Methanol hydrogen oxidation heating system

A technology for producing hydrogen from methanol and oxidizing methanol, which is used in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of polluting products, easy generation of formaldehyde, etc., and achieve convenient transportation, storage and transportation, and thermal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

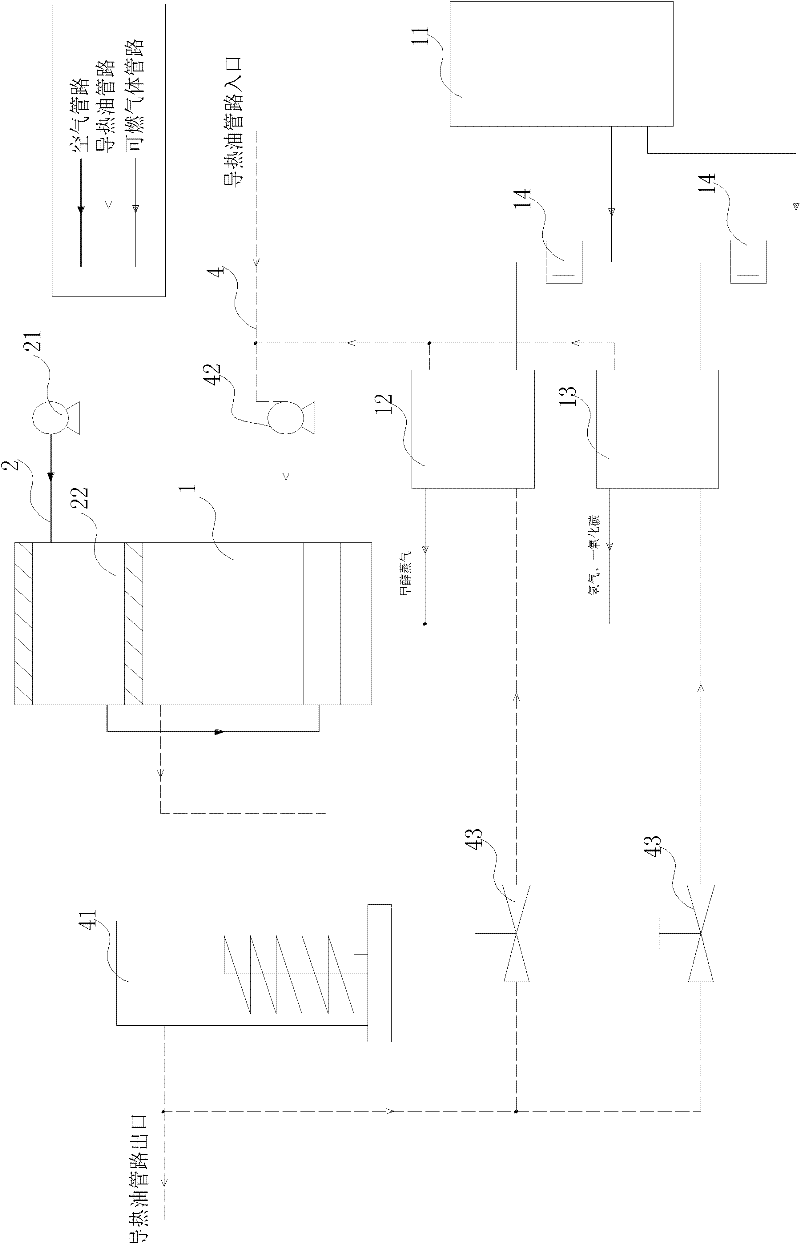

[0041] Example 1 Methanol Hydrogen Oxidation Heat Supply System Using Methanol Cracker

[0042] Such as figure 1 As shown, the methanol-to-hydrogen oxidation heating system includes a methanol oxidation heater 1 for methanol catalytic oxidation reaction, a methanol storage tank 11, a methanol evaporator 12, a methanol cracker, and supply of outside air to the methanol oxidation heater 1 The air pipeline 2, the combustible gas pipeline 3 that supplies the methanol vapor produced by the methanol evaporator and the hydrogen gas produced by the methanol cracker to the methanol oxidation heater 1, and the combustible gas pipeline 3 is provided outside the methanol oxidation heater 1 There is a heat-conducting oil pipeline 4, and a heat-conducting oil heating device 41 is installed on the heat-conducting oil pipeline 4. After being heated by the heat-conducting oil heating device 41, the heat-conducting oil is connected to the methanol oxidation heater 1 by the heat-conducting oil p...

