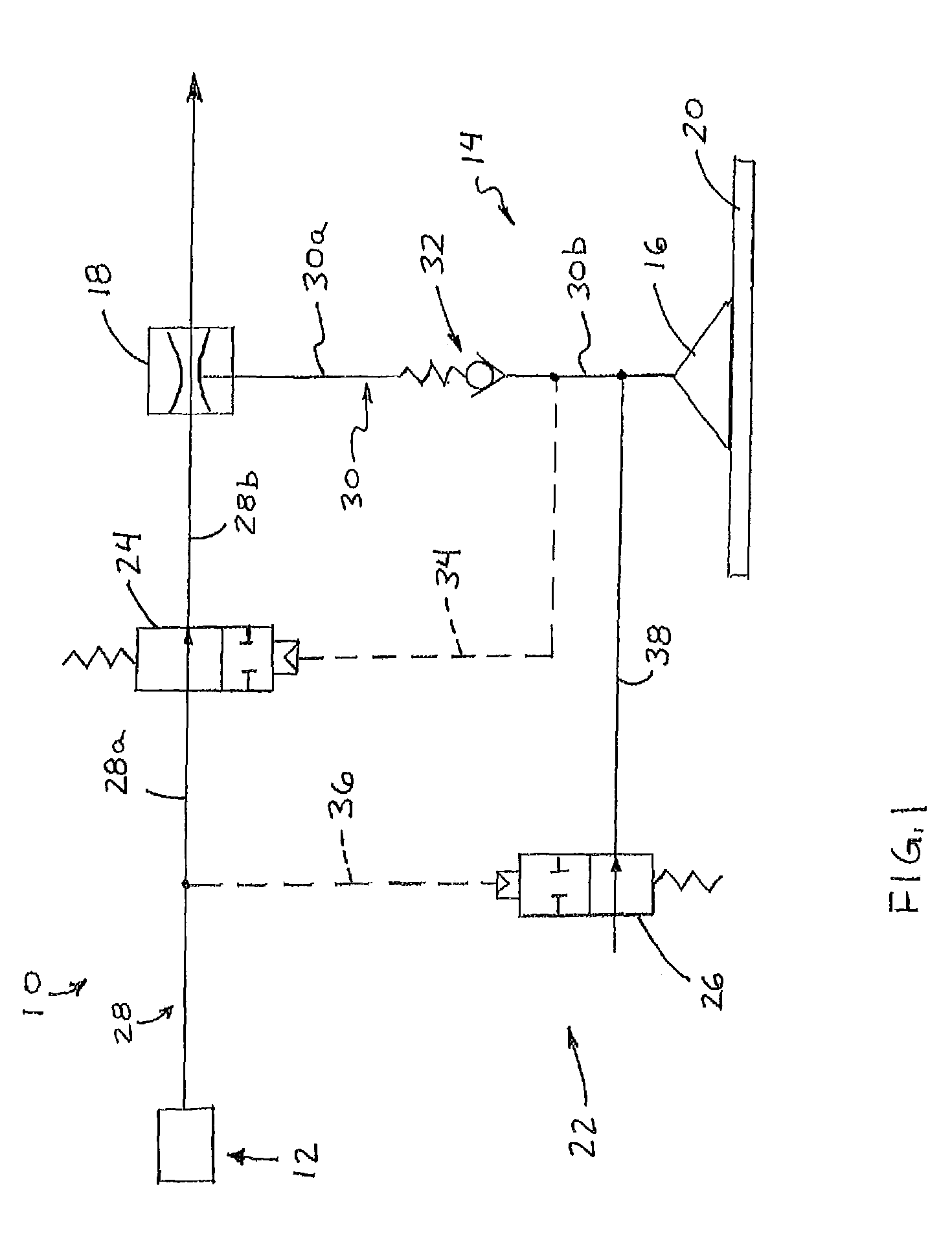

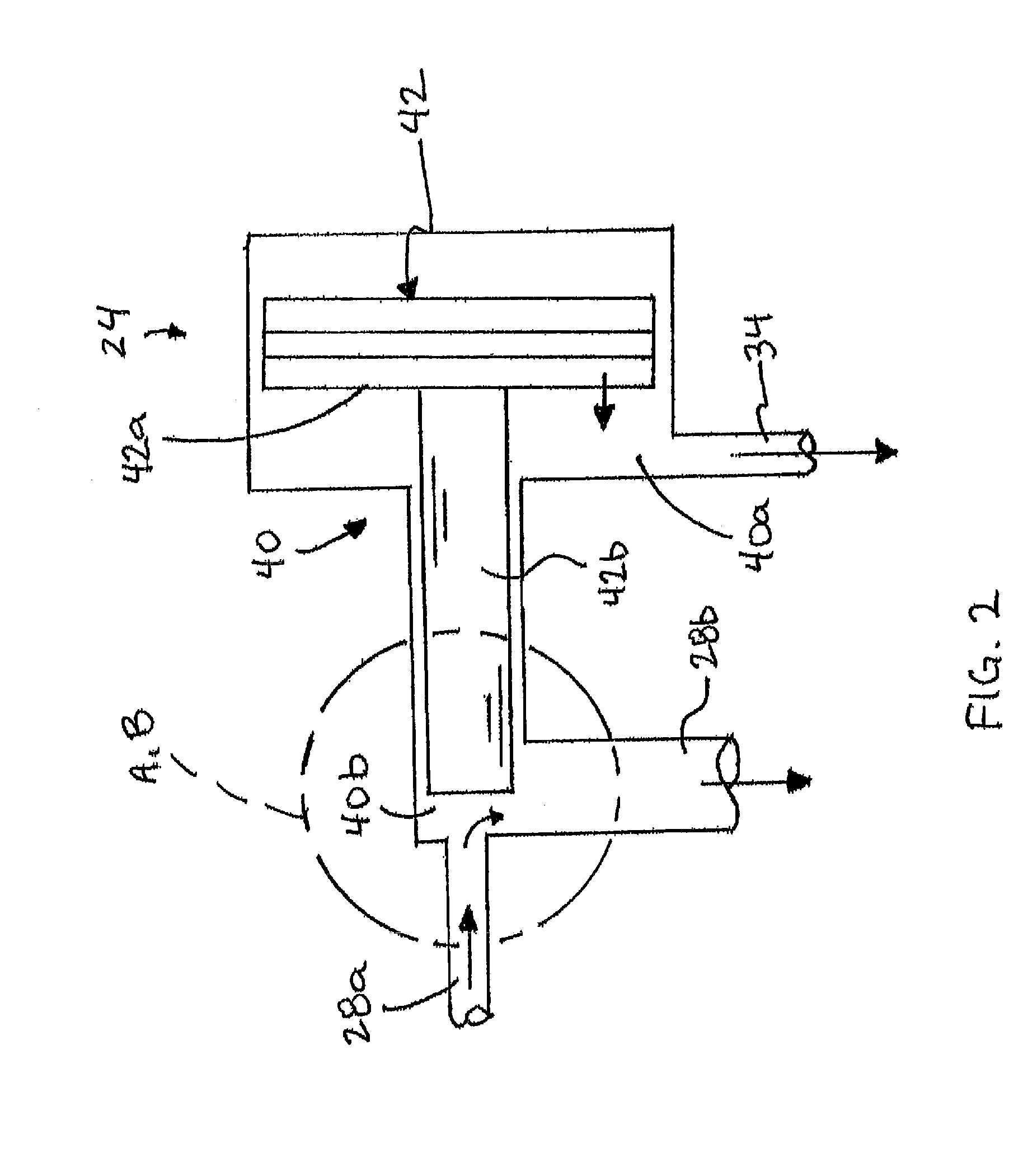

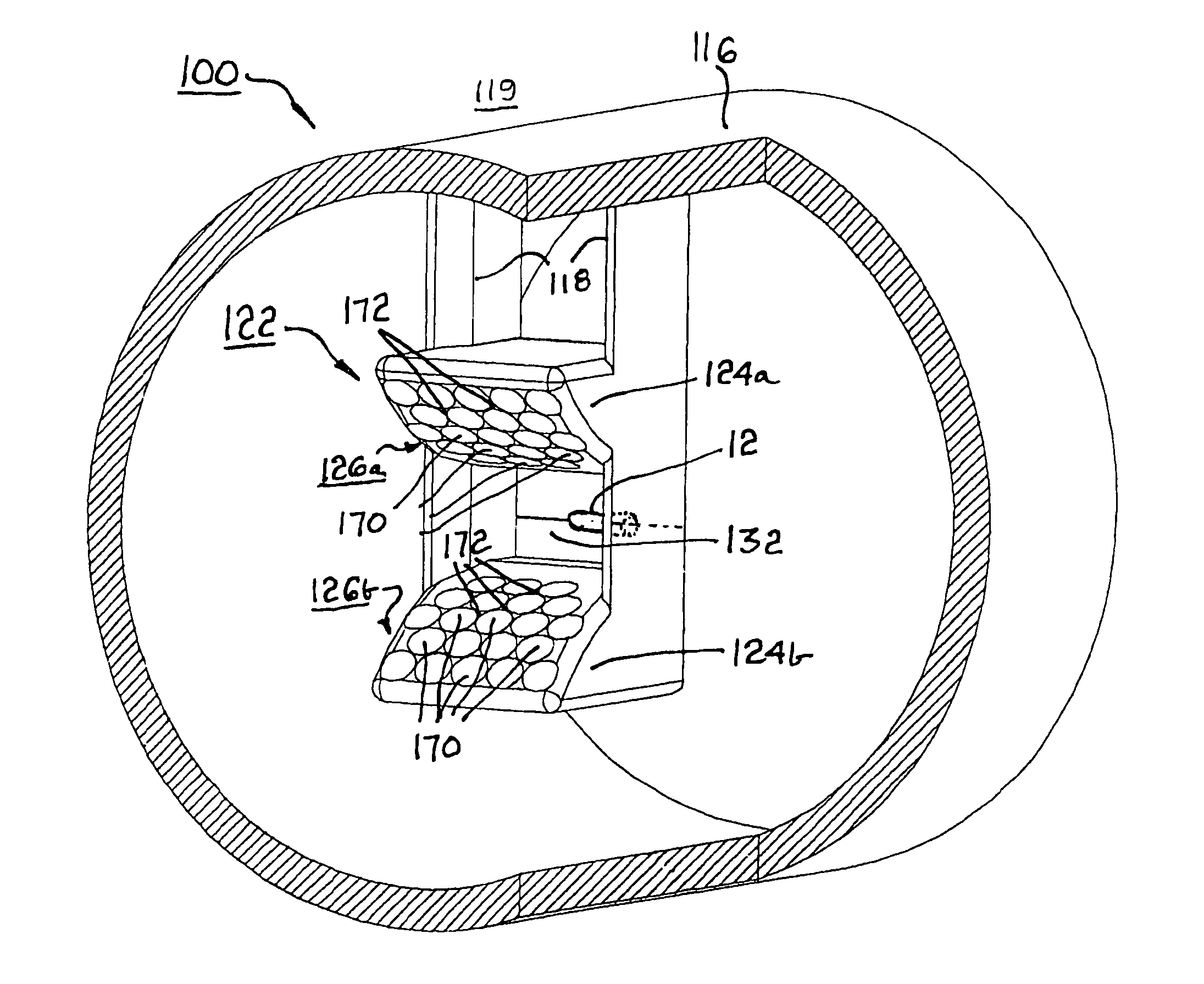

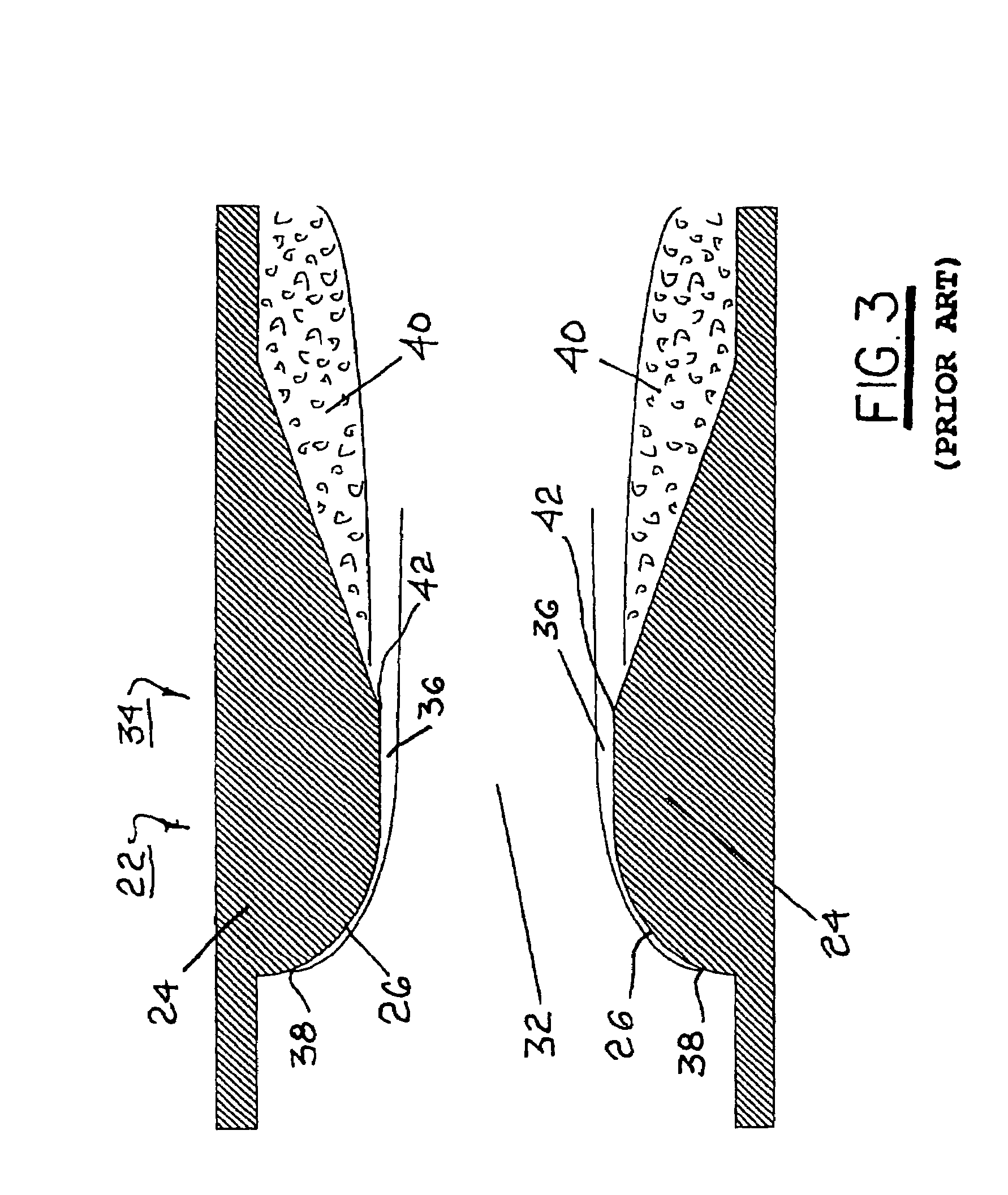

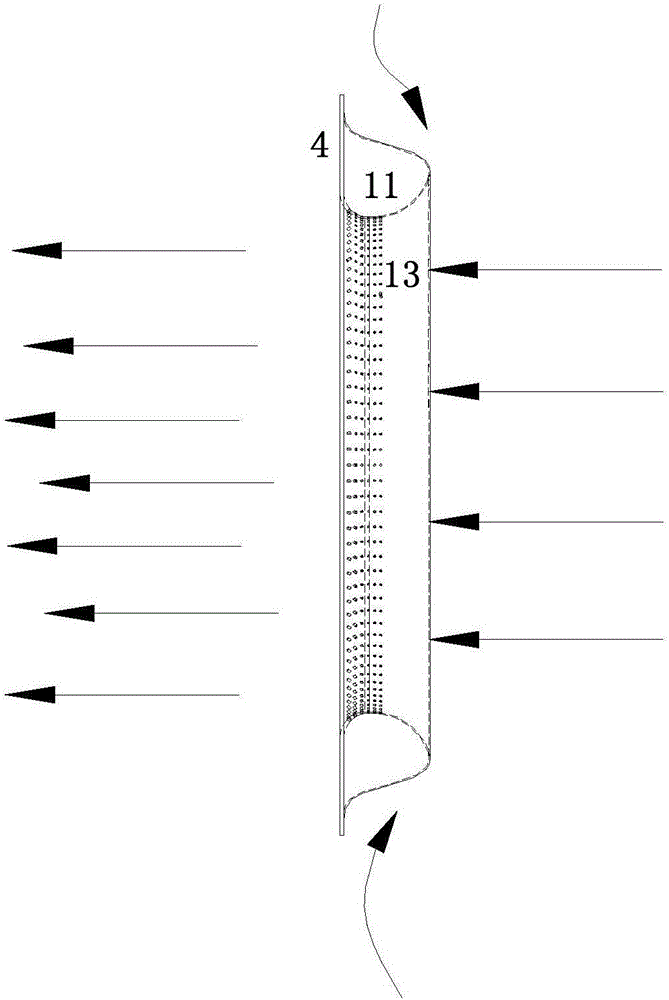

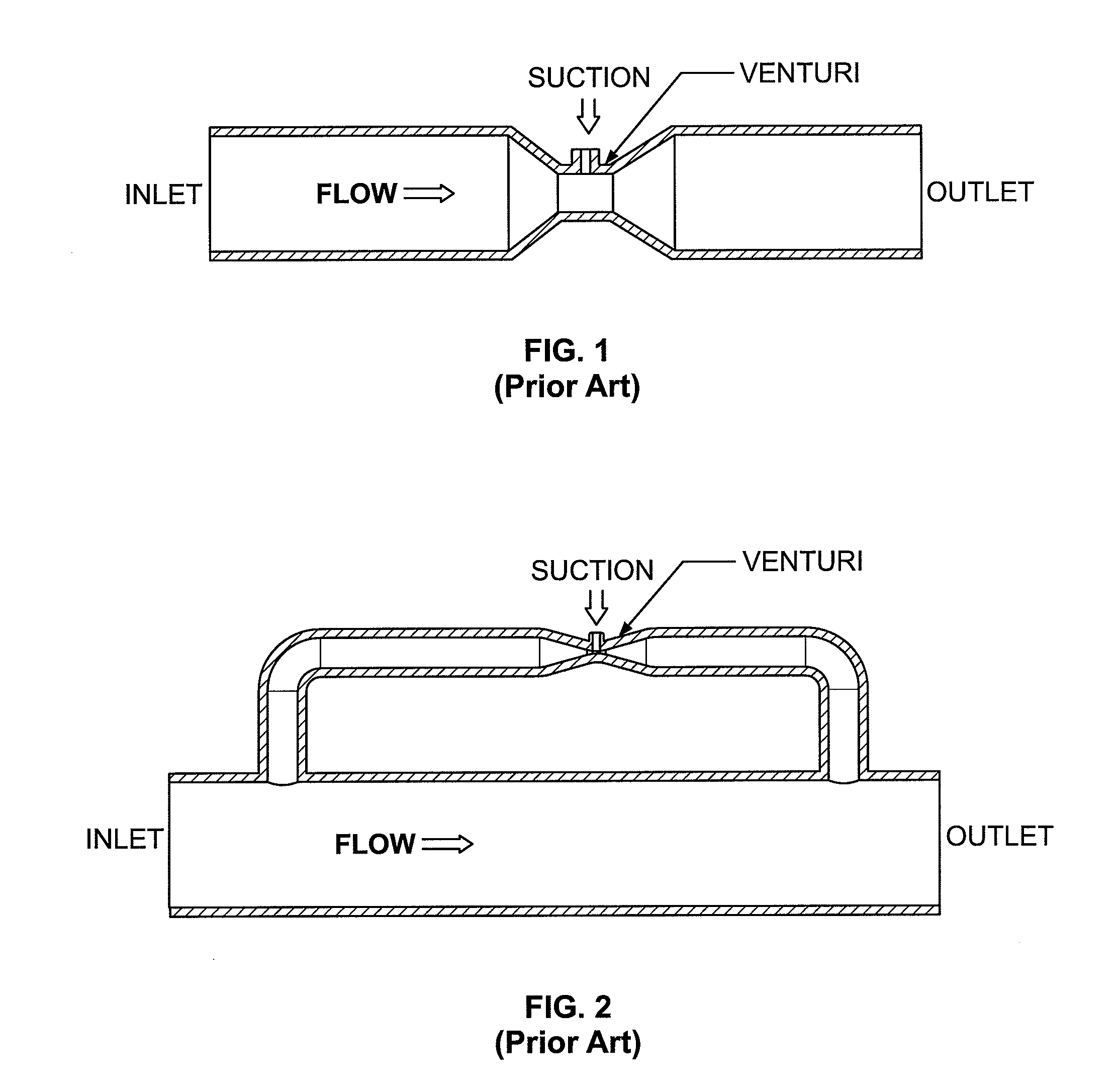

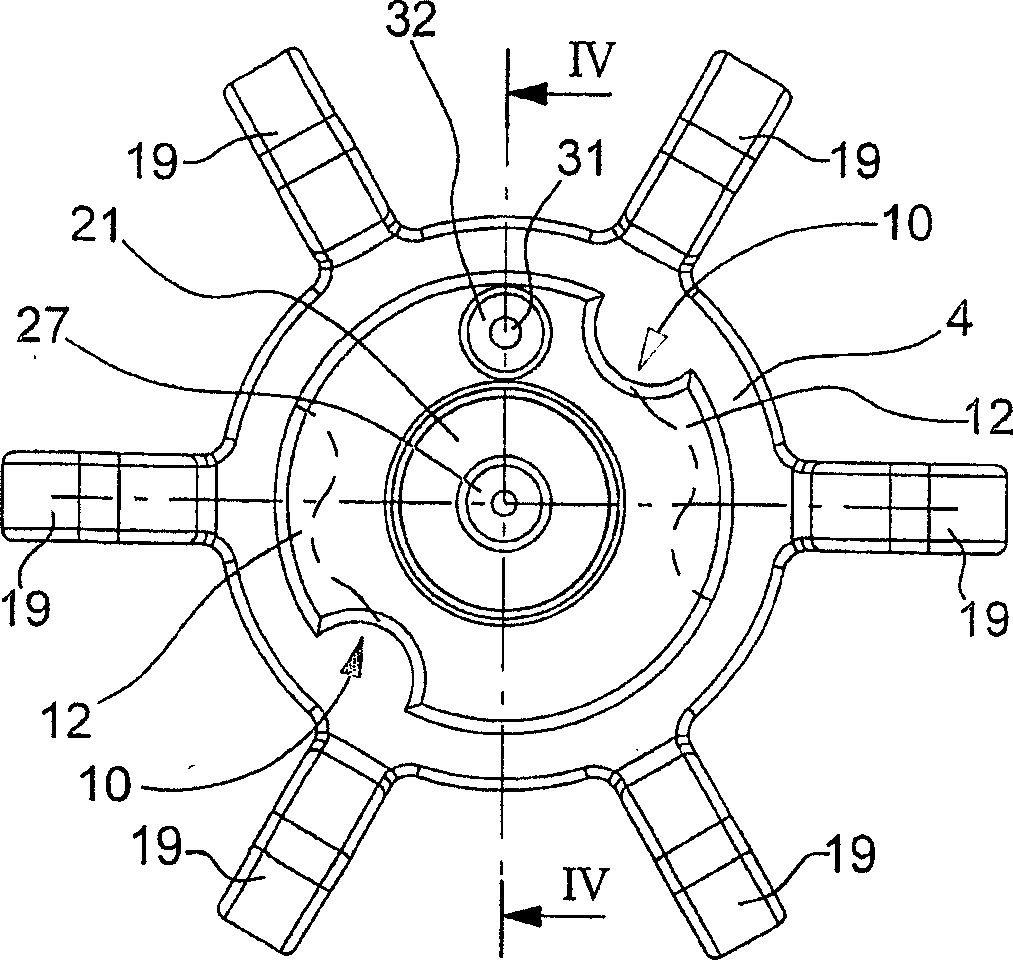

Methods and apparatus for enhancing venturi suction in eductor mixers

InactiveUS20050173336A1Increase the lengthIncrease the amount addedFlow mixersSettling tanks feed/dischargeEngineeringLinearity

An apparatus is provided for suction of a secondary fluid into a primary fluid through one or multiple gaps in contact with a venturi. The venturi imparts a high velocity on the primary fluid to flow across a gap in contact with the venturi and draw in the secondary fluid. The apparatus employs a linear venturi with the flow area, or opening, in the form of a narrow ring or narrow rectangle to increase the length of the gap in contact with the venturi. One gap is provided and positioned in contact with one side of the narrow venturi opening, or two gaps are provided having one positioned in contact each side of the narrow venturi opening. The linear venturi is housed in assemblies referred to as “eductors.” Various eductor embodiments are provided including: 1), cylindrical housings with one or multiple concentric linear venturi with openings in the form of narrow rings; 2), rectangular housings with a single rectangular linear venturi with an opening in the form of a narrow rectangle, with multiple rectangular linear venturi with inlets positioned around a primary fluid inlet to flow radially outward through the multiple venturi, with multiple rectangular linear venturi with outlets positioned around a mixing chamber to cause circulation of the flow of fluids; 3), a cylindrical housing with linear venturi with an opening in the form of a narrow ring adapted for inserting into piping; and 4), cylindrical housings with linear venturi with an opening in the form of a wide ring adapted for installation in piping.

