Large space burning method of water coal slurry and its special device

A combustion method and technology of coal water slurry, which is applied in the direction of burners, lighting and heating equipment, and the combustion of block fuel and liquid fuel, etc., can solve the problem of high investment cost and operation cost of coal water slurry, ignition, and unstable combustion Power plants and other issues, to achieve the effect of enhancing wear resistance and robustness, reducing consumption, and reducing the generation of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The weight percent of the coal-water slurry that uses is made up as follows:

[0040] 69% dry coal powder, 30% water and 1% chemical additives.

[0041] The coal-water slurry enters the combustion chamber 6 from the atomizer at a flow rate of 400kg / h; the gas with an oxygen volume percentage content of 80% is a combustion aid, and the gas is 440m 3 The flow rate of / h enters the annular gas box 3 through the oxygen-enriched conduit 5, and most of the gas is sprayed into the combustion chamber 6 through the tangential tuyere 8 through the conduit. After ignition, the coal-water slurry burns violently in the combustion chamber, and the combustion temperature can reach above 2000°C.

Embodiment 2

[0043] The weight percent of the coal-water slurry that uses is made up as follows:

[0044]65% dry coal powder, 34% water and 1% chemical additives.

[0045] The coal-water slurry enters the combustion chamber 6 from the atomizer at a flow rate of 400kg / h; the gas with an oxygen volume percentage content of 90% is used as a combustion aid, and the 400m 3 The flow rate of / h enters the annular gas box 3 through the oxygen-enriched conduit 5, and most of the gas is sprayed into the combustion chamber 6 through the tangential tuyere 8 through the conduit. After ignition, the coal-water slurry burns violently in the combustion chamber, and the combustion temperature can reach above 1900°C.

Embodiment 3

[0047] This example further explains the device of the present invention.

