Nanofiber filtration material and forming method thereof

A nanofiber and filter material technology, applied in the field of nanofiber filter material, can solve the problems of low soft mechanical strength, high pressure loss, and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

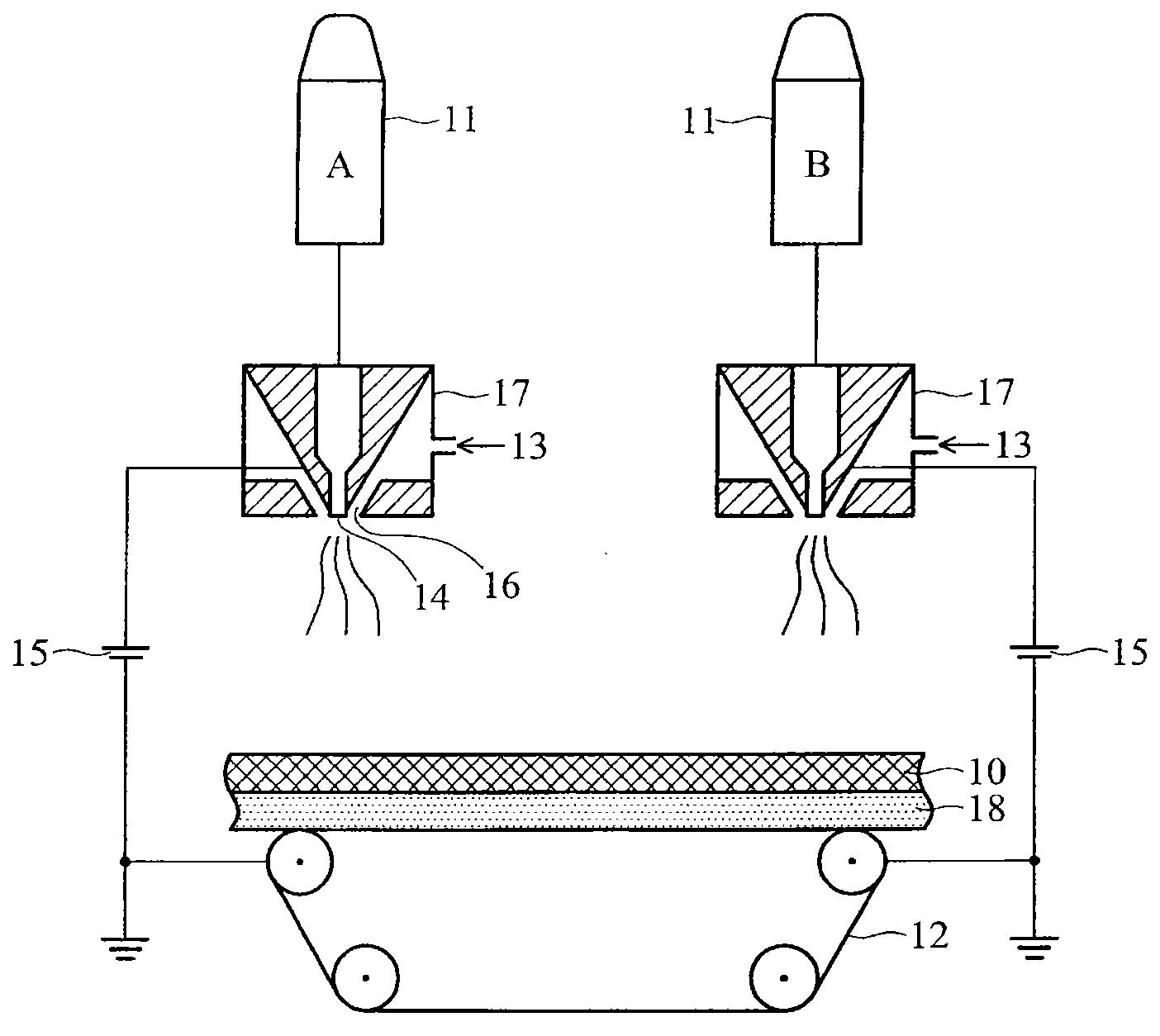

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the polymer solution is polycarbonate dissolved in a mixed solvent of tetrahydrofuran and dimethylethylamine, and the concentrations are 12% and 15% (by weight, the same below). The polymer solutions 12% and 15% are respectively interwoven in an electric field environment by electrospinning in a uniform interlaced manner to form two kinds of nanofiber diameter distributions and uniformly mixed to form a nanofiber layer cotton web and deposited on a grammage of 15g / m 2 Meltblown nonwoven cotton mesh substrate. The distance between the spinneret and the collecting cotton net base material is 20cm, the applied voltage is 40kV and the output speed of 25μL / min / hole, and there is gas-assisted stretching of the fiber at the spinneret at the same time, the polymer solution is 12% and 15% %The two concentrations are interwoven in the above-mentioned electric field environment in a uniform interlacing manner to form two kinds of nanofiber diameter distribution...