Owner:HYDROTREAT

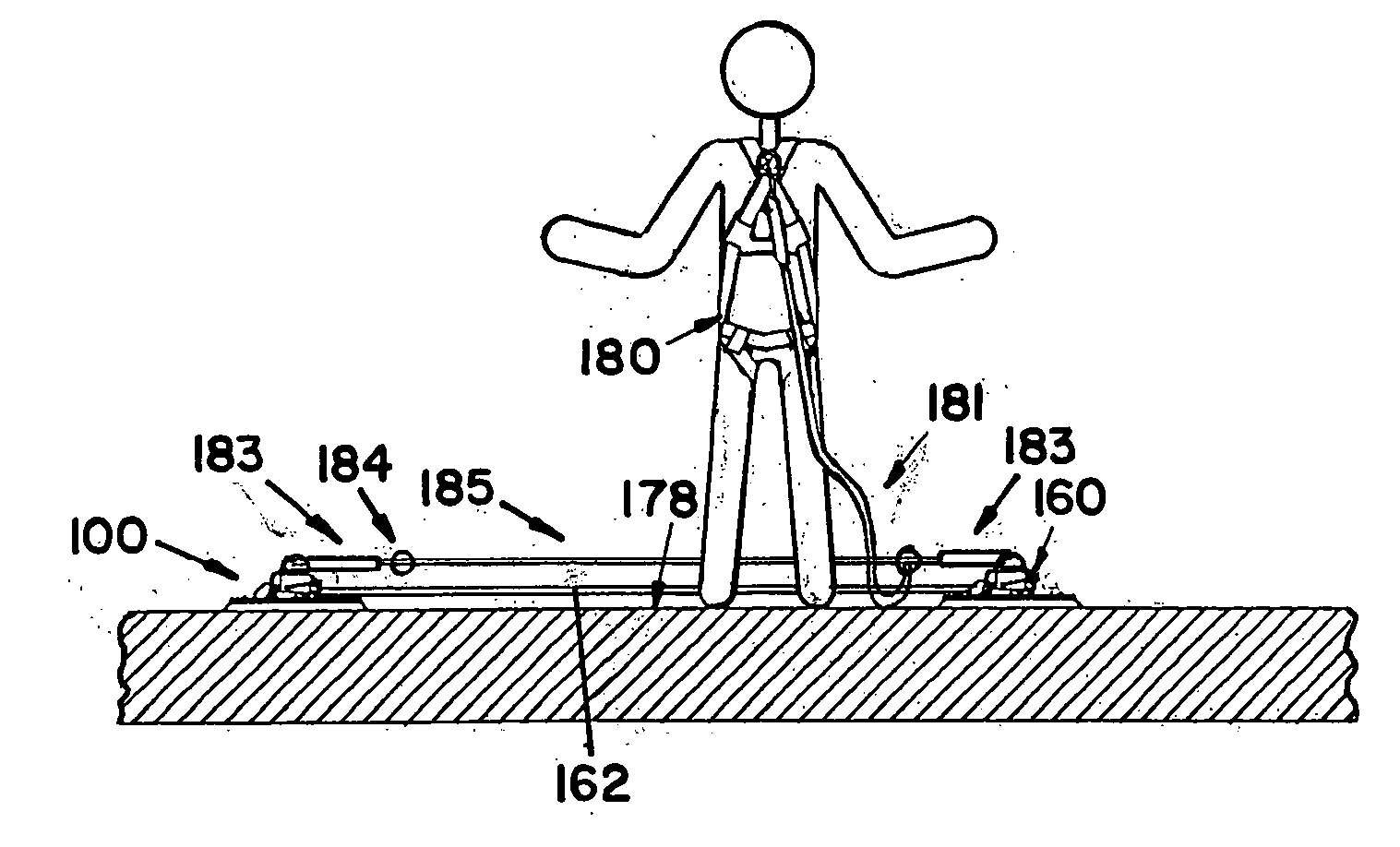

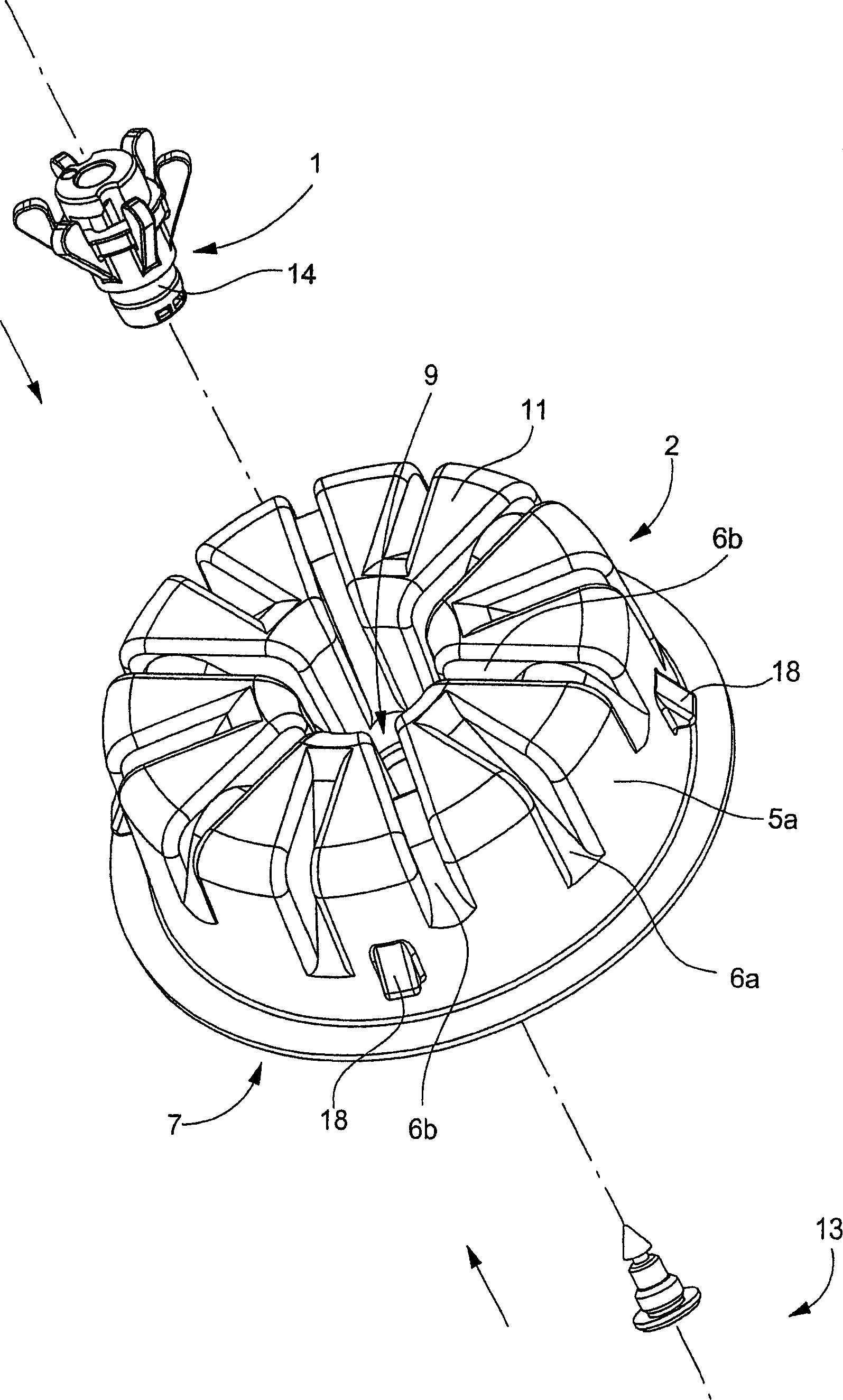

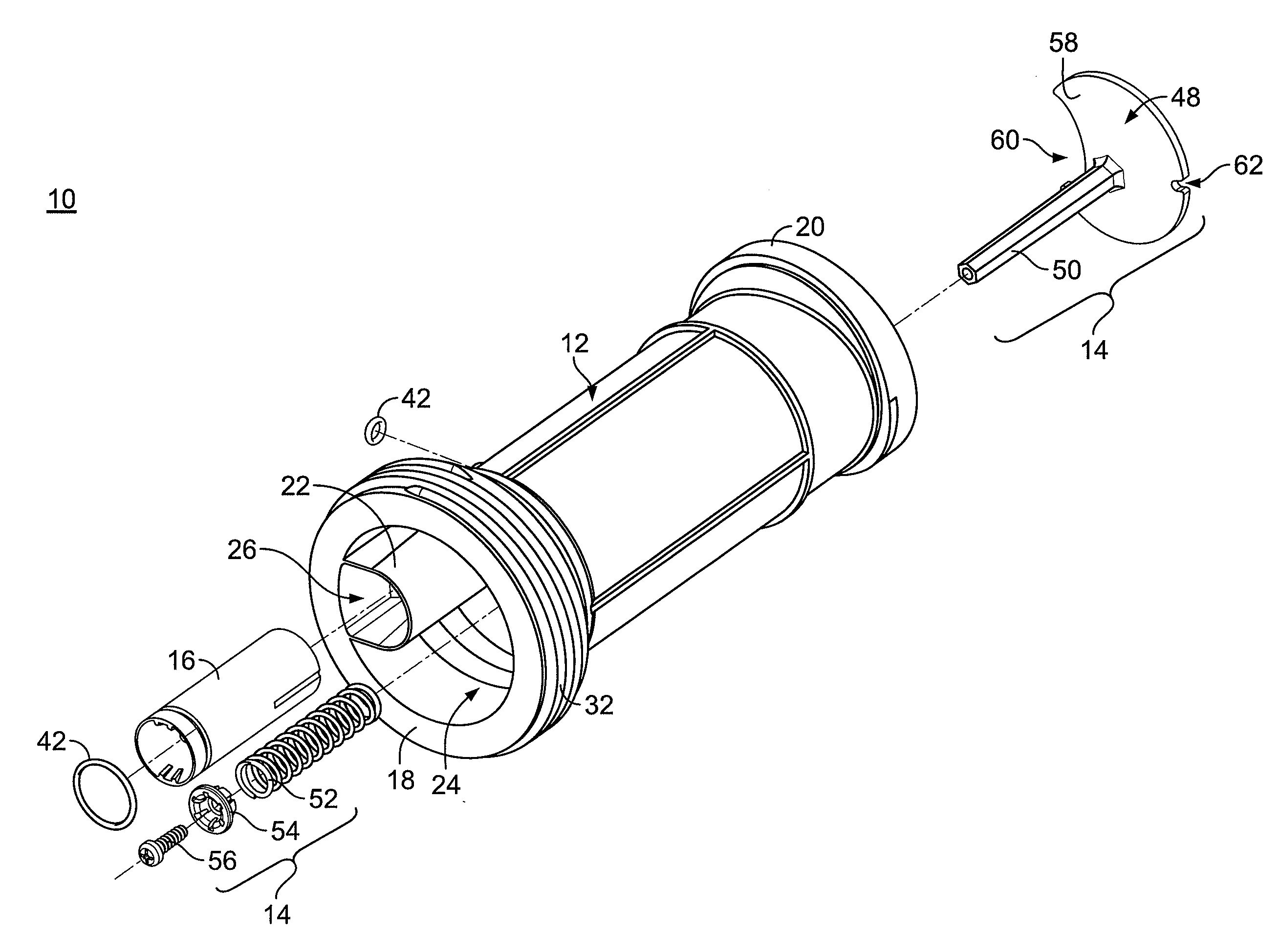

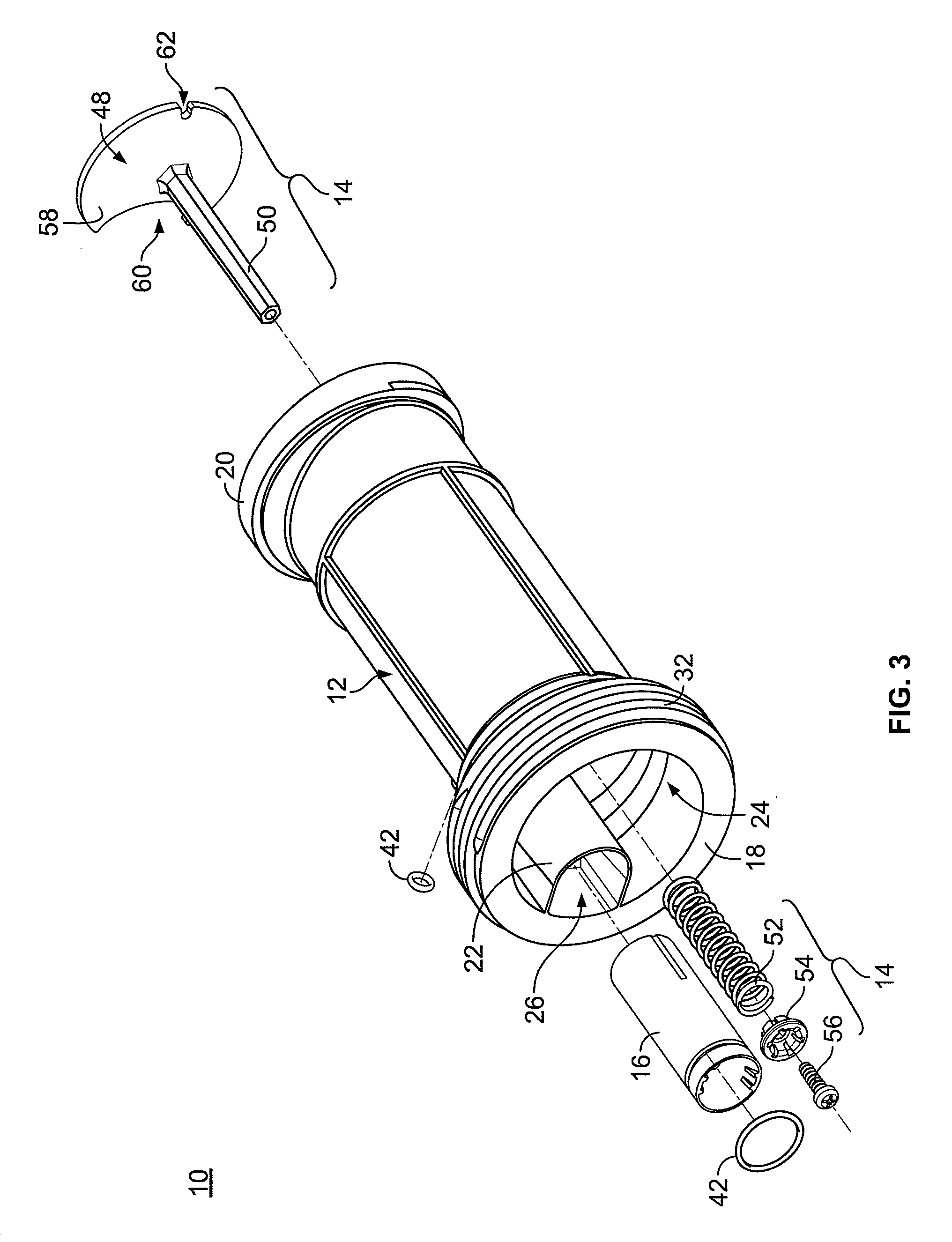

Vacuum anchor

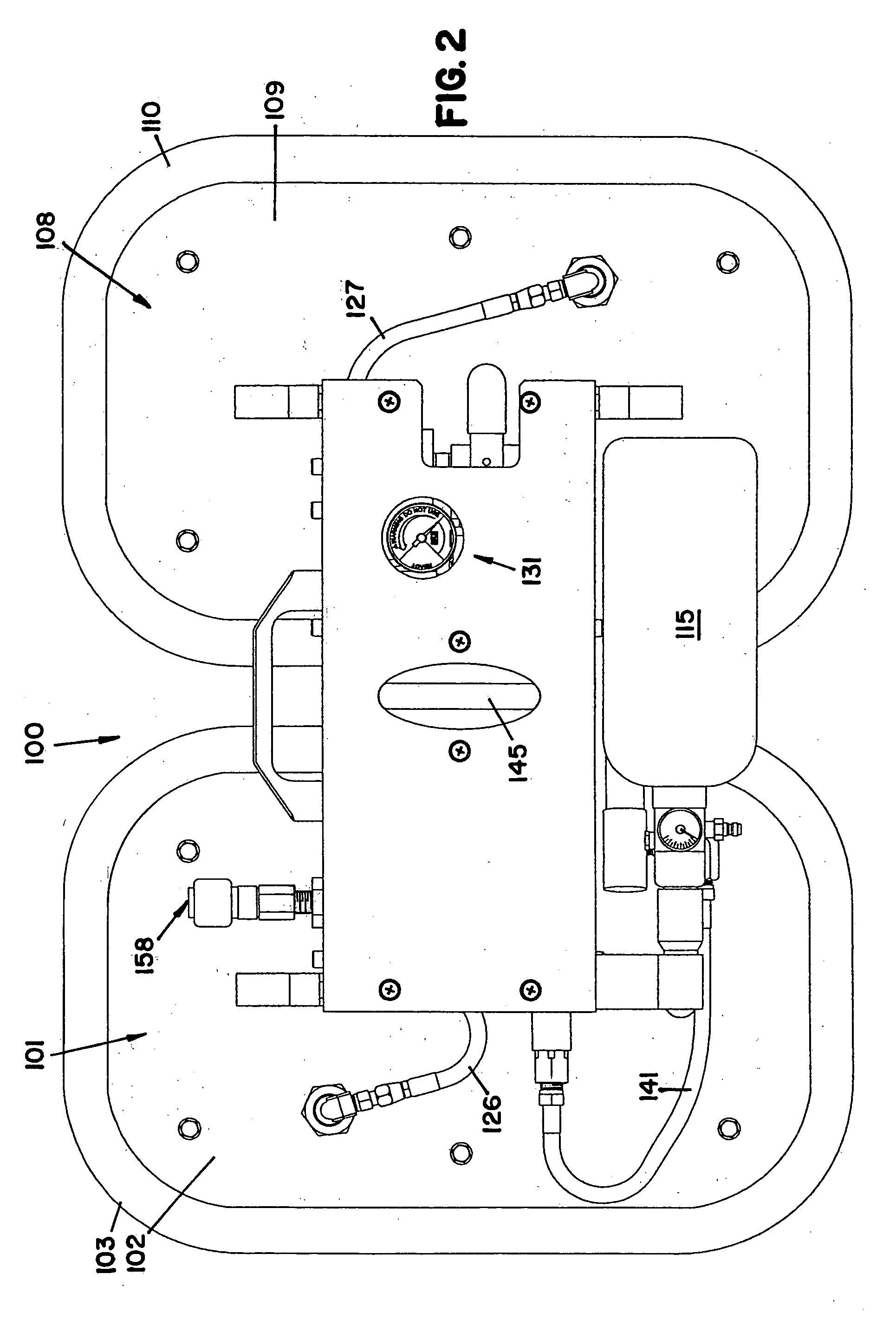

In one aspect of the invention, a vacuum anchor assembly for anchoring a fall protection system to a surface of an anchorage structure comprises an anchor member having an air input connector, a venturi, and a seal member incorporated into the anchor member. The air input connector is configured and arranged to receive air from a pressurized air source. The venturi is in fluid communication with the air input connector and is configured and arranged to receive air and create a vacuum therefrom. The seal member is in fluid communication with the venturi and is configured and arranged to receive the vacuum and resulting suction and create a seal between the anchor member and the surface of the anchorage structure sufficient to operatively connect the anchor member to the surface of the anchorage structure with the vacuum and resulting suction created within the anchor member.

Owner:D B IND

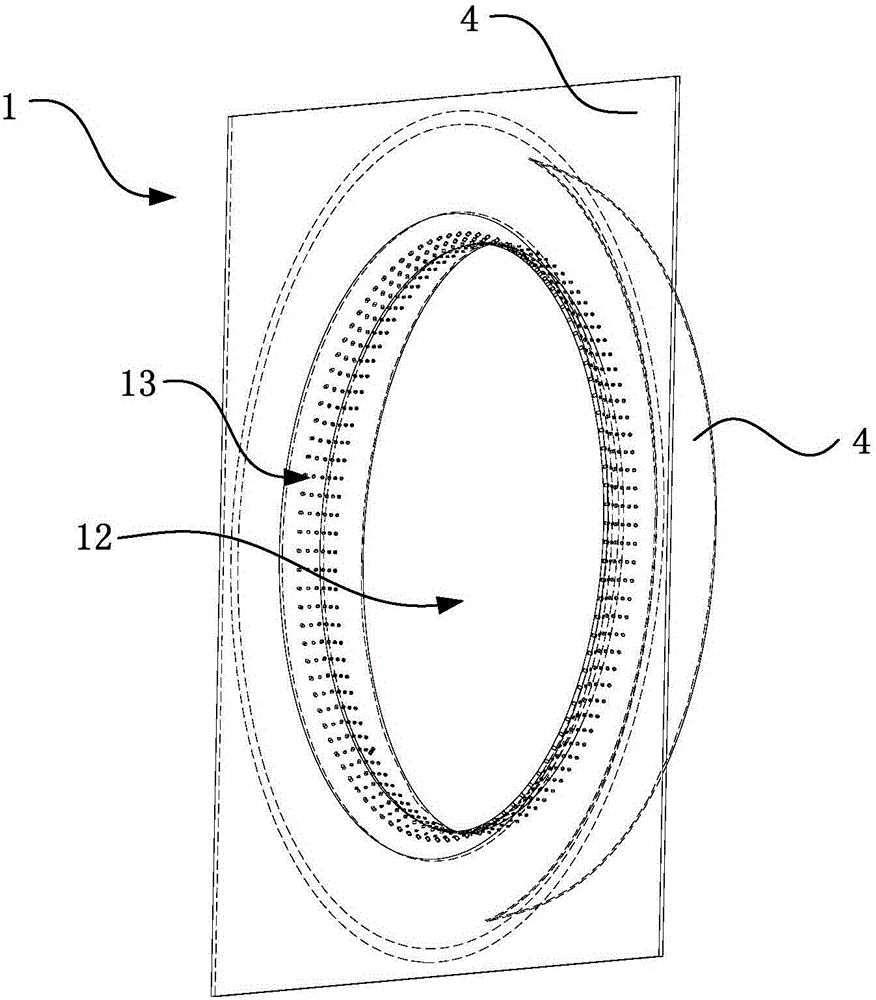

Microbubble generation device and use thereof

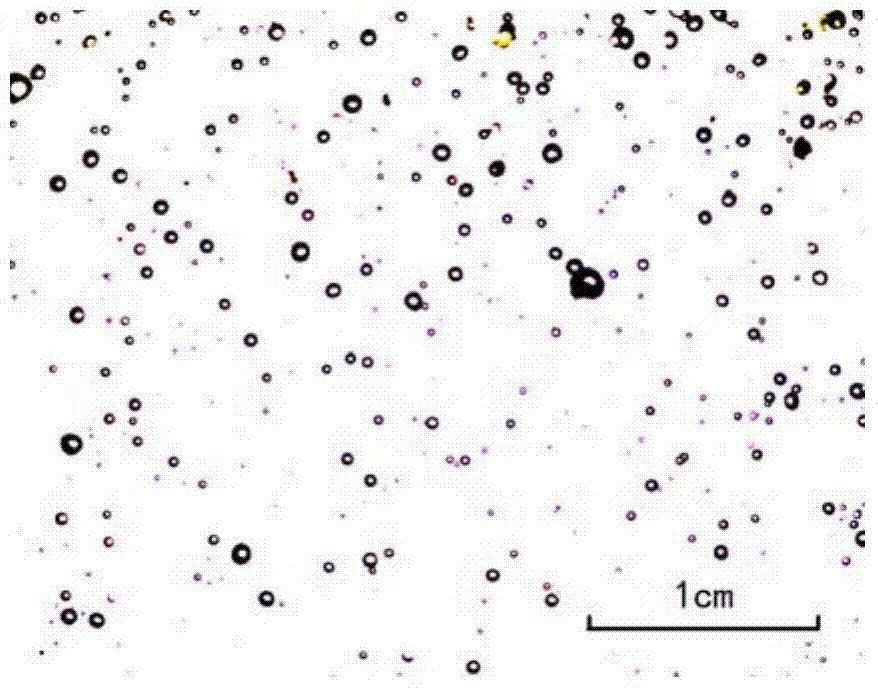

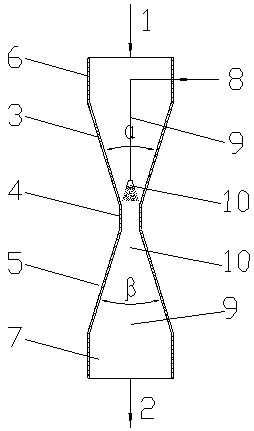

The invention discloses a microbubble generation device and a use thereof. The microbubble generation device comprises an input pipe, a Venturi tube and an output pipe, and the three parts are orderly communicated. The input pipe, the Venturi tube and the output pipe are arranged on the same straight line. The Venturi tube comprises a contraction section, a throat section and an expansion section, and the three parts of orderly communicated. The outer pipe wall of the throat section is provided with a ventilation ring. The ventilation ring is a hollow columnar sealed chamber. The columnar body of the hollow columnar sealed chamber is provided with a gas inlet. The pipe wall of the throat section is provided with thorough vents symmetrically distributed along the axle center of the Venturi tube. The cross section formed from the vents is perpendicular to the axis of the Venturi tube. The vents are located in the hollow columnar sealed chamber. The device can uniformly feed gas into a liquid so that micro-bubbles are produced in the liquid. The ventilatory capacity and the number and sizes of the bubbles can be adjusted and effectively controlled by device structure adjustment.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Auto-release venturi with vacuum switch

ActiveUS8096598B2Efficient use ofMaintain standardGripping headsWork holdersHandling systemVacuum switch

A material handling system has a vacuum cup assembly engagable with an object and movable to move the object using a pressurized air source, a vacuum cup, a venturi device and a vacuum valve and auto-release valve. The venturi device is in fluid communication with the vacuum cup and connected to the supply line so that pressurized air can be supplied to and through said venturi device to generate a partial vacuum when the perimeter seal of the vacuum cup is engaged with the object surface. The vacuum valve may open and close the supply line at a location upstream of the venturi device in response to a pressure level at the vacuum cup cavity. The auto-release valve may vent the vacuum cup cavity to atmosphere in response to reduced pressure in the supply line at a location upstream from the vacuum valve.

Owner:DELAWARE CAPITAL FORMATION INC

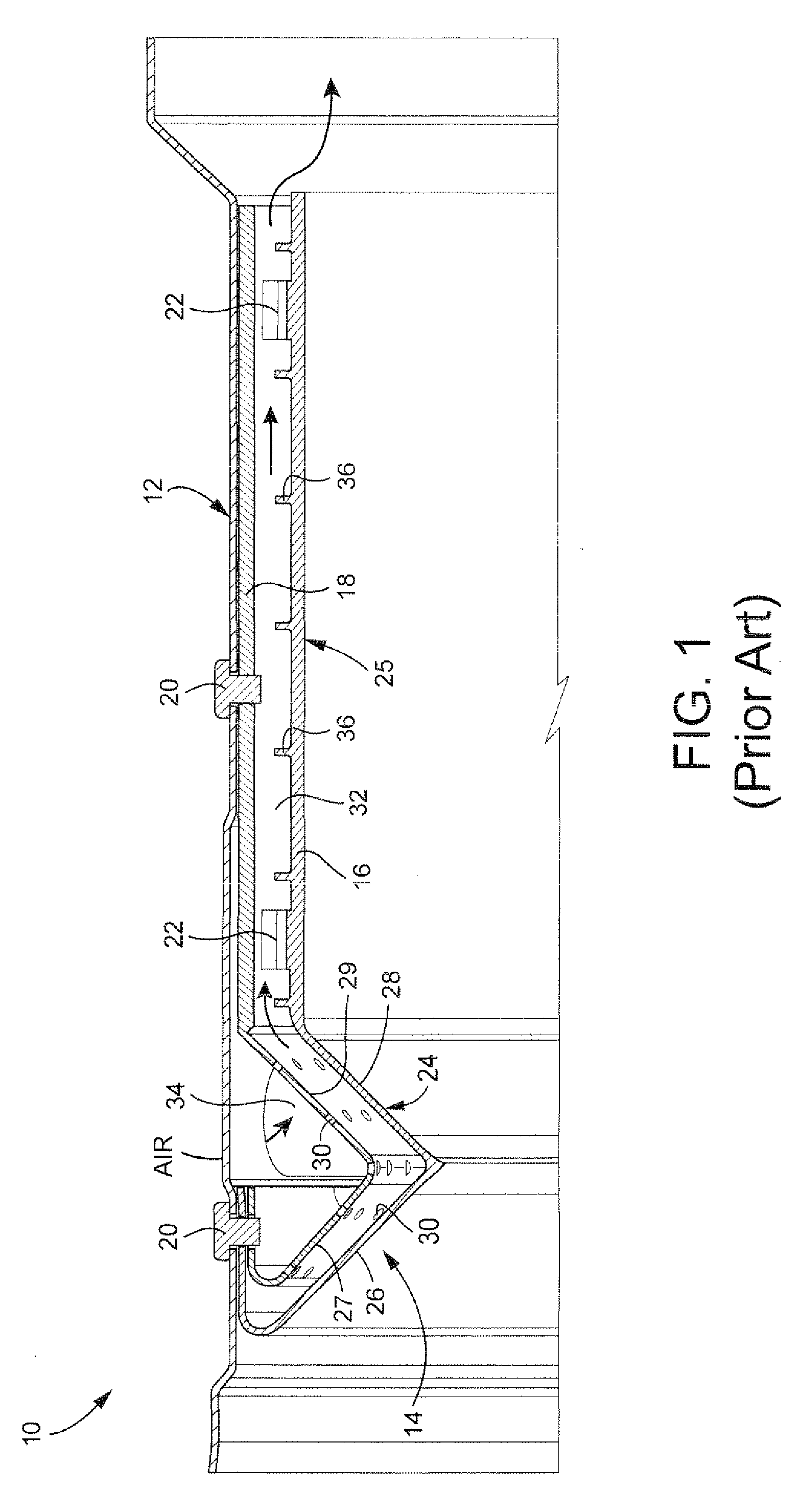

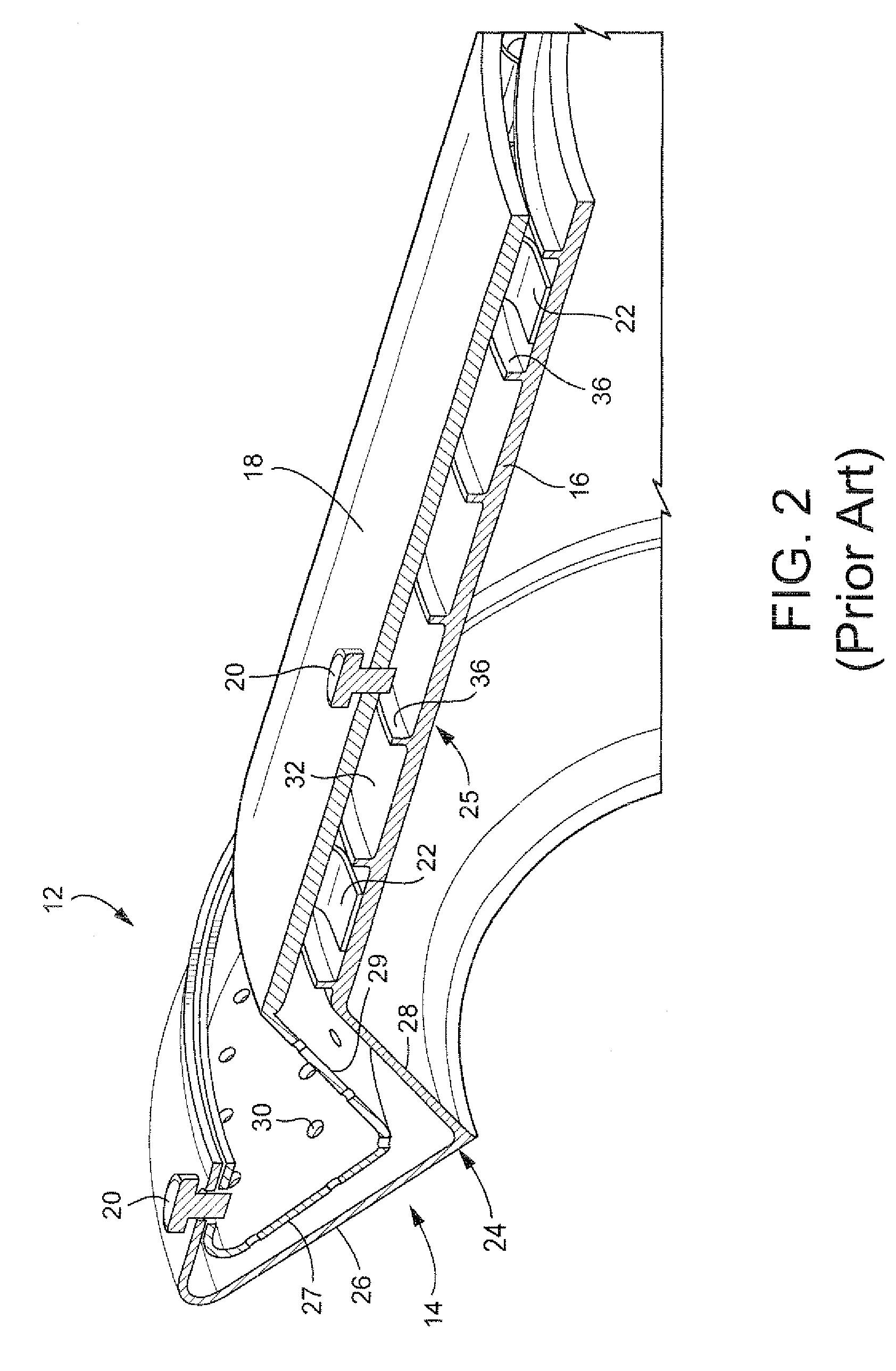

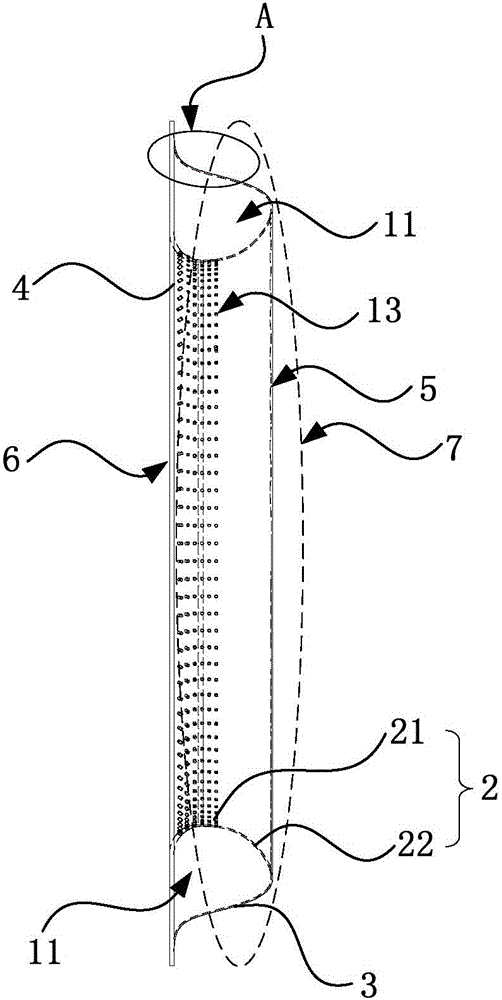

Fully impingement cooled venturi with inbuilt resonator for reduced dynamics and better heat transfer capabilities

ActiveUS20120272654A1Reducing screech-tone venturi dynamicsContinuous combustion chamberGas turbine plantsCombustorEngineering

A venturi assembly for a turbine combustor includes a first outer annular wall and a second intermediate annular wall radially spaced from each other in substantially concentric relationship. The first outer annular wall and said second intermediate annular wall shaped to define a forward, substantially V-shaped throat region, and an aft, axially extending portion. A third radially innermost annular wall is connected to the second intermediate annular wall at an aft end of said throat region. A first plurality of apertures is provided in the first outer annular wall in the substantially V-shaped throat region, and a second plurality of apertures is provided in the aft, axially extending portion of said second intermediate annular wall so that cooling air flows through the first and second pluralities of apertures to impingement cool the third radially innermost annular wall.

