Low-temperature modified grouting reinforcement material

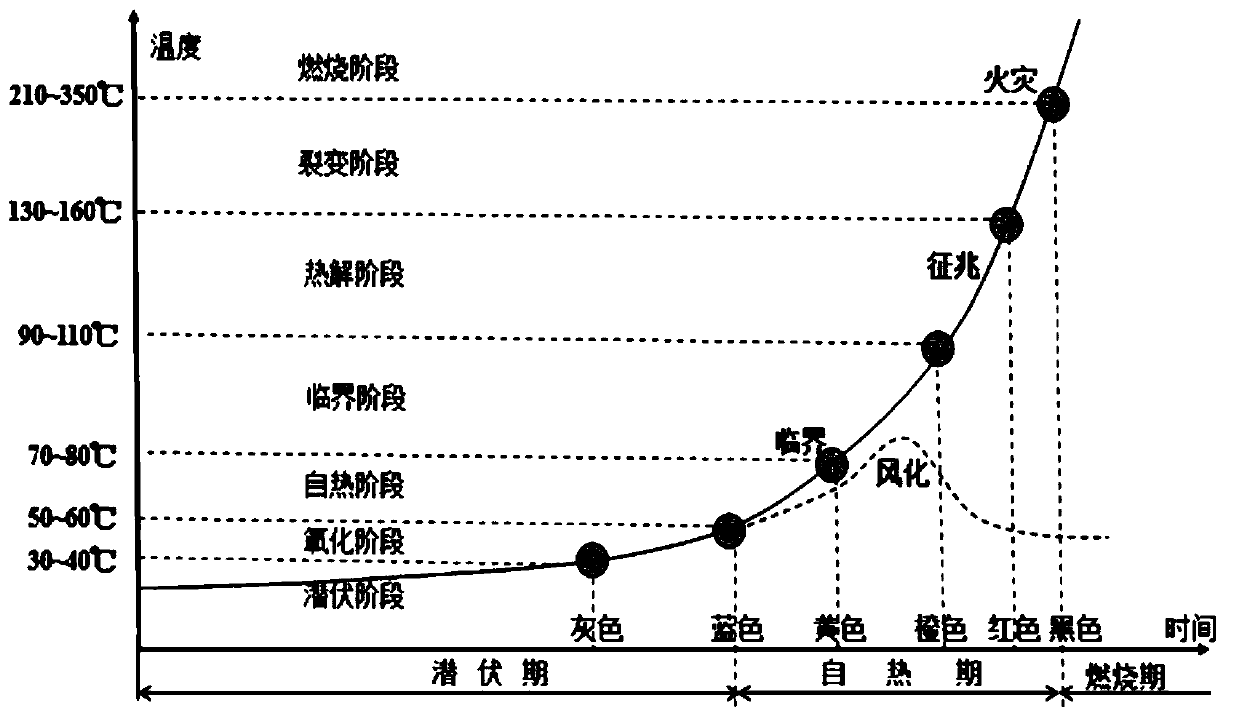

A grouting reinforcement, low-temperature technology, applied in the field of coal seam filling, reinforcement and bonding, and surrounding rock, can solve problems such as explosion and natural coal, and achieve the effect of avoiding potential safety hazards and preventing spontaneous combustion of coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] A low-temperature modified grouting reinforcement material, which is made by mixing materials A and B in equal volumes. Material A is made of 90% water glass, 0.5% catalyst (ZR70), 4% polyol and water, and material B 50% polyisocyanate, 6.75% polyether polyol, 4% oligoether polyol, 6.75% diethylene glycol, 12% complex vegetable ester, 2% silicone, 4% triphosphate Ethyl chloride and 1% antioxidant mixed.

[0035] Mix the weighed components of material A and material B according to 1:1 equal volume, and then stir in the container for 90-100s through the stirring device, then quickly insert the thermometer into the container containing the material, and measure the temperature produced by the material. The temperature is 80°C, which is below the critical temperature for coal mines. It will not cause coal mines to spontaneously ignite and explode with high concentrations of dust in the air. It is a safe temperature and meets the low temperature characteristics of the materi...

example 2

[0037] A low-temperature modified grouting reinforcement material, which is made by mixing materials A and B in equal volumes, and material A is mixed with 90% water glass, 0.5% catalyst (ZR70), 4% polyol, water and antistatic agent Formed, material B consists of 60% polyisocyanate, 8% polyether polyol, 5% oligoether polyol, 8% diethylene glycol, 15% compound vegetable ester, 2% silicone, 4% trichloroethyl phosphate and 2% antioxidant.

[0038] Mix the weighed components of material A and material B according to the equal volume of 1:1, and then stir in the container for 90-100 seconds through the stirring device, and quickly pour the uniformly stirred reinforcement material into the mold, and the material solidifies rapidly , After the material in the mold is taken out, its compressive strength is measured to be 41.3Mpa, and the measured material strength meets the strength required by the state.

example 3

[0040] A low-temperature modified grouting reinforcement material, which is made by mixing materials A and B in equal volumes. Material A is made of 90% water glass, 0.5% catalyst (ZR70), 4% polyol and water, and material B 60% polyisocyanate, 8% polyether polyol, 3% oligoether polyol, 8% diethylene glycol, 10% complex vegetable ester, 2% silicone, 4% triphosphate Ethyl chloride and 1% flame retardant are mixed with 2‰ carbon fiber.

[0041] Mix the weighed components of material A and material B according to the equal volume of 1:1, and then stir in the container for 90-100 seconds through the stirring device, and quickly pour the uniformly stirred reinforcement material into the mold, and the material solidifies rapidly After the material in the mold is taken out, its compressive strength is measured to be 48.9Mpa, which is significantly higher than the national standard strength. Therefore, this experiment shows that the addition of carbon fiber will increase the overall co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com