A heat exchanger, combination with heat exchanger and method of manufacturing the heat exchanger

A technology of heat exchangers and heat exchange devices, applied in heat exchange equipment, heat exchangers, heating methods, etc., can solve the problems that heat transfer is not well controlled and efficiency is not the highest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

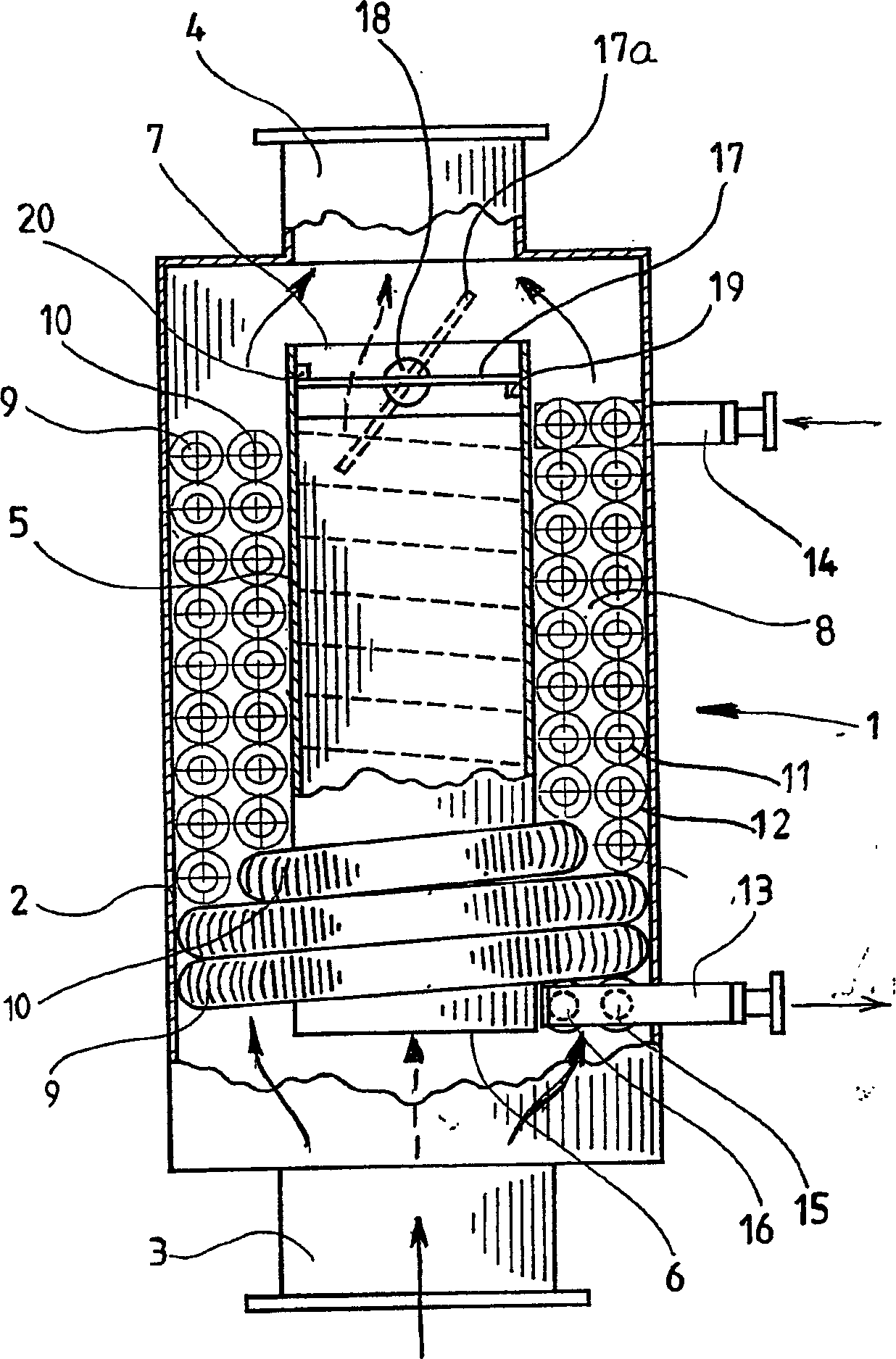

[0067] In the following, the basic technical parameters of the inventive combination of the two heat exchangers of the invention and the turbine fueled by natural gas are listed as non-limiting examples:

