Flying ash sampling ejector

A kind of ash discharger and fly ash technology, which is applied in the direction of instruments, sampling devices, scientific instruments, etc., and can solve the problems of difficult sealing, complex structure, inconvenient use and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

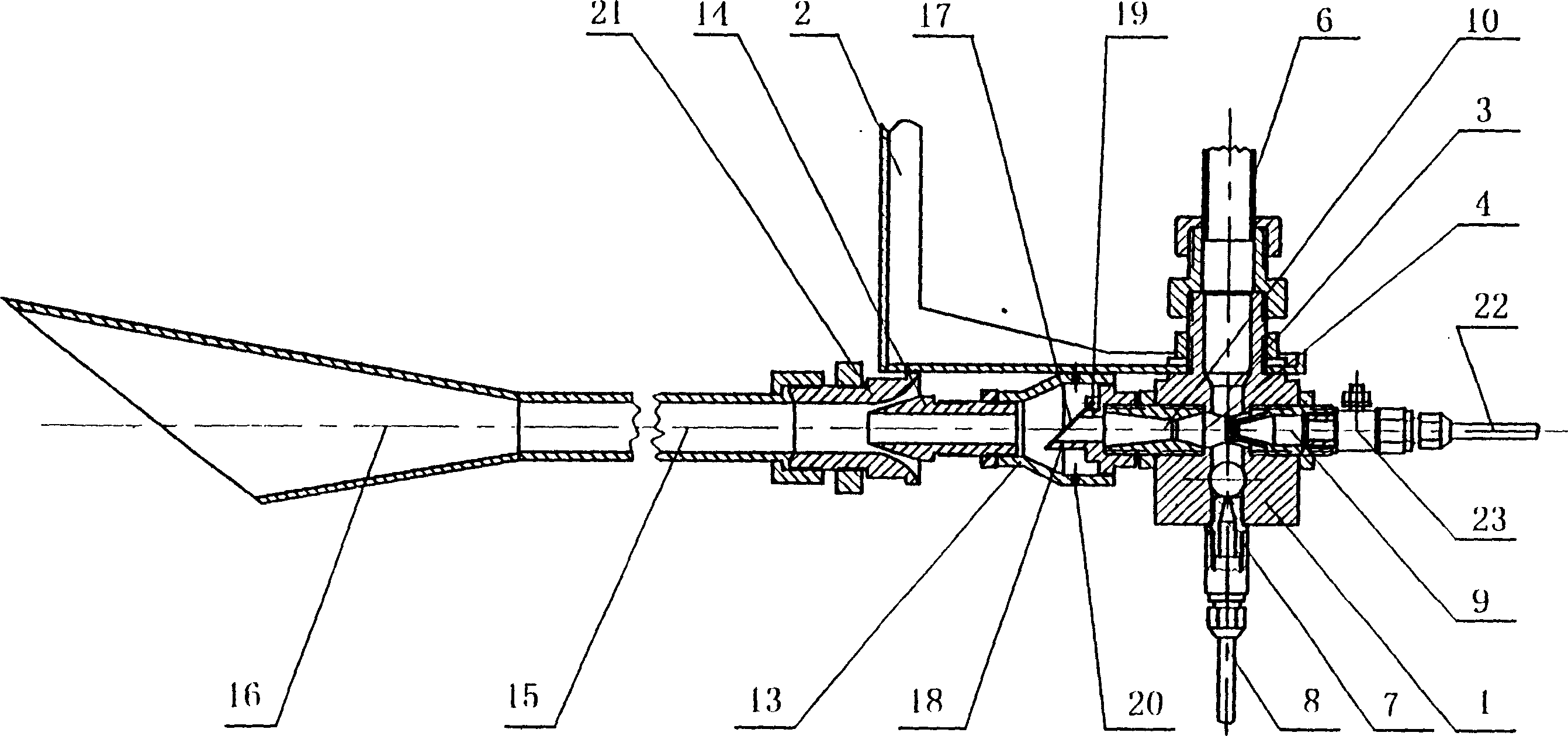

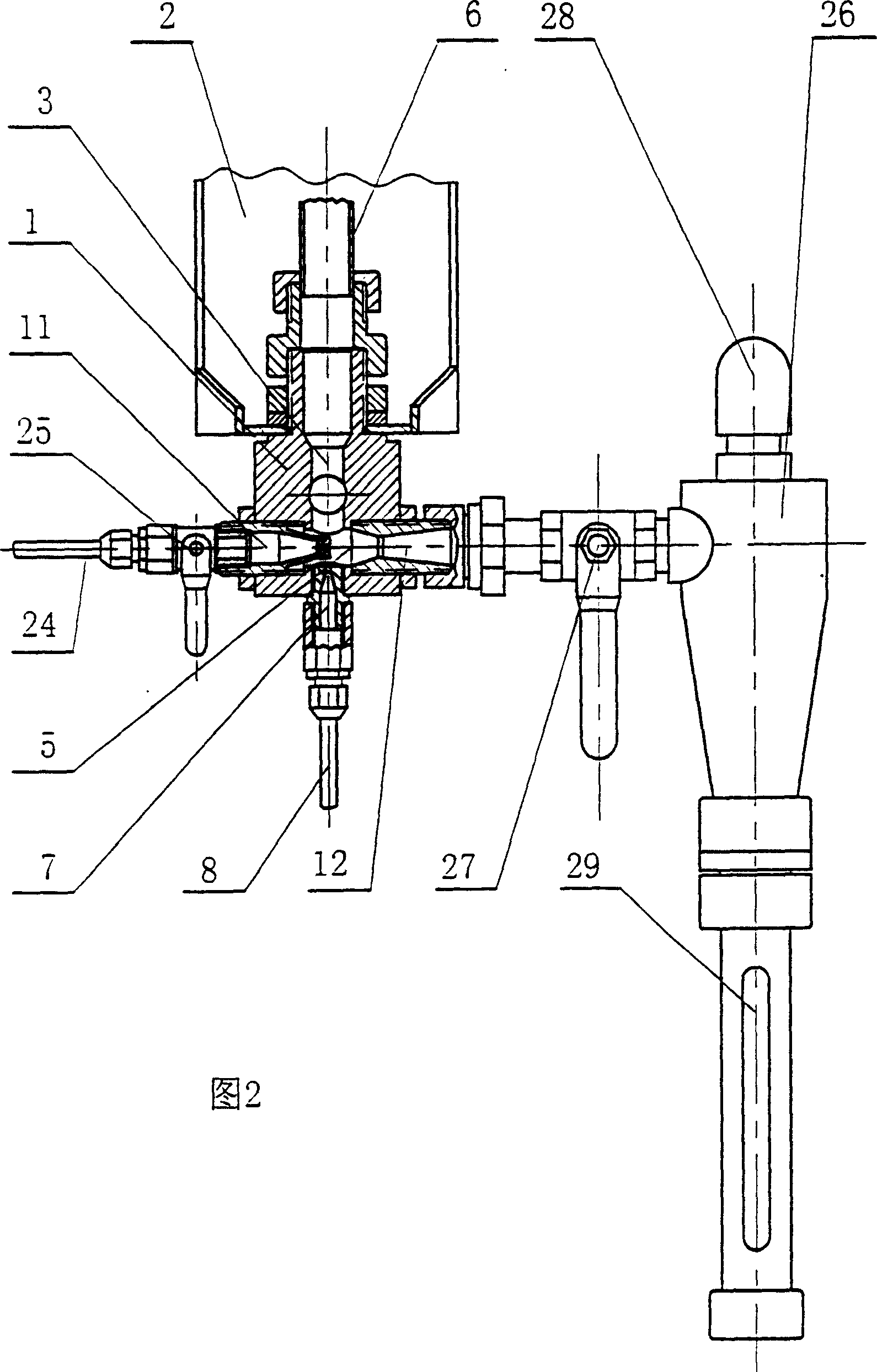

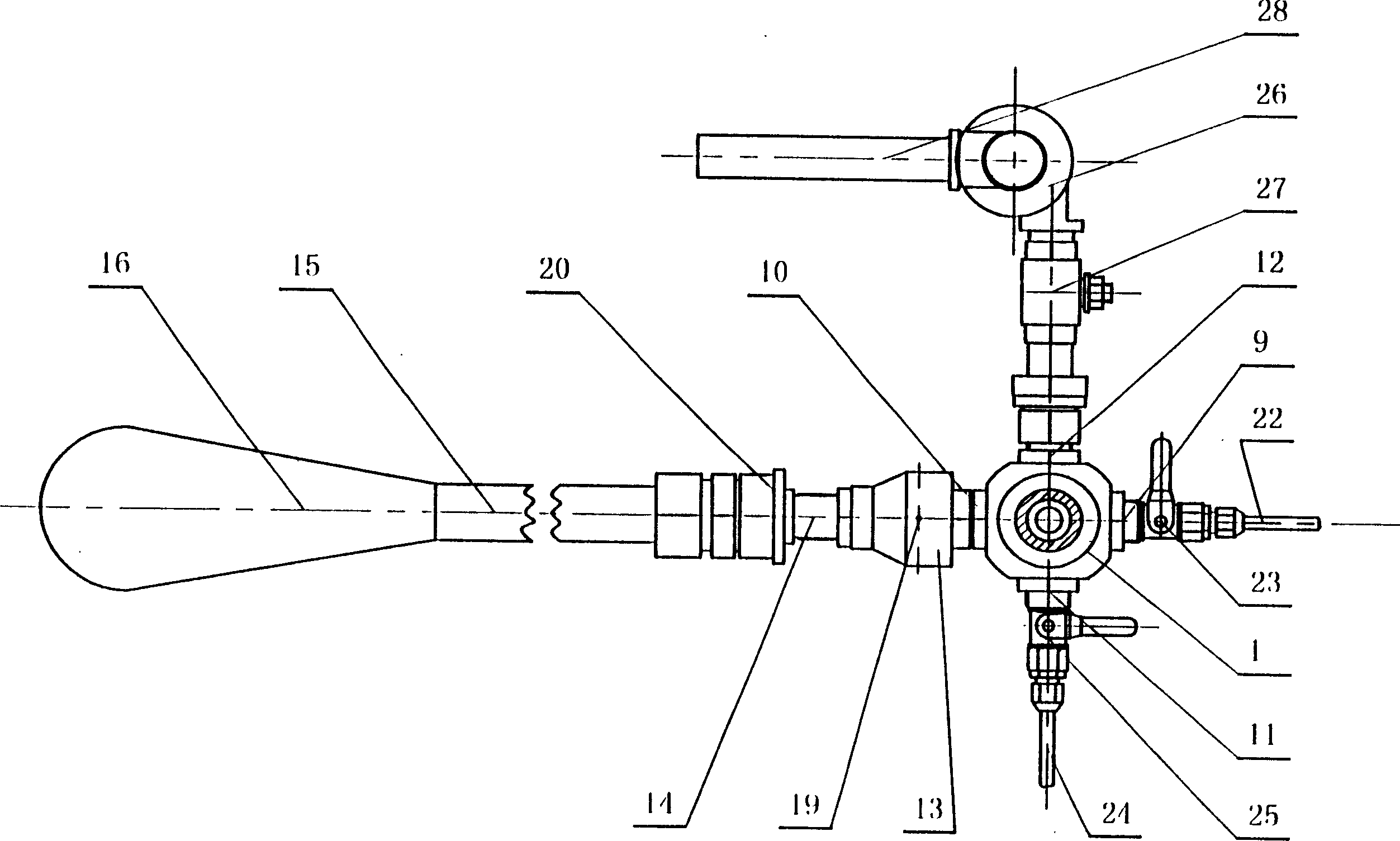

[0013] Give an embodiment below in conjunction with accompanying drawing: as figure 1 , as shown in Figure 2, the ash discharge seat 1 of the fly ash sampling ash discharge device is cubic, and it is fixed on the support 2 below by the ash discharge seat nut. The ash discharge seat 1 has through holes 3, 4, 5 up and down, left and right, front and back, and the upper hole 3 is connected to the quartz detection tube 6, and the quartz detection tube 6 is equipped with a casing, and is locked by a lock nut. The lower hole 3 leads to a blowback nozzle 7 and a compressed air inlet 8 . Left and right, front and back two groups of through holes 4,5 are installed in a criss-cross pattern on the upper and lower floors, and all communicate with the upper and lower through holes 3 . The left and right through holes 4 of the upper layer are ash discharge passages, equipped with ash discharge nozzles 9 and ash discharge acceleration tubes 10, and the ash discharge acceleration tubes 10 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com