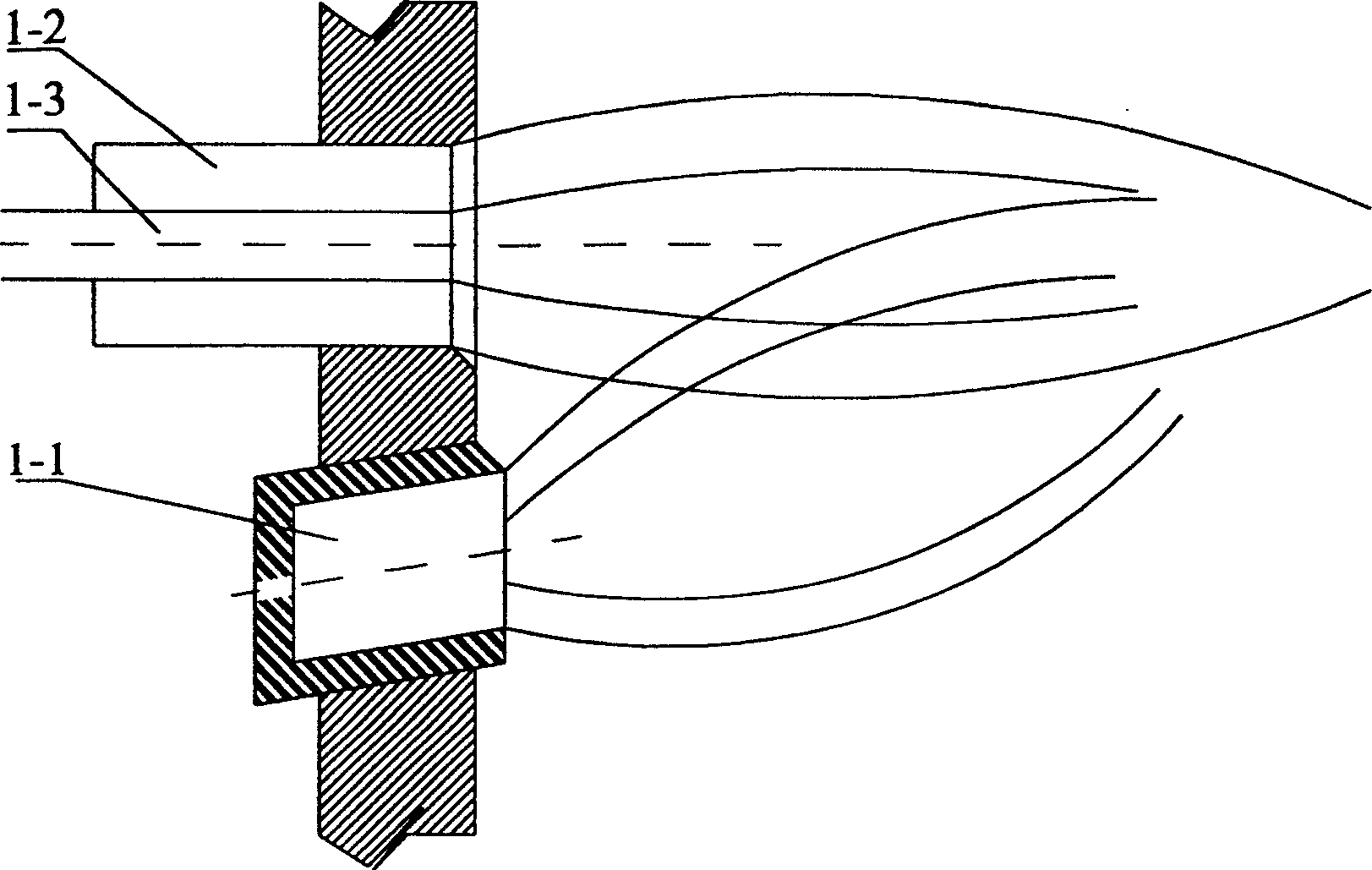

[0048] Such as figure 1 Shown, the large air combustion method of coal-water slurry of the present invention is used for power plant boiler ignition, uses special equipment 1-1 of the present invention to burn coal-water slurry, the flame of combustion is sprayed into boiler and ignites pulverized coal, pulverized coal and primary air 1- 3 is sent to the boiler, and the secondary air 1-2 is blown in at the same time, and the pulverized coal burns stably under the ignition of the coal-water slurry flame.

