Mager vorgemischte dual-fuel-ringrohrbrennkammer mit radial-mehrring-stufenduse

A burner, dual-fuel technology, used in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as expensive and uncertain, and units that cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

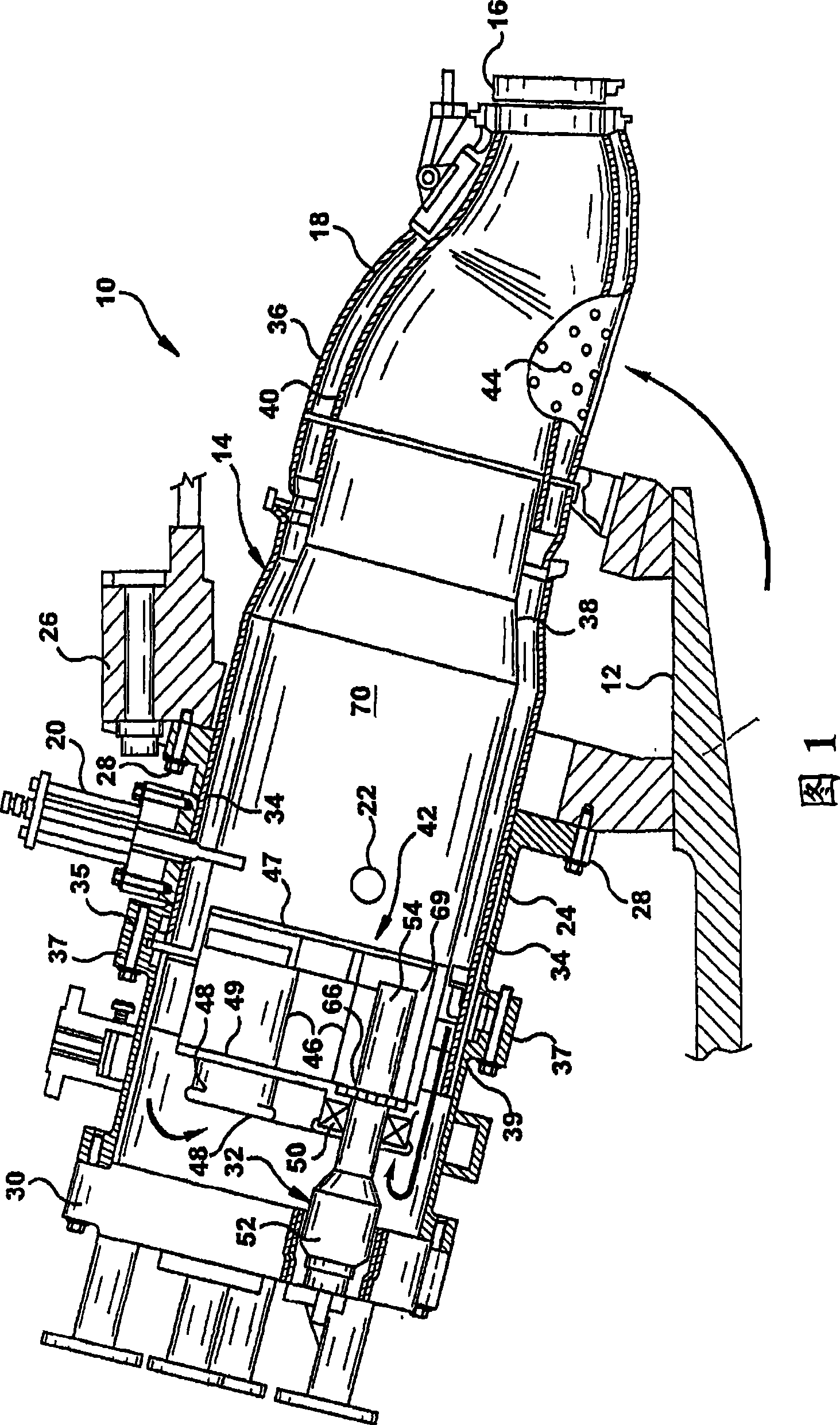

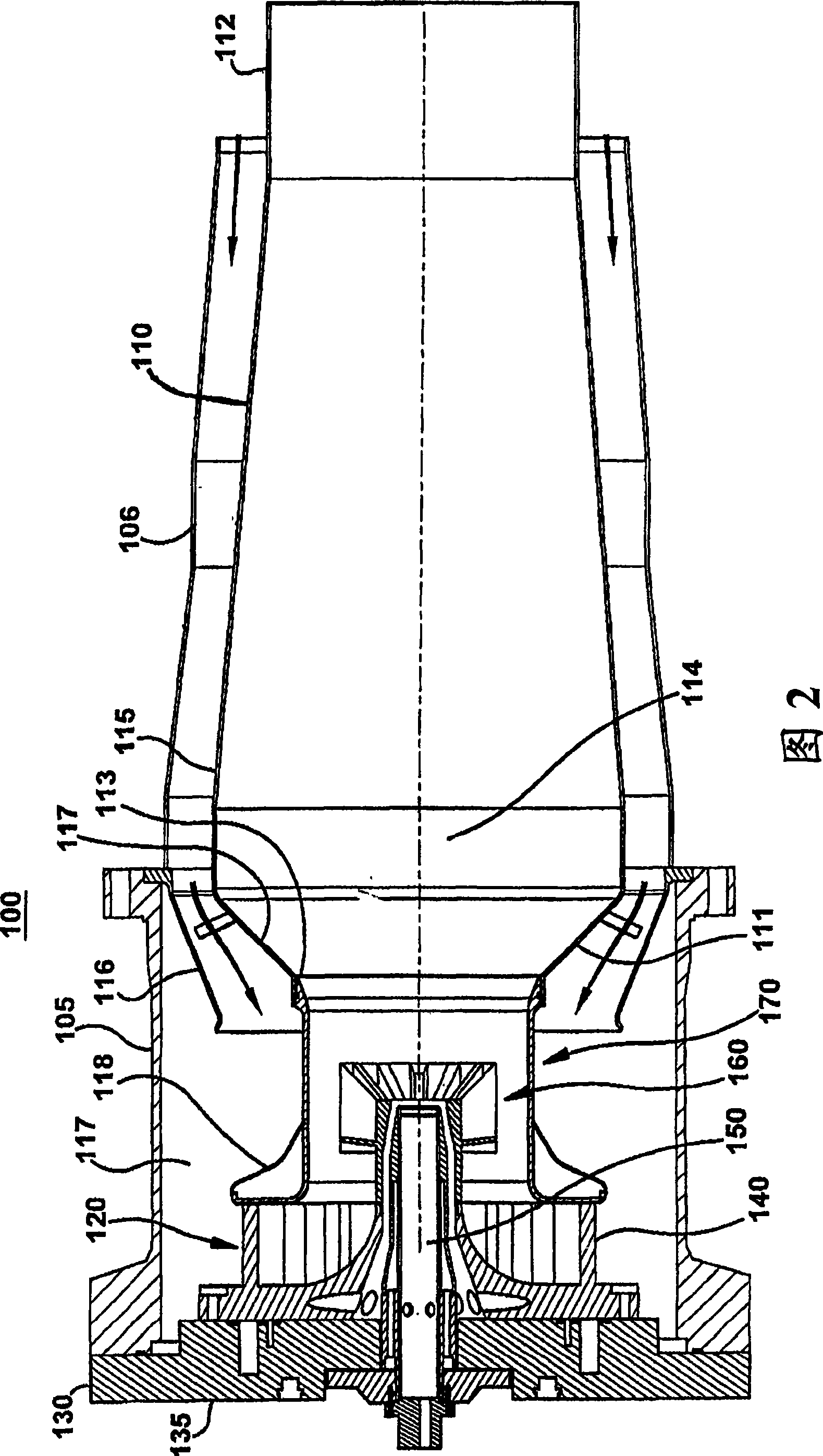

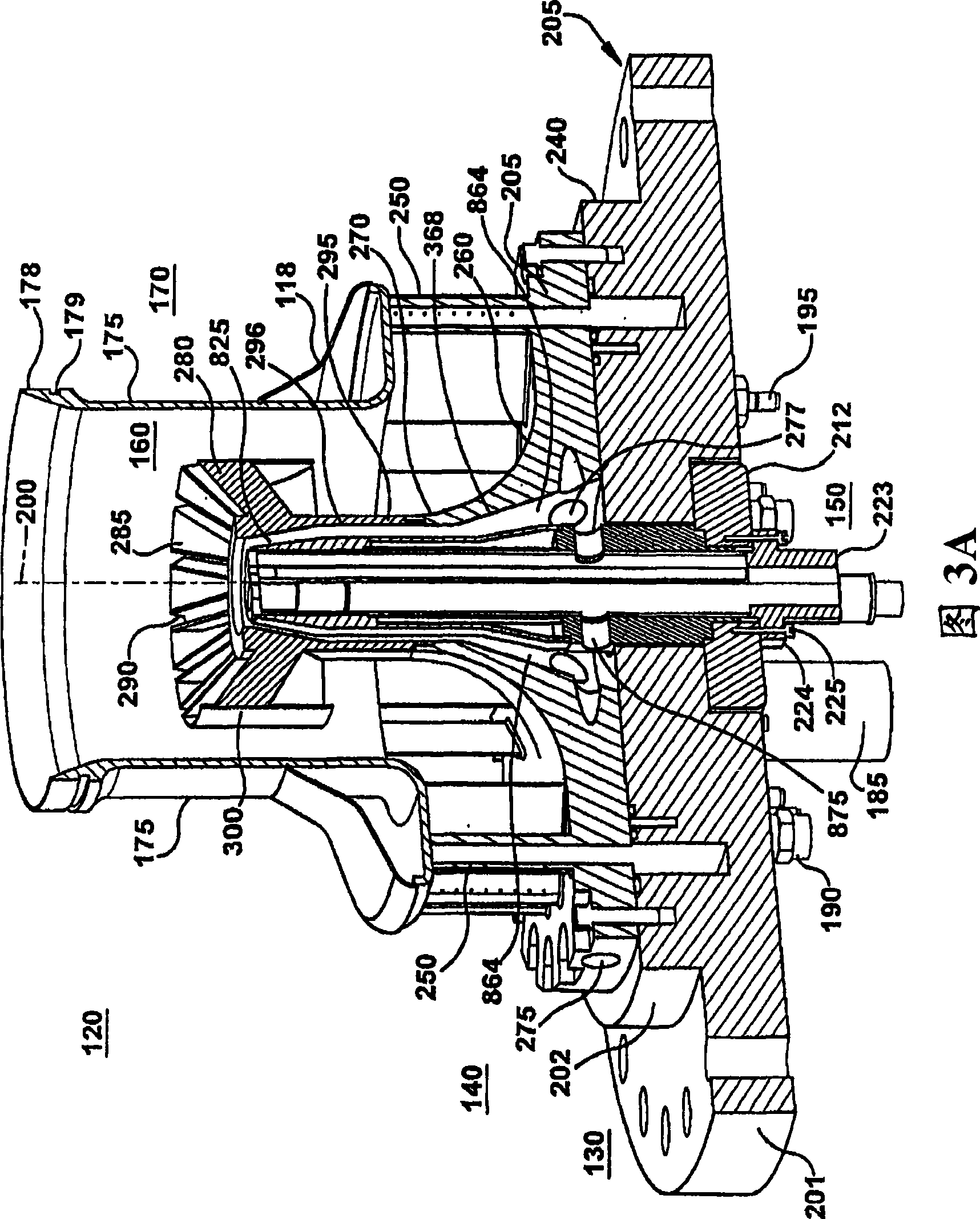

[0152] The following embodiments of the present invention have many advantages, including several innovative and unique features as follows: (1) Allows for the replacement of multiple (e.g., six) premixing nozzles (each can) and combustor cover, thereby achieving a significant reduction in parts count, saving cost, and significantly simplifying the head end of the combustor; (2) using a dome diffuser design to convectively cool the dome of the liner from the back, and in Allows fuel and air to be premixed in large radial nozzles while simultaneously restoring static pressure, resulting in less parasitic pressure loss and making more air available for premixing; (3) provides a relatively low pressure drop (e.g. <4%) the ability to quickly (e.g. <3msec) and completely vaporize and mix large quantities of fuel (~2lbm / sec) and air (~60lbm / sec); and (4) using gaseous or liquid fuels, It does this by strategically distributing or distributing heat release (in time and space) and fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com