Venturi cleaner, cleaning system comprising Venturi cleaner and application

A Venturi scrubber and Venturi tube technology, which is applied in the use of liquid separation agents, chemical instruments and methods, and the petroleum industry, can solve the problems of erosion and wear, leakage, and influence on safe and stable operation at the venturi throat, and achieves Increased effective contact, reduced washout, improved wash results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

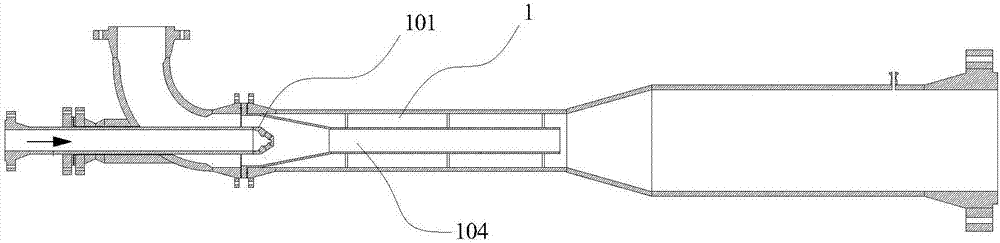

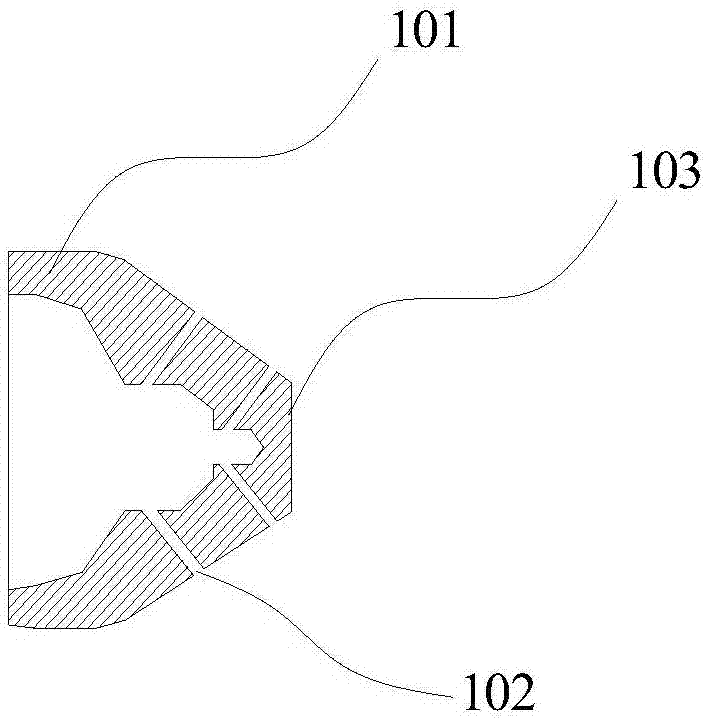

[0042] This unit proposes a new type of Venturi scrubber structure, see Figure 4 and Figure 5 , a Venturi scrubber, including a nozzle 101 and a throat 104, the water outlet hole 102 on the nozzle is along the direction of water flow ( Figure 4 The direction indicated by the arrow in the middle) is arranged in 3 layers, and the water outlet direction of each layer is different. The angle between the axis of the venturi tube is 90 degrees, and the angle between the water outlet direction of the third layer water outlet hole and the axis of the venturi tube is 25 degrees.

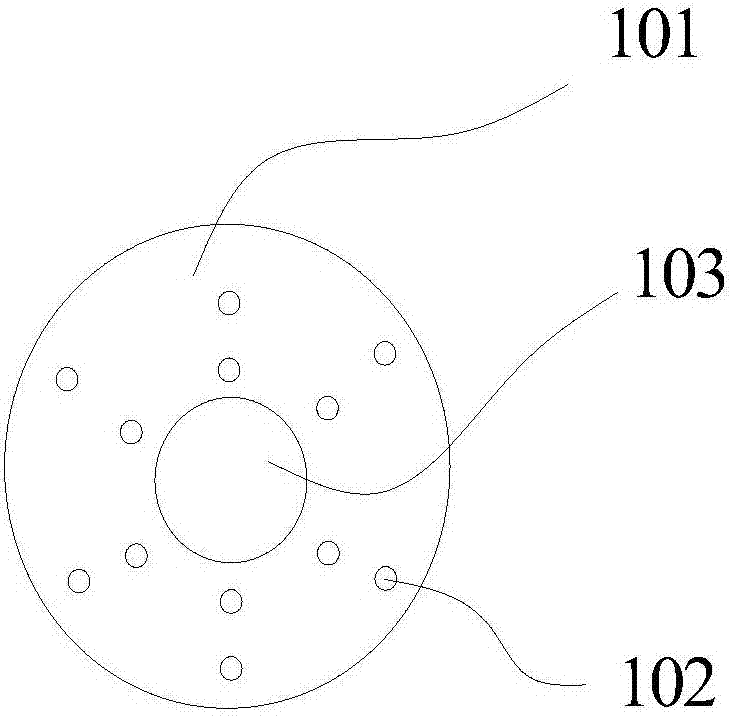

[0043] There are a total of 4 water outlet holes on the first layer of nozzles, and a total of 4 water outlet holes on the second layer of nozzles. The first layer and the second layer are arranged in parallel (see Image 6 right view). The third layer of water outlet holes is arranged on the water outlet end face 103 of the nozzle, and the end face is perpendicular to the axis of the venturi.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com