Method for preparing super-hydrophobic antireflex micron and nano composite structure surface

A nano-composite and super-hydrophobic technology, applied in the direction of silicon, can solve the problems of expensive instruments, restricted applications, and limited applications, and achieve the effects of low cost, reduced pressure loss along the process, and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Select n-100 type silicon wafer and clean its surface. The treatment process is as follows: ultrasonically clean the silicon wafer in acetone, chloroform, ethanol, and water respectively, with an ultrasonic power of 100W for 5 minutes. Then put the silicon chip into the HF solution with a mass fraction of 1% for 5 minutes to remove the silicon dioxide on the surface, and finally wash it with deionized water and dry it with high-purity nitrogen gas.

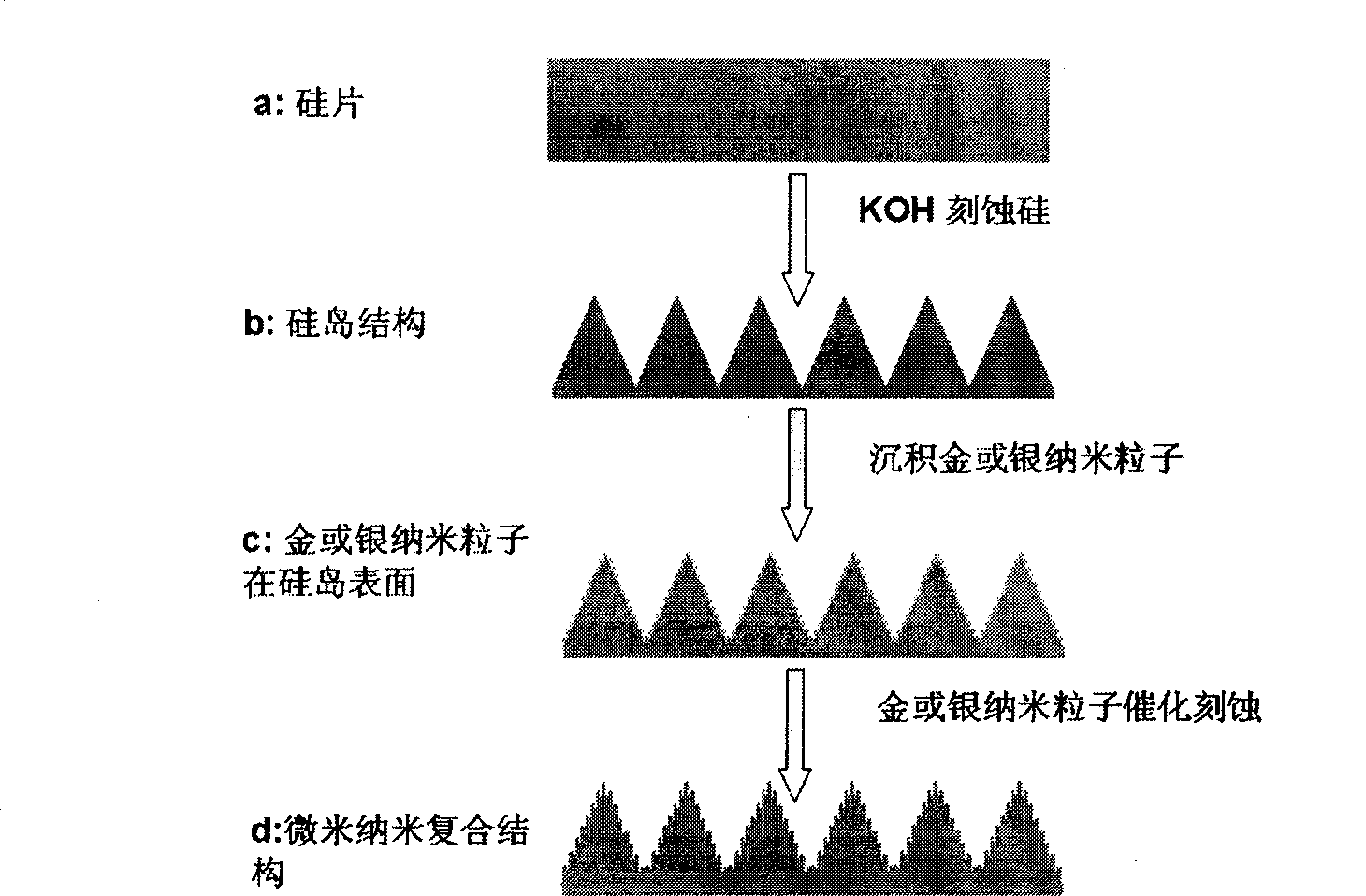

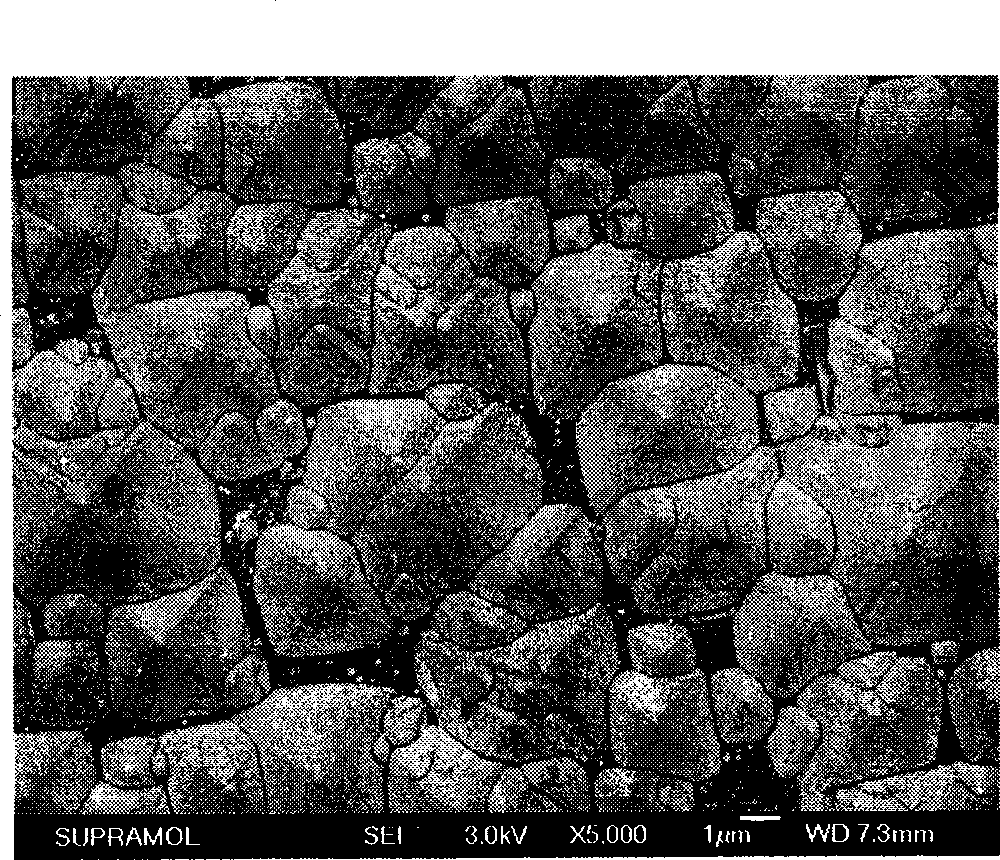

[0046] (2) Prepare micron-scale silicon island structures on the silicon surface. The process is as follows: put the cleaned silicon wafer into a KOH solution at 60°C with a pH of 14 for 1 hour, and silicon is etched anisotropically in the alkaline solution. , thereby preparing a silicon island structure on the silicon surface, the bottom side of the silicon island is 4-6 μm long, and the height is 5-7 μm. like figure 2 shown.