Owner:GENERAL ELECTRIC CO

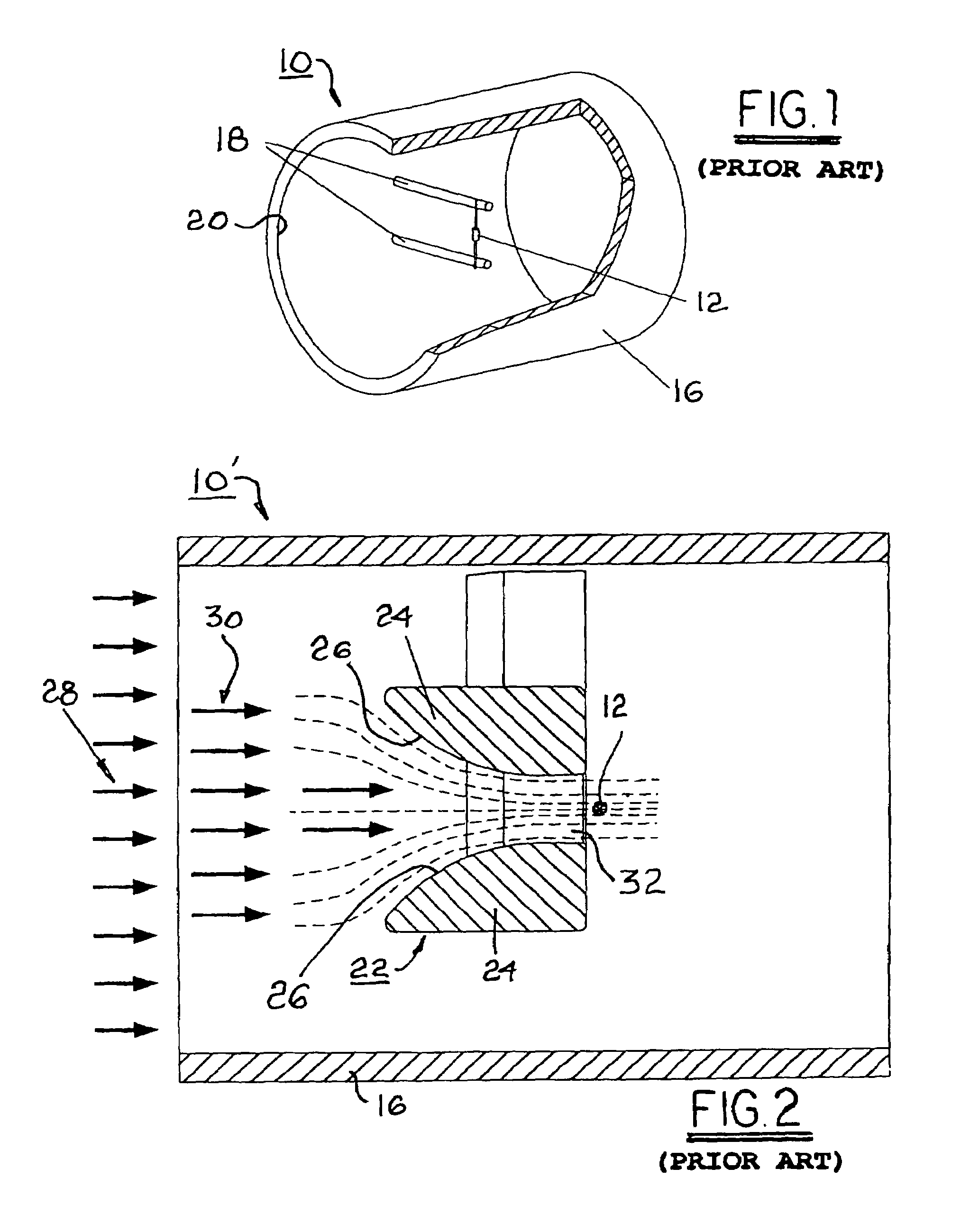

Air flow measurement system having reduced sensitivity to flow field changes

InactiveUS7036366B2Maintaining attachment of flowing airReduce sensitivityVolume/mass flow by thermal effectsVolume flow proportion measurementThroatEngineering

A system for measuring air flow rate in a duct includes an air flow sensor and an air flow conditioning device for collecting and accelerating a portion of the total air stream to the sensor, which may be means as known in the art. The conditioning device includes two opposed converging walls defining a nozzle, preferably a venturi, the sensor being disposed in the throat of the nozzle. The surfaces of the venturi walls are textured to trip the boundary layer near the wall surface into turbulence to maintain attachment of flowing air to the walls even when the angle of attack of the air is significantly non-axial. The wall texturing may be random or may be an organized pattern. A further embodiment includes a second flow conditioner / sensor in parallel with the first whereby an averaged flow measurement is taken for a more accurate reading.

Owner:DELPHI TECH INC

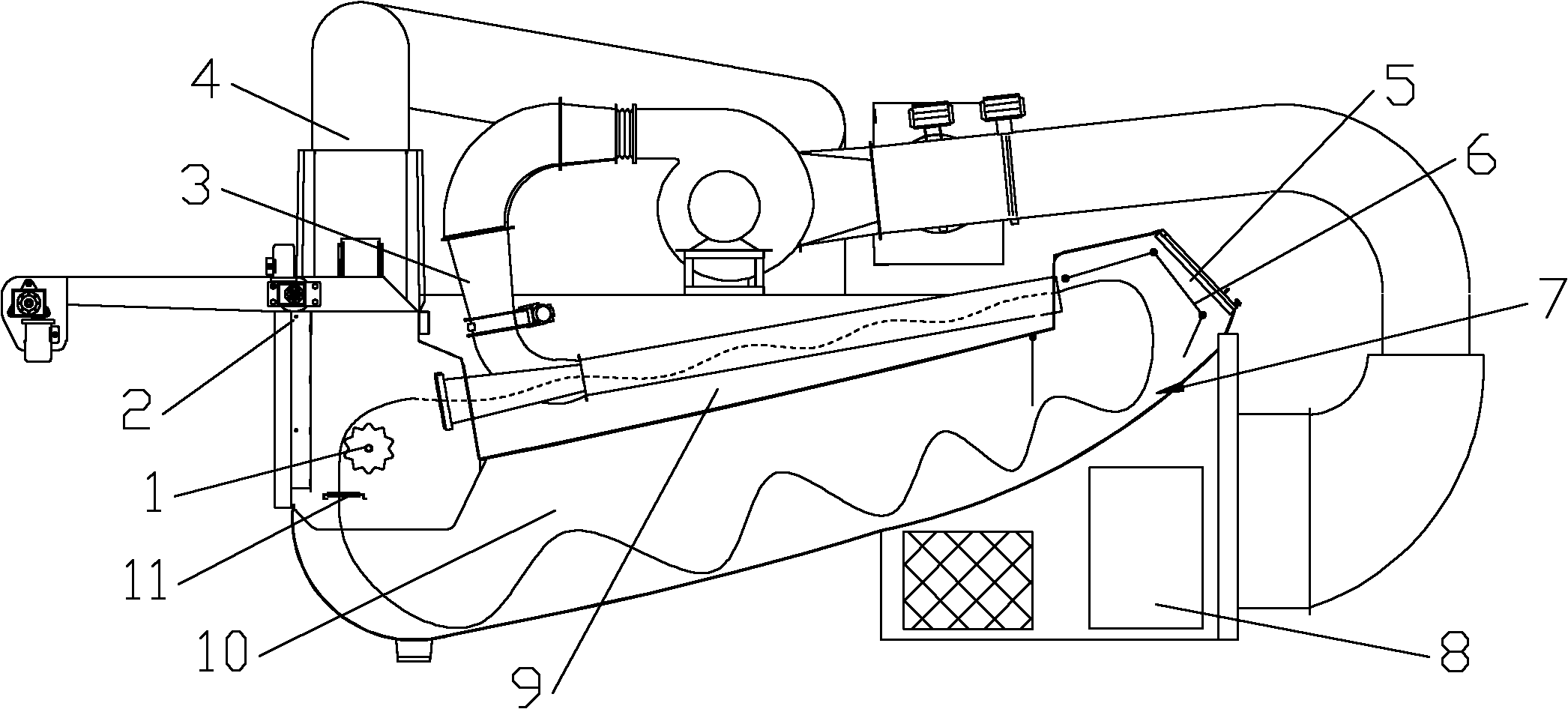

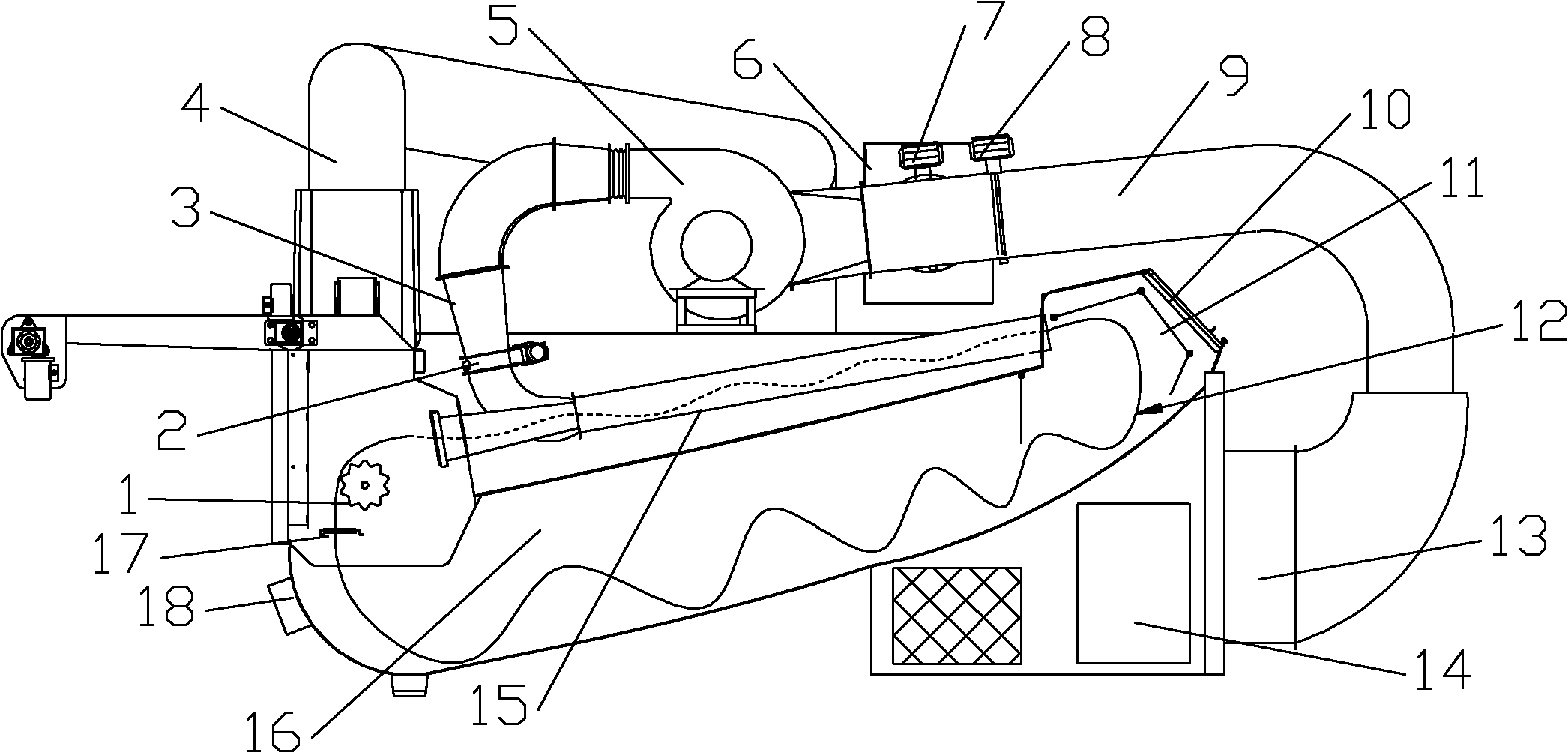

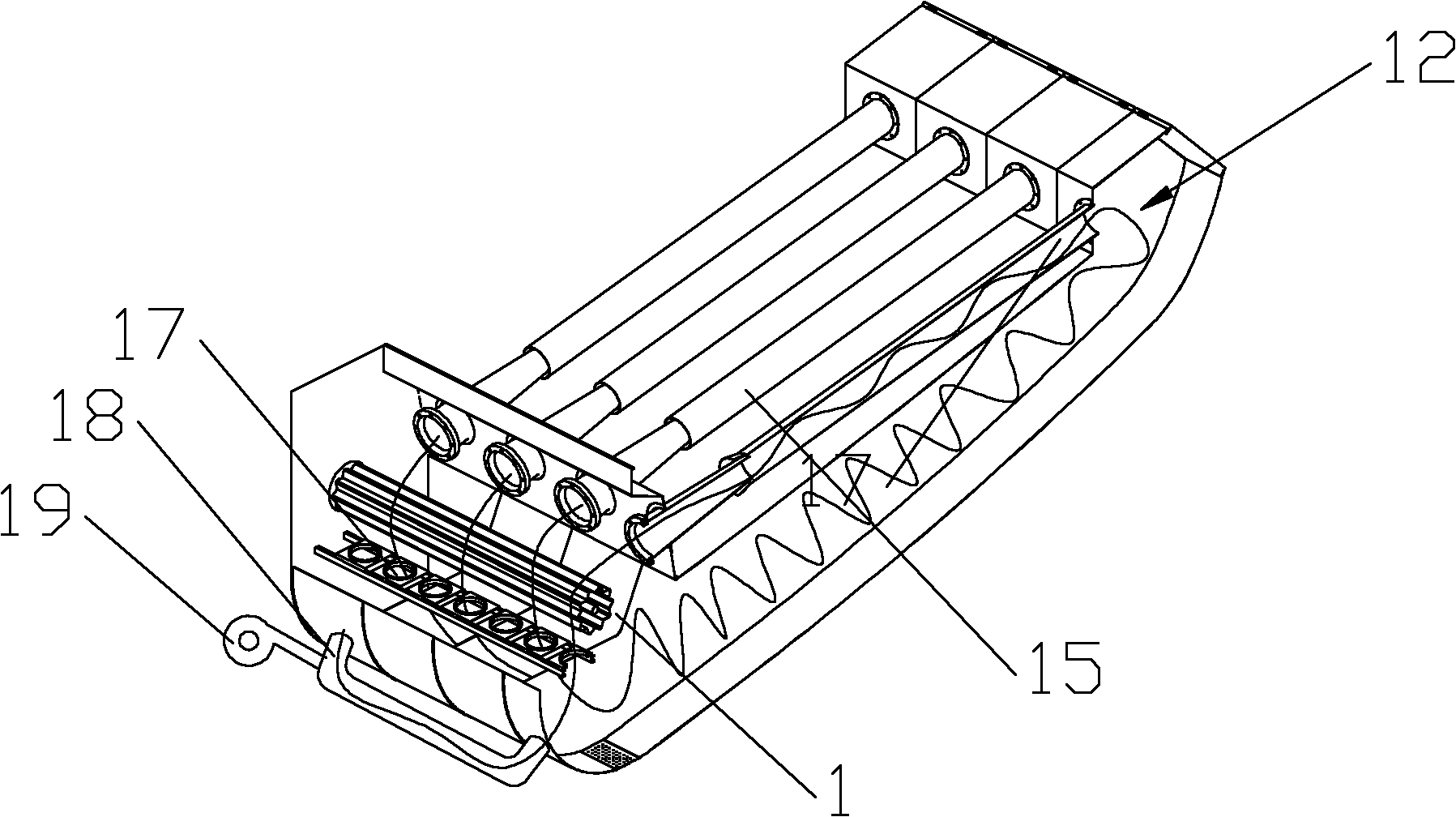

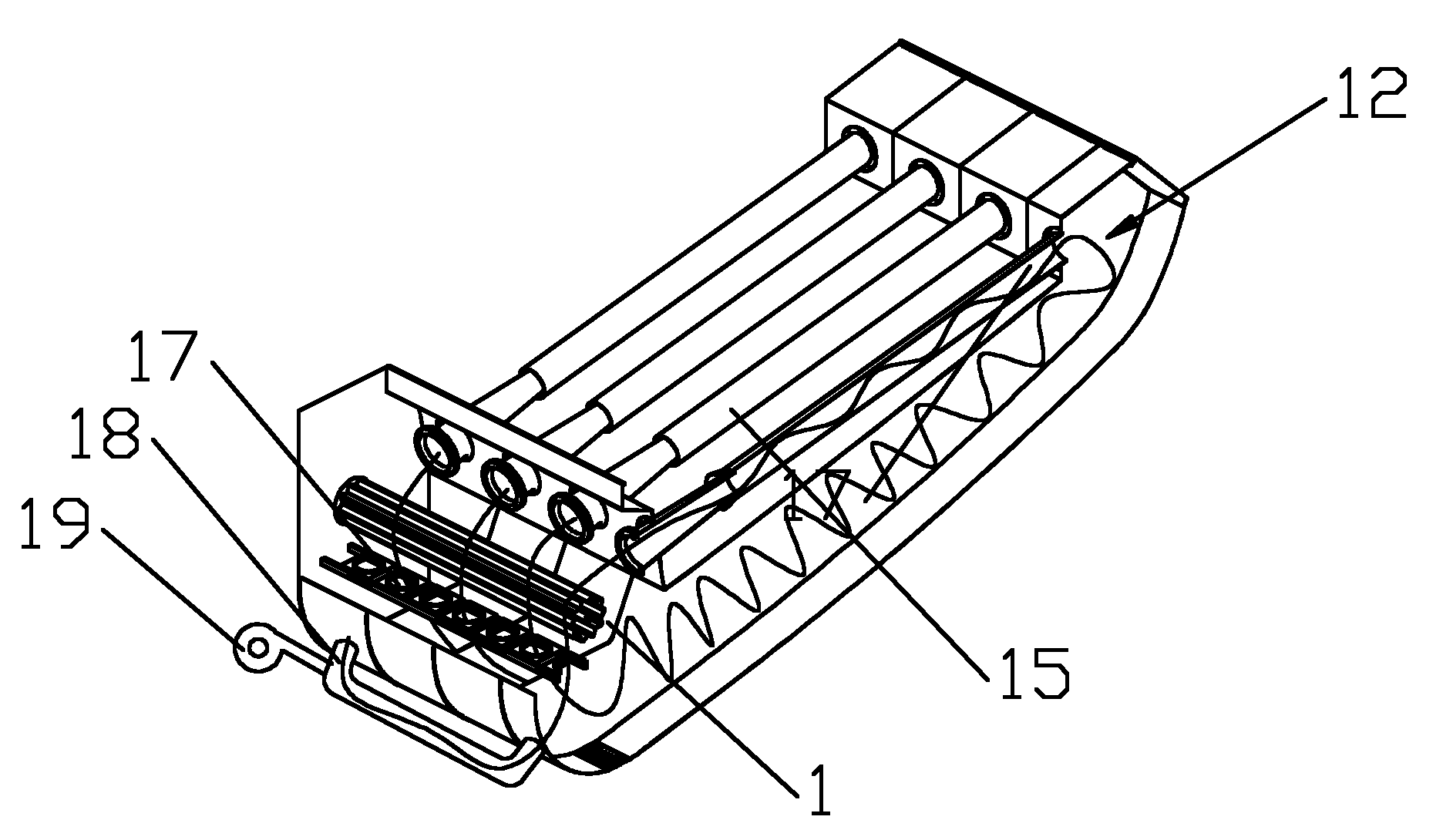

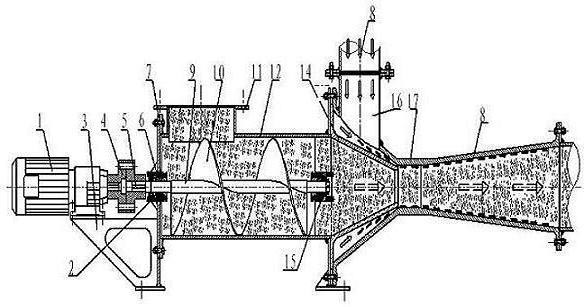

Polarizing machine

ActiveCN102061586ASoft touchPlump surfaceHeating/cooling textile fabricsRougheningEngineeringMechanical engineering

The invention relates to a polarizing machine comprising a stand and a machine case, wherein the machine case is arranged on the stand and internally comprises a venturi tube, a cloth guide device and an impacting grating plate, wherein the cloth guide device is positioned on the front end of the venturi tube, the impacting grating plate is positioned on the rear end of the venturi tube, and the venturi tube is communicated with an air inlet tube; the machine case comprises a high-temperature box, a heat insulation box and a cooling box, wherein the heat insulation box is communicated with the high-temperature box, and the cooling box is communicated with the heat insulation box; the air inlet tube comprises a high-temperature air tube, a heat insulation air tube and a cooling air tube, wherein the high-temperature air tube is communicated with the venturi tube positioned in the high-temperature box, the heat insulation air tube is communicated with the venturi tube positioned in the heat insulation box, and the cooling air tube is communicated with the venturi tube positioned in the cooling box; the machine case also externally comprises a cloth conveying device and a cloth discharge device, wherein the cloth conveying device is used for conveying fabrics into the high-temperature box, and the cloth discharge device is used for discharging the fabrics out of the cooling box. The invention can uninterruptedly polarize the fabrics, thereby ensuring that the fabrics have soft hand feeling, surface plumpness and bulkiness; and in addition, the invention generates certain preshrinking effect.

Owner:江苏保丽洁环境科技股份有限公司

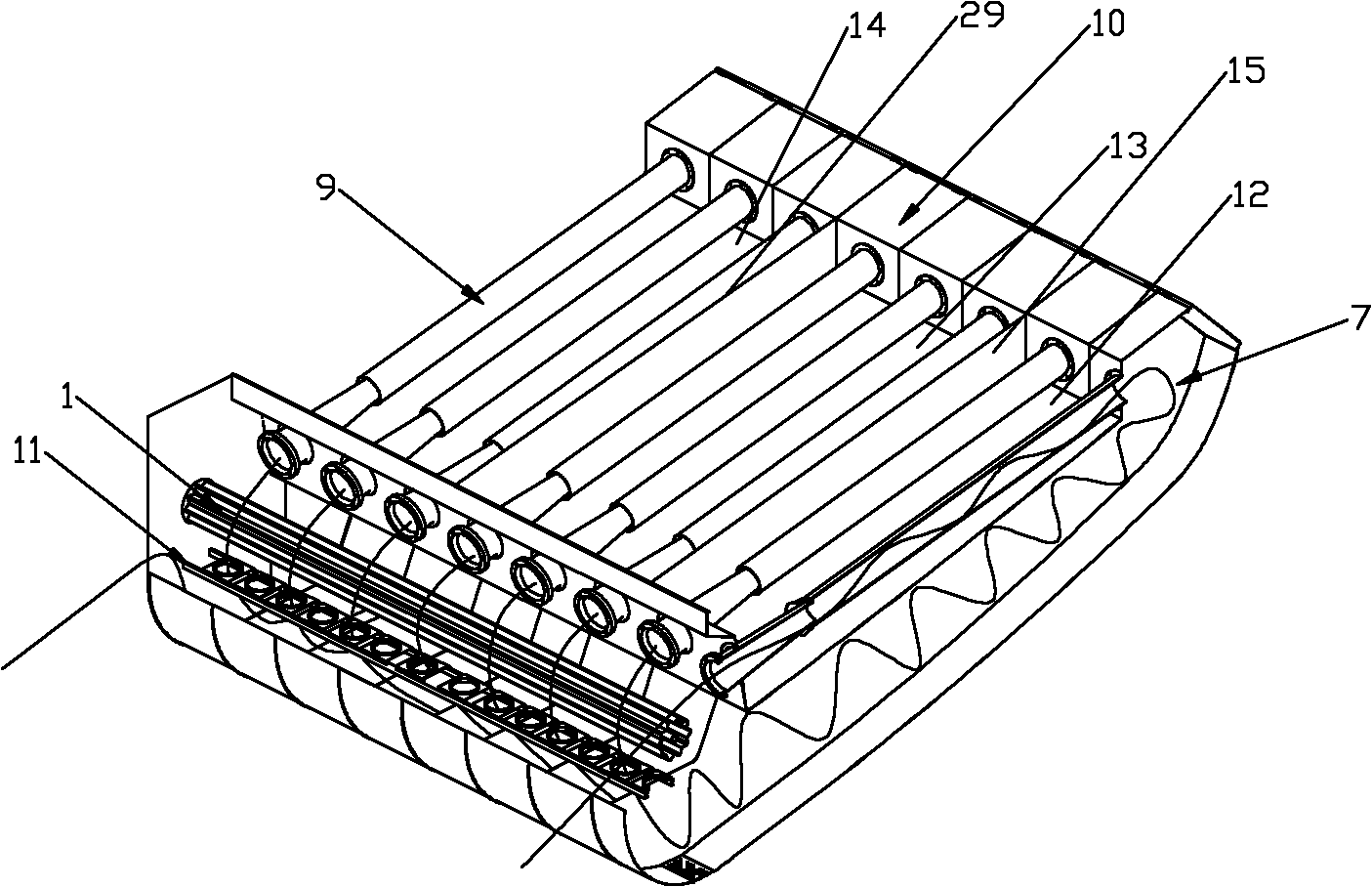

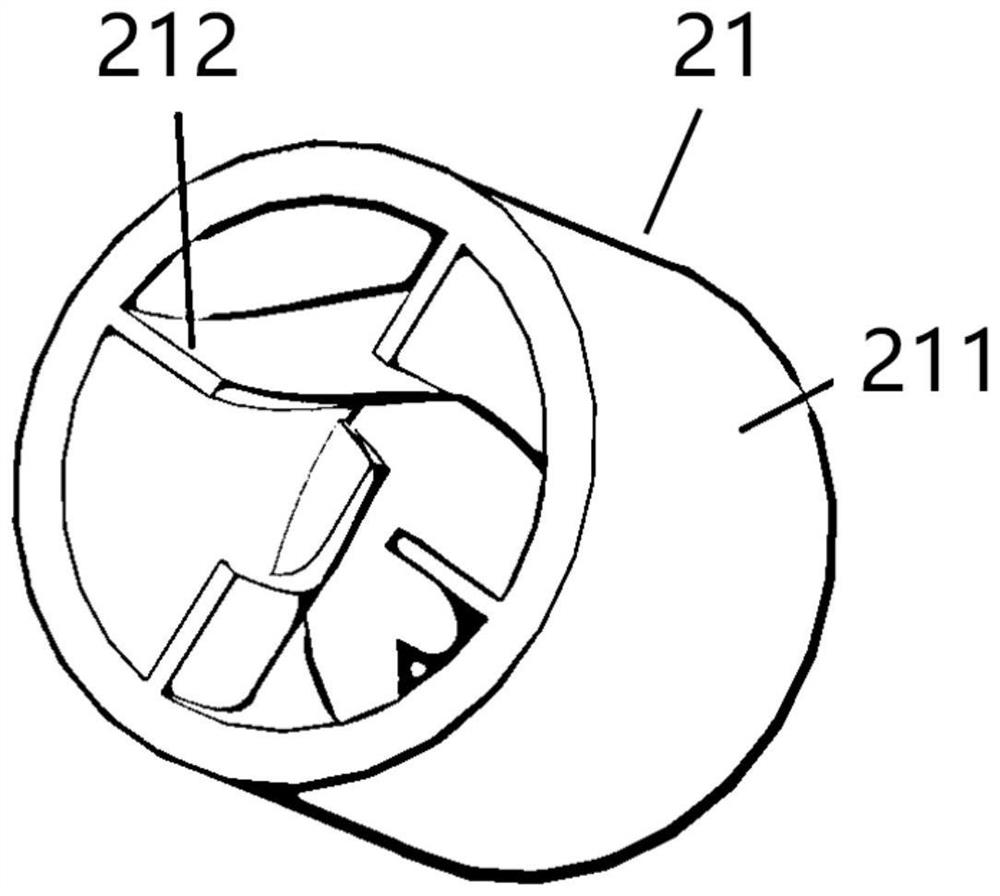

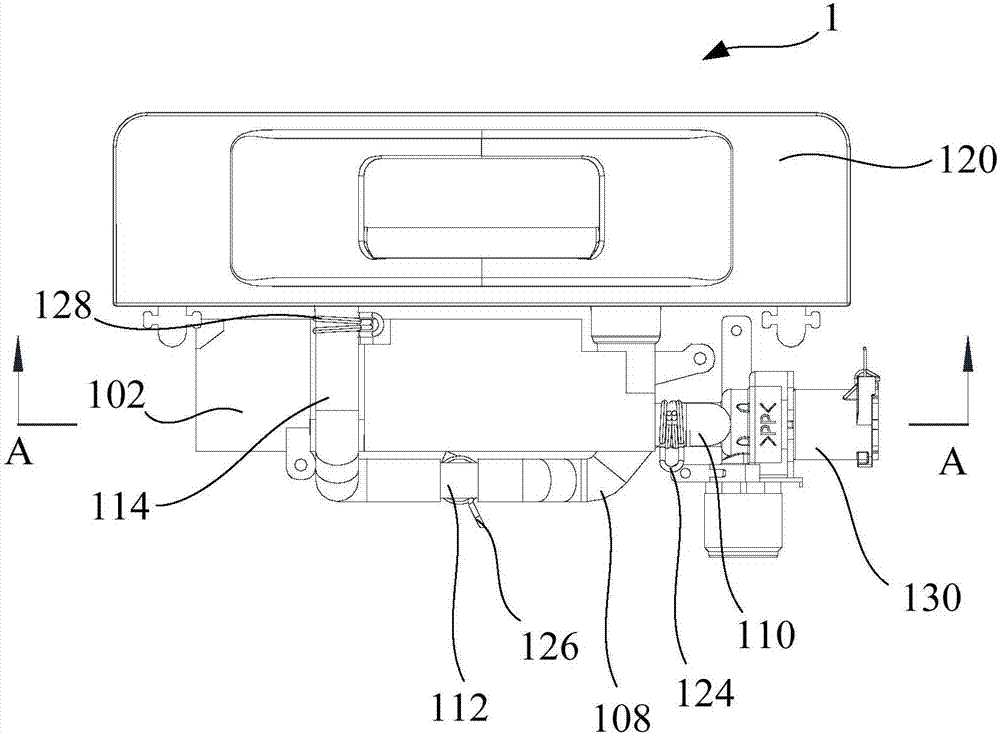

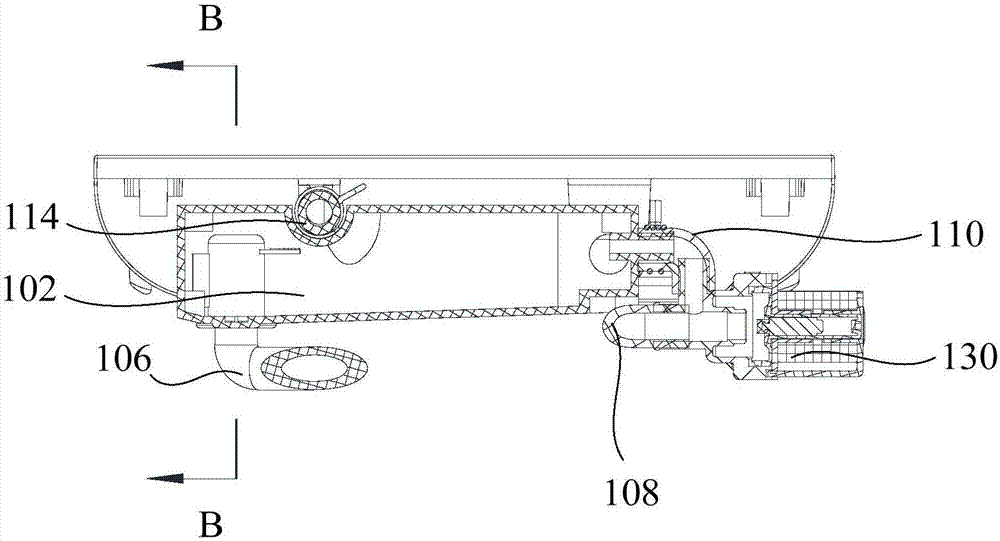

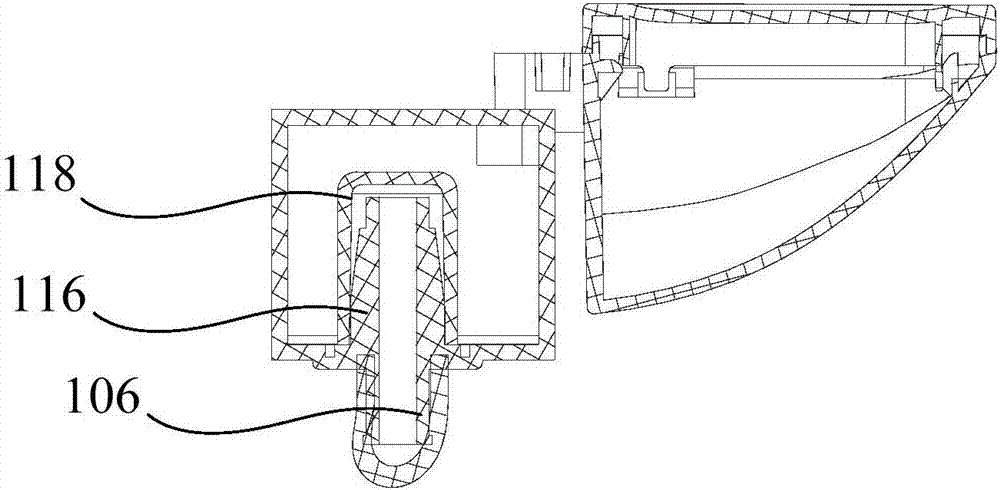

Airflow type particle swing machine

The invention relates to an airflow type particle swing machine, which comprises a rack and a chassis which is arranged on the rack and provided with a fabric channel. The interior of the chassis comprises at least two Venturi tubes communicated with the fabric channel, fabric guide devices positioned at the front ends of the Venturi tubes and grille striking plates positioned at the rear ends of the Venturi tubes; each Venturi tube is communicated with an air inlet pipe, and the air inlet pipe is connected with a heating device outside the chassis; and a pipeline, two ends of which are communicated with the fabric channel to form a cycle, is arranged outside the chassis. The airflow type particle swing machine has simple structure, swings particles for fabrics by adopting mechanical and physical methods, is suitable for particle swing treatment of long fabrics, and can produce the fabrics in accordance with standard length; and after particle swing, the fabrics have soft handfeel and plump surfaces, are fluffy, and generate certain pre-shrinkage effect at the same time.

