Oil cooling system for high-temperature equipment

A technology of oil cooling system and high-temperature equipment, which is applied in the field of cooling systems, can solve the problems that corrosion, explosion or other accidents, and corrosion of equipment materials cannot be completely eliminated, so as to omit water treatment systems and equipment, reduce complexity, and improve cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

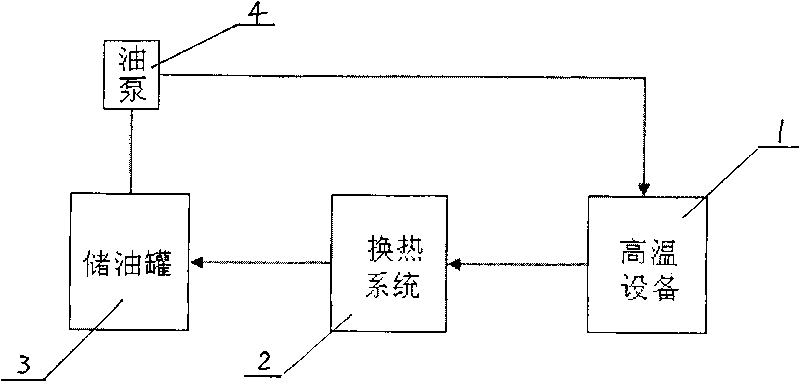

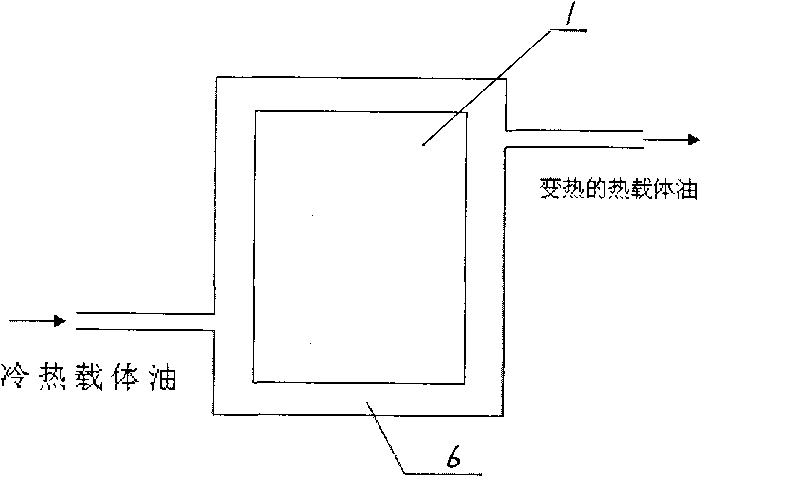

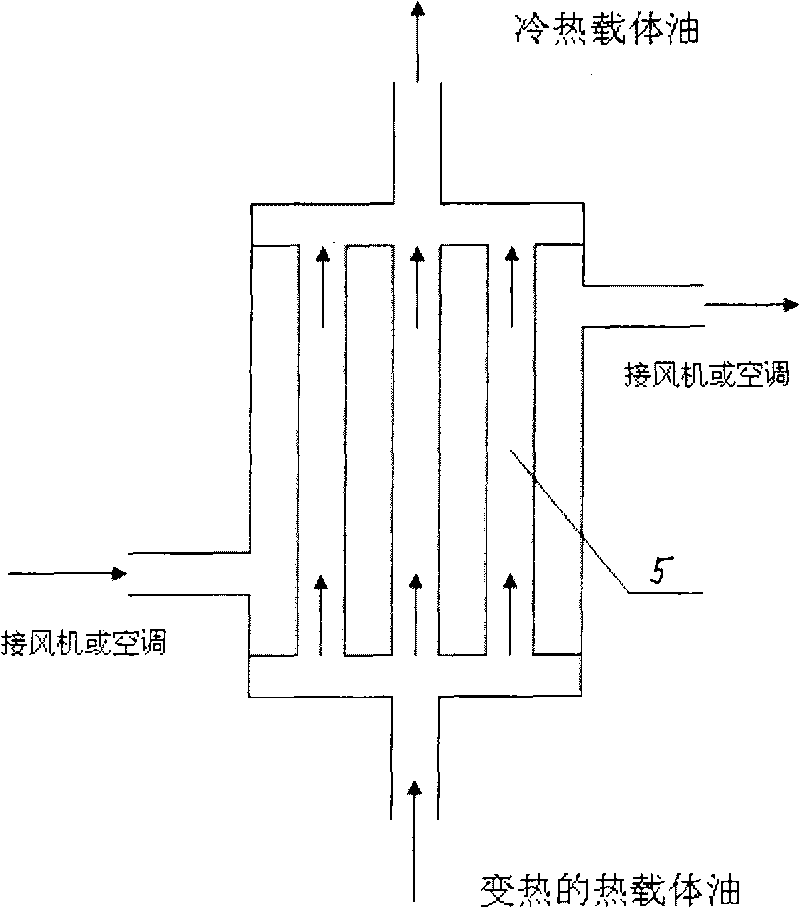

[0023] Such as figure 1 As shown, the heat carrier oil cooling system includes: an oil storage tank 3, an oil pump 4, a heat exchange system 2, a pipeline system and a measurement control system, which are connected to the high temperature equipment 1 through the pipeline system. A certain volume of heat carrier oil is stored in the oil storage tank 3 as a cooling medium. The heat carrier oil in the storage tank 3 is transported to the high-temperature equipment 1 through the oil pump 4, and the excess heat generated in the high-temperature equipment 1 is taken away. Set up two oil pumps, once one of the oil pumps fails, the other will start running immediately. The heat carrier oil flowing out from the cooling system of the high-temperature equipment enters the heat exchange system 2. The heat exchange system 2 consists of two parts, one is a heat exchanger and the other is a cooler. The heat exchanger adopts stainless steel tube heat exchanger. The cooler uses a centrifug...

Embodiment 2

[0028] Others are the same as in Embodiment 1, except that the heat exchanger adopts a copper tube heat exchanger. The cooler uses industrial air-conditioning, and the air-conditioning refrigeration takes away the heat of the hot oil in the tubes to cool down the hot oil. The conveying pipeline is a plastic oil pipe widely used in industry.

[0029] The high-temperature equipment is a resistance heating furnace with a power of 15kw. It is required that the temperature of the outer surface of the furnace wall is not higher than 30°C when working, and the heat that needs to be taken away from the furnace wall when maintaining the temperature of the outer surface of the induction heating furnace wall is not higher than 30°C is 1.5kw, and the flow rate of heat carrier oil is 35L / min. The heat exchange system is an industrial air conditioner with a power of 2kw. It runs for 24 hours after starting up. The average surface temperature of the induction heating furnace is measured at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com