Transmission with gear and oil channel

A transmission and oil channel technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem that the wear-free operation of the transmission is no longer guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

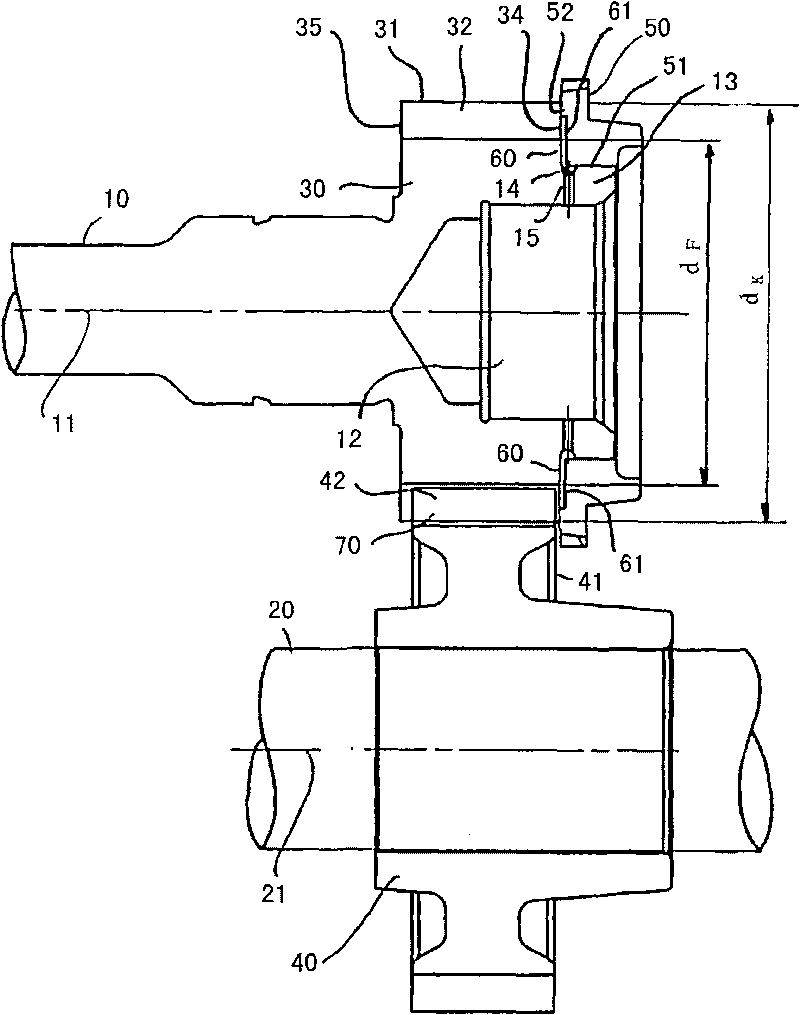

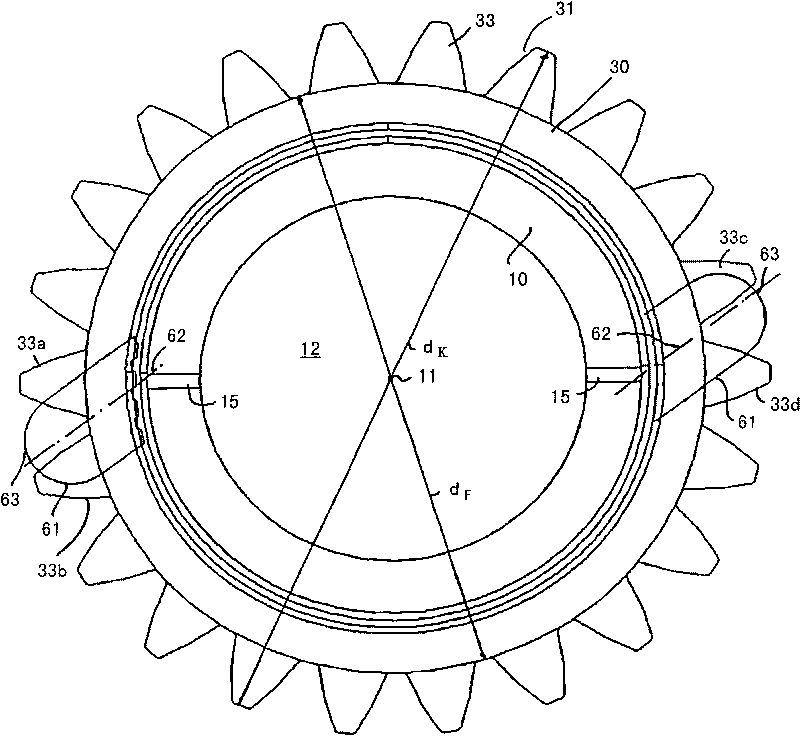

[0029] figure 1 A longitudinal section through a first shaft 10 and a second shaft 20 of a transmission, not further shown here, is shown. The central axis 11 of the shaft 10 and the central axis 21 of the second shaft 20 extend parallel to each other. Arranged on the first shaft 10 is a first gear wheel 30 which meshes with a second gear wheel 40 seated on the second shaft 20 .

