Device for melt spinning multi-component fibers

A multi-component fiber and melt-spinning technology, applied in fiber processing, textile and papermaking, spinneret assemblies, etc., can solve problems such as large melt flow, small throughput, and large manufacturing complexity, and achieve high manufacturing Effect of precision, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

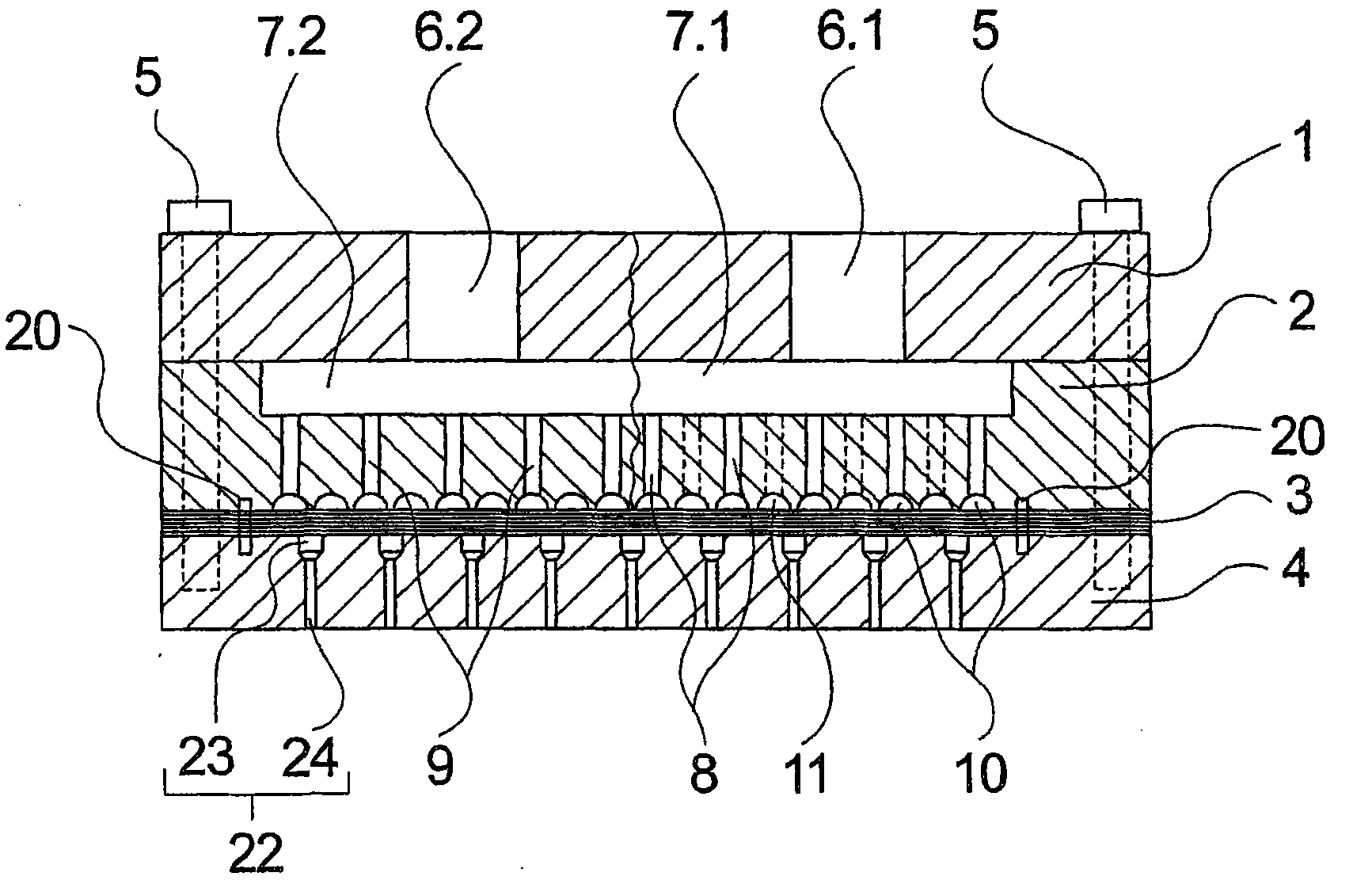

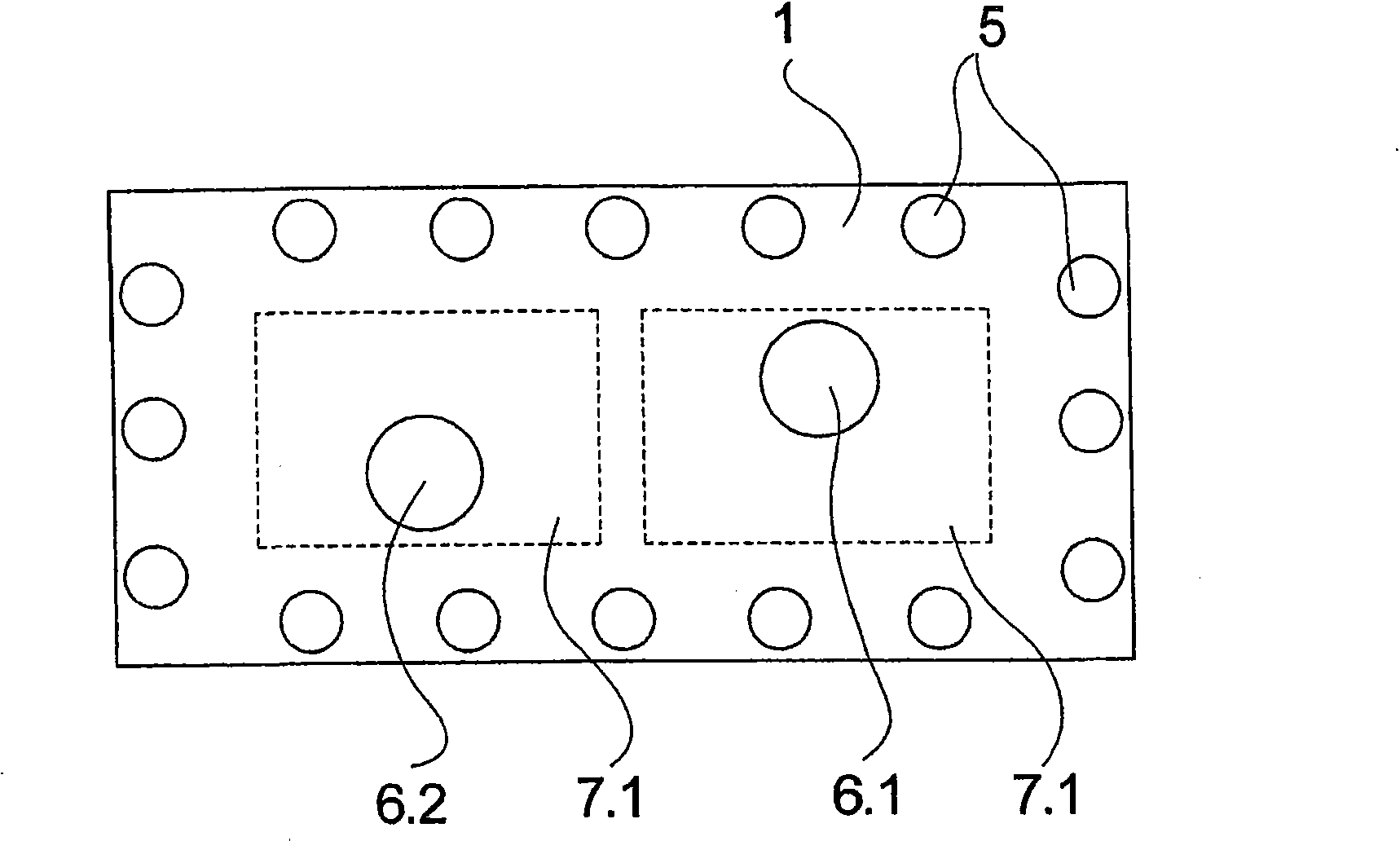

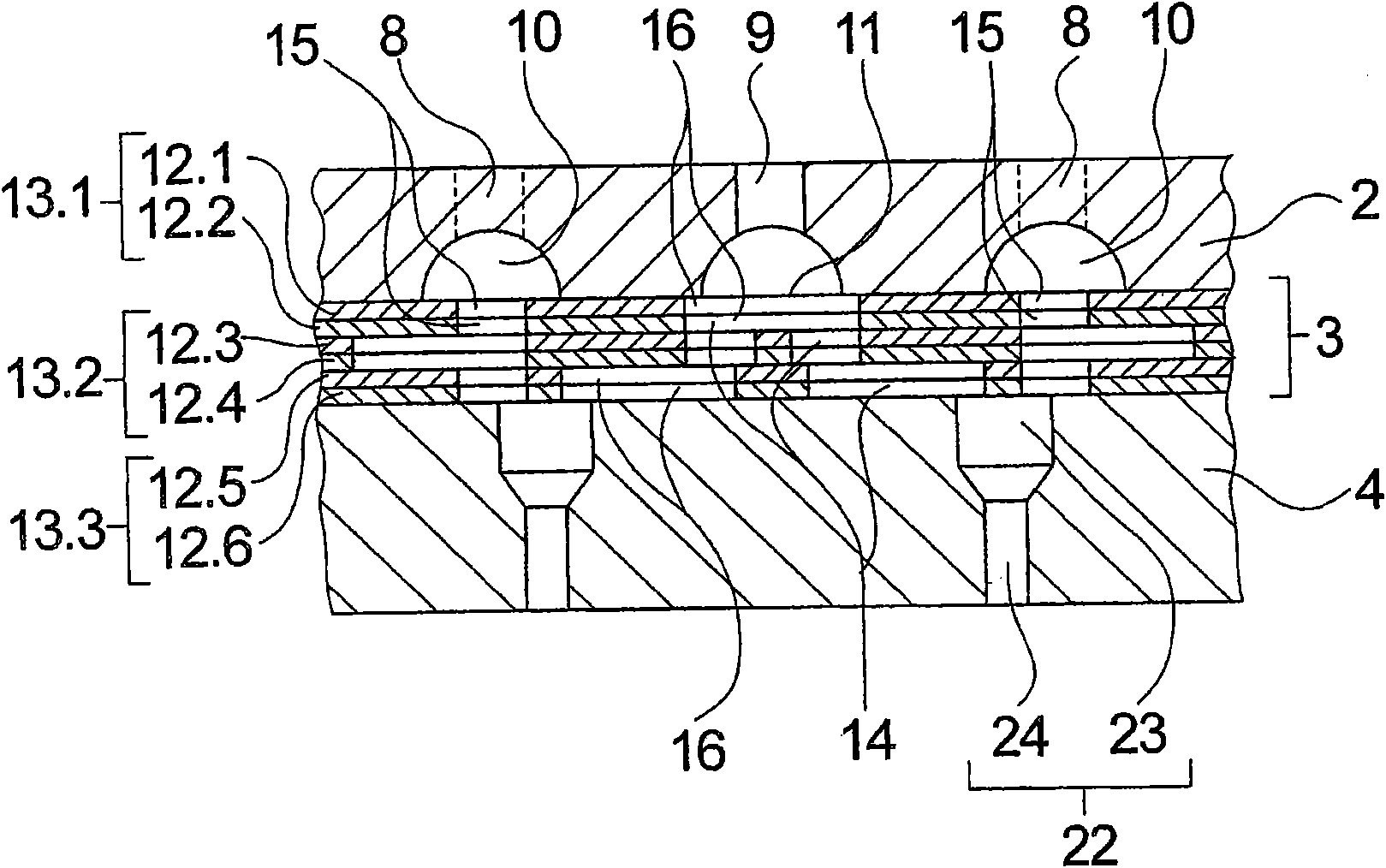

[0032] figure 1 and 2 Several views of the first embodiment are shown schematically. figure 1 is a cross-sectional view of the device, and figure 2 is a top view of the device. The following description applies to both figures, as long as it is not expressly indicated which figure is referred to.

[0033] according to figure 1 and 2The embodiment of has a plate structure formed by combining a plurality of rectangular plates. Therefore, an upper web 1 is provided which has two melt inlets 6.1 and 6.2. The melt inlets 6.1 and 6.2 are connected to two separate melt sources through melt pipes during operation, so that the two melt components can be independently fed to the device.

[0034] Feed plate 2 is connected to connecting plate 1 and has feed chambers 7.1 and 7.2 on the upper side for each melt inlet 6.1 and 6.2 respectively. Feed chambers 7.1 and 7.2 are connected to the underside of feed plate 2 via a plurality of melt channels. In this embodiment, the melt chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com