Owner:江苏保丽洁环境科技股份有限公司

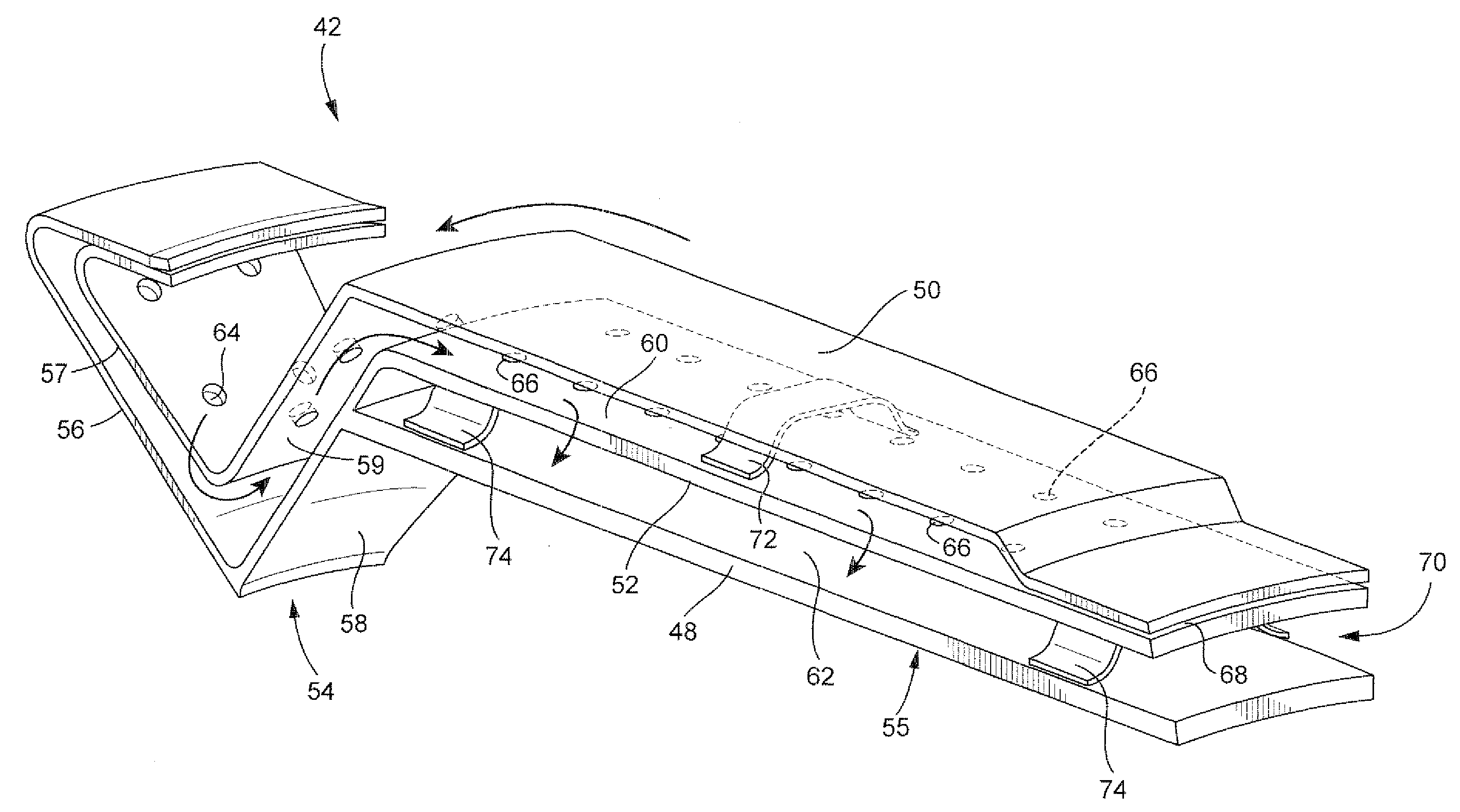

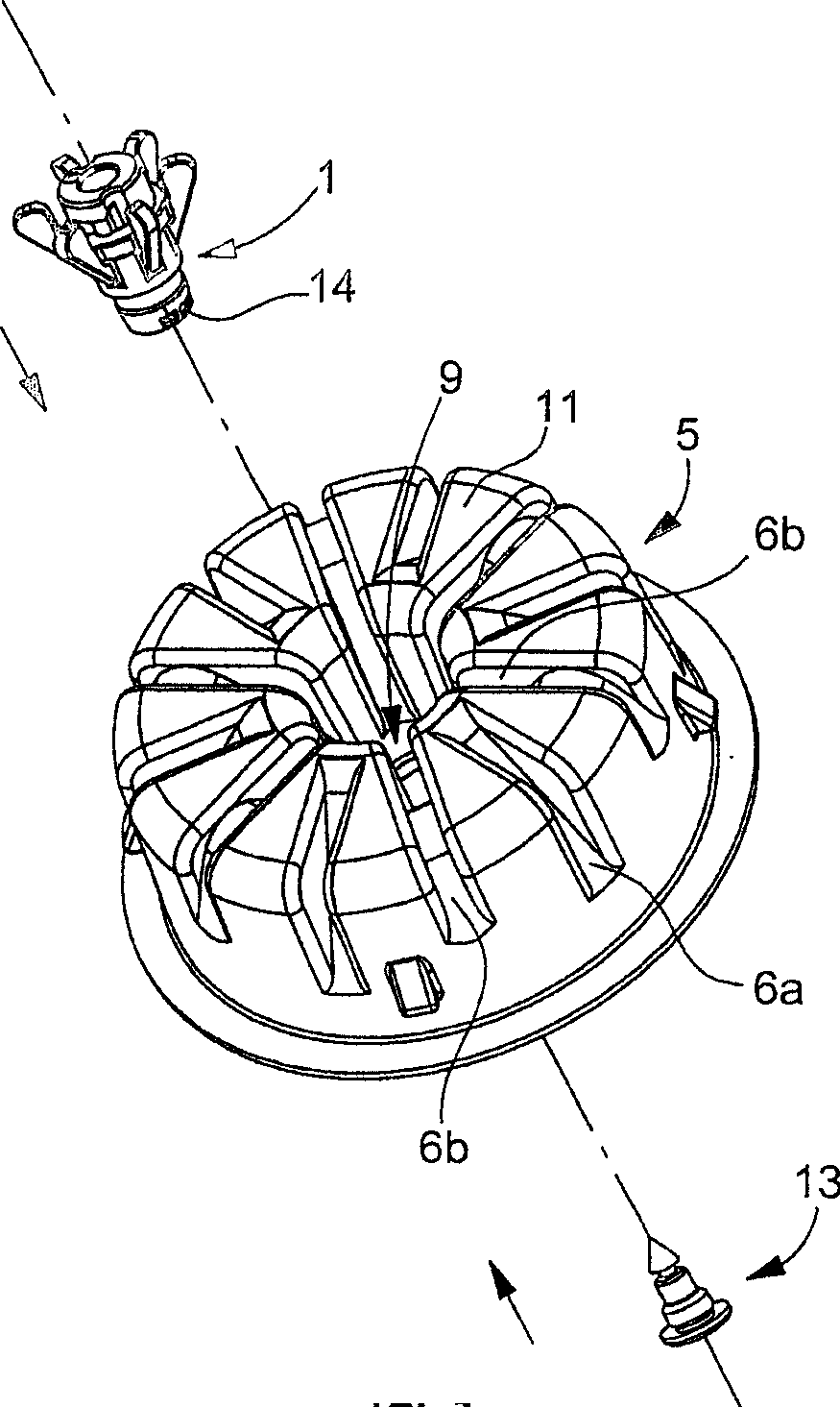

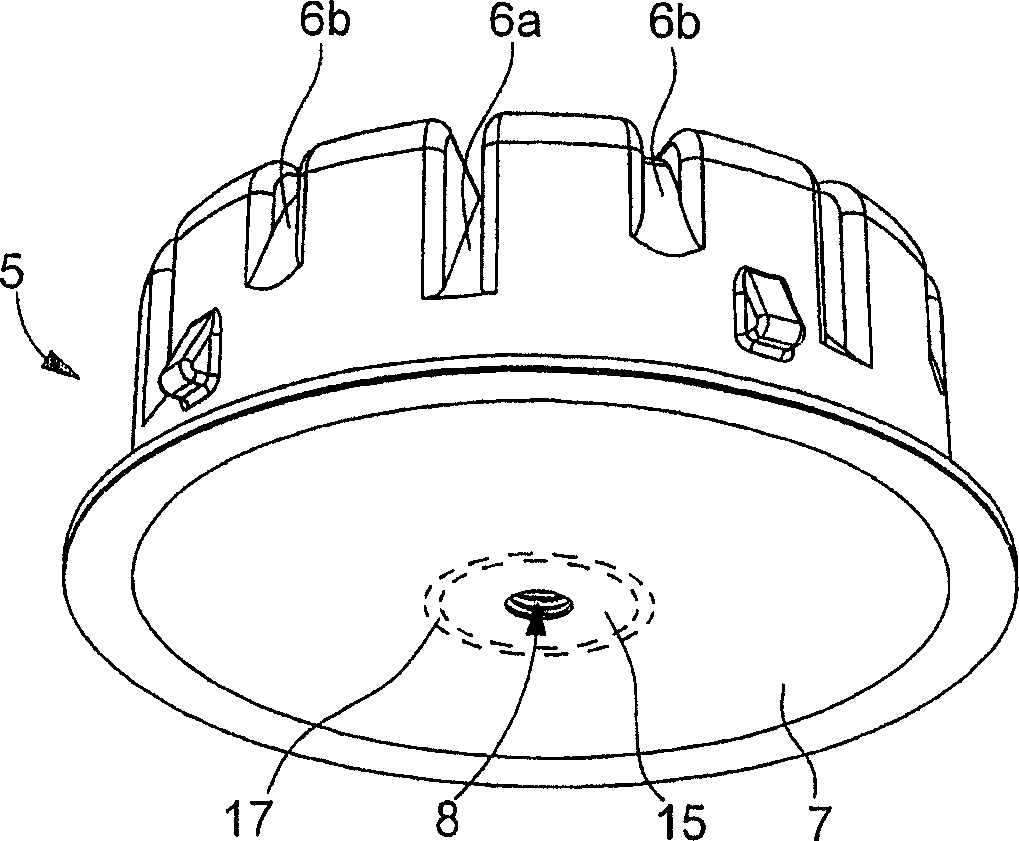

Disposable package for the distribution of a liquid pumpable by a venturi device

The invention relates to a disposable package (2) for dispensing at least one edible preparation based on an edible liquid, said package comprising at least one closed compartment containing the edible liquid, said compartment including a venturi Tubular device for extracting and mixing elements (1) and device (17) for closing said package. The invention is characterized in particular by a lumen (8) through the base (7) and a cover, said lumen providing a venturi nozzle (13) which can be removed by piercing or Seal (10) to extract the edible liquid within the package. The invention finds particular application in the production of hot beverages and / or cappuccino-type emulsified beverages or the like.

Owner:NESTEC SA

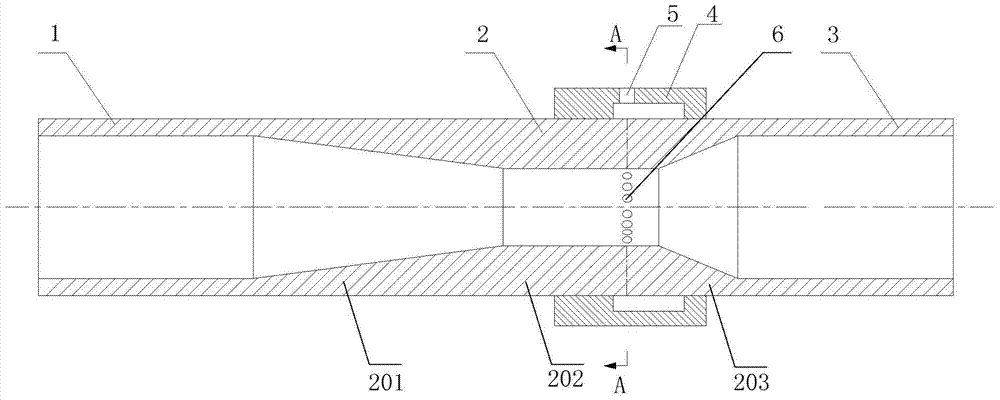

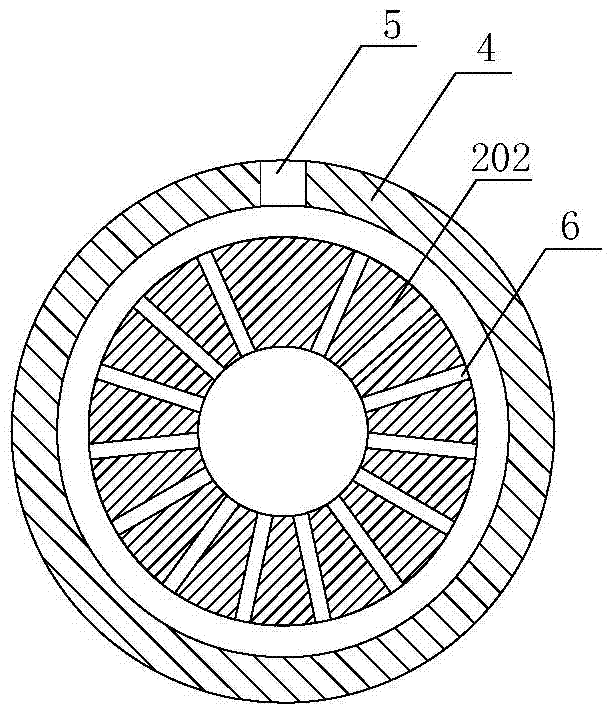

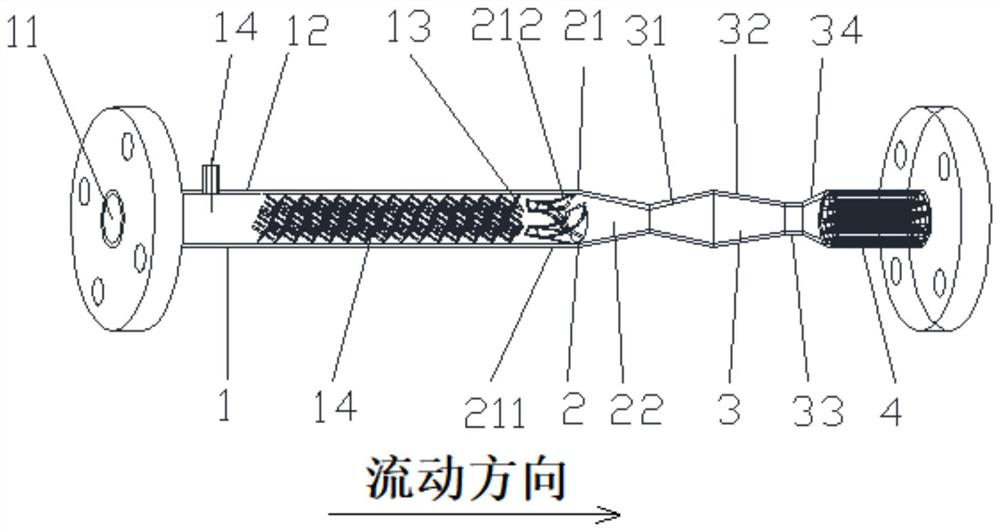

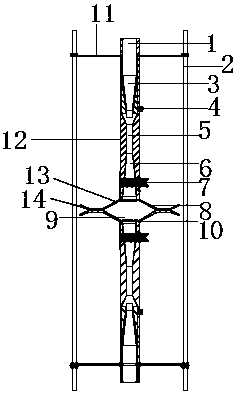

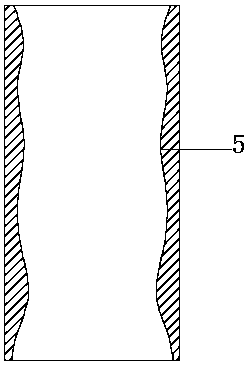

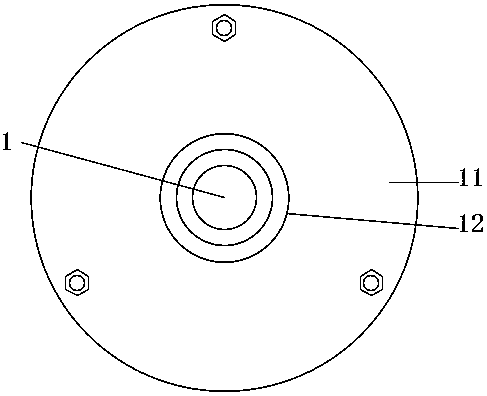

Extension-type Venturi tube and processing method and application method thereof

InactiveCN101893462AHigh compressive strengthImprove assembly accuracyVolume/mass flow by differential pressureWorking pressureEngineering

The invention discloses an extension-type Venturi tube and processing method and application method thereof, comprising a Venturi tube; wherein the Venturi tube is externally sheathed with a Venturi tube sleeve. The Venturi tube is composed of a front constricted tube, a middle tube and a rear diffusion tube, the inner diameter of the sleeve is equal to the maximum outer diameter of the front tube of the Venturi tube, and the two ends of the front constricted tube and the rear diffusion tube are fixed in the sleeve. The invention adds a sleeve to the original rolling plate type Venturi tube, thus greatly improving assembling accuracy. Fluid moves in a totally-enclosed sleeve, thus greatly improving compression strength of the invention and reducing possible leakage point, so that the Venturi tube can bear overhigh working pressure or can be used for flow measurement of danger medium. Meanwhile double insurance function is realized when bearing overhigh working pressure or being used for flow measurement of danger medium.

Owner:江阴市节流装置厂有限公司

Flow guiding ring structure, axial flow fan and air conditioner

The embodiment of the invention discloses a flow guiding ring structure, an axial flow fan and an air conditioner, relates to the denoising field and is used for lowering the pneumatic noise of the axial flow fan in the using process on the premise that the air outflow amount of the fan is guaranteed. The flow guiding ring structure comprises a ring body; the ring body comprises a closed cavity and a through hole; the minimum diameter position of the ring body is provided with open holes; the cavity is communicated with the through hole through the open holes; and fluid in the through hole can enter the cavity through the open holes. Due to the above technical scheme, on the premise that the Venturi tube effect of the flow guiding ring structure is guaranteed, the open structure is added on the surface, the turbulent energy of blade top airflow is transmitted out of a fan area in the radial direction, and therefore the denoising purpose is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

