Pyridaben water dispersible granule and preparation method thereof

A technology for dispersing granules and pyridaben, applied in the field of pesticides, can solve the problems of harming human health, environmental pollution, and high use costs, and achieve the effects of less environmental pollution, reducing environmental pollution, and saving packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 80% pyridaben water-dispersible granules.

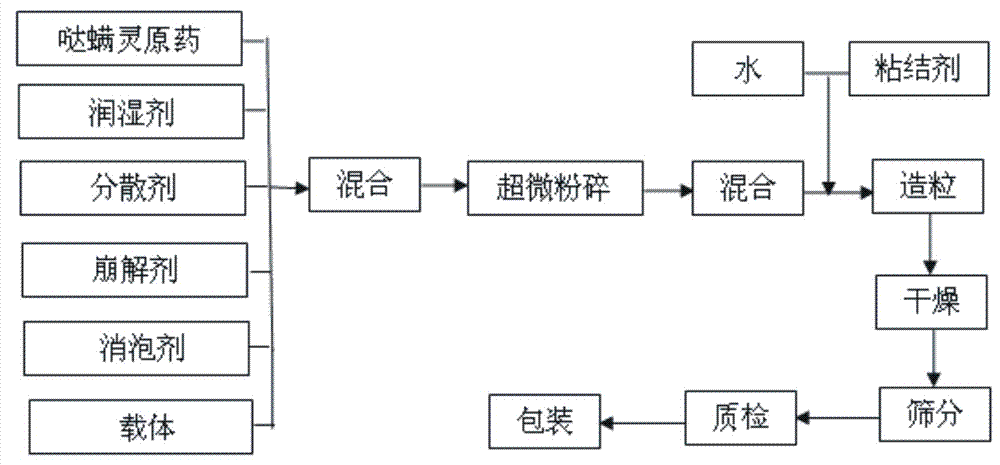

[0034] Weigh 80% of pyridaben powder, wetting agent sodium lauryl sulfate 4%, dispersant naphthalene sulfonate formaldehyde condensate 2%, lignosulfonate calcium salt 3%, disintegrant sodium sulfate 5% , defoamer isooctyl alcohol 0.5%, binder sucrose 0.5%, carrier kaolin to 100%; mix pyridaben and other additives except binder in a gravity-free mixer for 20 minutes according to the formula ratio , and then put the mixture into the twin-screw mixer (I), and pulverize it through the airflow mill while mixing to reach a particle size of more than 1000 mesh, collect it through the cyclone separator and bag filter, and finally put it in the double-helix mixer (II) Mix again for 30 minutes to obtain a uniform mother powder. Then accurately weigh the quantitative mother powder in the cyclone fluidized bed granulator, spray the binder aqueous solution according to the formula, and finally dry to obtain irregular granul...

Embodiment 2

[0035] Example 2: 50% pyridaben water-dispersible granules.

[0036] Weigh 50% of pyridaben powder, wetting agent sodium lauryl sulfate 4%, dispersant polycarboxylate 3%, sodium lignosulfonate 4%, disintegrant urea 25%, binder sucrose 0.5%, antifoaming agent organic silicone 0.3%, carrier diatomaceous earth to 100%, mix pyridaben and other additives except binder in a gravity-free mixer for 20 minutes according to the formula ratio, and then mix The mixture is put into the twin-screw mixer (Ⅰ), crushed by the airflow mill while mixing to reach a particle size of more than 1000 mesh, collected by the cyclone separator and bag filter, and finally mixed again in the double-screw mixer (II) 30 minutes to get a uniform mother powder. Then accurately weigh the quantitative mother powder in the cyclone fluidized bed granulator, spray the binder aqueous solution according to the formula, and finally dry to obtain irregular granular water-dispersible granules, and then sieve to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com