Vibration damper with stroke-dependent damping force

A technology of shock absorbers and shock absorbers, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as complete confidence in results, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

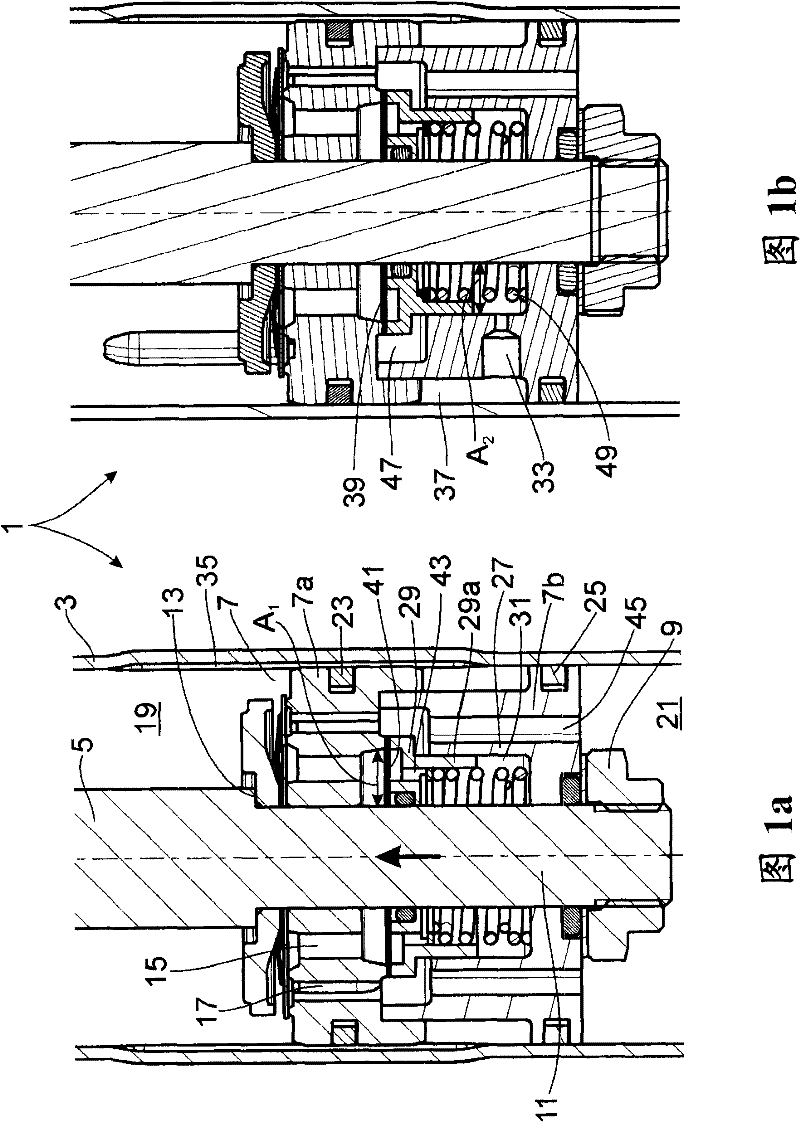

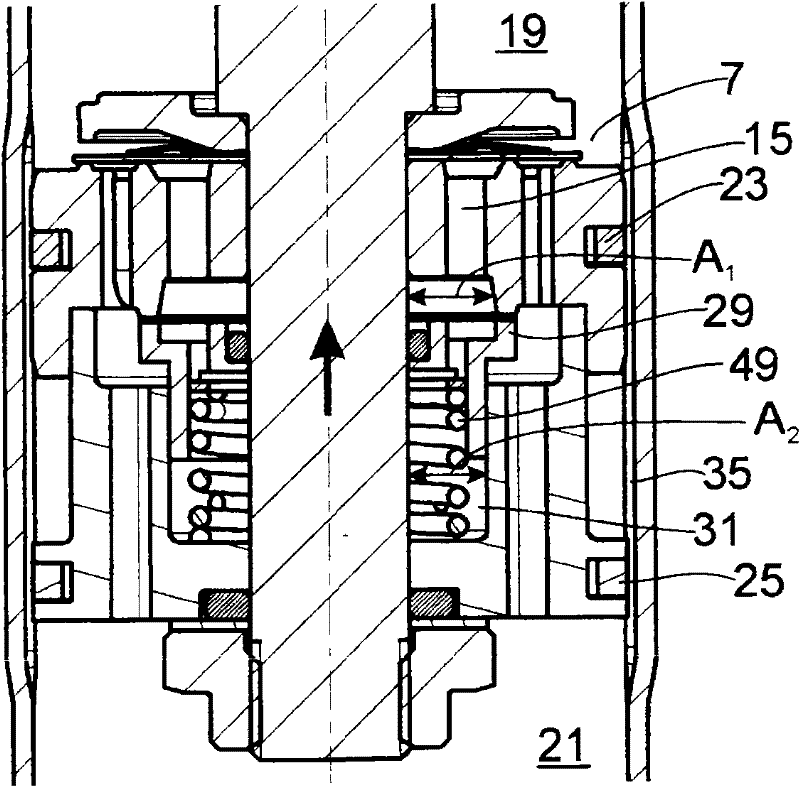

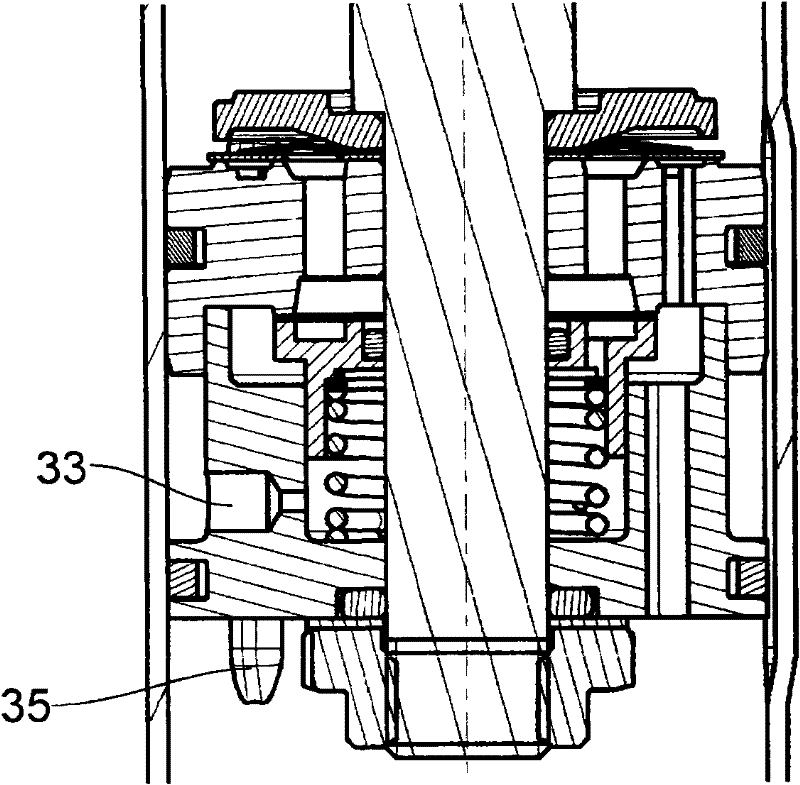

[0044] Figure 1a ; 1b shows a section of the shock absorber 1 in two different sections. A piston rod 5 with a piston 7 is guided axially movable in the cylinder 3 . In this case, it has no influence on the functionality of the invention whether this is a single-tube shock absorber or a double-tube shock absorber.

[0045] The piston 7 is designed in two parts, wherein the two piston parts 7 a , 7 b are fastened to the piston rod pin 11 at the shoulder 13 of the piston rod 5 by means of a fastening nut 9 . The first piston part 7a has separate through-flow channels 15; 17 for two opposite flow directions of the damping medium in the piston, which divides the cylinder 3 into a working space on the piston rod side and away from the piston rod. 19;21. The two working spaces 19; 21 are completely filled with damping medium and are separated by two spaced apart piston rings 23; 25 (one piston ring in each piston part).

[0046] The second piston part 7 b has a cup-shaped cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com