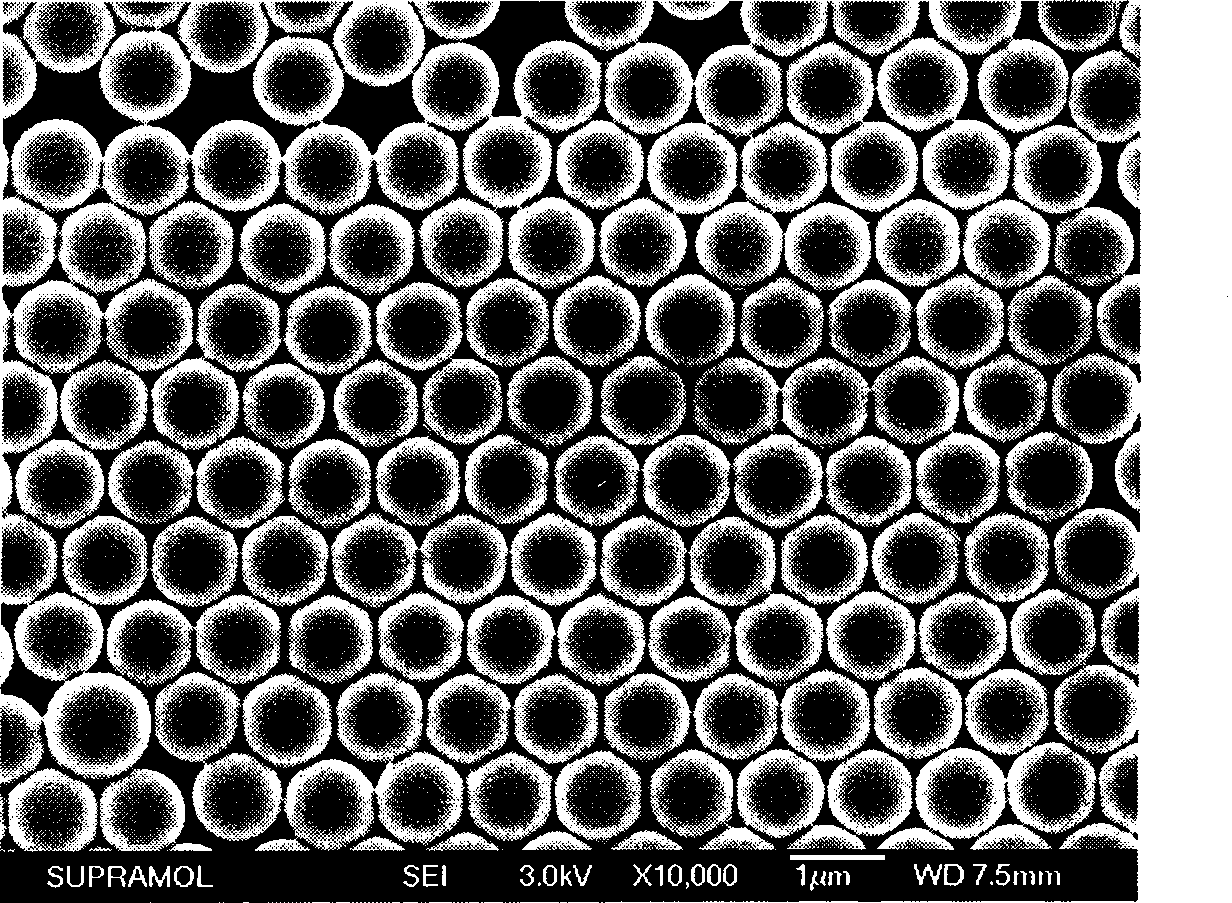

[0047] (3) To prepare nanoscale pores on the surface of micron-scale silicon islands, fi...

Embodiment 2

[0050] According to the method and steps of Example 1, the electroless deposition of silver nanoparticles is changed to electrodeposition, and the electrolyte is AgNO of 0.01M. 3 Solution, deposition voltage is 400mv, deposition time is 15min, other steps are the same as embodiment 1, superhydrophobic anti-reflection silicon surface can be obtained equally, the silicon island height of preparation structure is 5~7 μ m, the size of nanoscale hole is about 130 nanometers, The contact angle is 153°, and the reflectance is lower than 8%.

Embodiment 3

[0052] According to the method and steps of Example 1, the electroless deposition of silver nanoparticles is changed to electrodeposition of gold nanoparticles, the electrolyte is 0.01M chloroauric acid solution, the deposition voltage is 500mv, and the deposition time is 10min. Other steps are the same as in the embodiment. 1. The superhydrophobic anti-reflective silicon surface can also be obtained. The height of the silicon island of the prepared structure is 5-7 μm, the size of the nanoscale hole is about 120 nanometers, the contact angle is 150°, and the reflectivity is lower than 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com