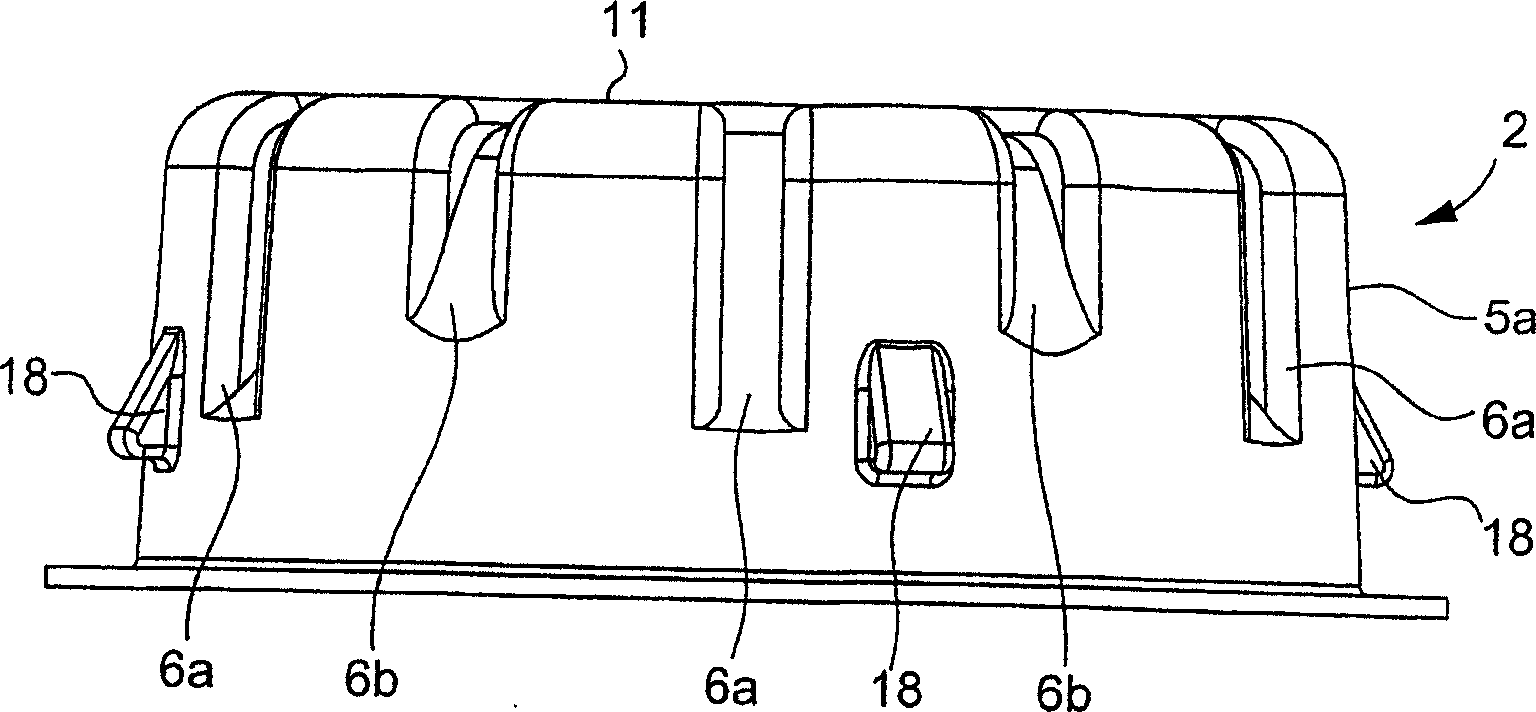

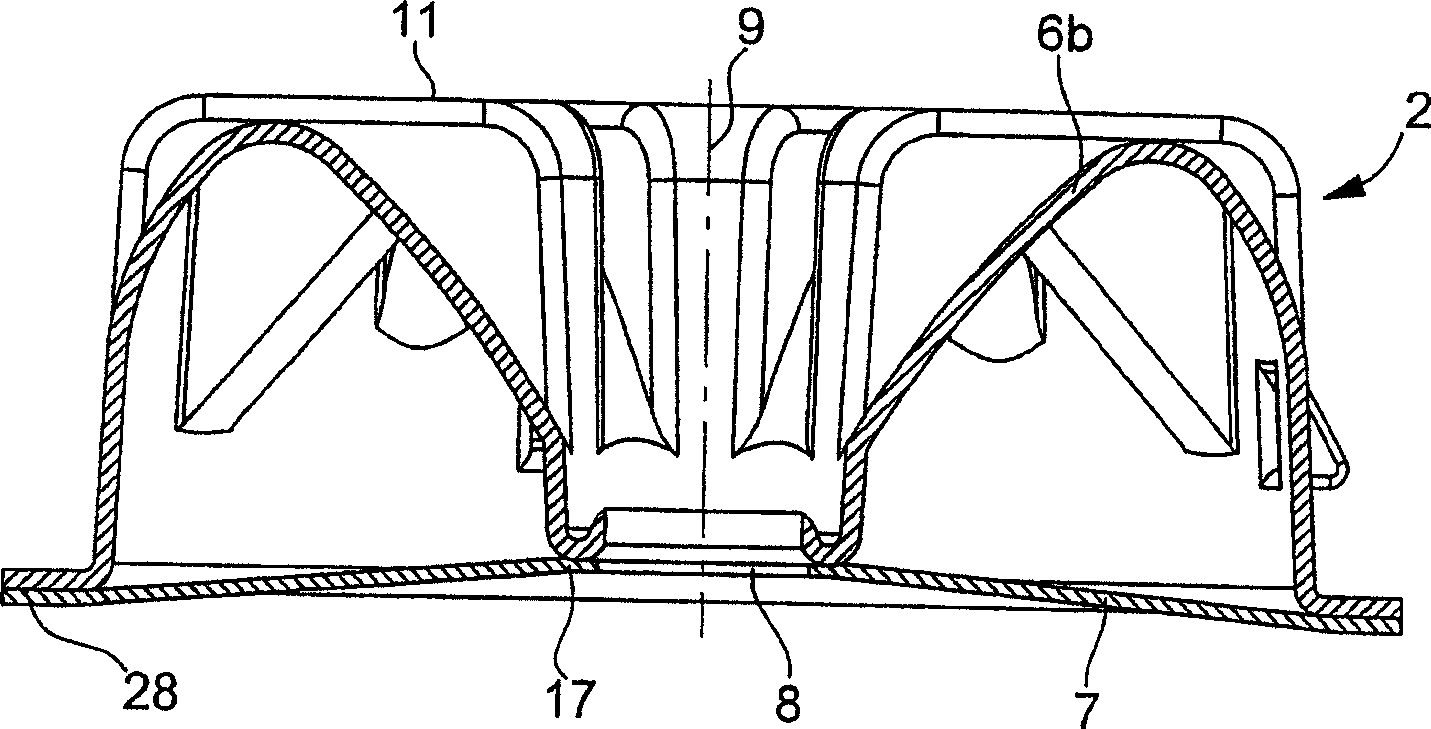

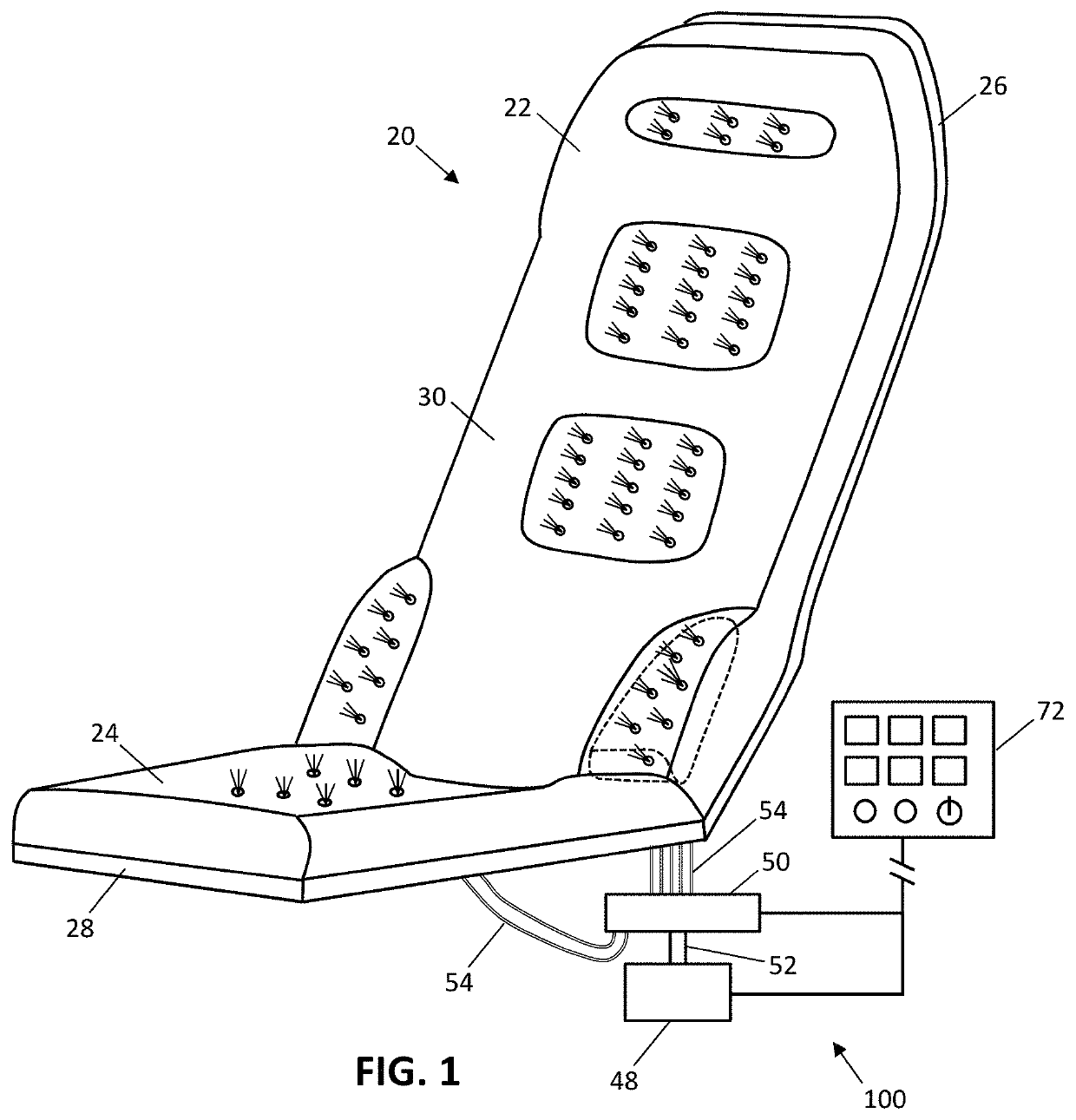

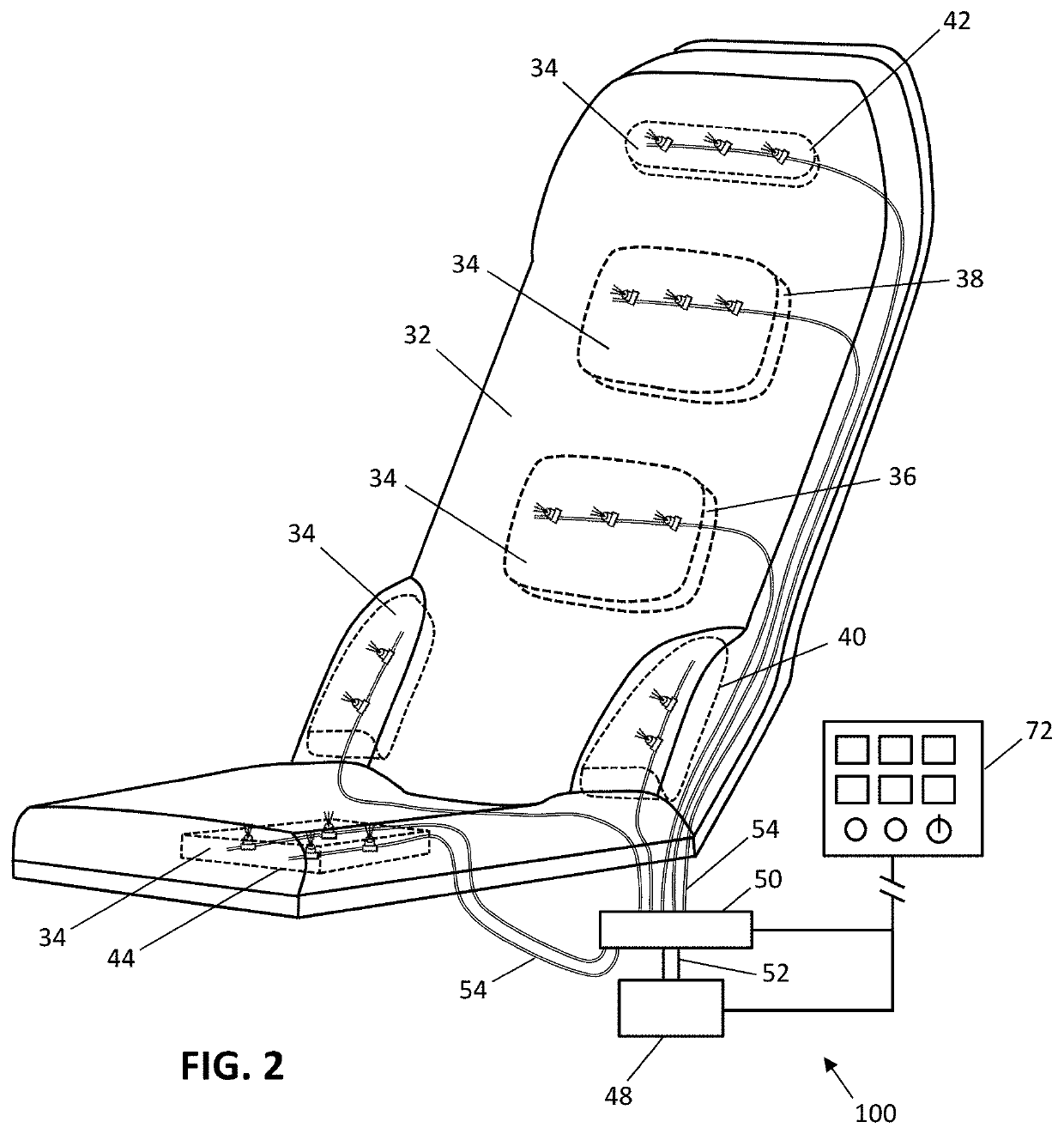

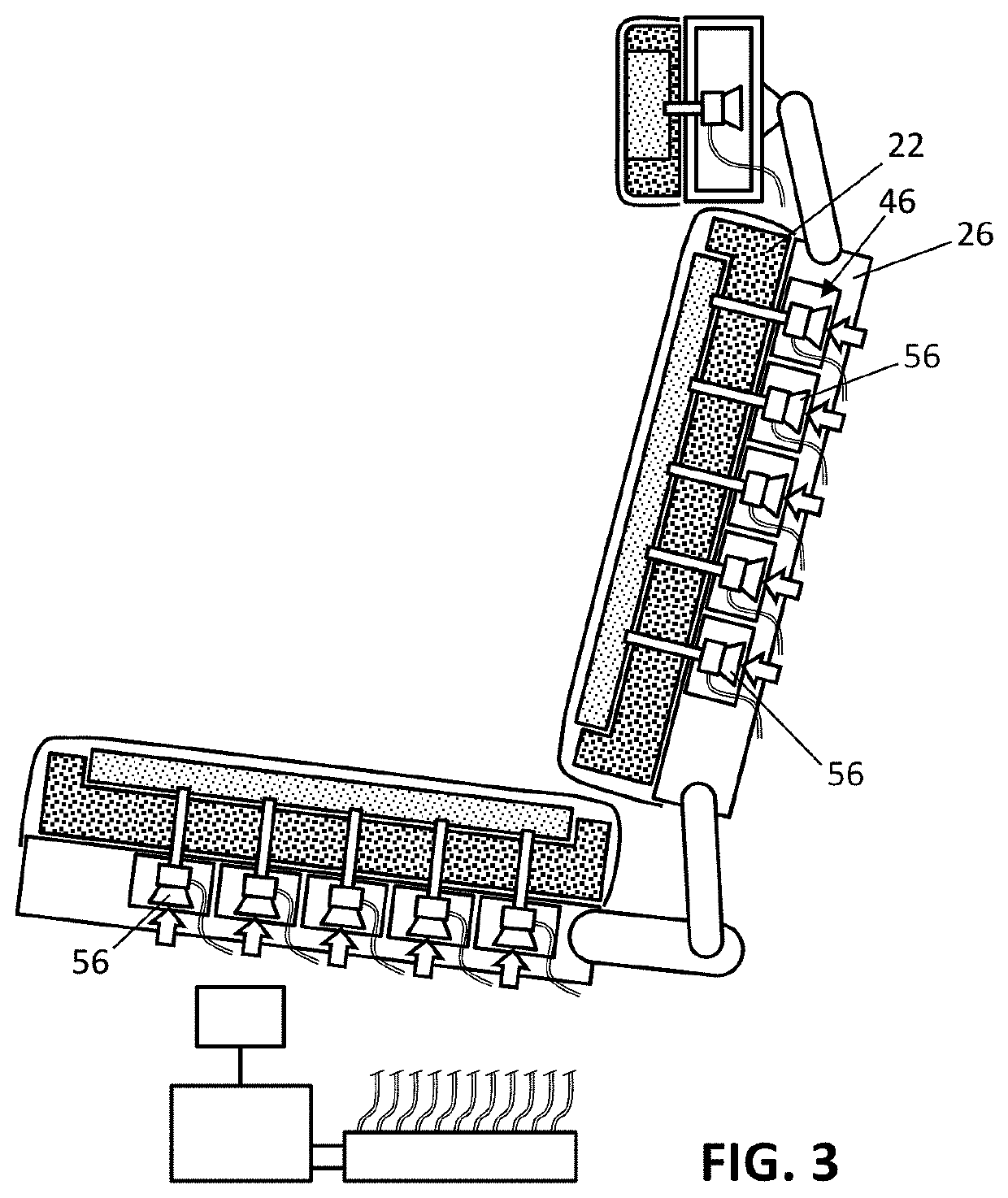

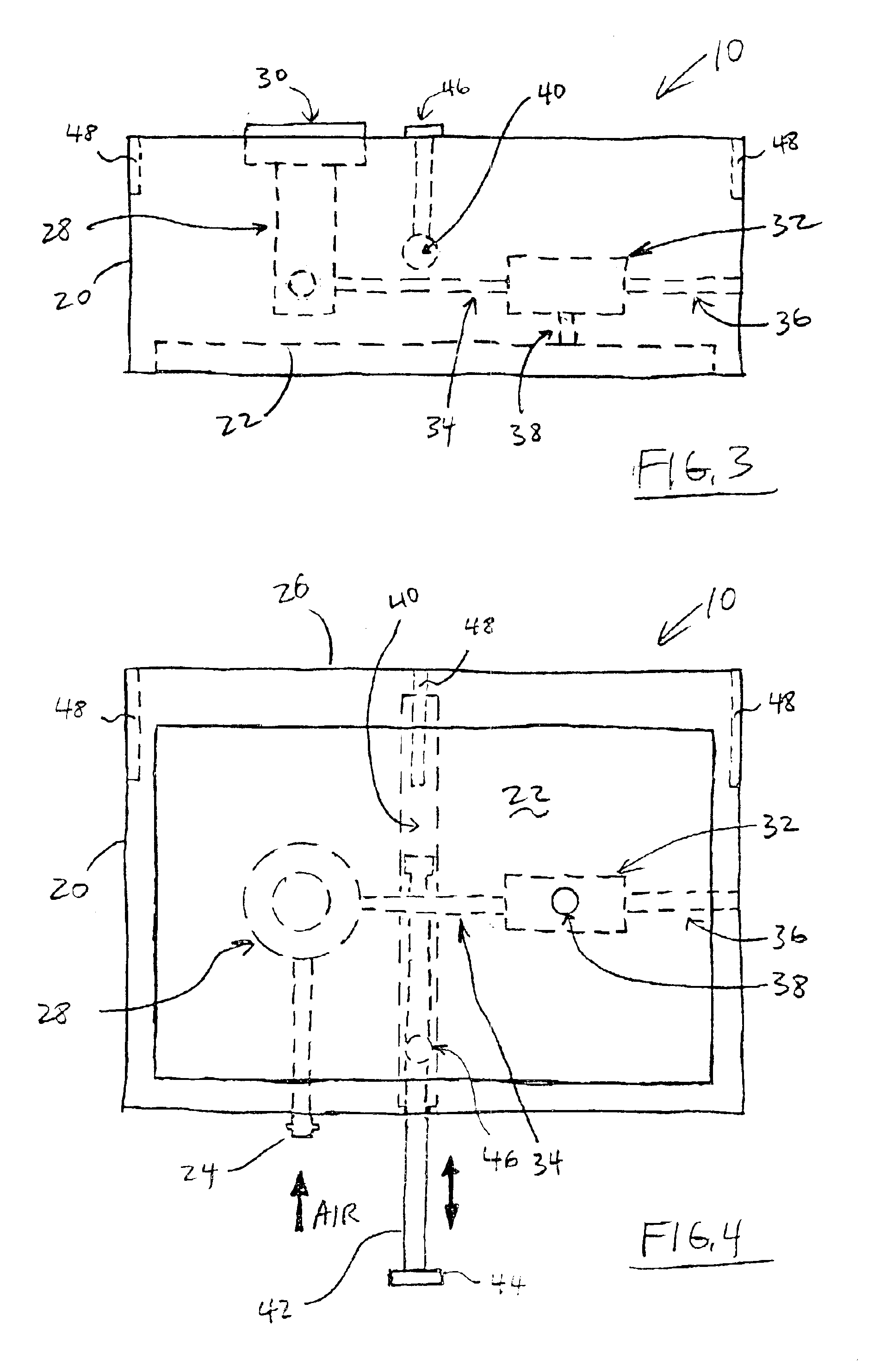

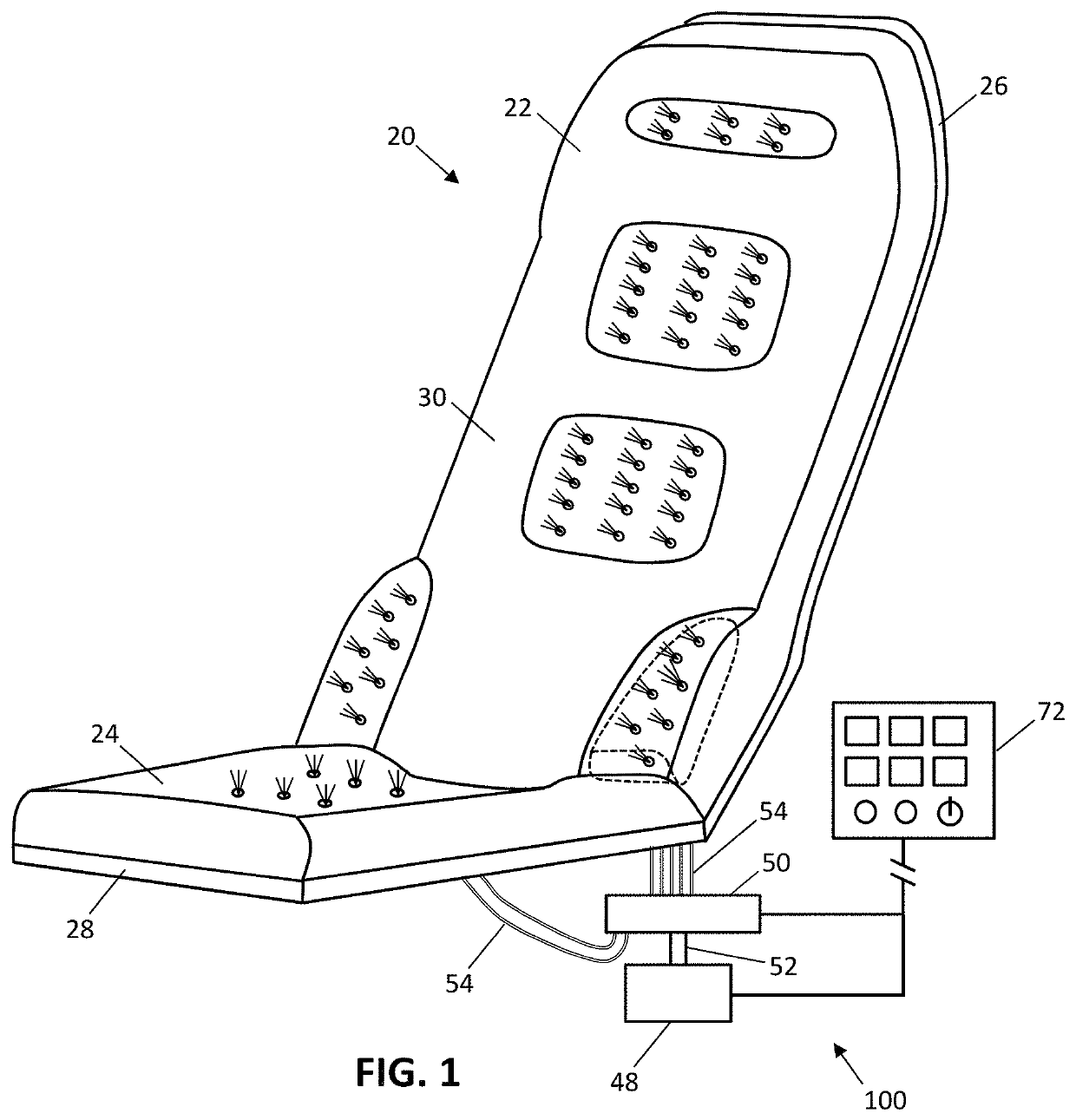

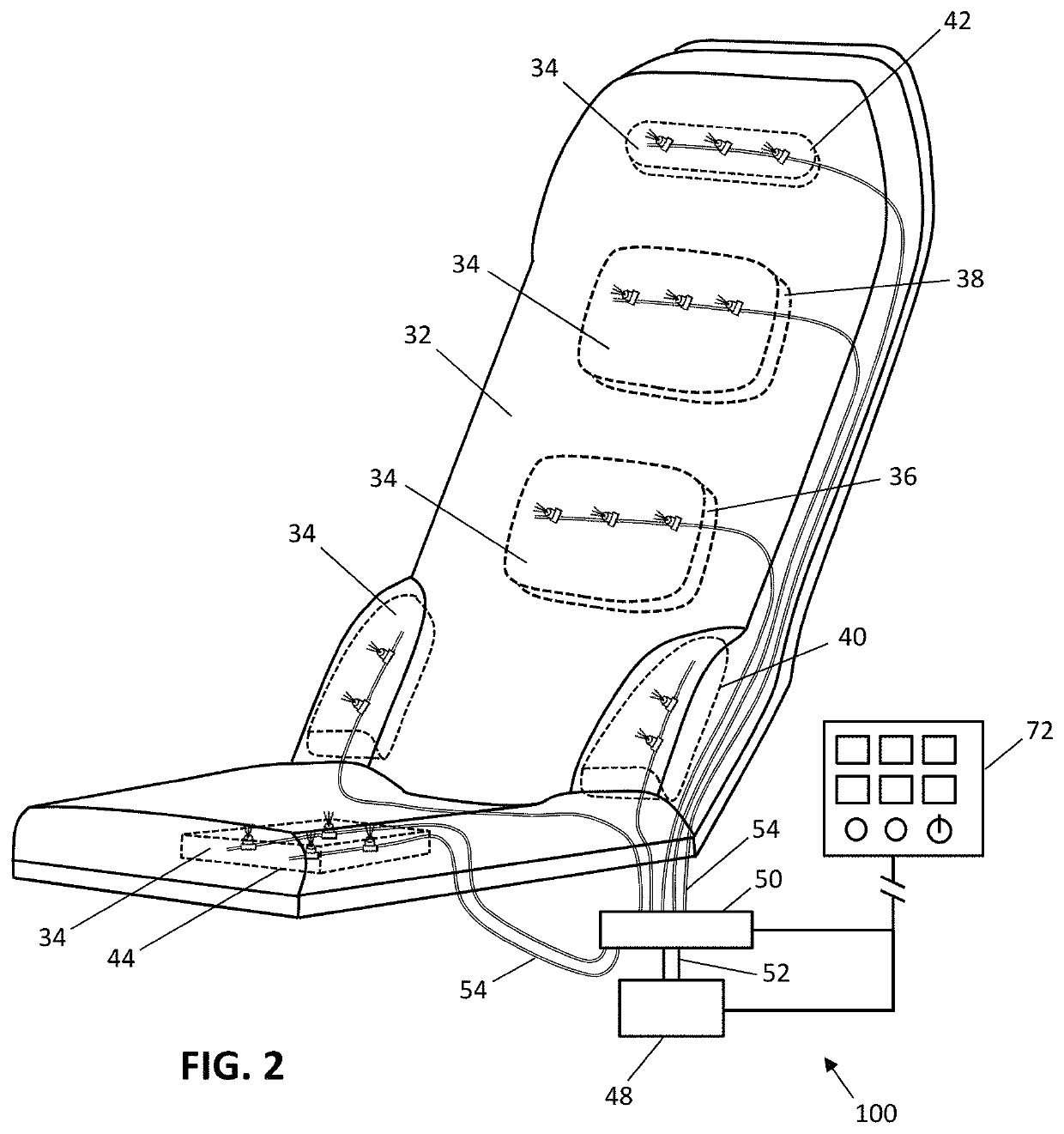

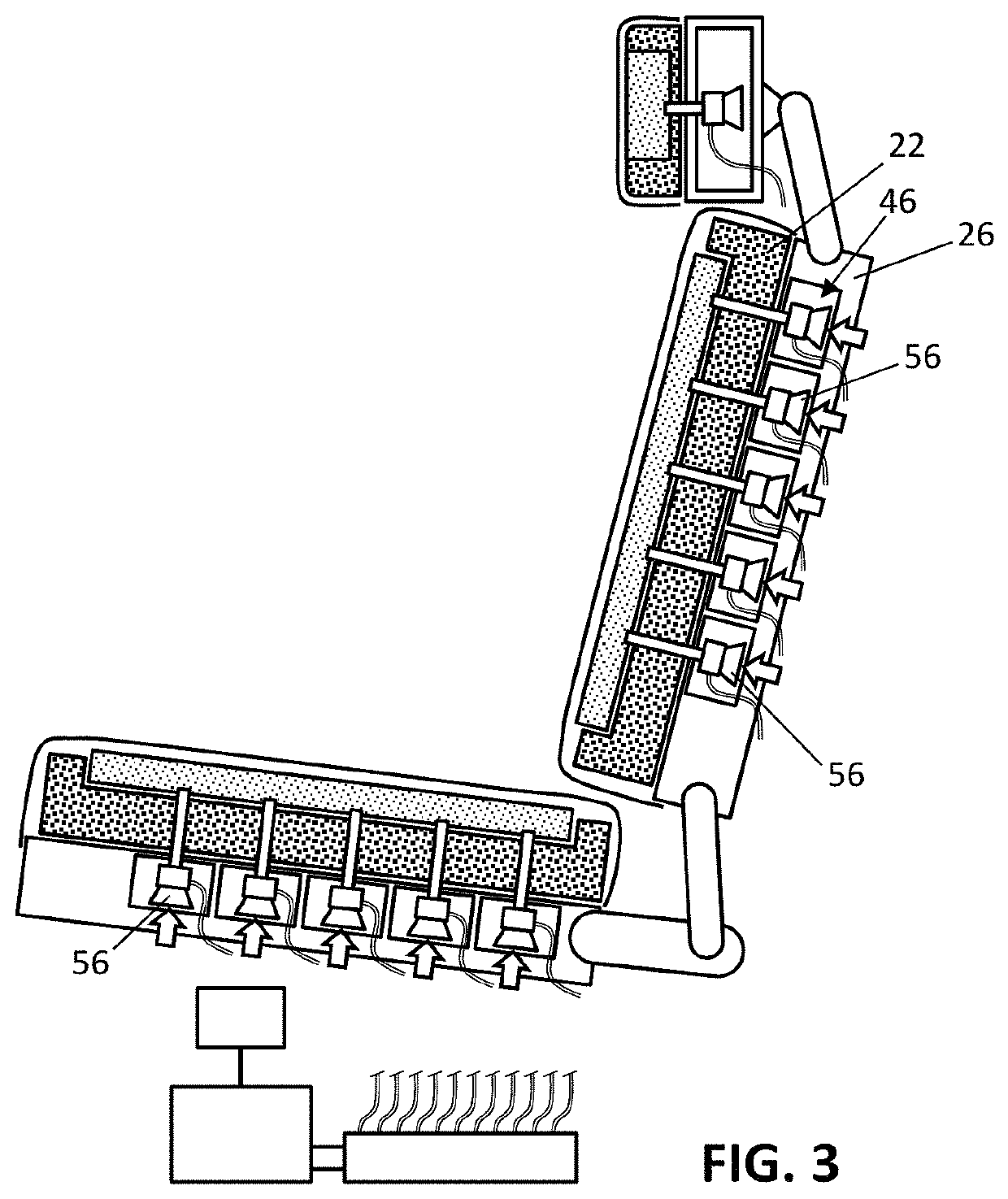

Seat assembly with ventilation system utilizing venturi effect to multiply air flow

ActiveUS20210039791A1Seat heating/ventillating devicesSeating arrangementsClassical mechanicsAir compressor

A ventilated seat assembly such as an aircraft passenger seat including a cushion assembly supported by a structural element, a plurality of Venturi tubes positioned to direct a flow of air through the cushion assembly, an air compressor supplying compressed air, a manifold assembly coupled in fluid communication with the air compressor, a conduit network fluidly coupling the manifold assembly with the plurality of Venturi tubes, and a controller for activating the air compressor and actuating the manifold assembly. Supplying a small volume of pressurized air to the Venturi tubes induces a larger flow of ambient air and a multiplied air effect to ventilate the passenger seat.

Owner:BE AEROSPACE INCORPORATED

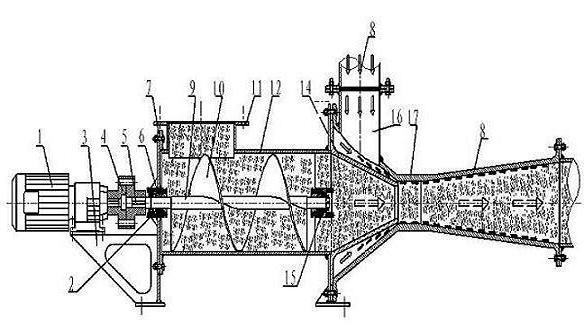

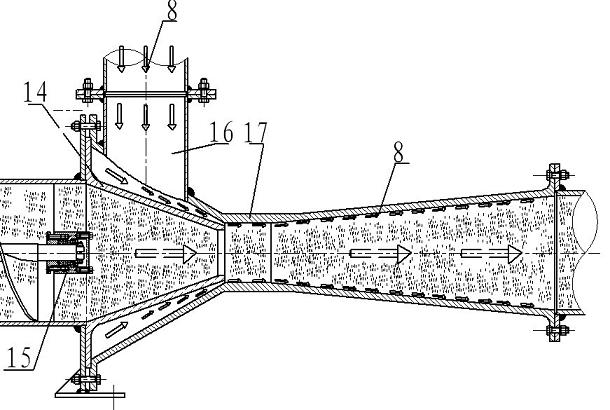

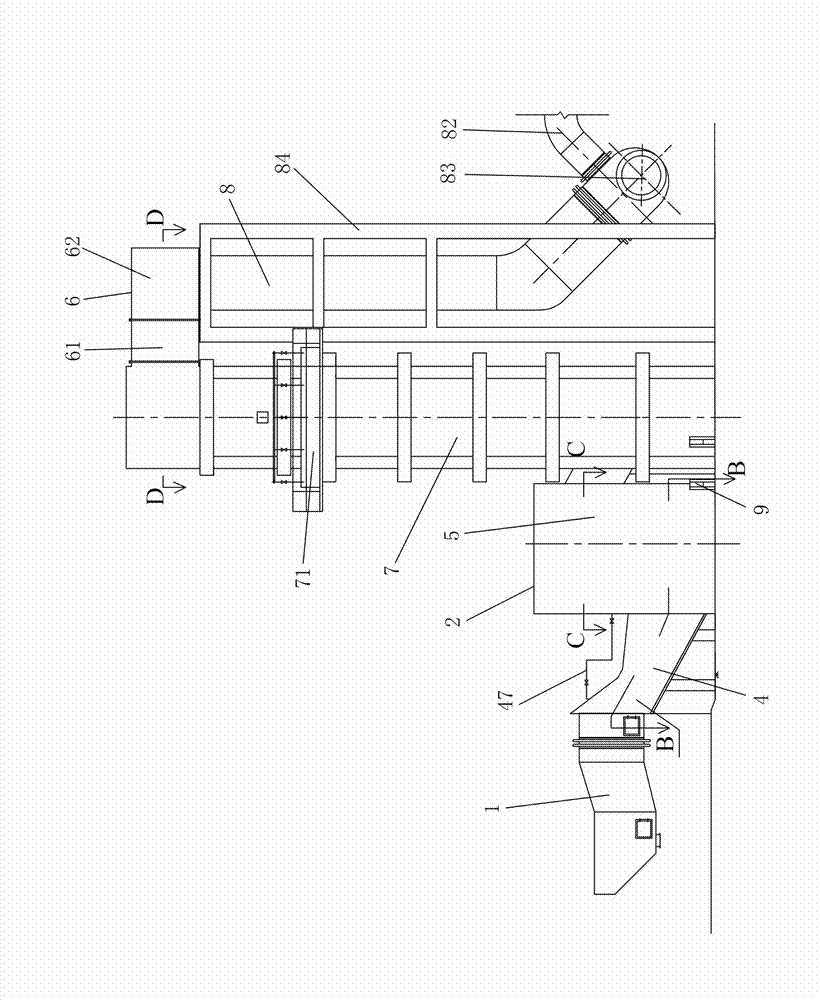

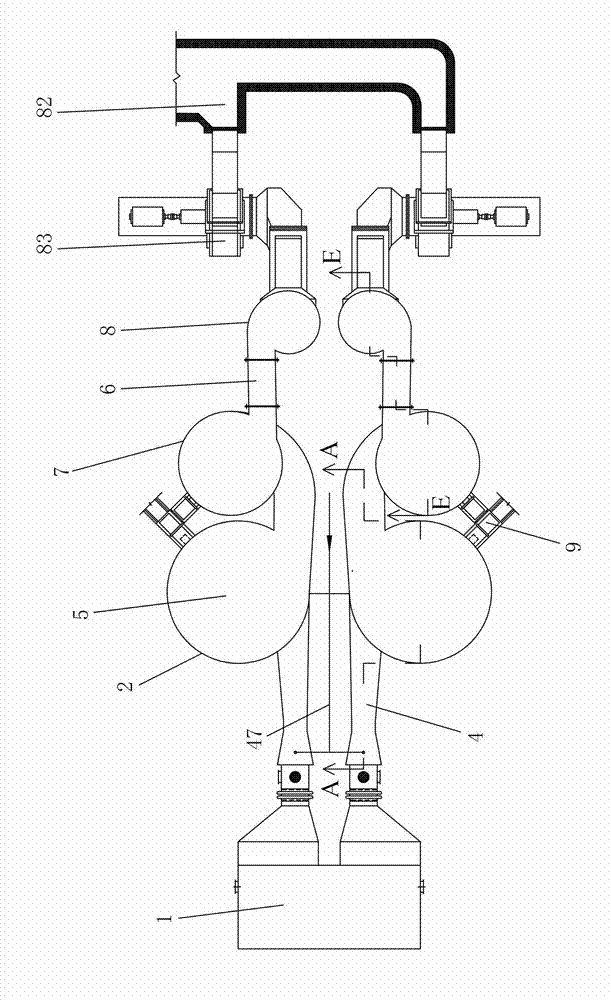

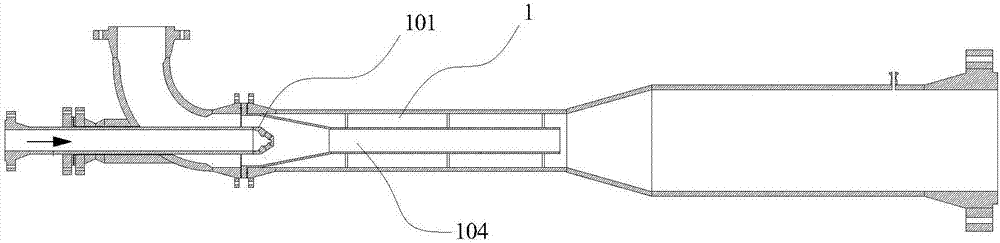

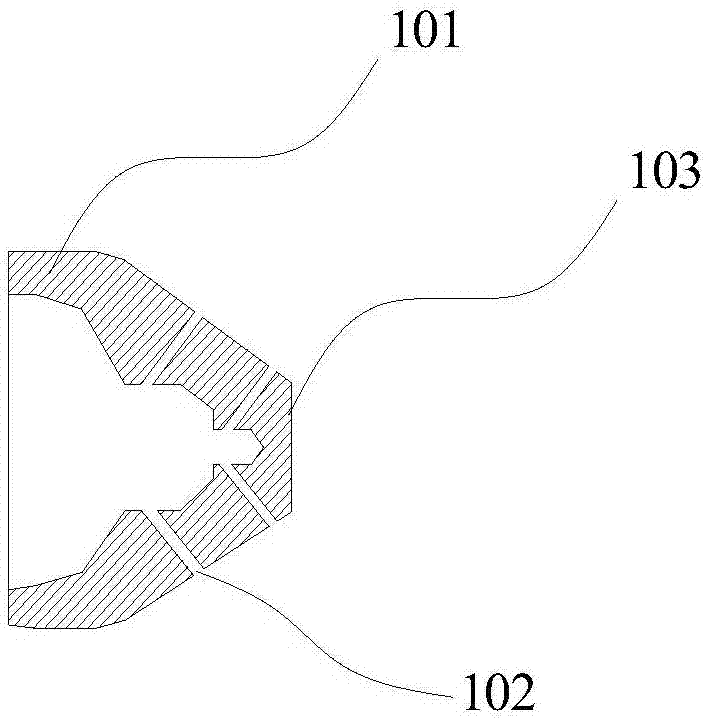

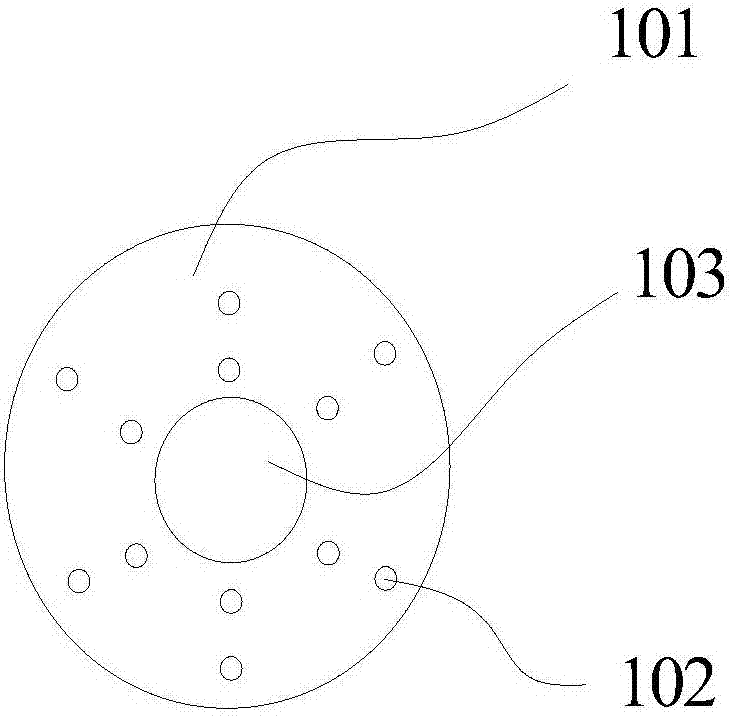

Material-in-air conveying theory principle and technical scheme of conveying material by fluid

The invention relates to the field of conveying materials by jetting fluid, in particular to a material-in-air conveying principle and technical scheme of conveying a material by fluid. The device comprises a power part, a base, a material conveying system and a material air-wrapped feeding system. A spiral blade (10) is driven by the power part (1), the spiral blade (10) provides power for the axial movement of materials when rotating, and the circumference movement of the spiral blade (10) is converted to the axial movement of the materials. High pressure air (8) enters an air pipe cavity from a side air inlet, and is annularly jet into a venturi pipe from a gas between the outer side of a nozzle and the venturi pipe. Due to the obvious action of Condar effect, the high pressure air (8) jet from the gap flows forward closely to the inner wall of the venturi pipe, one layer of continuous air film is attached to the inner side of the venturi pipe, and middle materials are wrapped by the air and conveyed forward. The invention has the advantages of good wear resistance property, small conveying resistance, large material to gas ratio, high efficiency, low price, small pump height, adaptability to the conveying of high-temperature materials, coarse powder particles and the like.

