Rotary sprayer

A sprayer and liquid technology, applied in the field of centrifugal sprayers, can solve the problems of easy blockage of pipes and uneven wetting of workpieces, and achieve the effect of preventing the formation of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

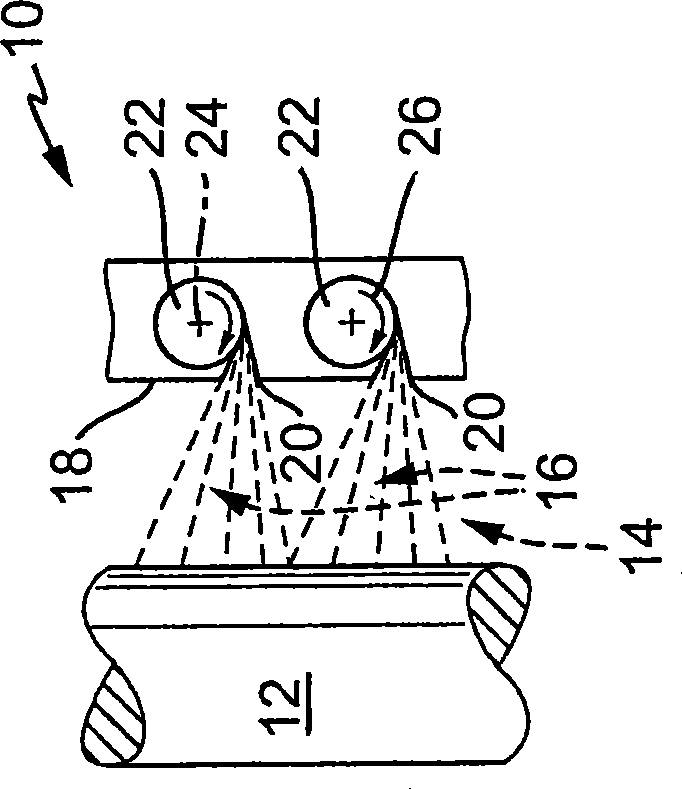

[0022] figure 1 A centrifugal sprayer, generally designated 10 , is shown, with which a workpiece 12 is sprayed with a liquid 14 . exist figure 1 A portion of the liquid shown in , forms an effective working flow 16 with which the workpiece 12 , for example a roll, paper web or fabric web, is wetted. The working flow 16 leaves the housing 18 , not shown in detail, through the perforated plate 20 , wherein a plurality of rotary disks 22 are arranged in the housing 18 , which rotate about an axis of rotation 24 , for example in the direction of the arrow 26 .