[0068] height, excluding entrance

1550mm

diameter, excluding insulation

633mm

insulation

100mm wrapped with galvanized steel

Exhaust gas outlet flange

DN450, DIN86044

Water In / Out Connections

Carbon steel pipe, OD 60.5x3.6mm,

2"RGW

Shell thickness (inner 5 and outer 2)

5mm

Heat exchanger weight, excluding water

475kg

Heat exchanger weight including water

500kg

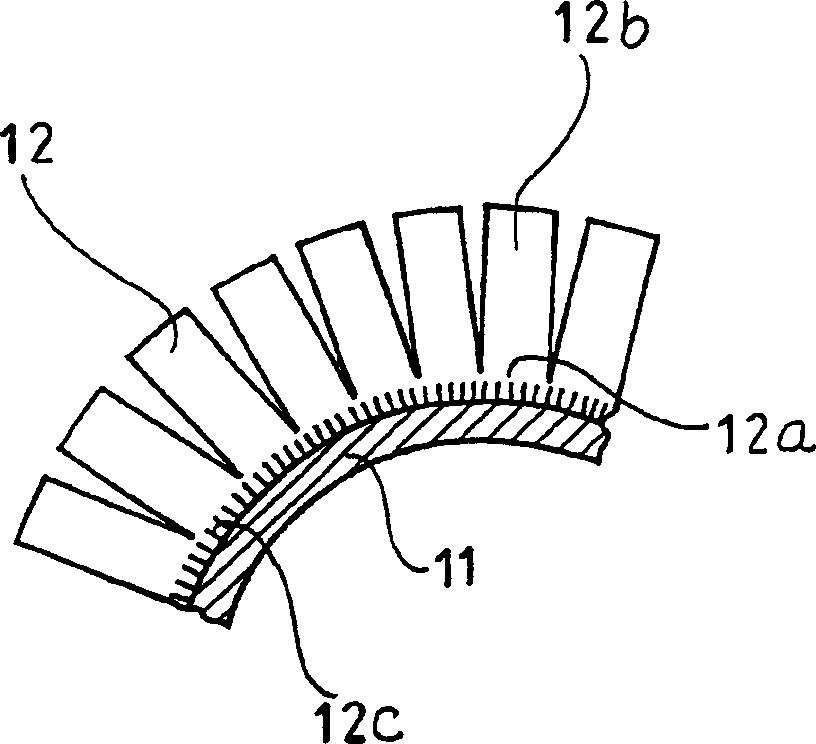

Tube 11 OD

38mm

Tube Material Thickness

3.6mm

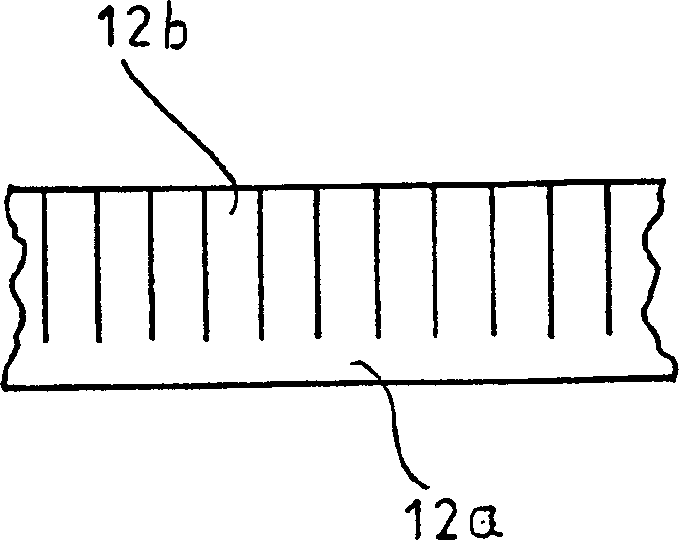

wing type

Zigzag spirally wound wings

wing height

15mm

wing density

250pcs / m

Fin thickness

1mm

Materials, Tubes and Fins

Tube configuration

Straight forward (Inline)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com