Integrated moist steam flow dryness measuring device and measuring method

A technology of measuring device and measuring method, applied in the direction of measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

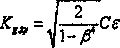

[0047] The invention discloses an integrated measuring device for wet steam flow and dryness. The connection between the two components. Double Venturi tubes with different diameter ratios are used in series to measure the dryness and flow rate of wet steam. The steam flow rate, pressure and dryness flowing through the double Venturi tubes are theoretically equal everywhere, so that two different Venturi tubes can be measured at one time. The pressure difference at the throat of the pipe is used to construct two different virtual height characteristic equations, which are convenient for joint solution to obtain the dryness and flow rate of wet steam.

[0048] Both the input venturi tube and the output venturi tube are connected with a differential pressure measuring device for measuring the pressure difference at their throats, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com