Owner:何智

Combination Venturi Check Valve

Disclosed herein is a combination venturi check valve for introducing a composition, such as ozone, into the fluid circulation line of a swimming pool, spa, and / or other recreational body of water. The combination venturi check valve preferably includes a fluid inlet, a fluid outlet, a venturi passage for suctioning in the composition, and a bypass passage with a valve enabling compatibility with pumps having different flow rates, for example. In an aspect of the invention, the venturi and bypass passages are inline with the fluid inlet and fluid outlet. In another aspect of the invention, the venturi and bypass passages share a common wall, and / or the housing is modular and / or integrally formed. In yet another aspect of the invention, the valve automatically adjusts the flow rate of fluid through the bypass passage without requiring human intervention.

Owner:HAYWARD IND INC

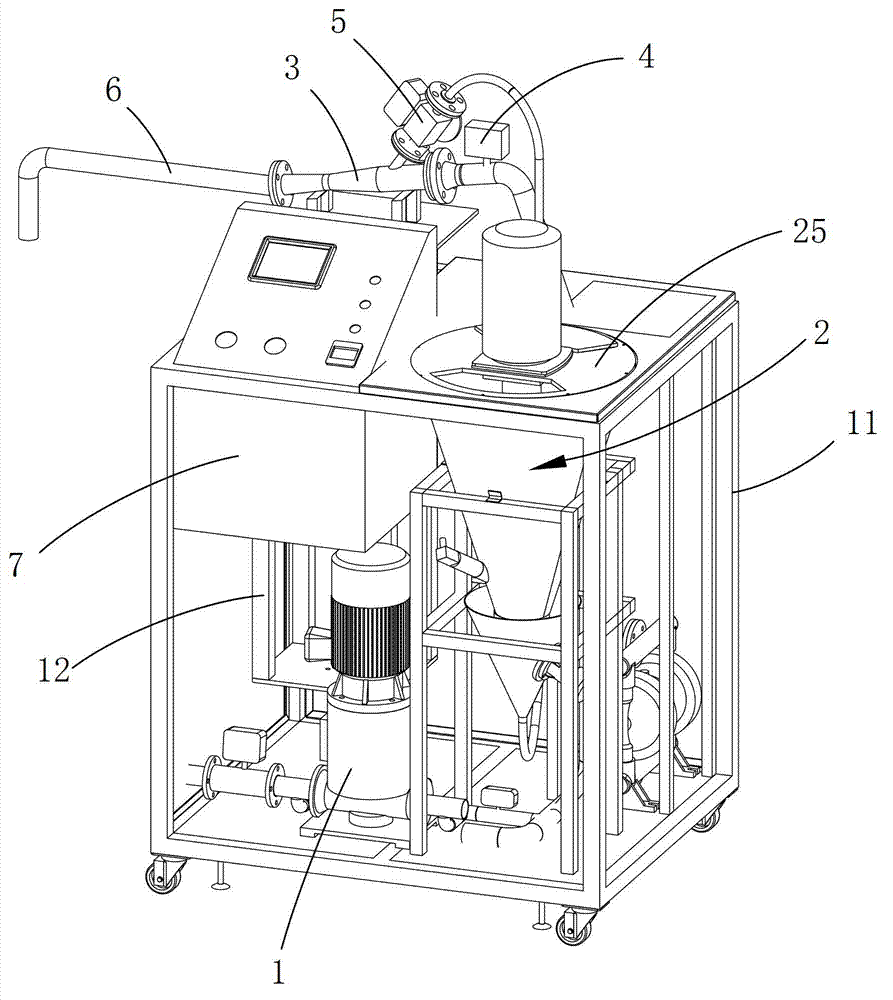

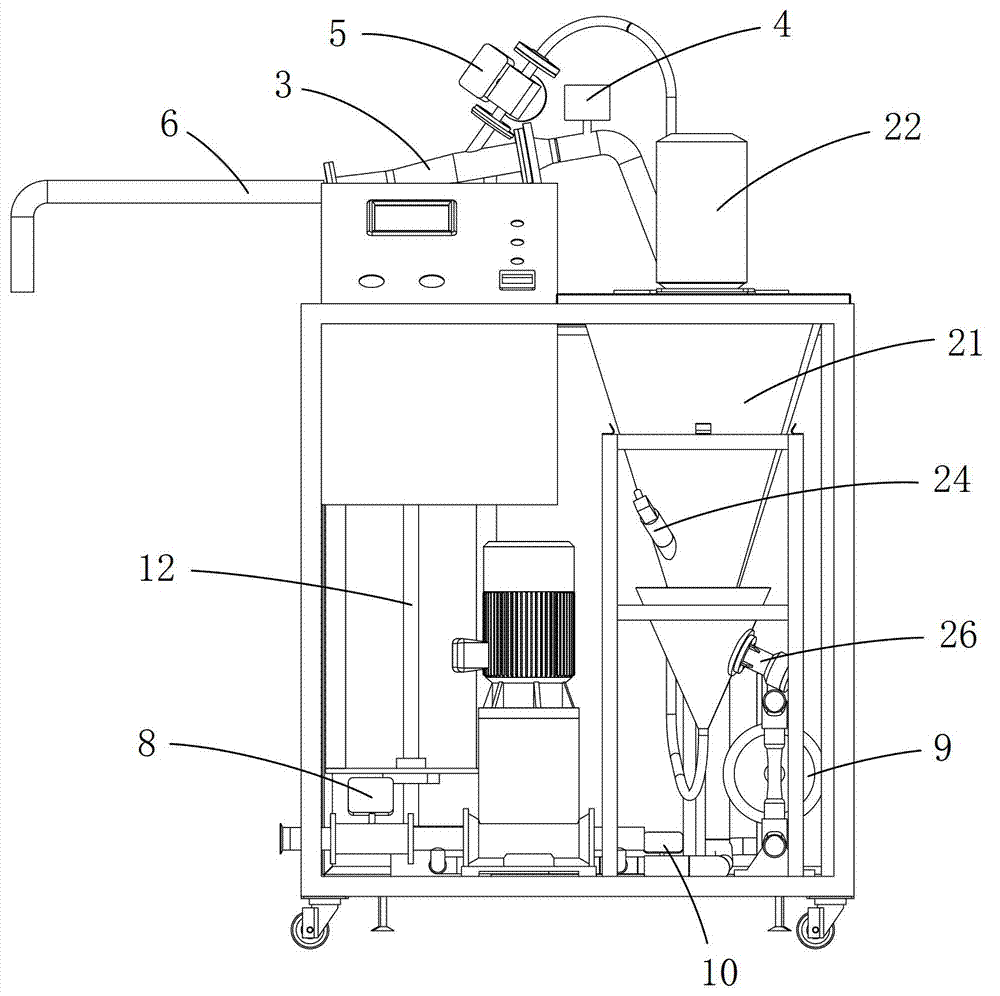

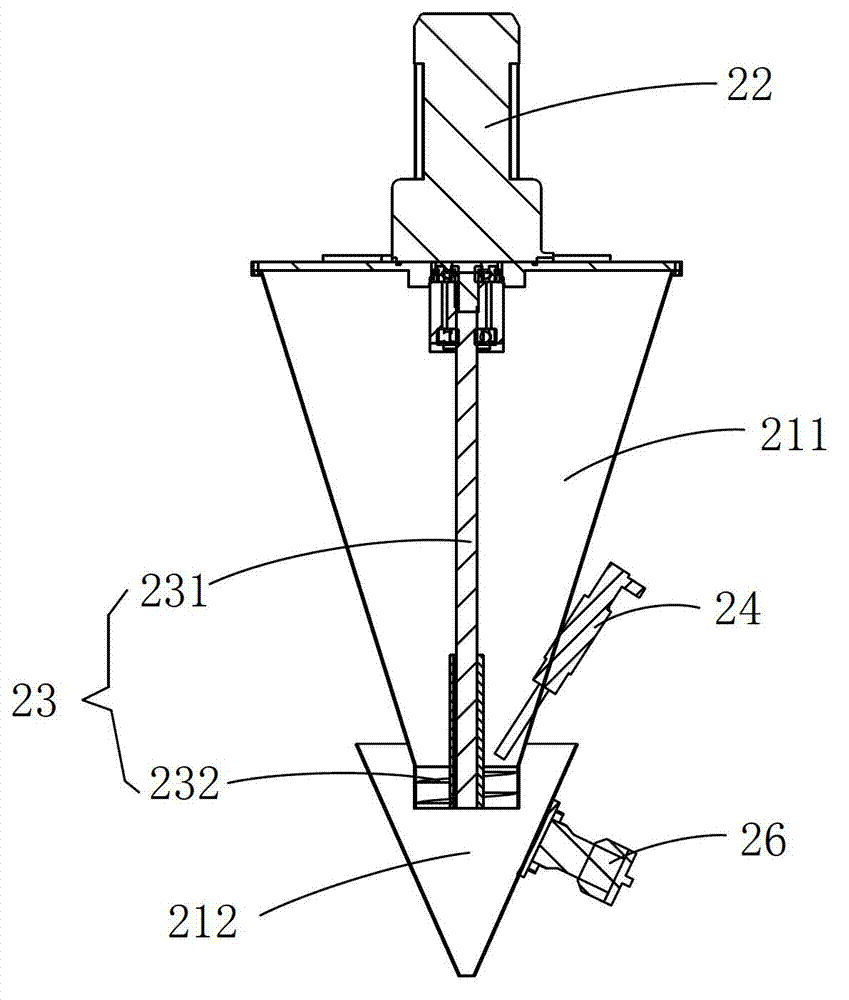

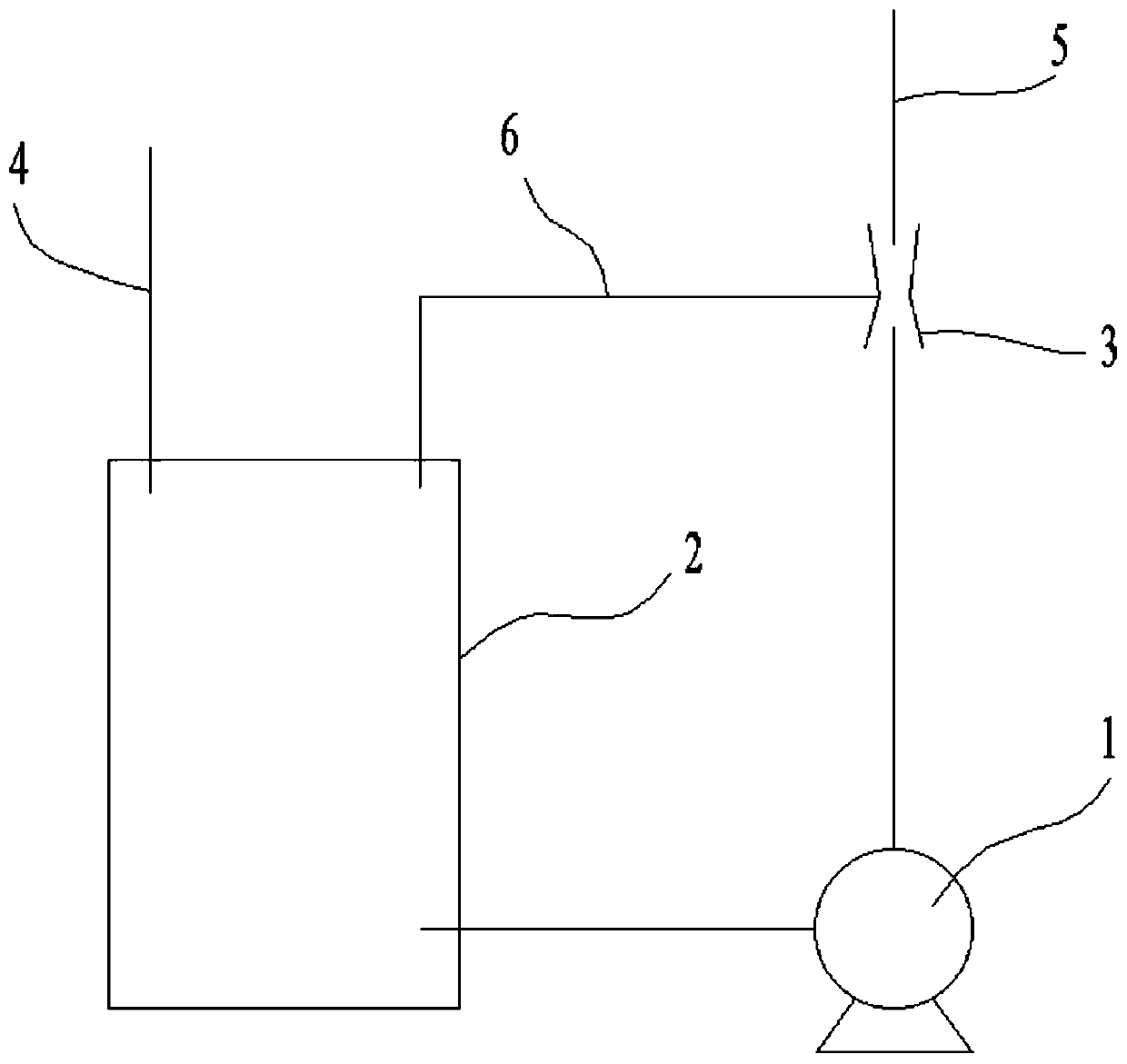

Automatic powder material feeding method and device

InactiveCN103111209AReduce pollutionGuaranteed smoothFlow mixersMixing methodsAutomatic controlPneumatic valve

The invention discloses an automatic powder material feeding method which comprises the following steps of: 1) installing a material mixing mechanism; 2) installing a liquid conveying mechanism; 3) installing a powder material conveying mechanism; 4) installing a control device; and 5) starting up a control device, and controlling the material mixing mechanism, the liquid conveying mechanism as well as a powder material conveying mechanism so as to achieve automatic feeding, material mixing and material conveying of the powder materials. The invention also discloses an automatic powder material feeder for achieving the method. The automatic powder material feeder comprises a centrifugal pump, a feeding mechanism, a Venturi tube, a pressure switch, a three-way pneumatic valve, a feeding pipe as well as a PLC (program logic controller). According to the automatic powder material feeding method, liquid and powder materials are directly mixed together in the Venturi tube by applying a Venturi vacuum principle, and the powder material conveying speed is controlled automatically according to different formulas so as to guarantee the mixed product concentration; and the solid content of products is high, additional equipment and working procedure steps are not increased in the whole process, and according to the automatic powder material feeding method, efficiency and energy conservation are realized, performances are reliable, and automation degree is high.

Owner:东莞市科锐机电设备有限公司

Device for pumping a liquid from a packaging or a container.

InactiveCN1764403AEasy and quick suctionEasy and quick to mixFlow mixersMixing methodsNozzleEngineering

The invention relates to a device for pumping liquid from a package (5) for dispensing the liquid in heated, foamed or emulsified form, the device comprising a venturi-type suction member adapted to be connected to a pressure A nozzle for carrying a fluid generator, said suction part comprising a body (4, 50, 52) having a carrying fluid introduction conduit (21, 27) leading into a suction chamber (25) and at least one outlet for suction. A suction tube (33) for sucking liquid contained in a package (5), characterized in that the suction part includes a nozzle (1, 2, 3) and a fixing and opening device (13, 15, 30), This fixing and opening device connects the nozzle (1, 2, 3) to the package (5) and puts the suction tube (33) into communication with the liquid inside the package (5). The invention is used for preparing cappuccino or other foaming beverages.

Owner:NESTEC SA

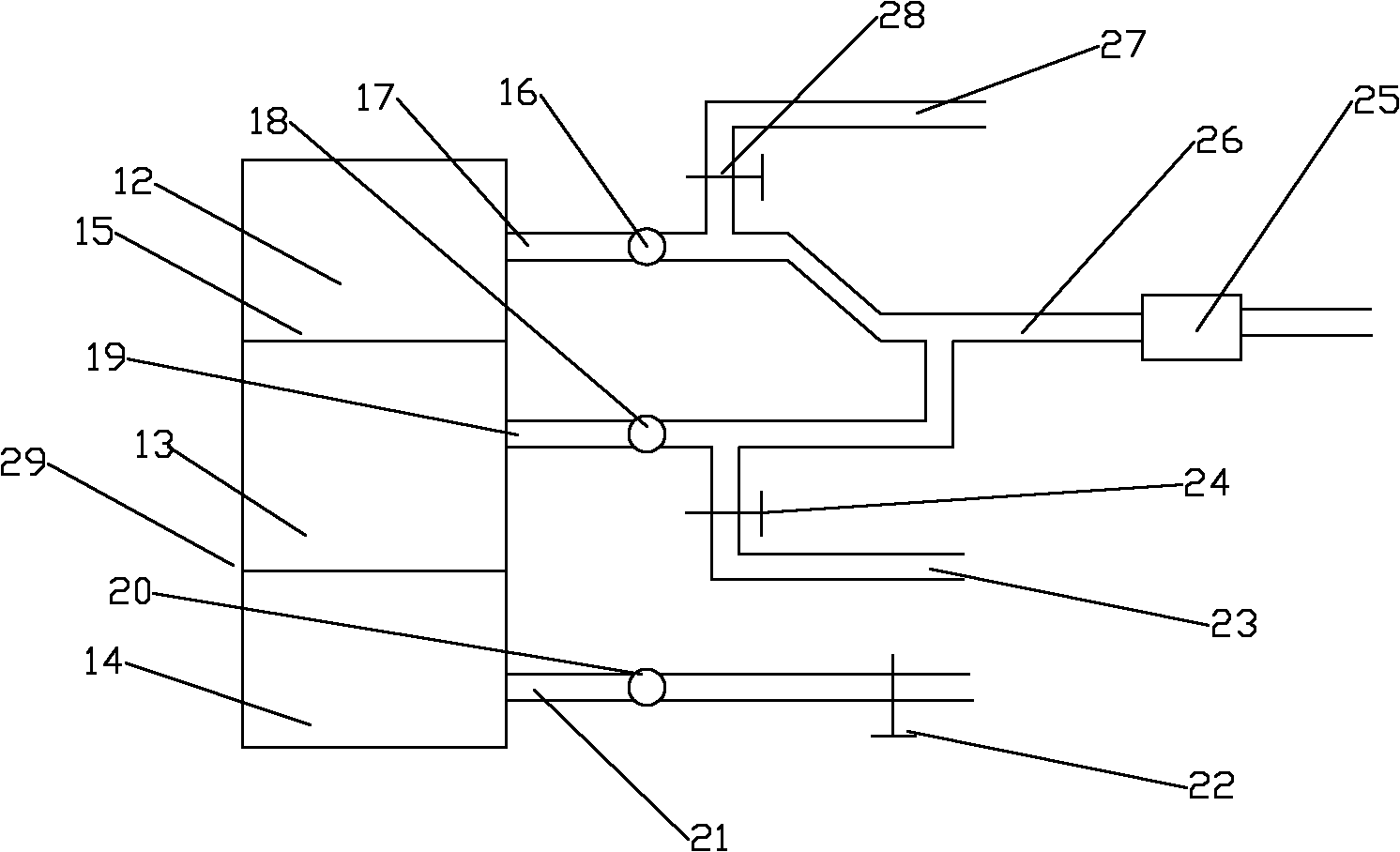

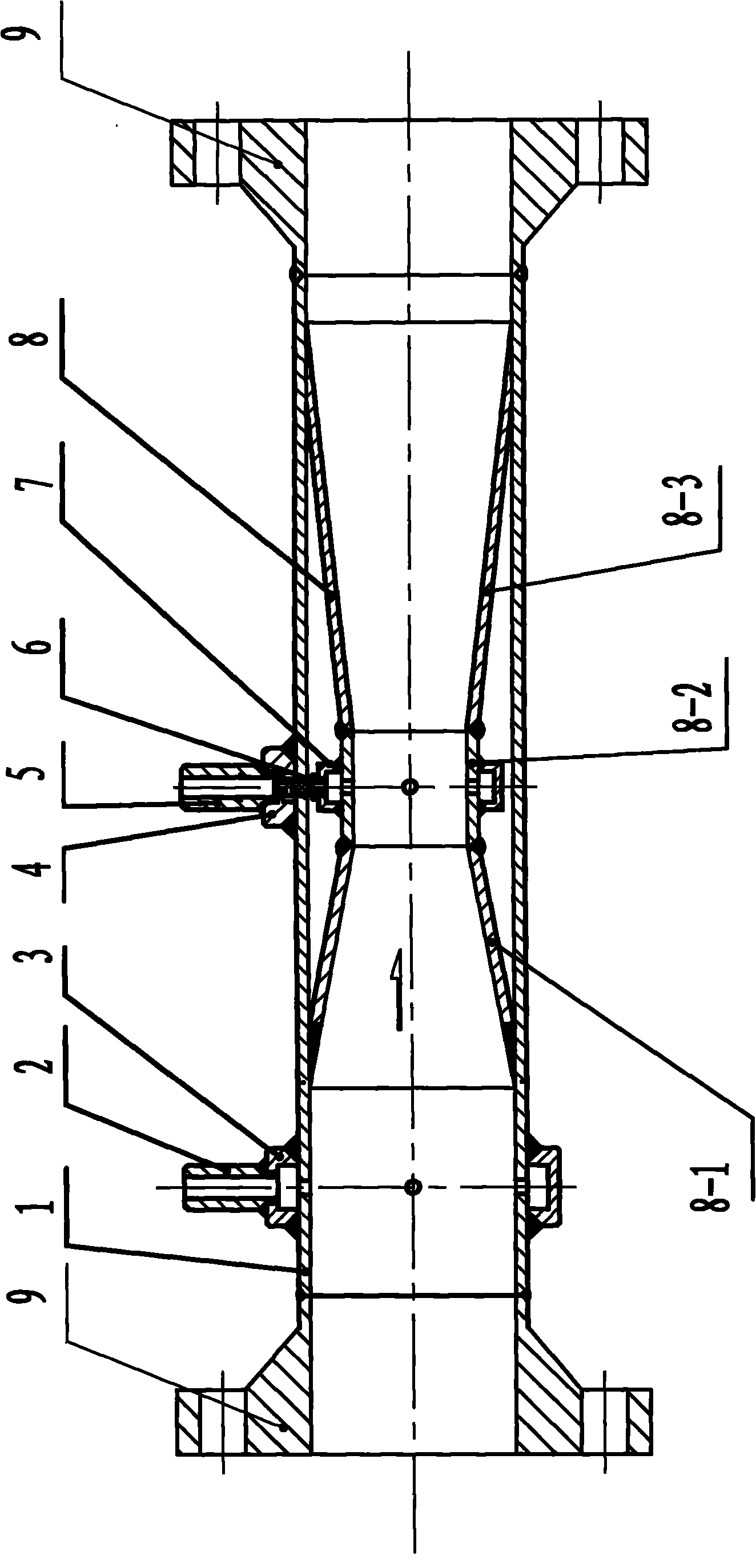

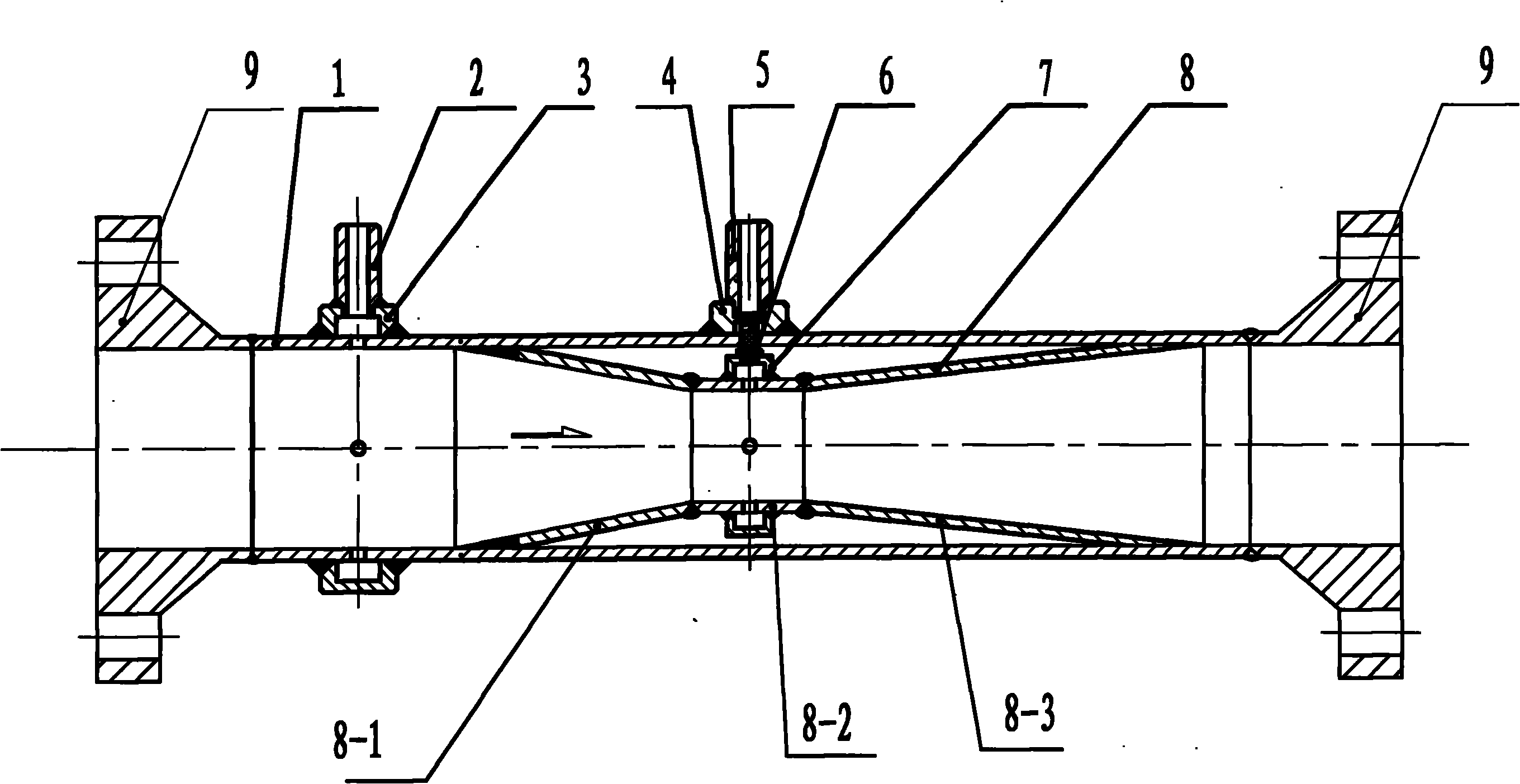

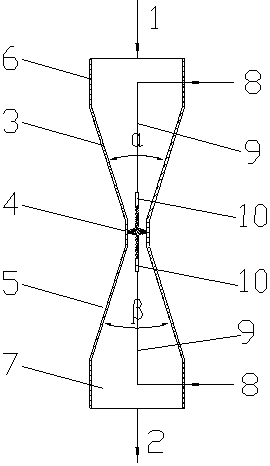

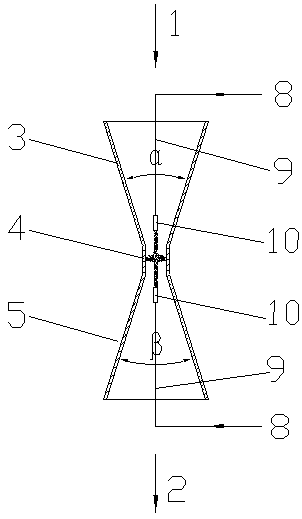

Integrated moist steam flow dryness measuring device and measuring method

ActiveCN103438931AReduce measurement errorMeasurement devicesMeasurement deviceDifferential pressure

