Electrical device cooling structure in vehicle

A technology for electrical equipment and vehicles, which is applied in cooling/ventilation/heating transformation, electrical components, vehicle energy storage, etc. It can solve problems such as assembly restrictions, inability to cool converters, and longer and larger power supply devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

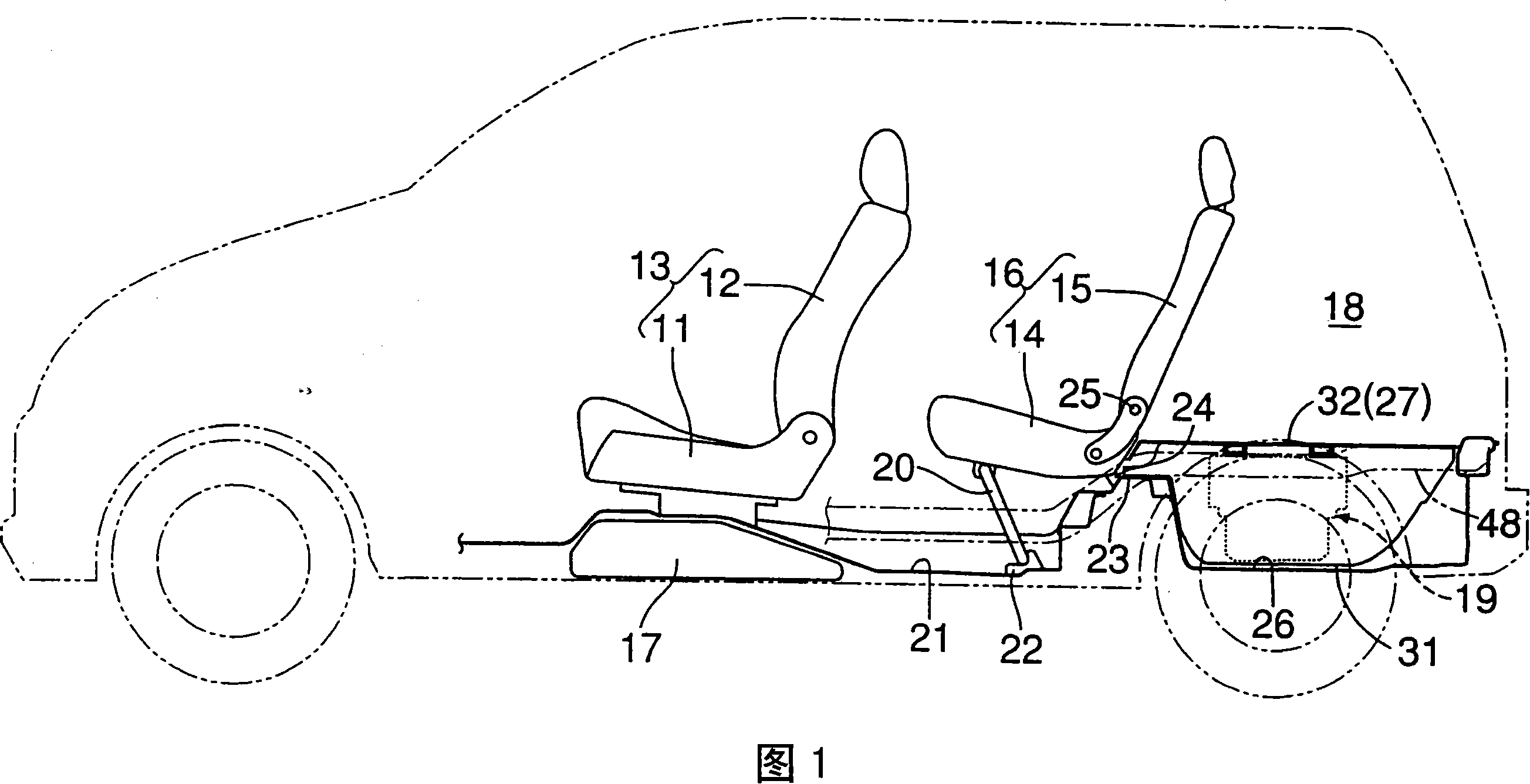

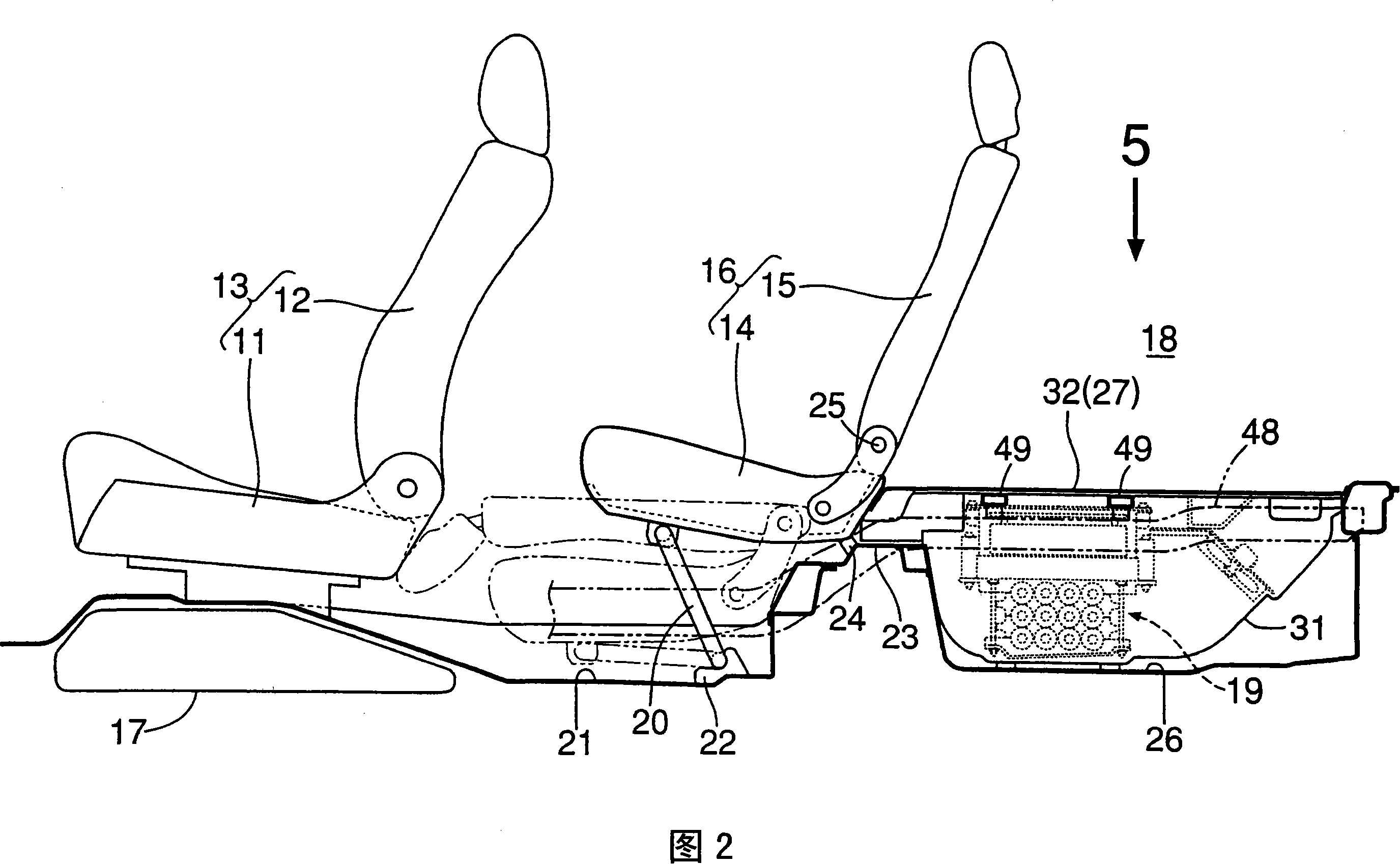

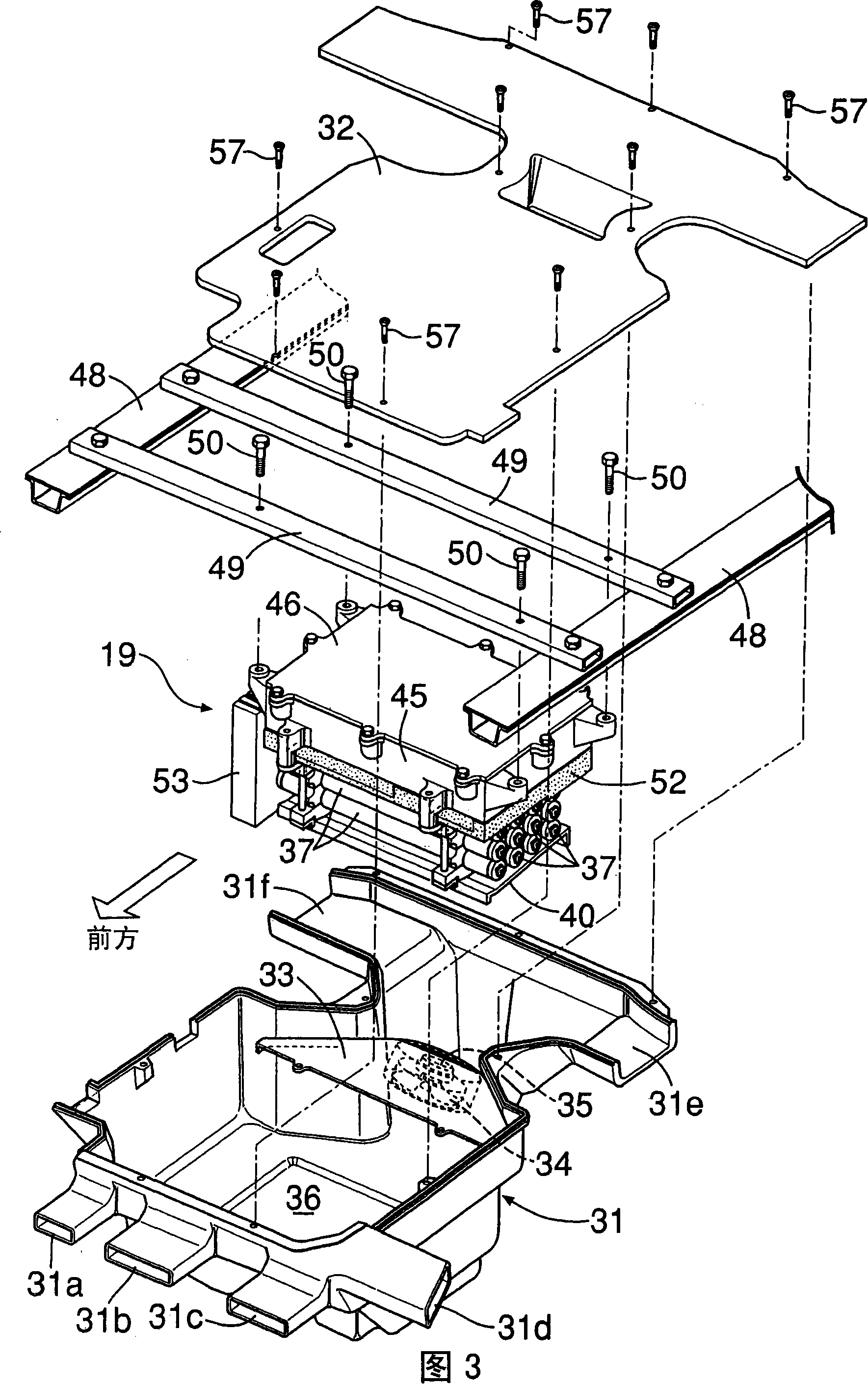

[0034] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 to 9 .

[0035] As shown in FIGS. 1 and 2 , a hybrid vehicle using an unillustrated engine and an electric motor as a driving source includes: a front seat 13 consisting of a seat cushion 11 and a seat back 12; a seat cushion 14 and a seat back 15; The rear seat 16. A fuel tank 17 is provided under a seat cushion 11 of the front seat 13 , and a power supply unit 19 for driving a motor is mounted under a luggage space 18 behind the rear seat 16 .

[0036] A pair of foldable pillars 20, 20 are arranged on the left and right below the seat cushion 14 of the rear seat 16. In the use state of the rear seat 16, the lower ends of the pillars 20, 20 are locked with the hooks 22, 22 arranged on the seat lower floor 21. and the rear end of the seat cushion 14 is locked and fixed with the seat cushion locking part 24 provided on the raised part 23 provided at the rear of the seat lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com