Device for cooling hot gas to be discharged from an aircraft

A technology for cooling air and aircraft, applied in the field of hot air devices, can solve problems such as increasing direct operating costs, increasing aircraft resistance, etc., and achieve the effects of saving thermal insulation materials and weight, reducing the number, and increasing the strength of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For a better understanding, several embodiments of the device according to the present invention will be described below in conjunction with an embodiment integrated, for example, in an Airbus A400M military transport aircraft. The device according to the invention is not limited to cooling APU exhaust gases, but can also cool other hot gases from other systems, for example from fuel cells. The general term "hot gas" is used in some contexts below. The turbine exhaust from the APU is considered a specific form of hot gas.

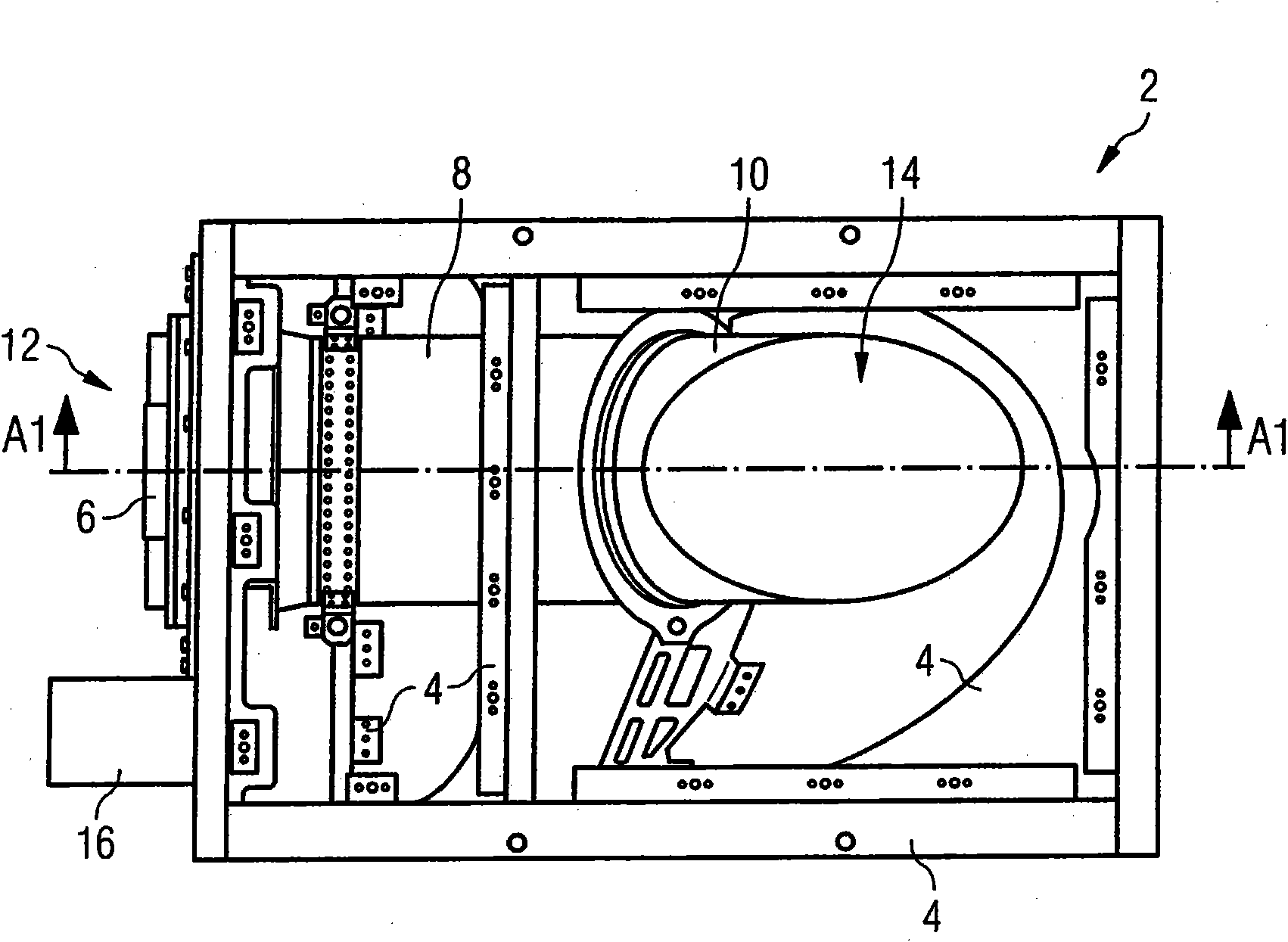

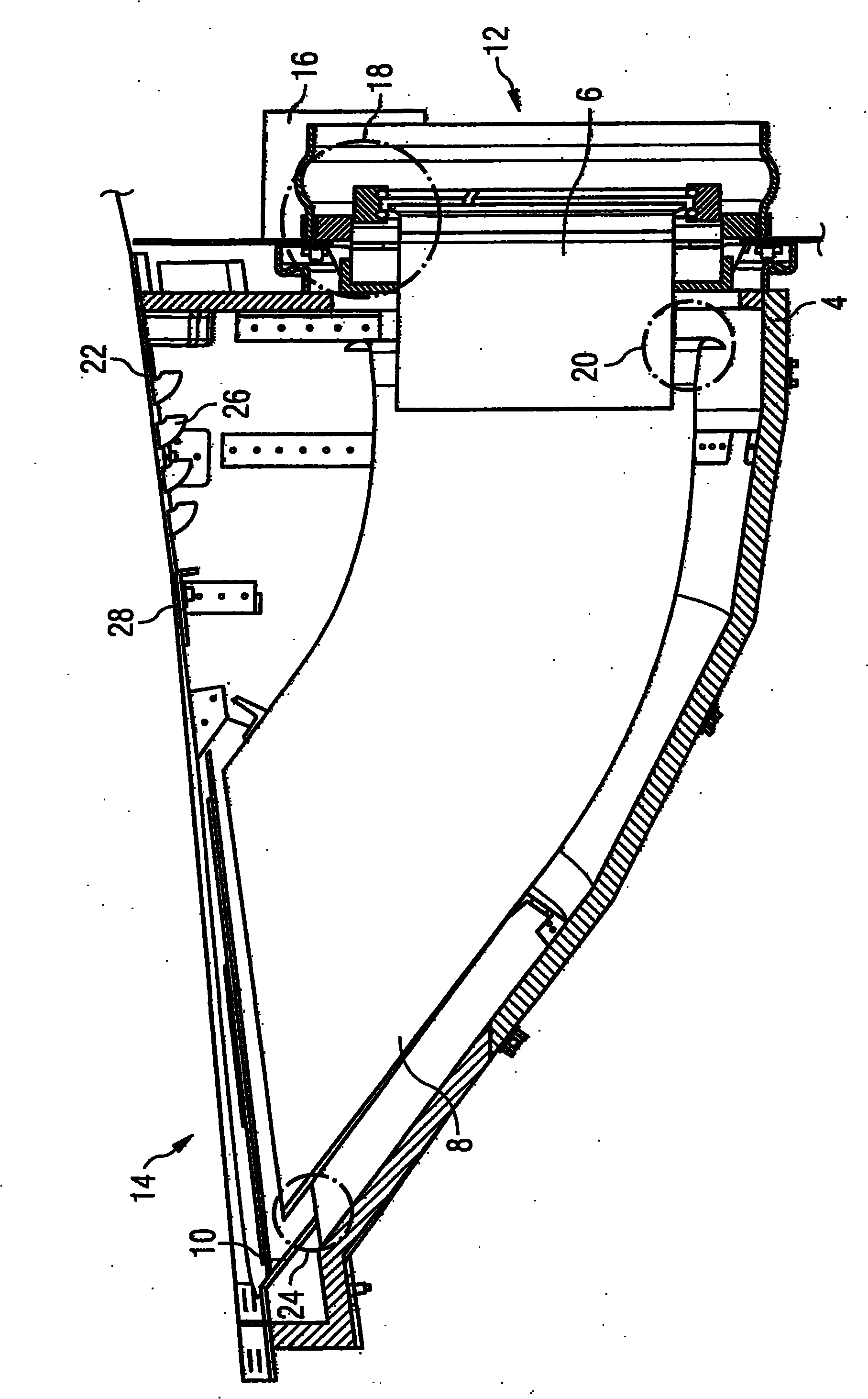