An integrated moist steam flow dryness measuring device comprises a double-Venturi tube. The double-Venturi tube is composed of an input Venturi tube and an output Venturi tube which are connected in series, the diameter of a port of the input Venturi tube is equal to the diameter of a port of the output Venturi tube but the diameter ratio of the throat part of the input Venturi tube is not equal to the diameter ratio of the throat part of the output Venturi tube. The input Venturi tube and the output Venturi tube are connected with differential pressure measuring devices for measuring the differential pressure of the throat parts of the input Venturi tube and the output Venturi tube. The input Venturi tube is further connected with a pressure measuring device used for measuring the pressure of a pipeline of the input Venturi tube. Preferably, each differential pressure measuring device comprises a condenser and a pressure difference transmitter, wherein the condenser is connected with a throat pipeline of the corresponding Venturi tube, and the pressure difference transmitter is connected with a pipeline of the condenser. By means of the integrated moist steam flow dryness measuring device, the total flow and dryness of the moist can be calculated on line in real time due to the fact that the two Venturi tubes with different structures are connected in series.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

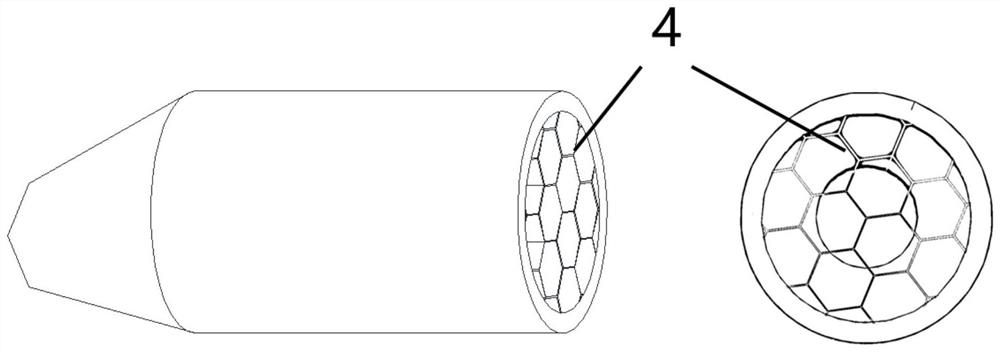

Premixing and homogenizing coupling type bubble generator

ActiveCN113144929AGuaranteed mixing effectReduce stratified flowFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a premixing and homogenizing coupling type bubble generator. The bubble generator comprises a gas-liquid premixing section, a gas-liquid intensified mixing section, a gas-liquid homogenizing section and a vortex breaking section which are connected in sequence; the gas-liquid pre-mixing section is configured to perform primary shearing dispersion on gas-liquid two phases by utilizing high-speed turbulent flow to form a gas-liquid mixing dispersion field; the gas-liquid reinforced mixing section comprises a swirling section and a contraction section which are sequentially distributed, and a multi-dimensional swirling flow field is formed in the swirling section and is configured to induce the gas-liquid mixed phase from the gas-liquid premixing section to generate swirling flow motion; a flow channel of which the diameter is gradually reduced along the flowing direction of the gas-liquid mixed phase is formed in the contraction section; at least two stages of venturi tube-shaped flow channels which are connected in series are formed in the gas-liquid homogenizing section; and a micro-channel is formed in the vortex breaking section.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

Venturi pipe and applications thereof

The invention discloses a venturi pipe and applications thereof. The venturi pipe comprises a contraction section, a throat pipe, a diffusion section and plural groups of liquid-phase spraying nozzlesarranged in parallel to the axial direction, wherein each group comprises two liquid-phase spraying nozzles with opposite spraying nozzle directions, the two liquid-phase spraying nozzles are respectively arranged at the tail end of the contraction section and the starting end of the diffusion section, the starting end of the contraction section is a gas-phase inlet, the tail end of the diffusionsection is a gas-liquid outlet, the liquid-phase inlet is arranged on the pipe wall of the contraction section and / or the diffusion section, and the liquid-phase inlet is communicated with the liquid-phase spraying nozzle through a pipeline. The venturi pipe provided by the invention is simple in structure and good in gas-liquid mixing effect, has good application prospect in a gas-liquid mass transfer process, and is particularly suitable for the fields of gas dust removal such as flue gas desulfurization, flue gas dust removal, cooling and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

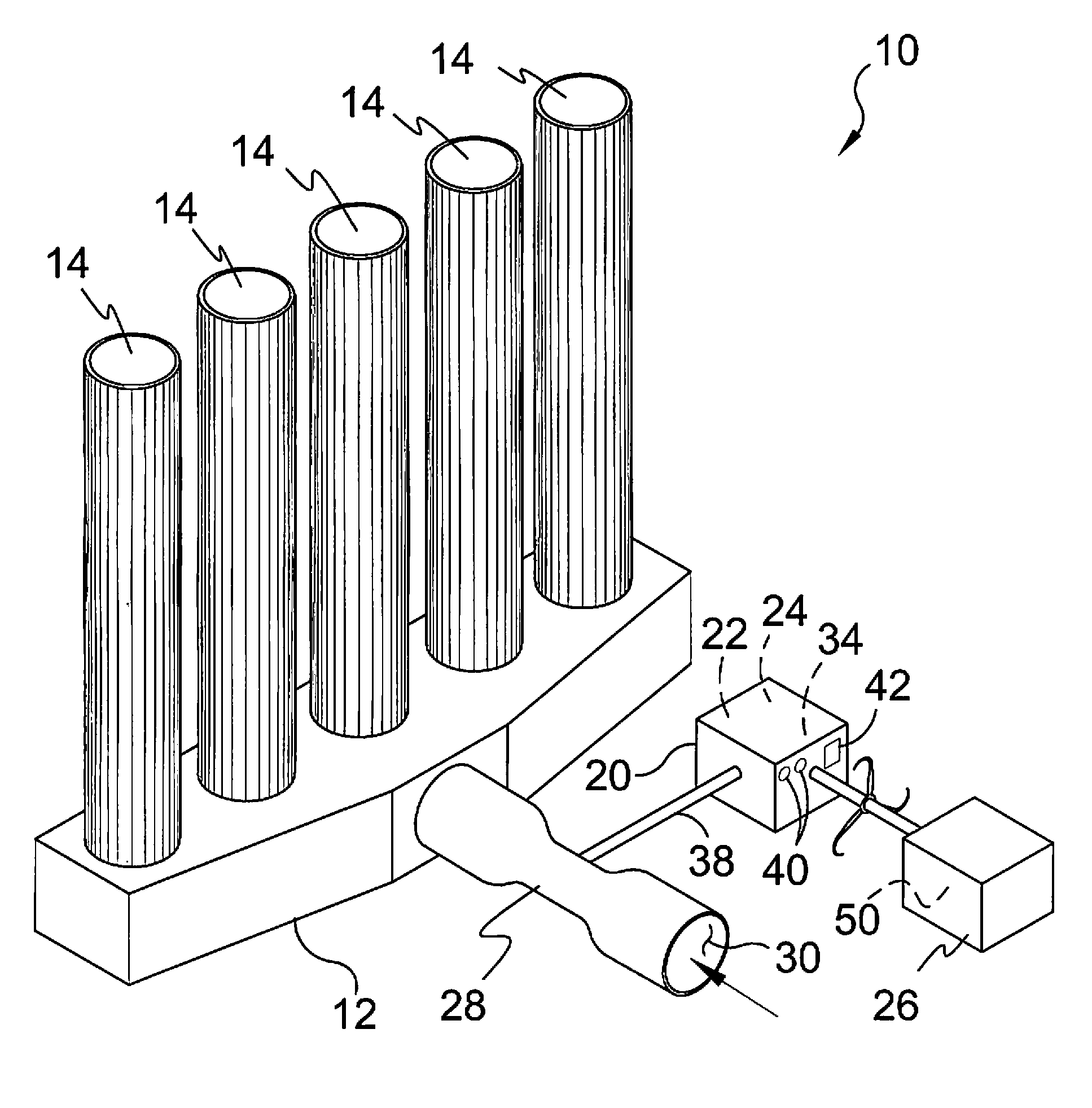

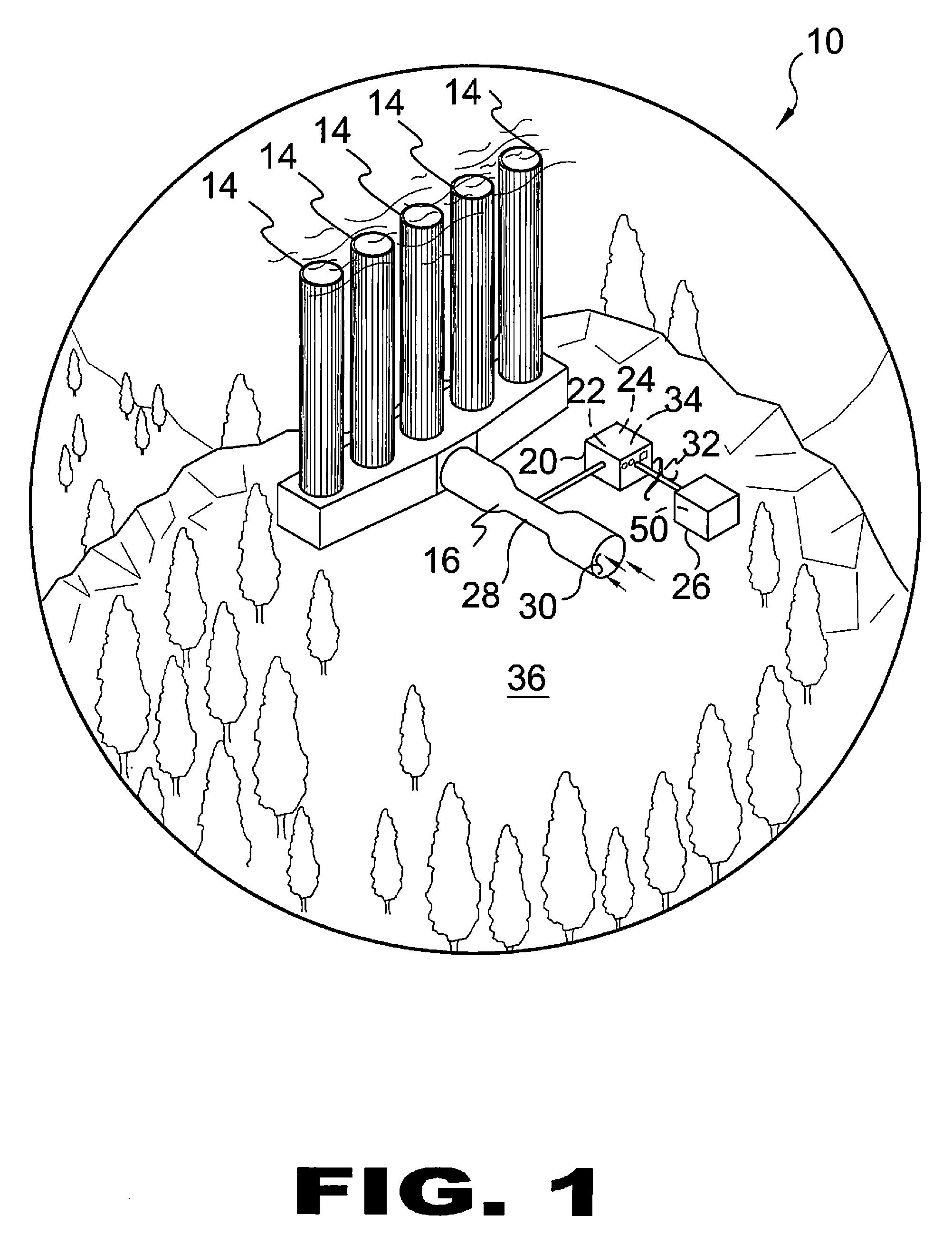

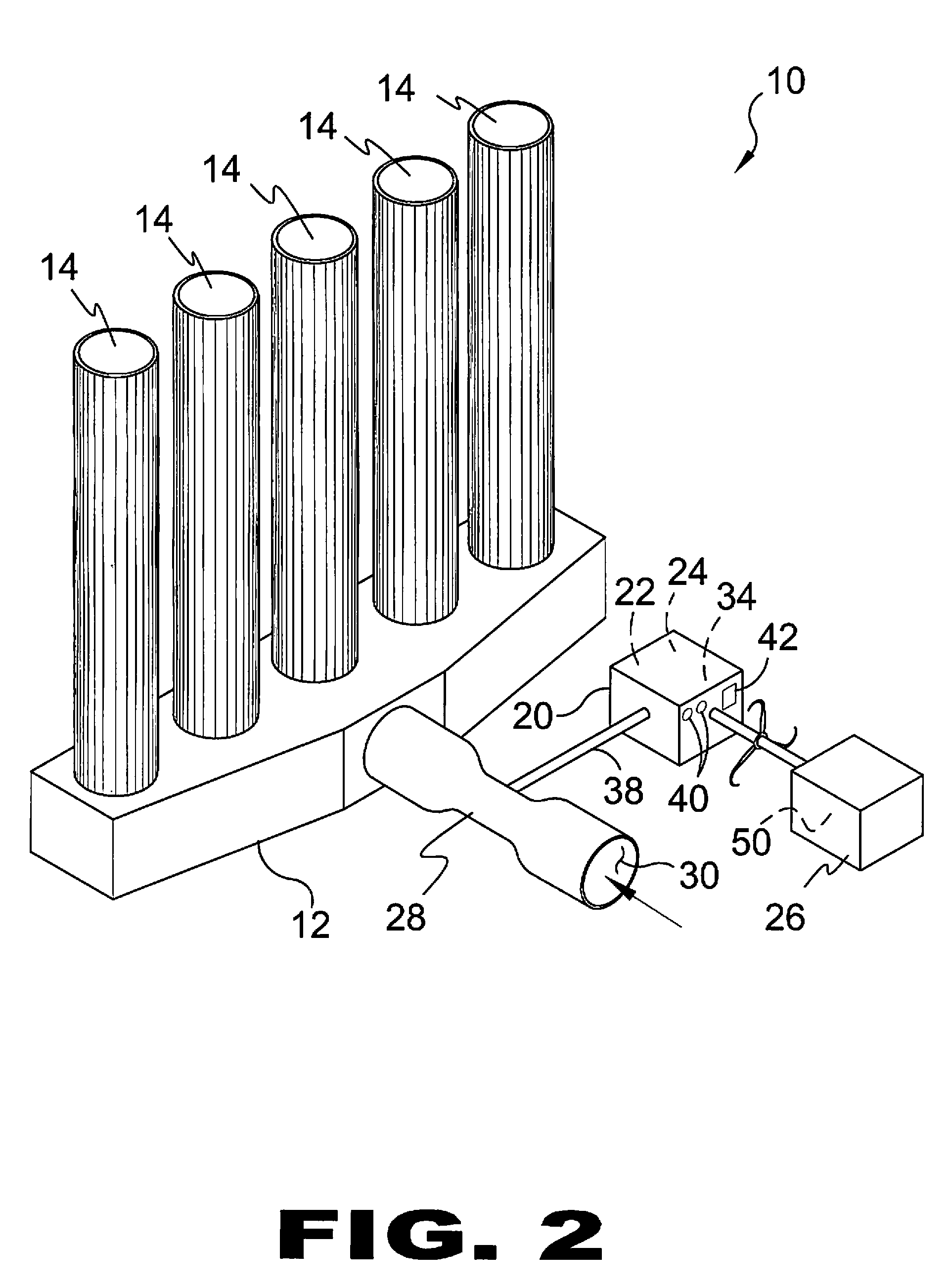

System for pressurizing fluid

InactiveUS7918650B2Low costProduce electric powerPump componentsWind motor controlNatural resourceGreenhouse

A system for providing low cost fluid pressurization without consumption of limited natural resources, pollution, or greenhouse gas emission, and is independent of wind conditions. Additionally, the system of the present invention includes a venturi-like collar positioned at the top of one or more stacks increasing air flow.

Owner:PAPP EUGENE

Generating device for micro-nano air bubbles and device

The invention discloses a generating device for micro-nano air bubbles and a device. The generating device comprises two fixing rods; two fixing trays are fixedly jointed between the two fixing rods;Venturi tubes are fixedly connected with the middle parts of the two fixing trays; water inlets are dug on opposite ends of the two Venturi tubes; stretchable pipes are fixedly jointed in the two Venturi tubes; chokes are fixedly connected with the middle parts of the inner walls of the Venturi tubes. According to the invention, a double flow colliding type vertical structure is adopted; micro-nano air bubbles generated by the two Venturi tubes collide with each other in colliding gaps, so that a strong turbulent flow is generated herein for secondarily breaking the micro-nano air bubbles; thecollided mixture passes by a contraction section; effluent is sprayed from a diffusion port and the air bubbles are broken again, so that more micro-nano air bubbles in smaller grain size can be acquired; convenience in use, high efficiency and wide range of application can be guaranteed.

Owner:北京环域生态环保技术有限公司

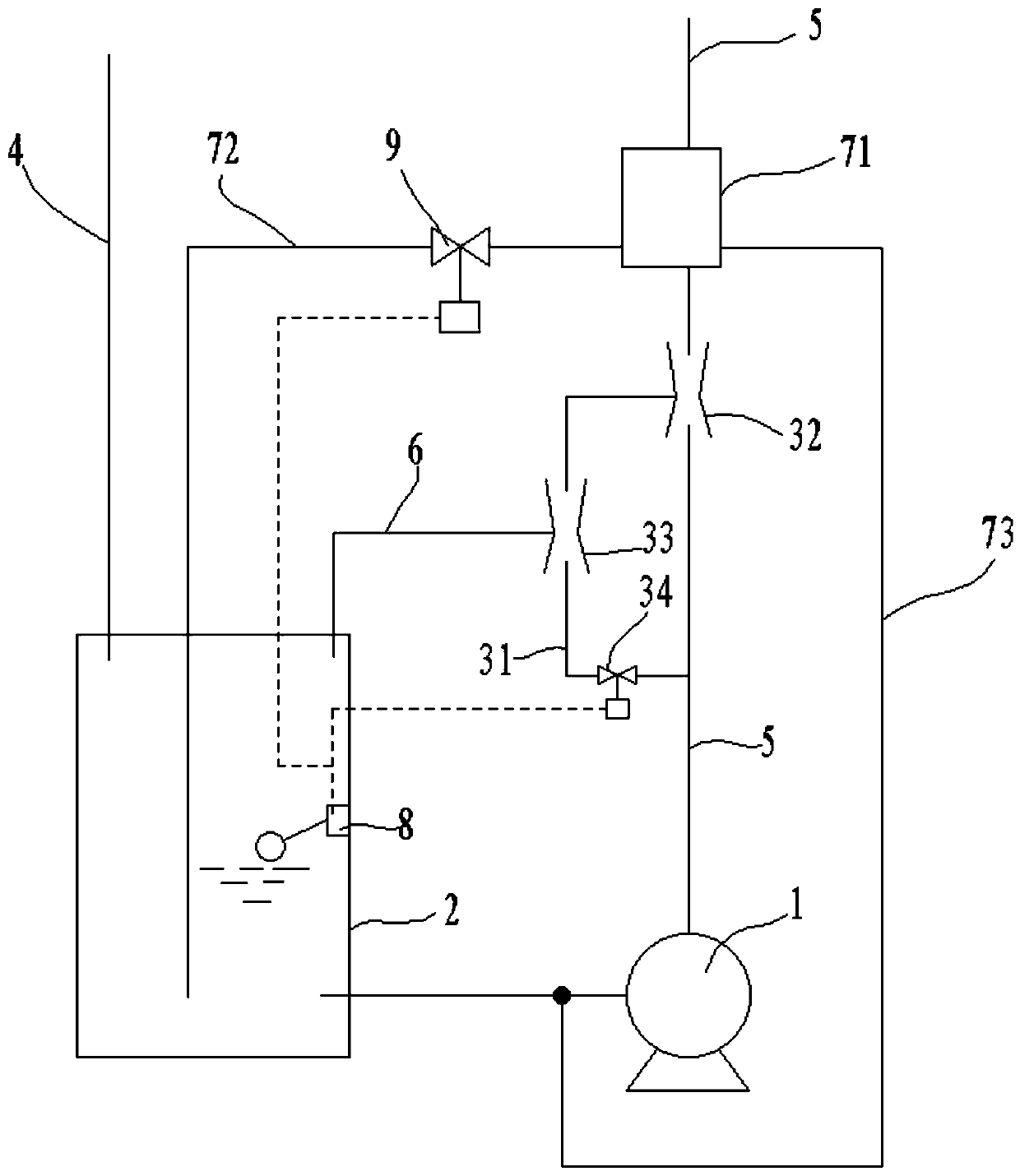

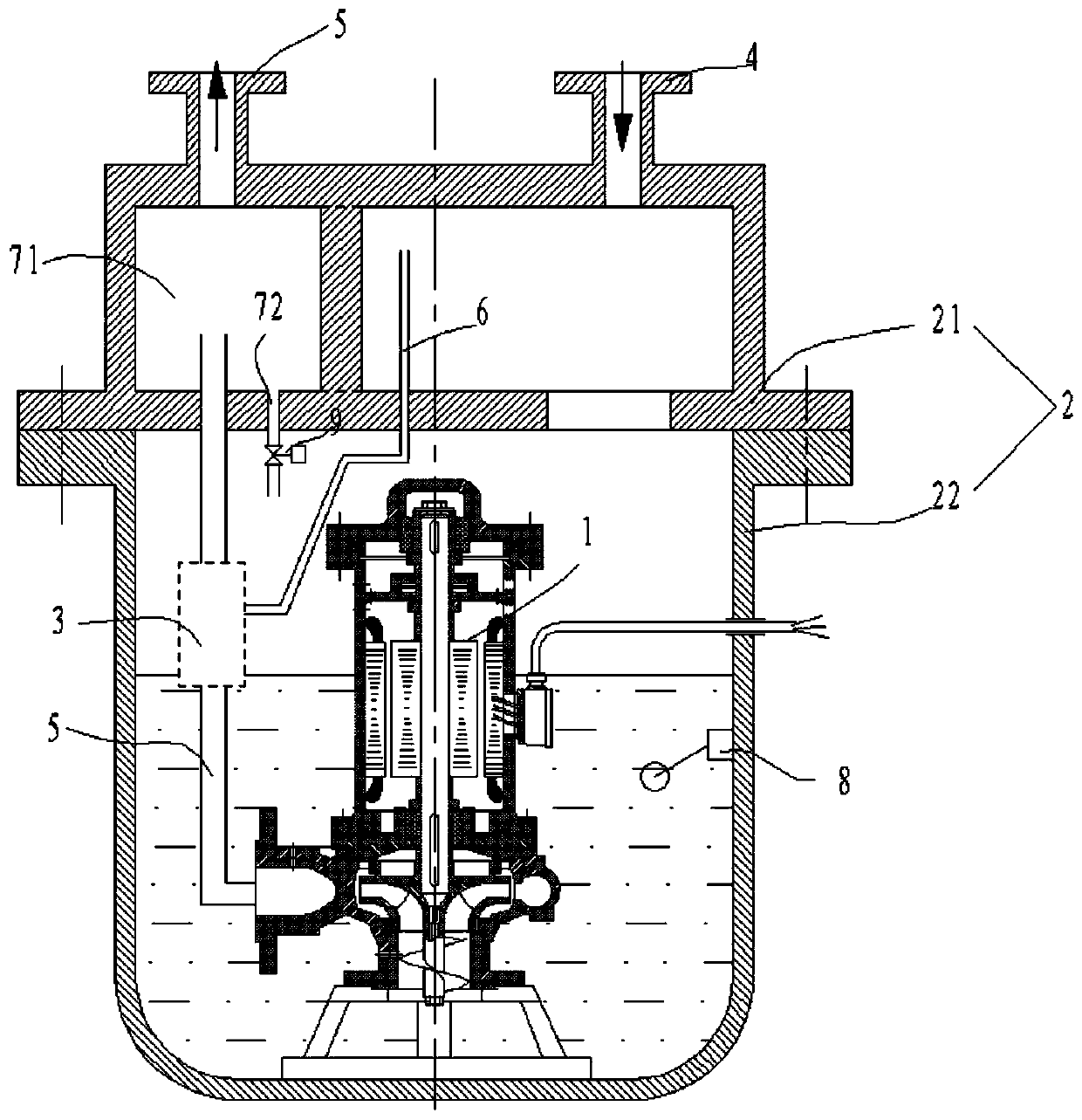

Gas-liquid two-phase flow heat insulation shield pump in air conditioner refrigeration cycle system

ActiveCN110895066AReduced service lifeMaintain fluid levelPump componentsJet pumpsEngineeringRefrigeration

The invention discloses a gas-liquid two-phase flow heat insulation shield pump in an air conditioner refrigeration cycle system. The pump comprises a main pump, a separation tank, an air exhaust assembly, an inlet pipe, an outlet pipe and an air entraining pipe. An inlet of the main pump is connected with the bottom of the separation tank, an outlet of the main pump is connected with the outlet pipe, the air exhaust assembly is arranged on the outlet pipe, one end of the air entraining pipe is connected with the air exhaust assembly, and the other end of the air entraining pipe is connected with the top of the separation tank. The air exhaust assembly comprises a branch pipe, a first venturi pipe, a second venturi pipe and a pressure regulating valve. The first venturi tube is arranged onthe outlet pipe; one end of a parallel pipeline of the branch pipe serving as the outlet pipe is connected to the throat of the first venturi pipe, the other end of the parallel pipeline is connectedwith the inlet end of the first venturi pipe, the second venturi pipe and the pressure regulating valve are arranged on the branch pipe, the pressure regulating valve is closer to the main pump thanthe second venturi pipe, and the throat of the second venturi pipe is connected with an air entraining pipe.

Owner:乐清市泰博恒电子科技有限公司

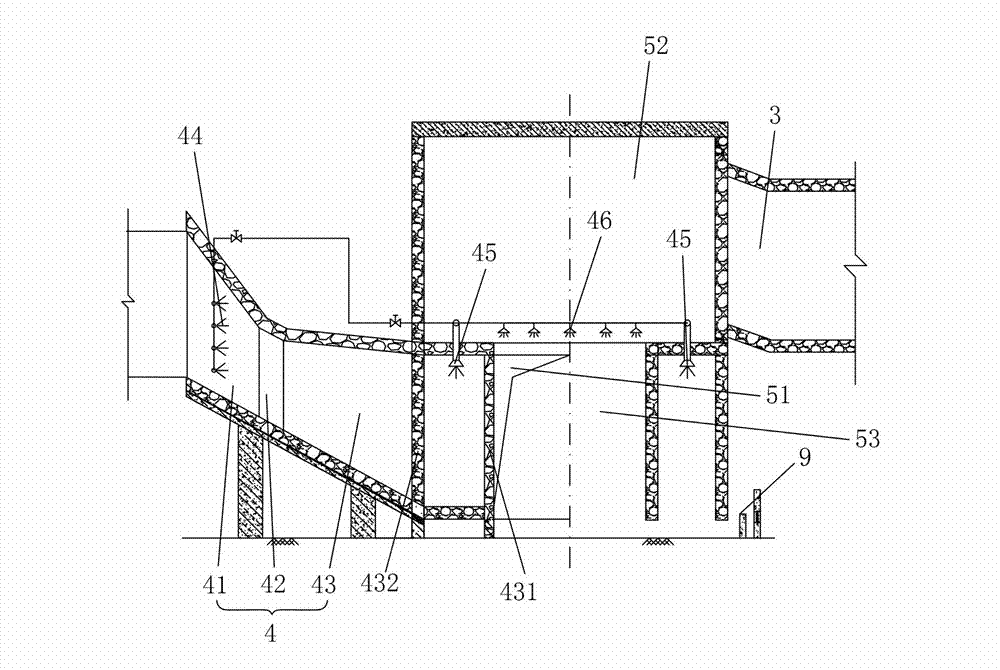

Spiral venturi scrubber and wet-method desulphurization and denitration dust-collecting system

InactiveCN102886189AHigh speed flowImprove centrifugal effectCombination devicesDust controlProcess engineering

The invention discloses a spiral venturi scrubber comprising a venturi pipe and a first water-sealing type water discharging device, wherein the venturi pipe is formed by connecting a retractable pipe, a compressed throat pipe and a spiral gradually-expanded pipe in sequence; the retractable pipe and the spiral gradually-expanded pipe are internally and respectively provided with first and second spraying and washing devices; and the bottom of the scrubber is provided with a water outlet which is connected with the first water-sealing type water discharging device. The invention further discloses a wet-method desulphurization and denitration dust-collecting system comprising a main desulphurization dust-collecting tower, a secondary desulphurization dust-collecting tower, a dehydrator and the spiral venturi scrubber; and the scrubber is communicated with the bottom end of the main desulphurization dust-collecting tower through a connecting flue; the top of the main desulphurization dust-collecting tower is communicated with the top of the secondary desulphurization dust-collecting tower through the dehydrator; and an air inlet of the secondary desulphurization dust-collecting tower is higher than the bottom surface of the dehydrator. The spiral venturi scrubber has the advantages of small volume, low energy consumption, high dust-collecting efficiency, good desulphurization and denitration effects and the like.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE

Venturi cleaner, cleaning system comprising Venturi cleaner and application

ActiveCN107019980ASimple structureReduce washoutUsing liquid separation agentCombustible gas purificationWater flowEngineering

The invention provides a Venturi cleaner, comprising a nozzle and a throat tube; water outlets on the nozzle are arranged in 3 layers along the direction in which a water flow travels; and an angel of the water outlet direction on the first layer of a water outlet with respect to an axis of the Venturi tube is 45 degrees, an angel of the water outlet direction on the second layer of the water outlet with respect to an axis of the Venturi tube is 90 degrees, and an angel of the water outlet direction on the third layer of the water outlet with respect to an axis of the Venturi tube is between 20 and 30 degrees. The invention further provides a cleaning system comprising the Venturi cleaner. The invention optimizes, with respect to the flush and leakage phenomena caused by the Venturi cleaner, the structure of the Venturi cleaner, changes the direction of the water outlet holes of the Venturi nozzle, intersects the water columns ejected by the water holes for intersecting with one another to reduce flushing on the throat tube, and increases effective contacts with the coal gas to improve the cleaning effect. Furthermore, by adding 5 water outlets with a smaller angle at an end surface of the nozzle, water passing through the water outlets forms a water film on an inner surface of the throat tube to improve the cleaning effect.