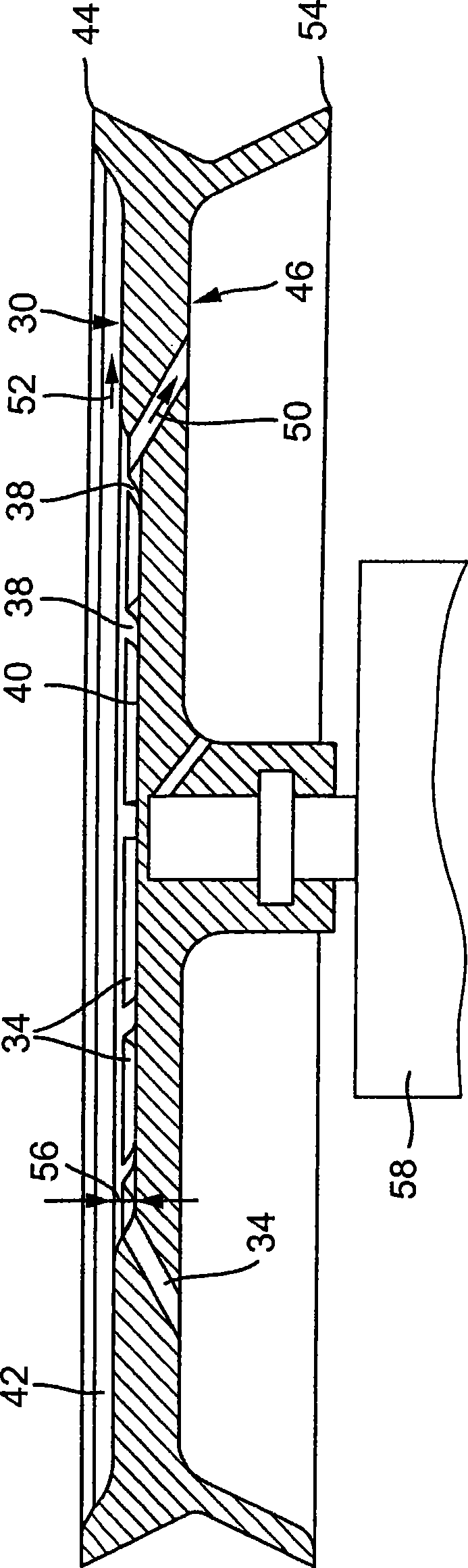

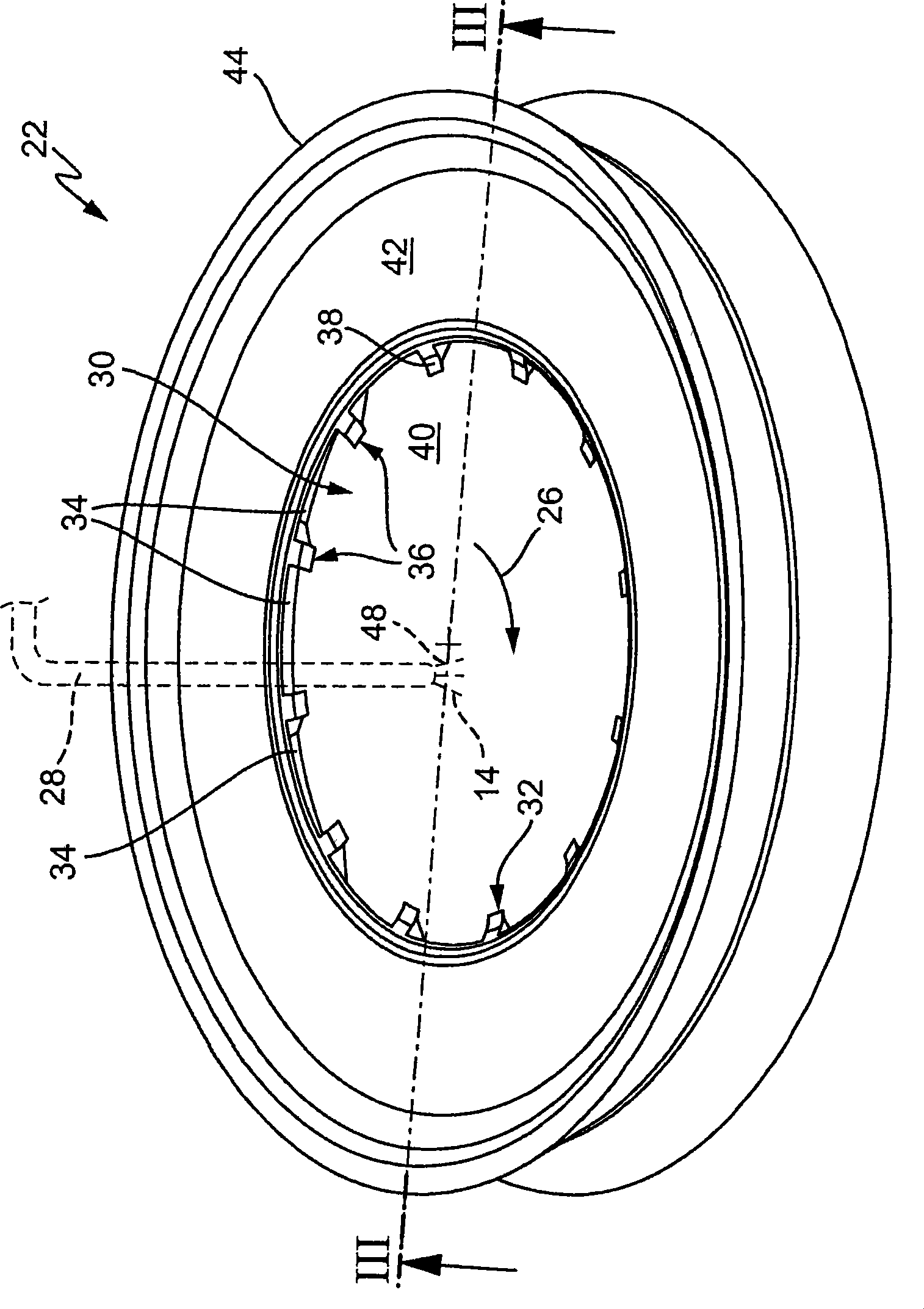

[0023] figure 2 A perspective view of a first embodiment of a carousel 22 is shown, on which the liquid 14 is sent by means of a pipe 28 shown only in a schematic manner. The liquid 14 flows onto a distribution surface designated as a whole by 30 , on which it flows radially outwards and reaches a region 32 in which a plurality of perforations 34 are arranged. Between the perforations 34 is a web 36 which has a web s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com