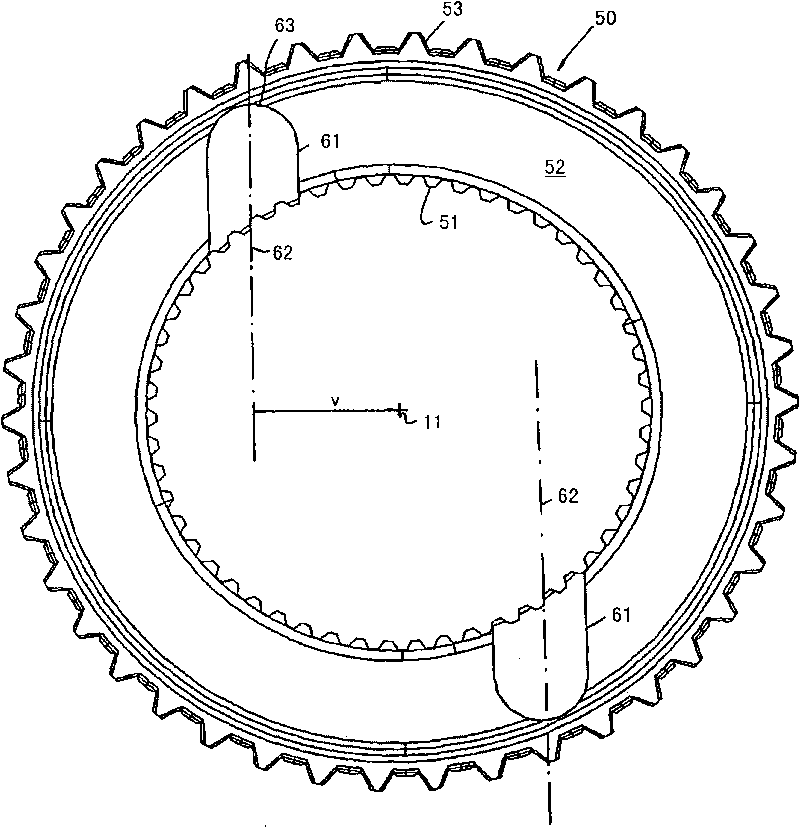

[0030] exist figure 1 In the embodiment, the first gear 30 and the first shaft 10 are integrally constructed. The first gear wheel 30 has toothing 32 on a circumference 31 . image 3 The individual teeth 33 of the toothing 32 can be seen in the figure. as from figure 1 As can be seen in , the tooth portion 32 has a dedendum circle diameter d F and addendum circle diameter d K .

[0031]The first gear wheel 30 surrounds in the radial direction a shaft cavity 12 for receiving a guide bearing (not shown here). Beside the first gear wheel 30 in the axial direction, a coupling ring or plug cone 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com