Embodiment 2

[0049] Example 2 Methanol Hydrogen Oxidation Heat Supply System Using Methanol Reforming Hydrogen Plant

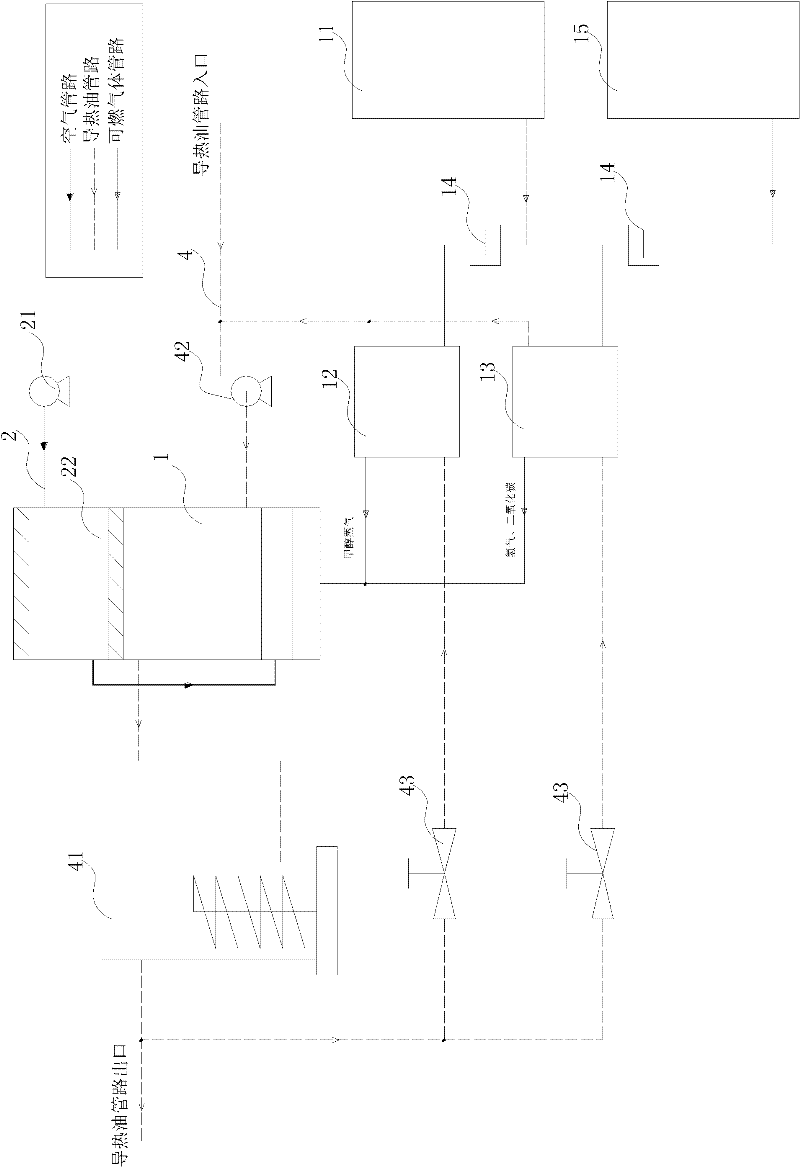

[0050] Such as figure 2 As shown, the methanol-to-hydrogen oxidation heating system includes a methanol oxidation heater 1 for methanol catalytic oxidation reaction, a methanol storage tank 11, a methanol evaporator 12, a methanol reforming hydrogen generator, and a methanol oxidation heater 1 Air pipeline 2 for supplying outside air, and combustible gas pipeline 3 for supplying combustible gas mixed with methanol vapor generated by methanol evaporator, hydrogen and carbon dioxide gas generated by methanol reforming hydrogen generator to methanol oxidation heater 1, said A heat-conducting oil pipeline 4 is provided outside the methanol oxidation heater 1, and a heat-conducting oil heating device 41 is arranged on the heat-conducting oil pipeline 4. After being heated by the heat-conducting oil heating device 41, the heat-conducting oil is connected to the methanol oxidati...