Owner:GNSG ANHUI HONG SIFANG

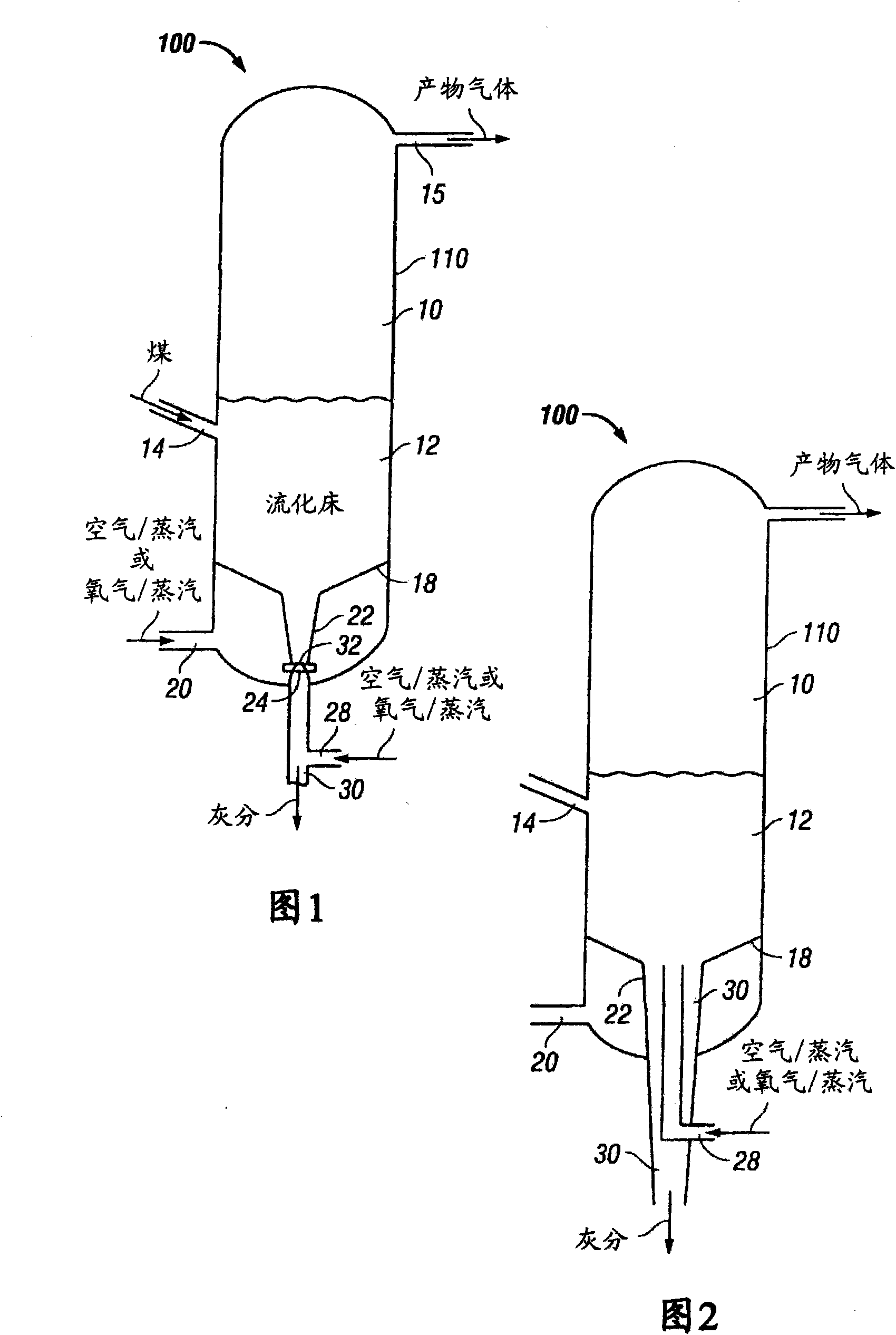

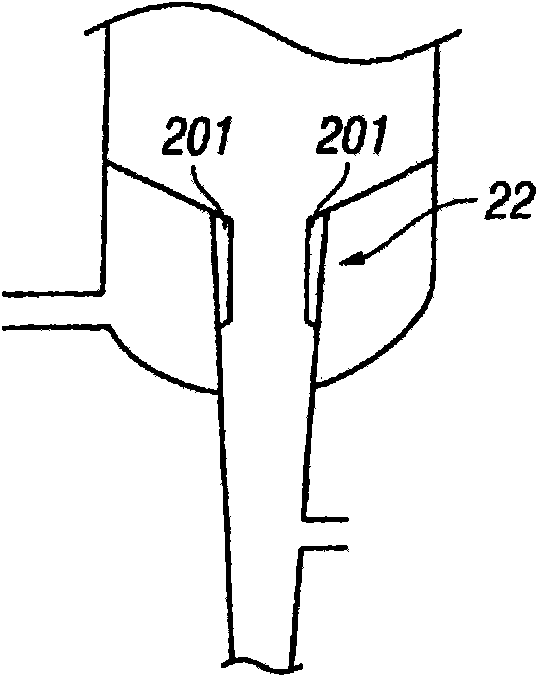

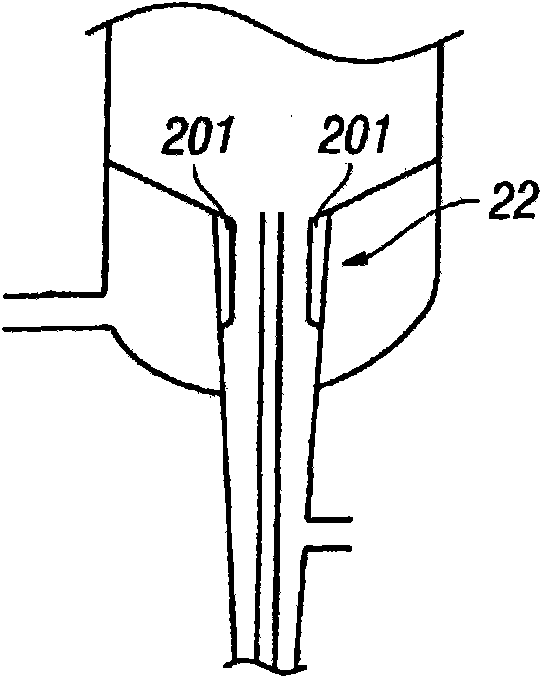

Venturi inserts, interchangeable venturis, and methods of fluidizing

InactiveCN101883630AGasifier mechanical detailsGasification processes detailsFluidized bedElectrical and Electronics engineering

A fluidized bed apparatus having an agglomeration passage in which is positioned a removeable venturi inset.

Owner:SYNTHESIS ENERGY SYST TECH

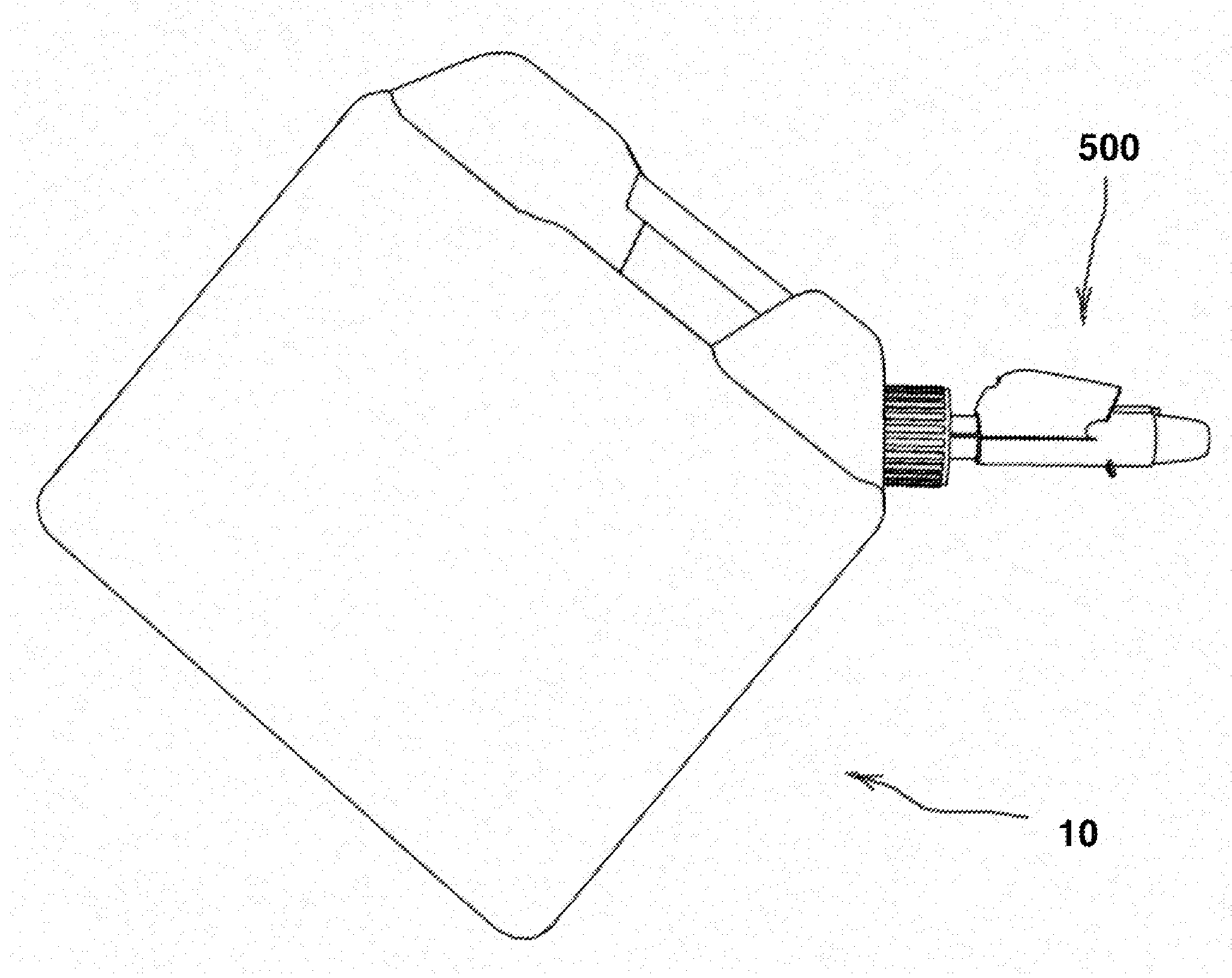

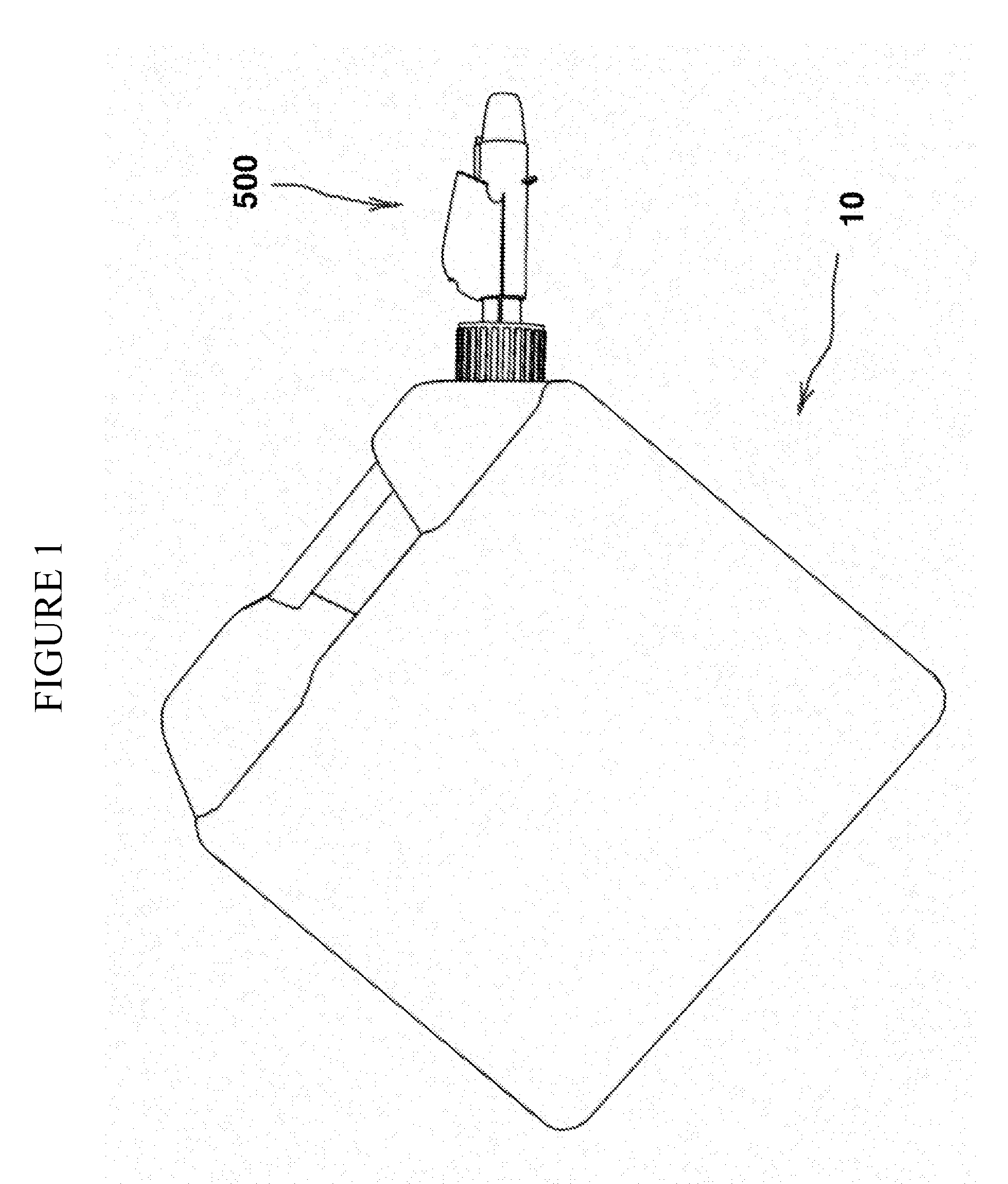

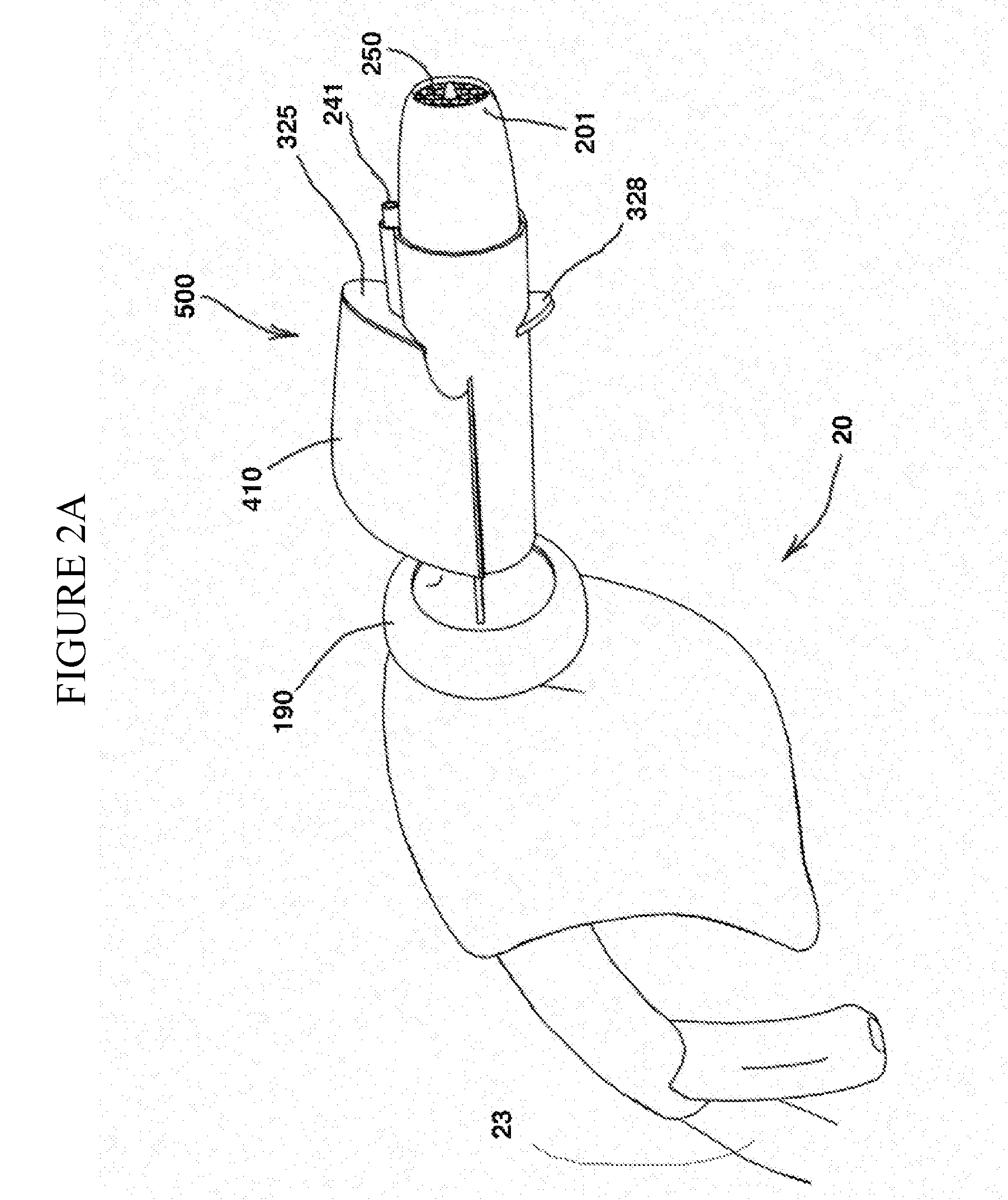

Dispensing spout

InactiveUS20070215242A1Reduce pressureBlock deliveryLiquid transferring devicesSolid materialEngineeringNozzle

This invention relates to a spout for a hose, nozzle or a container and to a hose, nozzle and a container used to dispense liquids into a receptacle from a liquid source such as a gas container, delivery hose or pump. In each case, there is a spout means having a delivery trunk body formed with a dispensing passageway leading to a dispensing opening for delivery of the liquid; a venturi means within the delivery trunk to reduce the pressure within the dispensing passageway as liquid flows through it during use; a control means; said control means having a deactivation means, said deactivation means including an air conduit with an air opening, the air conduit being in communication with the dispensing passageway to permit the drawing of air into the dispensing passageway through the air opening when pressure is reduced by the venturi means, but inhibiting the flow of air into the dispensing passageway when the air opening is blocked or covered as the liquid level of dispensed liquid reaches the air opening and cuts off access of air into the air opening; a deactivation means to shut off the dispensing opening when the air opening is closed to inhibit air from entering during use.

Owner:BONNER MARK

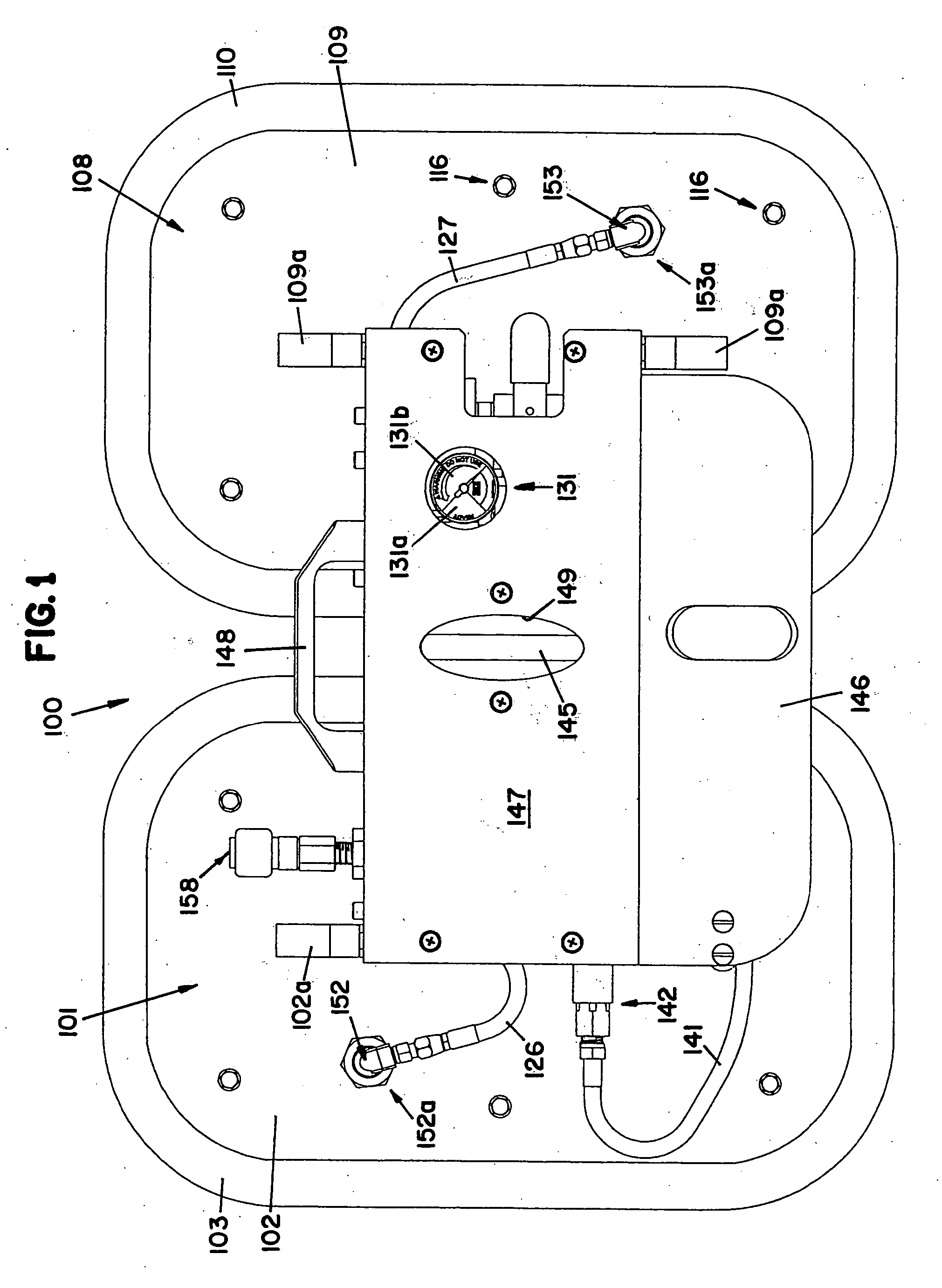

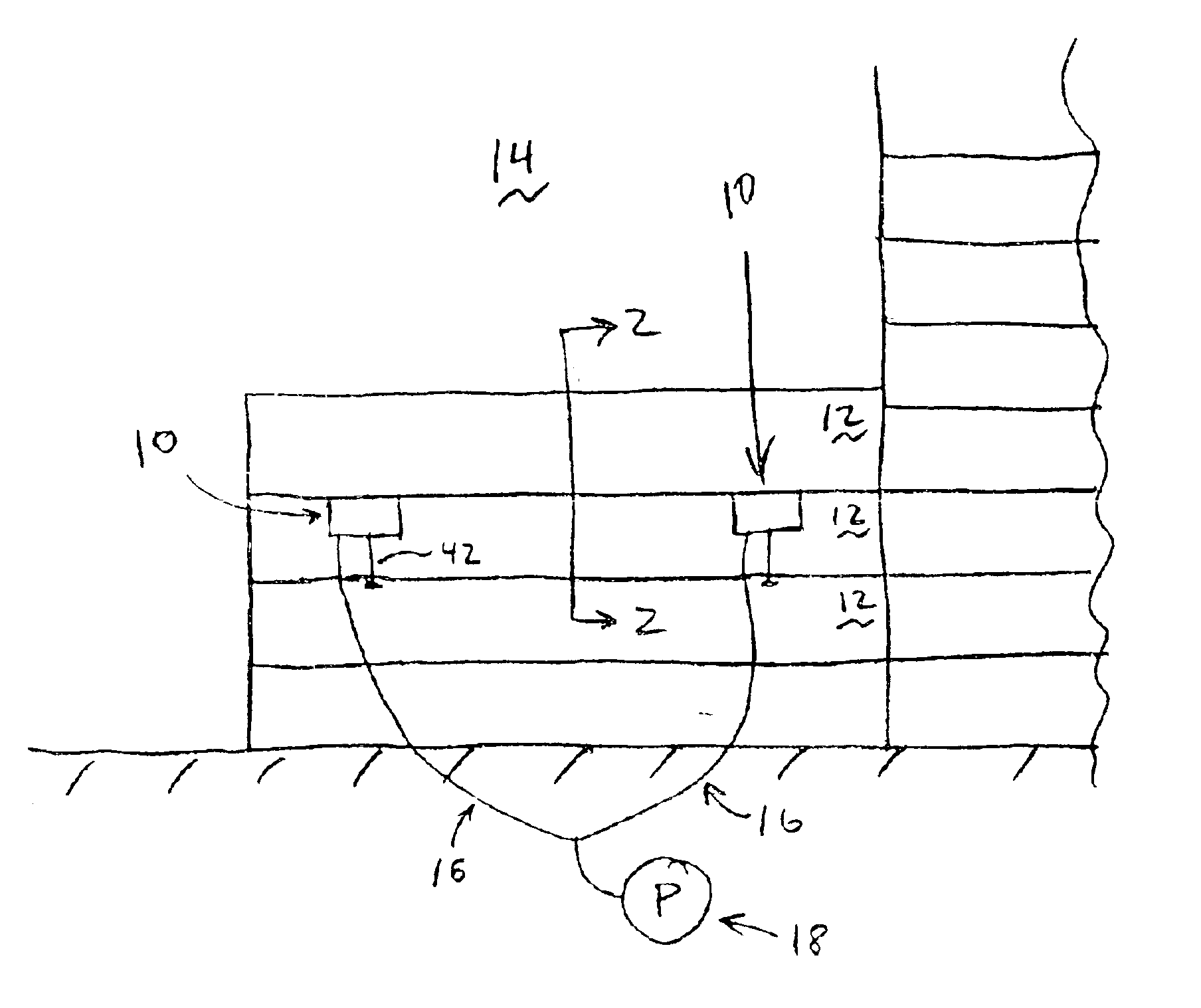

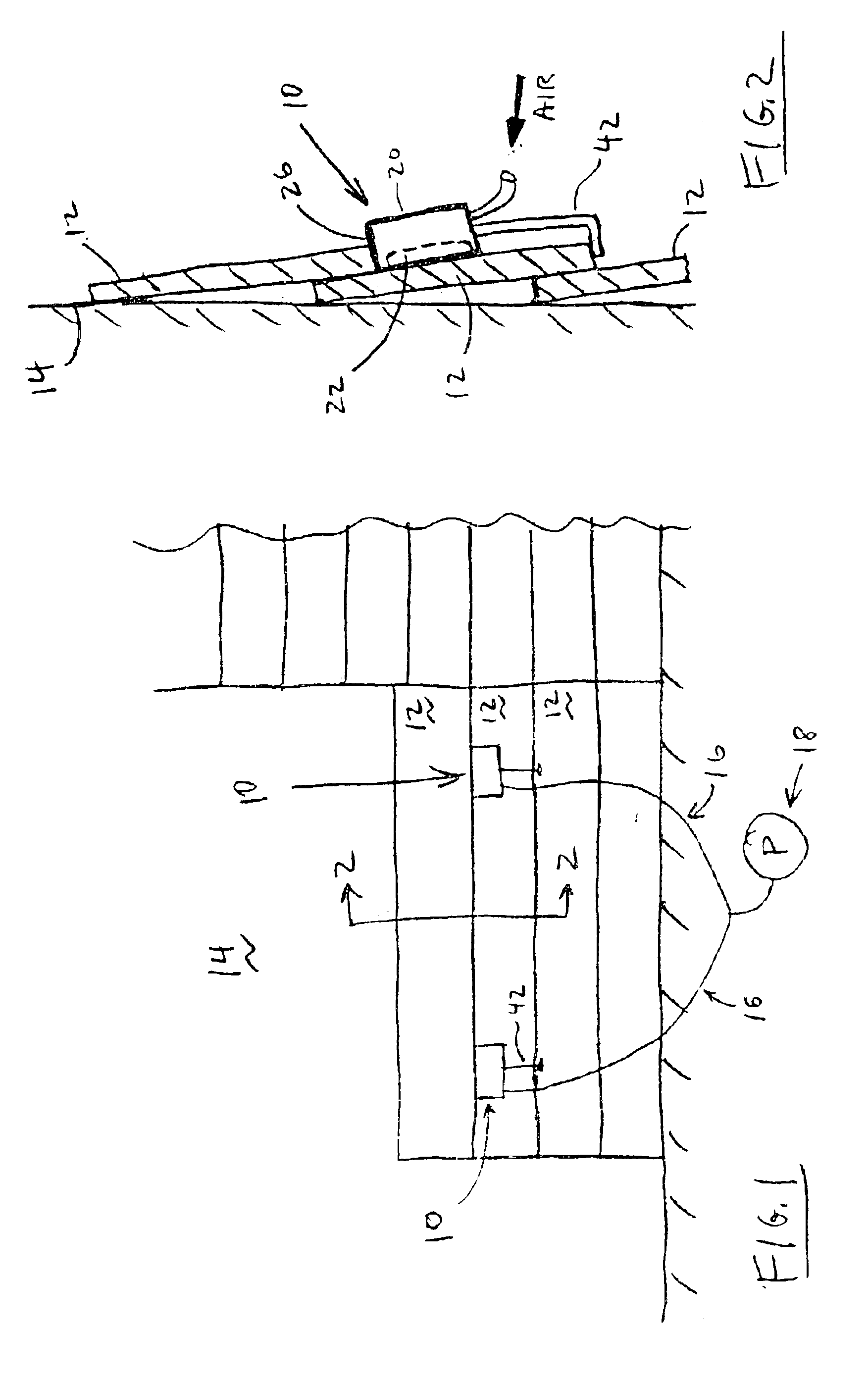

Suction-attached support device and method

InactiveUS6871846B2Quickly and easily positionWorkpiece holdersBuilding repairsSuction stressArchitectural engineering

A body has a support surface for temporarily supporting a siding, trim, or other construction piece that is to be installed on a building wall. A suction cup is controllable to temporarily adhere by suction the support device to the building wall. An extendible spacer is used to accurately position the support device on the building wall. Notches in the body receive the ends of a tape measure or chalk line for accurately sizing and positioning the construction pieces. The support device can be used with existing compressors, vacuum pumps, or other suction-inducing devices. A venturi tube in the body generates the suction when an air compressor is used. A method of installing the siding, trim, or other construction pieces is also provided.

Owner:ANTILL KEITH R

Seat assembly with ventilation system utilizing venturi effect to multiply air flow

ActiveUS10919633B1Seat heating/ventillating devicesSeating arrangementsClassical mechanicsAir compressor

A ventilated seat assembly such as an aircraft passenger seat including a cushion assembly supported by a structural element, a plurality of Venturi tubes positioned to direct a flow of air through the cushion assembly, an air compressor supplying compressed air, a manifold assembly coupled in fluid communication with the air compressor, a conduit network fluidly coupling the manifold assembly with the plurality of Venturi tubes, and a controller for activating the air compressor and actuating the manifold assembly. Supplying a small volume of pressurized air to the Venturi tubes induces a larger flow of ambient air and a multiplied air effect to ventilate the passenger seat.

Owner:BE AEROSPACE INCORPORATED

Feeding device and washing device

ActiveCN107119421ASimple structureLow costOther washing machinesTextiles and paperEnvironmental engineeringMaterial storage

The invention provides a feeding device and a washing device. The feeding device comprises a storage cavity, a first water inlet pipe, a second water inlet pipe, a venturi tube and a water outlet pipe, wherein a feed inlet is formed in the storage cavity, a discharging pipe is arranged at the bottom of the storage cavity, the second water inlet pipe is connected with the storage cavity, the venturi tube comprises a first port, a second port and a third port, the first port is connected with the first water inlet pipe, and the second port is connected with the discharging pipe; the water outlet pipe is connected with the third port, materials enter the material storage cavity through the feed inlet, water enters the material storage cavity through the second water inlet pipe and is mixed with the materials, the mixture of the water and the materials flows to the venturi tube through the discharging pipe, and water in the first water inlet pipe enters the venturi tube to be mixed with the mixture and flows out through the water outlet pipe. According to the feeding device, the materials can be fully mixed with water, so that no residues exist in the storage cavity; meanwhile, the device is simple in structure, low in manufacturing cost and convenient to popularize.

Owner:JINHUA HONGCHANG ELECTRLCAL EQUIP CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com