Embodiment 2

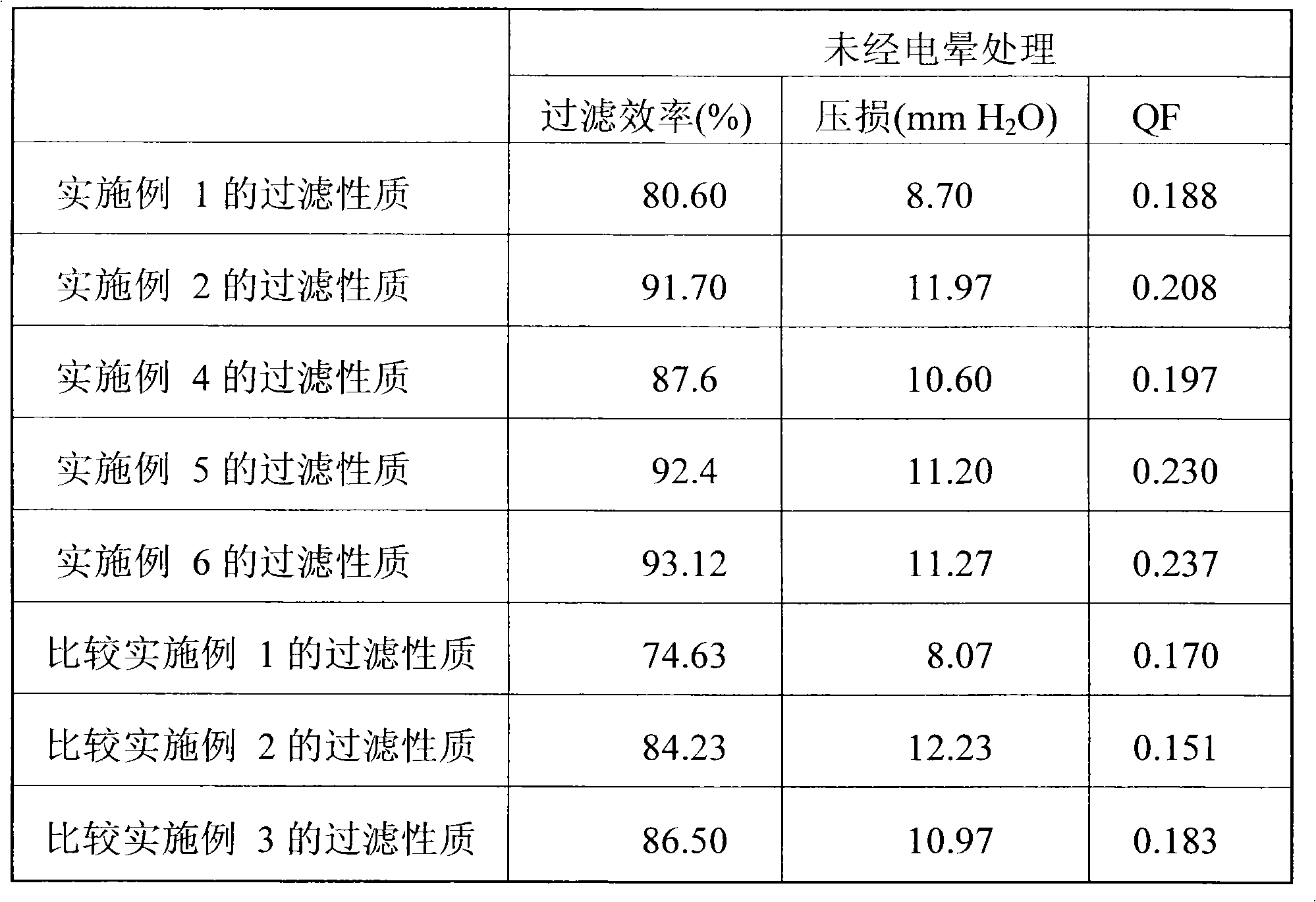

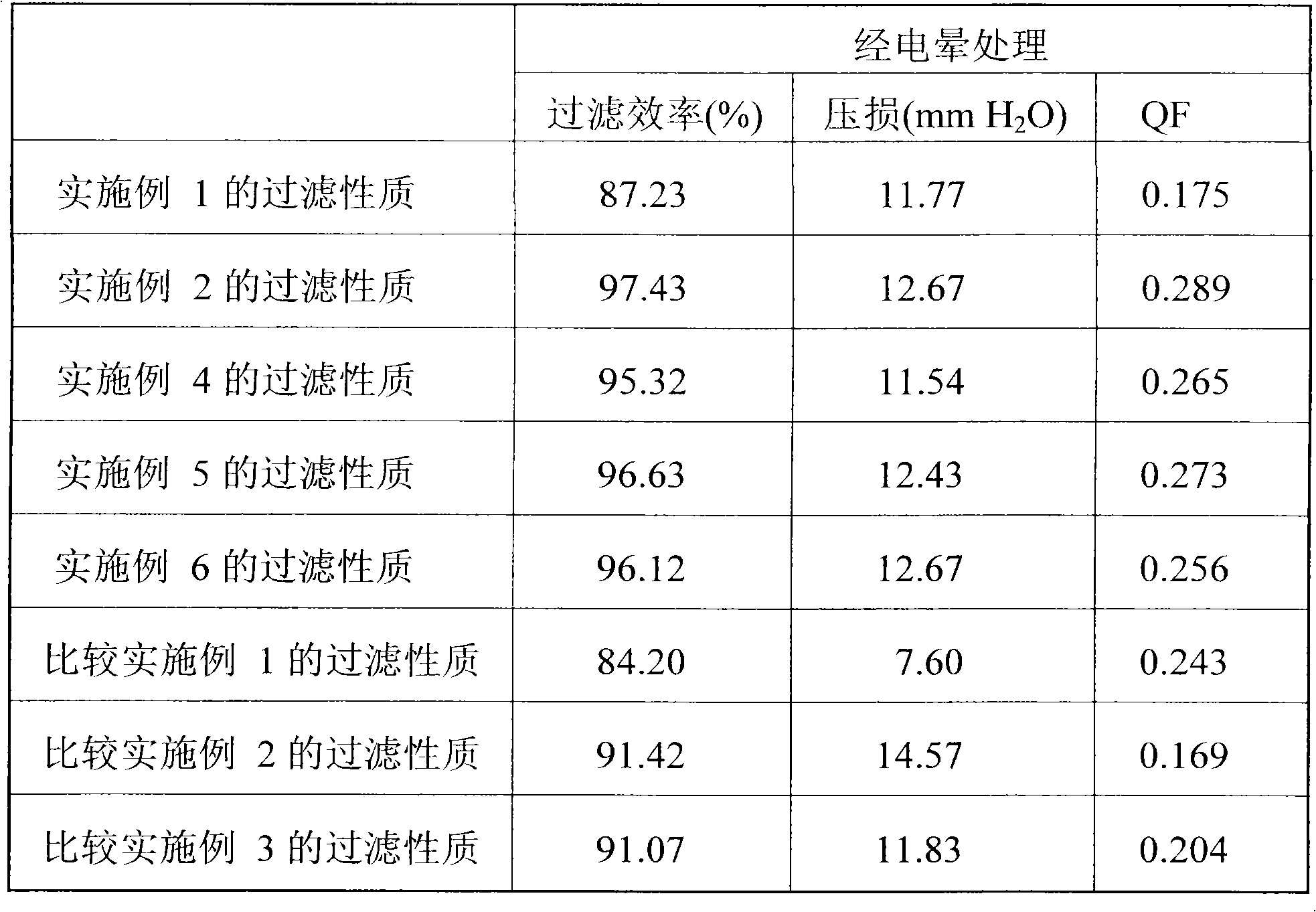

[0025] In this embodiment, the polymer solution is polycarbonate dissolved in a mixed solvent of tetrahydrofuran and dimethylethylamine, and the concentrations are 12%, 13.5%, and 15% respectively. Under the same electrospinning conditions and substrate as in Example 1, a nanofiber cotton web is formed, the difference is that the three concentrations of polymer solutions of 12%, 13.5%, and 15% are used to interweave in a uniform interlaced manner to form three A nanofiber layer cotton web with nanofiber diameter distribution and uniform mixing, the nanofiber layer gram weight is measured as 1.36g / m 2 , the thickness is 11 μm, and the average fiber diameter of the nanofiber cotton web formed by uniform mixing is 150nm±30nm. The nanofibrous layer formed by uniformly interlacing the three concentrations of polymer solutions of 12%, 13.5%, and 15% respectively, and the filtration properties of the 260nm particles measured by TSI 8130 at a gas flow rate of 14cm / s are shown in Table...

Embodiment 3

[0027] In this example, under the same electrospinning conditions as in Example 2, a composite nanofiber cotton web is formed, the difference is that the corona-treated single-layer composite nanofiber cotton web is laminated to form a double-layer composite nanofiber Cotton web, with 260nm particles, was measured by TSI 8130 at a gas flow rate of 5.3cm / sec, and its filtration properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com