Embodiment 3

[0055] Example 3 Methanol Hydrogen Oxidation Heat Supply System Using Methanol Reforming Hydrogen Plant

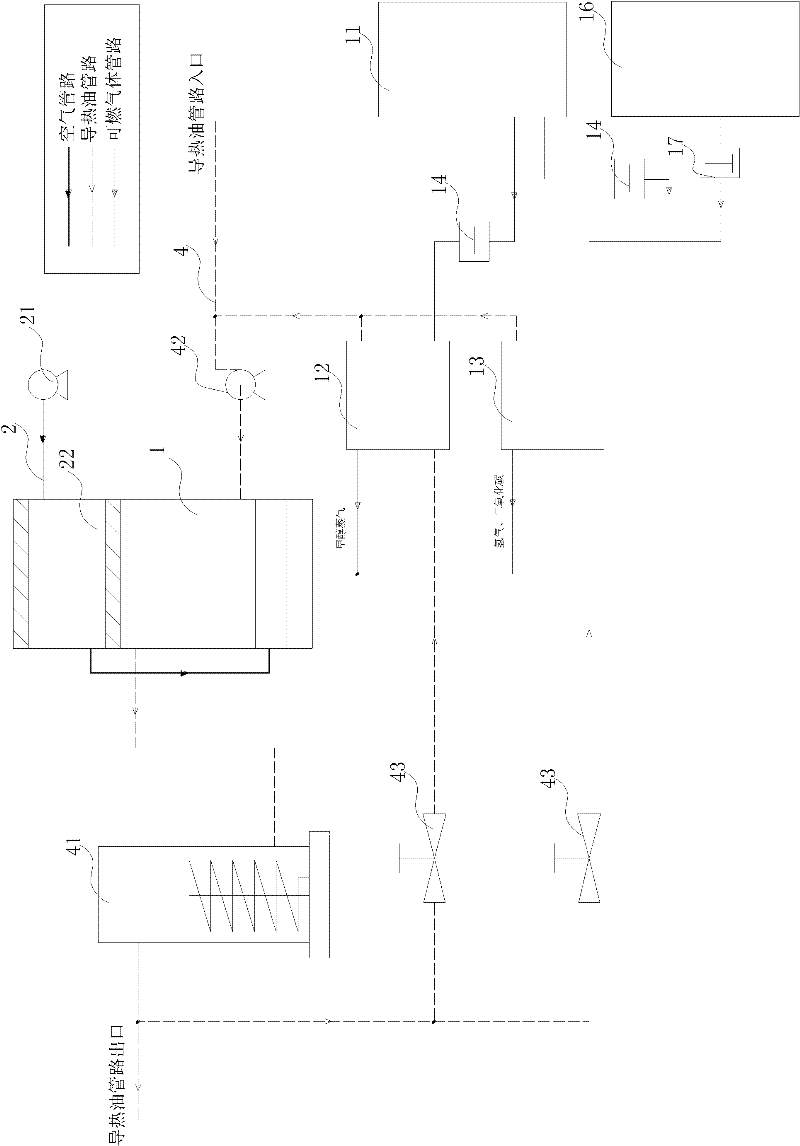

[0056] Such as image 3 As shown, the methanol-to-hydrogen oxidation heating system includes a methanol oxidation heater 1 for methanol catalytic oxidation reaction, a methanol storage tank 11, a methanol evaporator 12, a methanol reforming hydrogen generator, and a methanol oxidation heater 1 Air pipeline 2 for supplying outside air, and combustible gas pipeline 3 for supplying combustible gas mixed with methanol vapor generated by methanol evaporator, hydrogen and carbon dioxide gas generated by methanol reforming hydrogen generator to methanol oxidation heater 1, said A heat-conducting oil pipeline 4 is provided outside the methanol oxidation heater 1, and a heat-conducting oil heating device 41 is arranged on the heat-conducting oil pipeline 4. After being heated by the heat-conducting oil heating device 41, the heat-conducting oil is connected to the methanol oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com