Switch type semi-active suspension system

A suspension system and switch-type technology, which is applied in the direction of suspension, elastic suspension, railway car body parts, etc., can solve the problems such as inability to adjust, and achieve the effects of convenient installation, reduced pressure loss, and compact oil circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

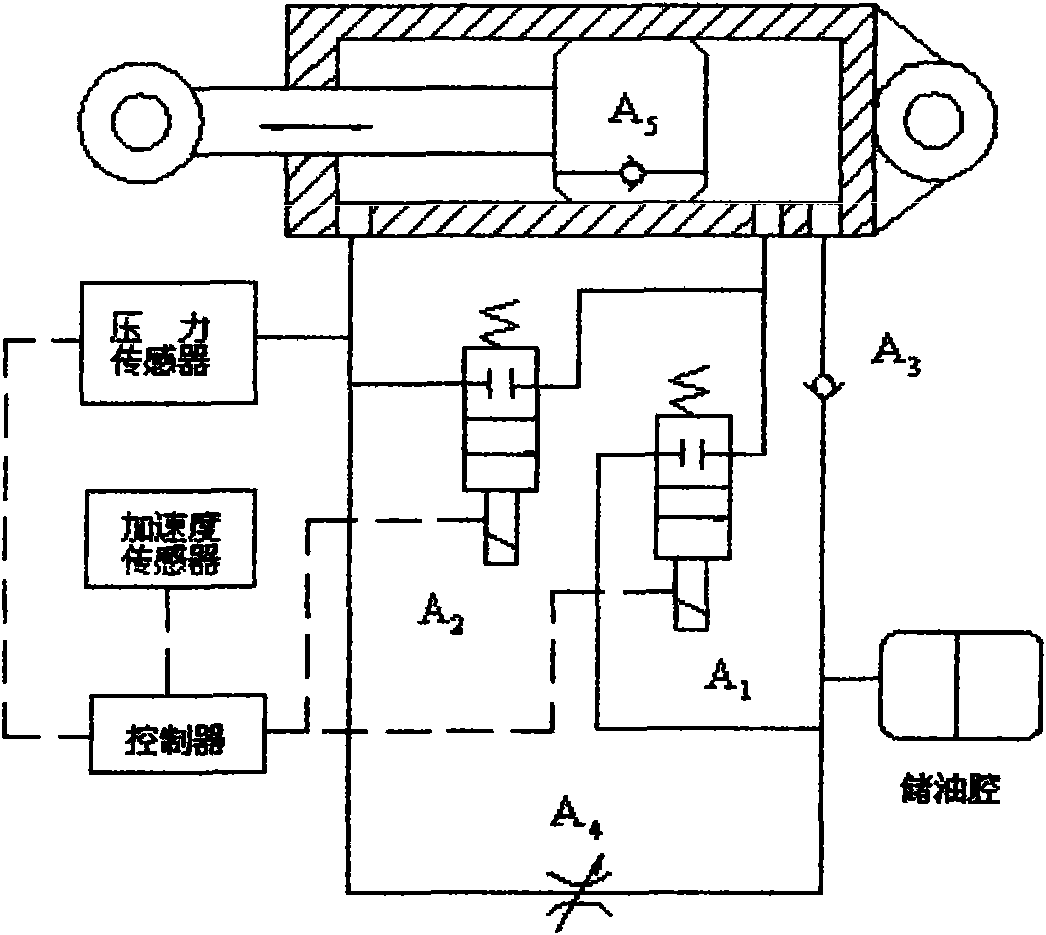

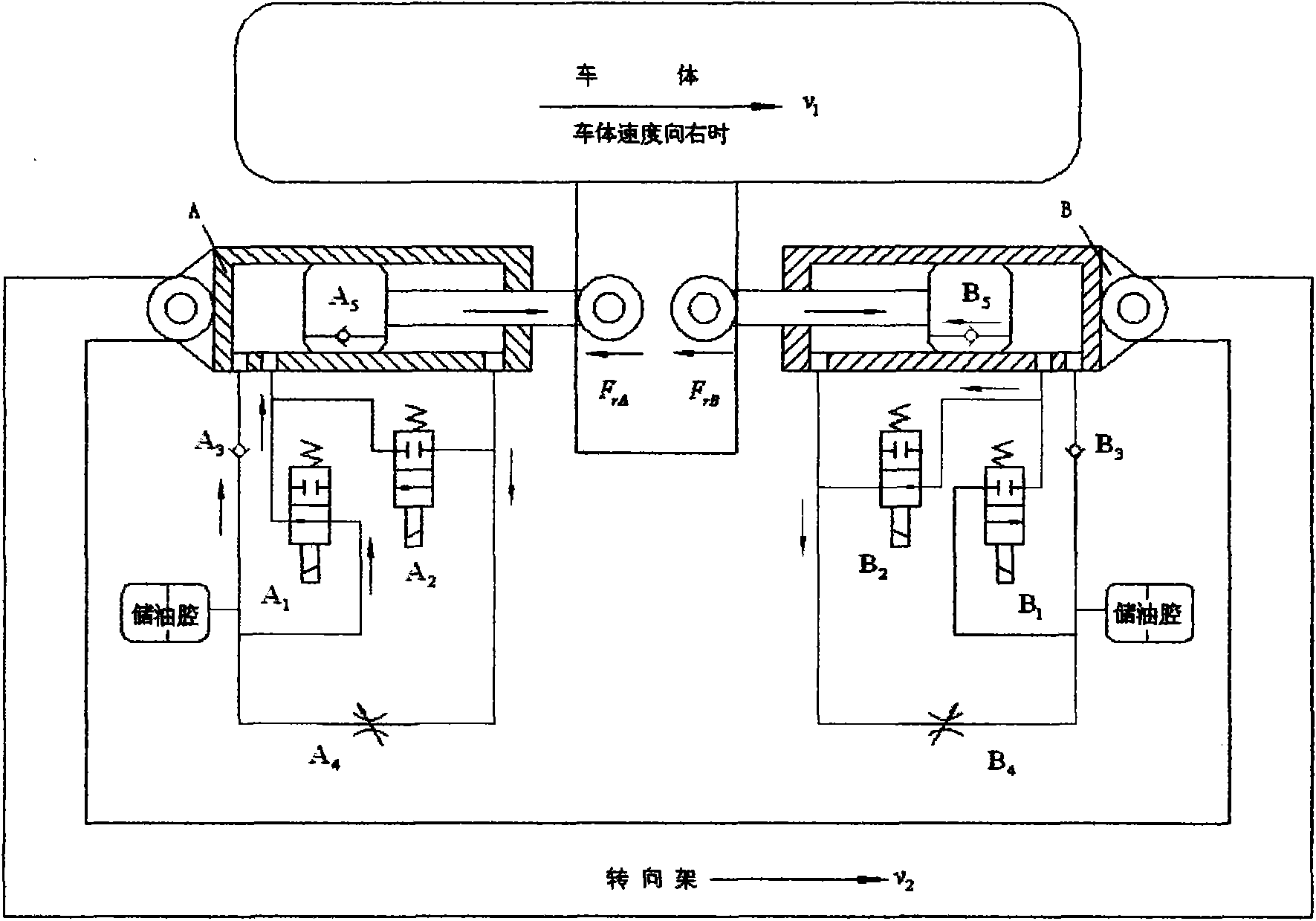

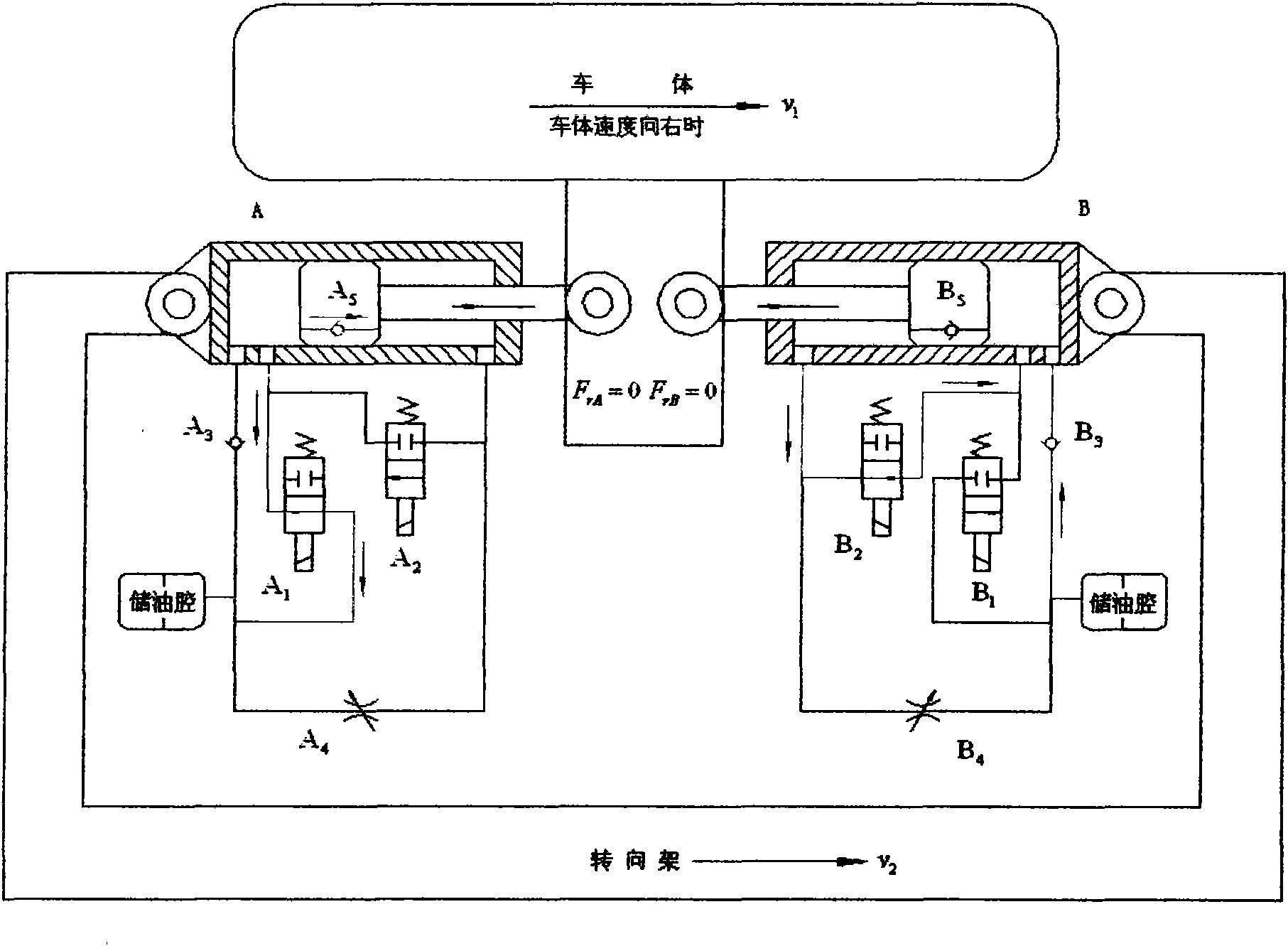

[0018] A switchable semi-active suspension system, including four sets of semi-switchable semi-active shock absorbers, two acceleration sensors and a detection and control system, each two sets of switchable semi-active shock absorbers are installed diagonally and act on the car body between the bogie and the bogie; each set of switch-type semi-active shock absorbers includes shock absorber body A, high-speed switching valve A1, A2 adjustable damping valve A4 and a pressure sensor, of which high-speed switching valve A1 is used to connect the shock absorber The rodless chamber and the oil storage chamber of the main body, there is a one-way valve A3 between the oil storage chamber and the rodless chamber, and the high-speed switching valve A2 is used to connect the rodless chamber and the rod chamber, and the connection between the rod chamber and the oil storage chamber An adjustable damping valve A4 is arranged between them, and the pressure sensor is used to detect the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com