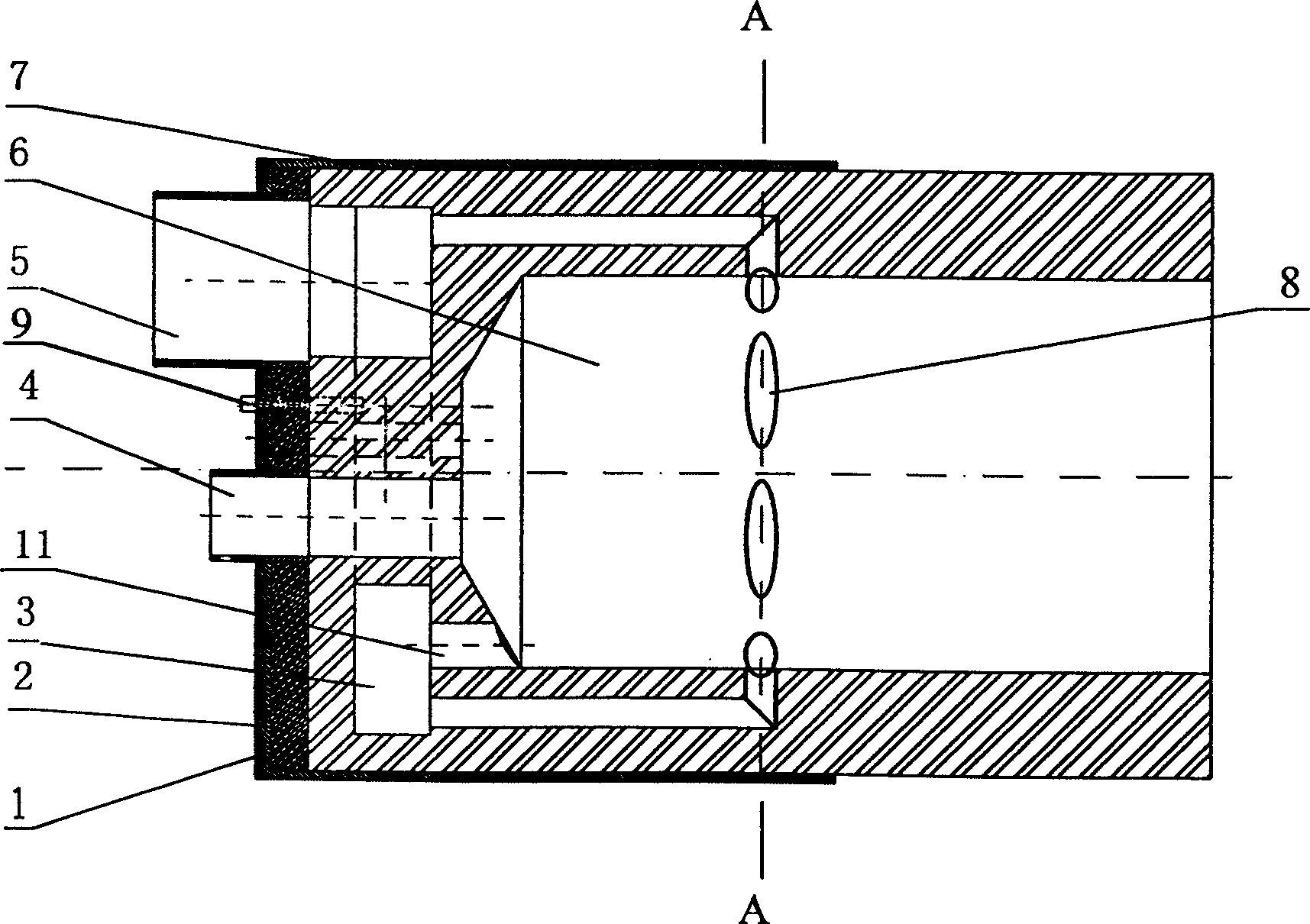

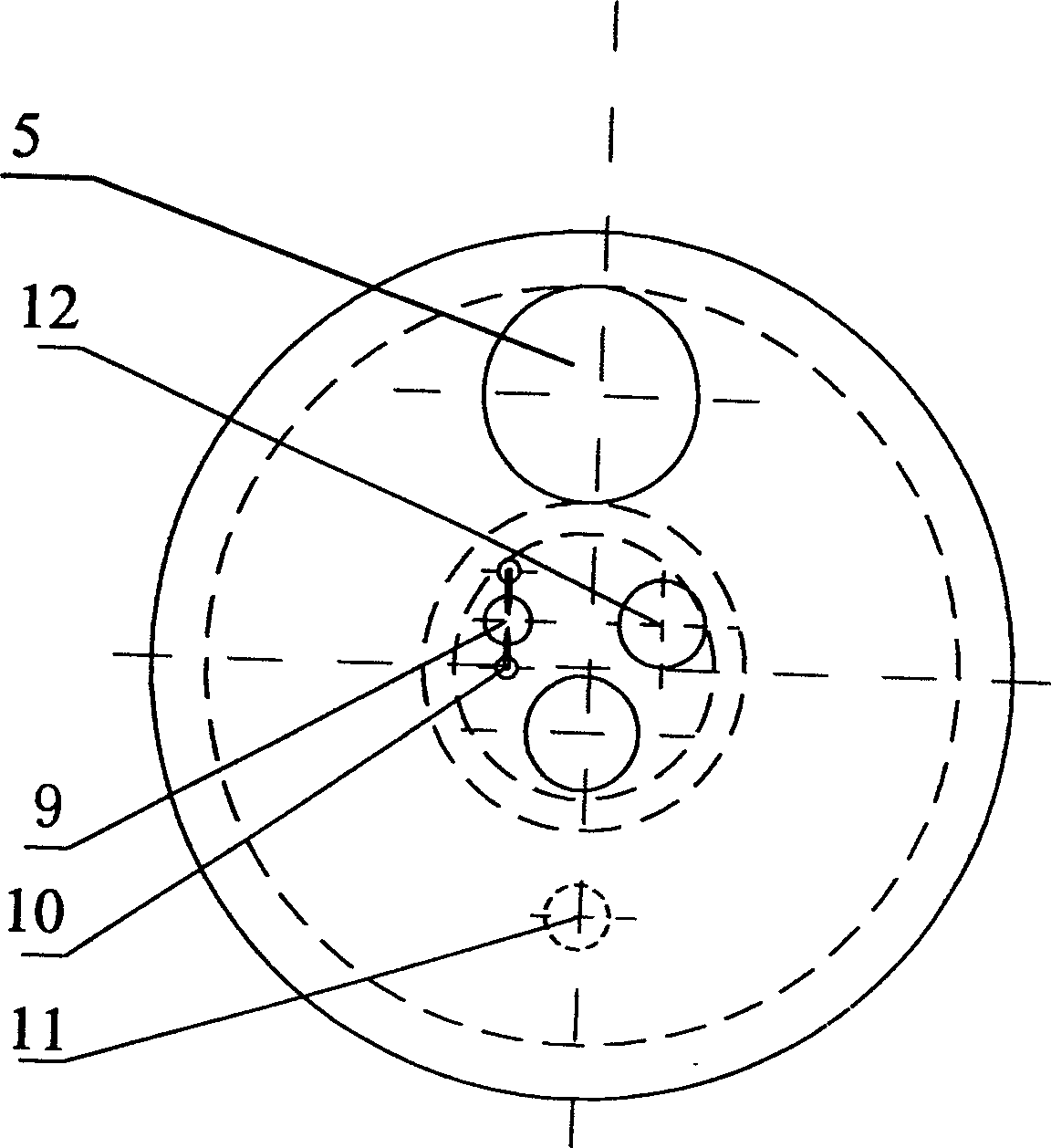

[0049] The device of the present invention such as figure 2 , 3 and 4. exist figure 2 Among them, the equipment includes a combustion chamber 6, an oxygen-rich conduit 5 located on the front wall of the combustion chamber 6, an annular gas box 3, an atomizer socket 4, a slag blowing hole 11, an ignition gas hole 9 and an ignition electrode 10, located in the combustion chamber 6, the tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com