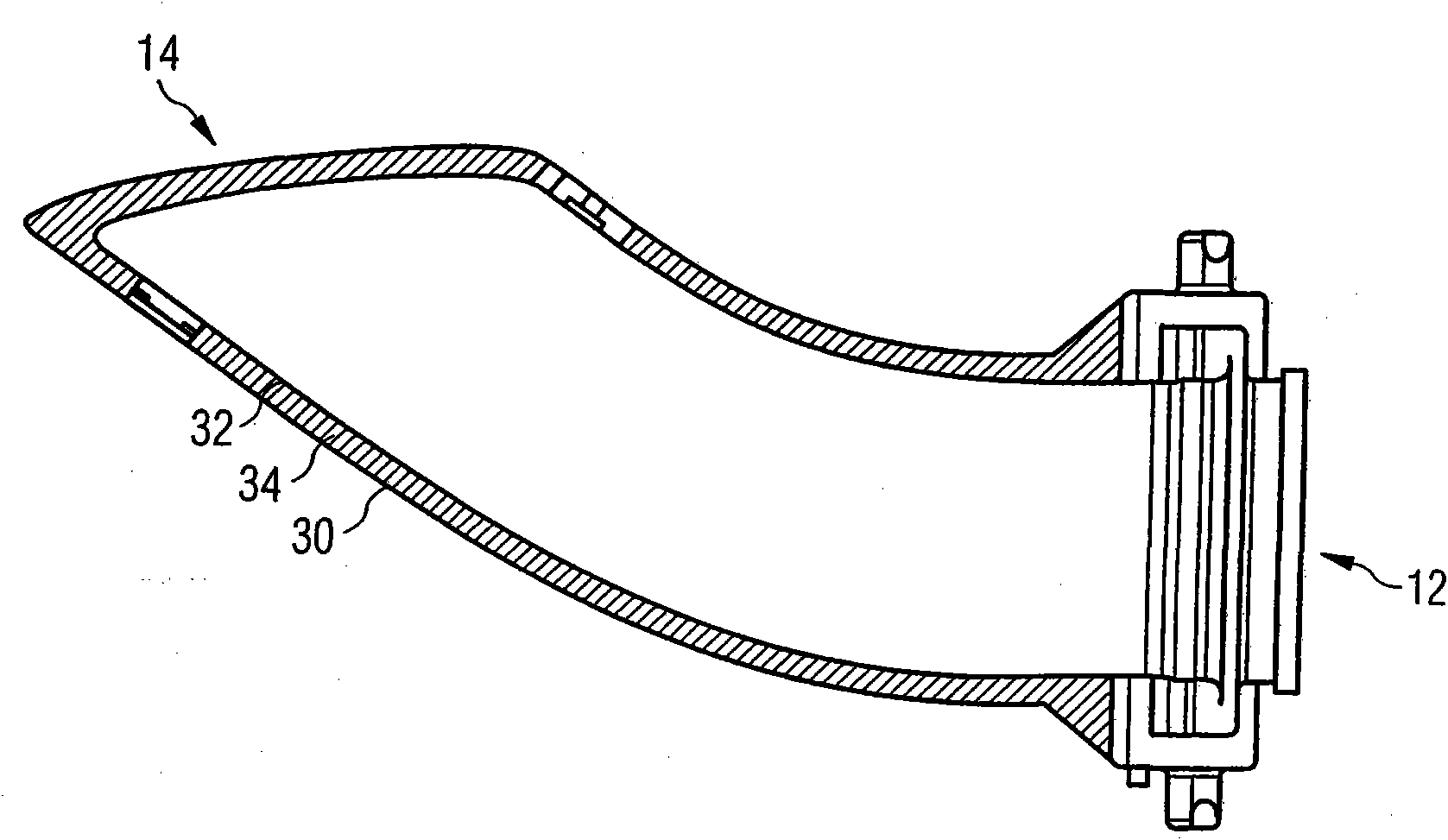

[0022] figure 1 An exhaust system 2 is shown in which, for better illustration, the housing cover installed during operation has been removed. The exhaust system 2 comprises a housing 4 formed of sheet metal troughs, reinforcement members, holders and accessories, and an exhaust system consisting of three continuous exhaust pipes 6, 8 and 10 extending into the housing 4 from an exhaust gas inlet location 12. Exhaust pipe. The exhaust pipe 6 guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com