Technique for purifying and recovering argon gas by rare earth lanthanide series radical alloy degasser in single-crystal silicon preparation

A rare earth lanthanum and getter technology, applied in non-metallic elements, inert gas compounds, inorganic chemistry, etc., can solve the problems of complex process flow, high impurity content, high labor intensity of workers, etc., and achieve cost reduction and high absorption. In addition to efficiency, the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

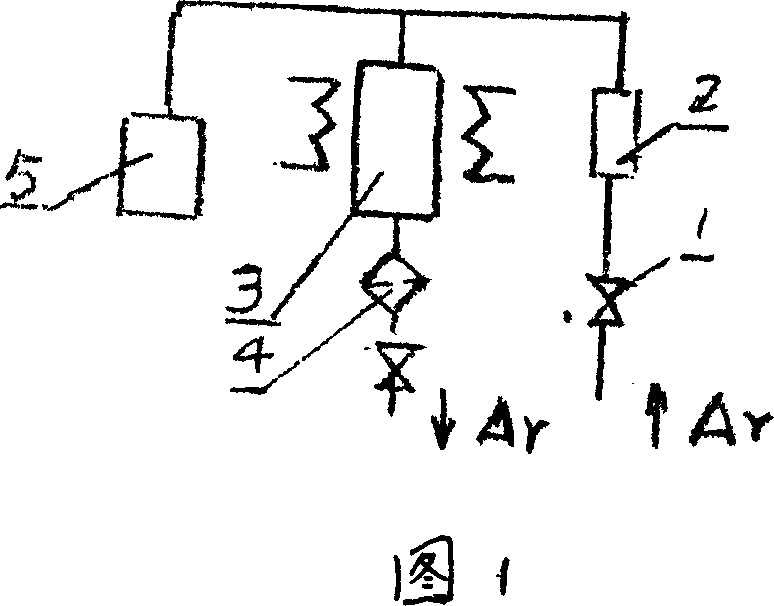

[0032] Combined with the process flow diagram 1: the non-high-purity argon gas entering the single crystal furnace is purified by the purification device (3) equipped with the above-mentioned getter to prepare high-purity argon (purity 99.999-99,9999%), and then micro The dust filter (4) removes dust (at this time, the dust content is no more than 3.5 pieces of 0.3 micron dust per liter) and then enters the single crystal furnace. The vacuum pump (5) is used to activate, ventilate and check for leaks of the CF01 agent, so as to ensure that the argon gas entering the single crystal furnace is high-purity and stable and has high economic benefits, and the process is simple and flexible.

[0033] During the preparation of single crystal silicon, volatiles are continuously produced in the single crystal furnace, and the volatiles must be taken out of the single crystal furnace by argon. Contaminated argon is discharged from the exhaust port of the single crystal furnace. For the ...

Embodiment 2

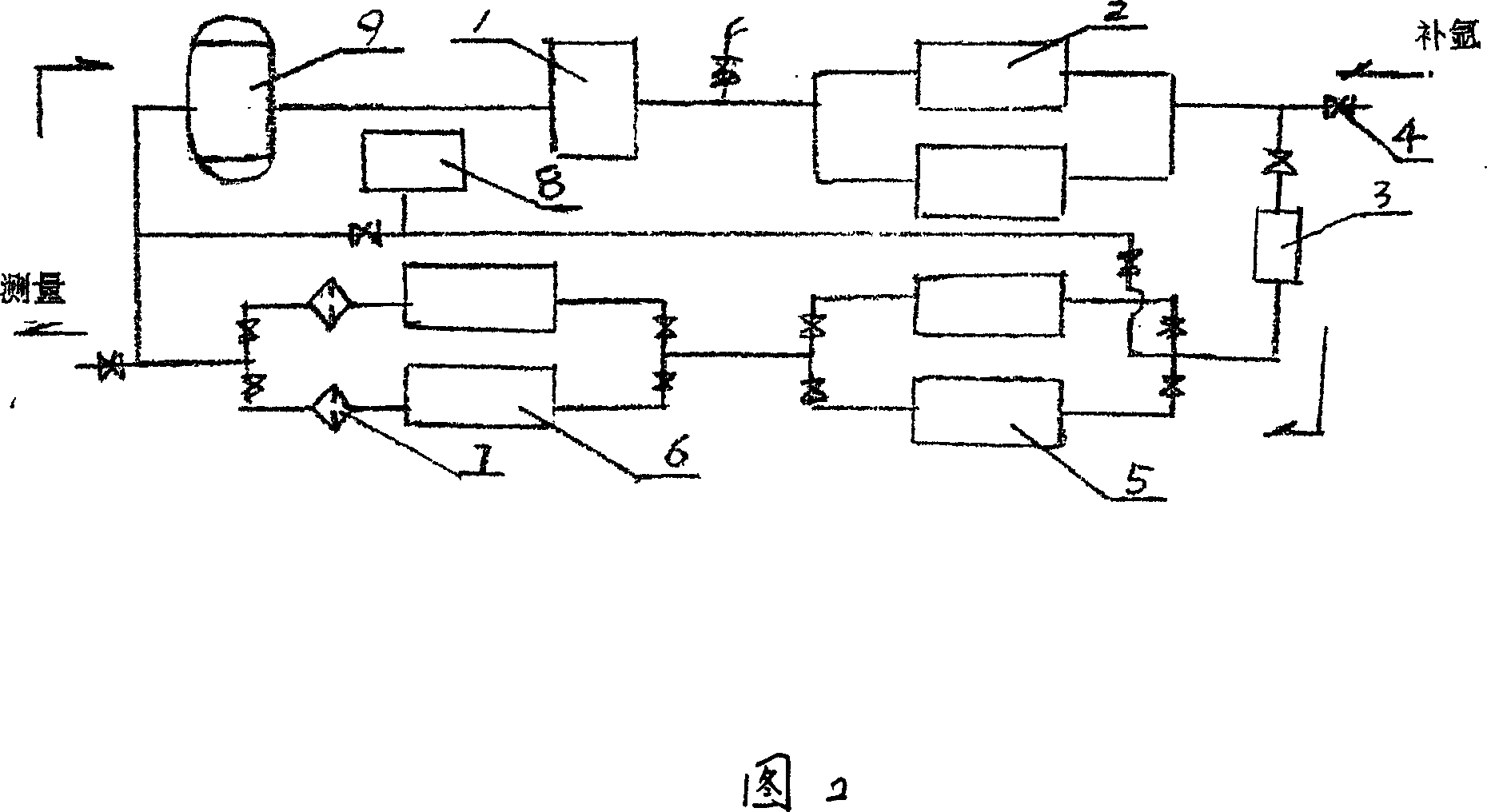

[0035] The method of using rare earth lanthanide-based alloy getters to purify and recycle argon gas in zone-melting single silicon crystals is shown in Figure 2 in conjunction with the process flow. Since there are very few volatile substances in the zone-melting single crystal furnace, the argon gas in the furnace is very low. The purity is relatively high, and the zone melting process is an atmospheric argon flow process, there is no large amount of oil mist generated by the vacuum pump to pump the single crystal furnace, so there is no need for degreasing treatment. The argon gas discharged from the single crystal furnace (1) is compressed by a membrane oil-free compressor (2) into a dryer (5) equipped with 4A molecular sieves for deep water removal. The other set is used to regenerate the 4A molecular sieve to ensure continuous operation. The regeneration process is as follows: After absorbing water at room temperature, the 4A molecular sieve has a strong water absorption...

Embodiment 3

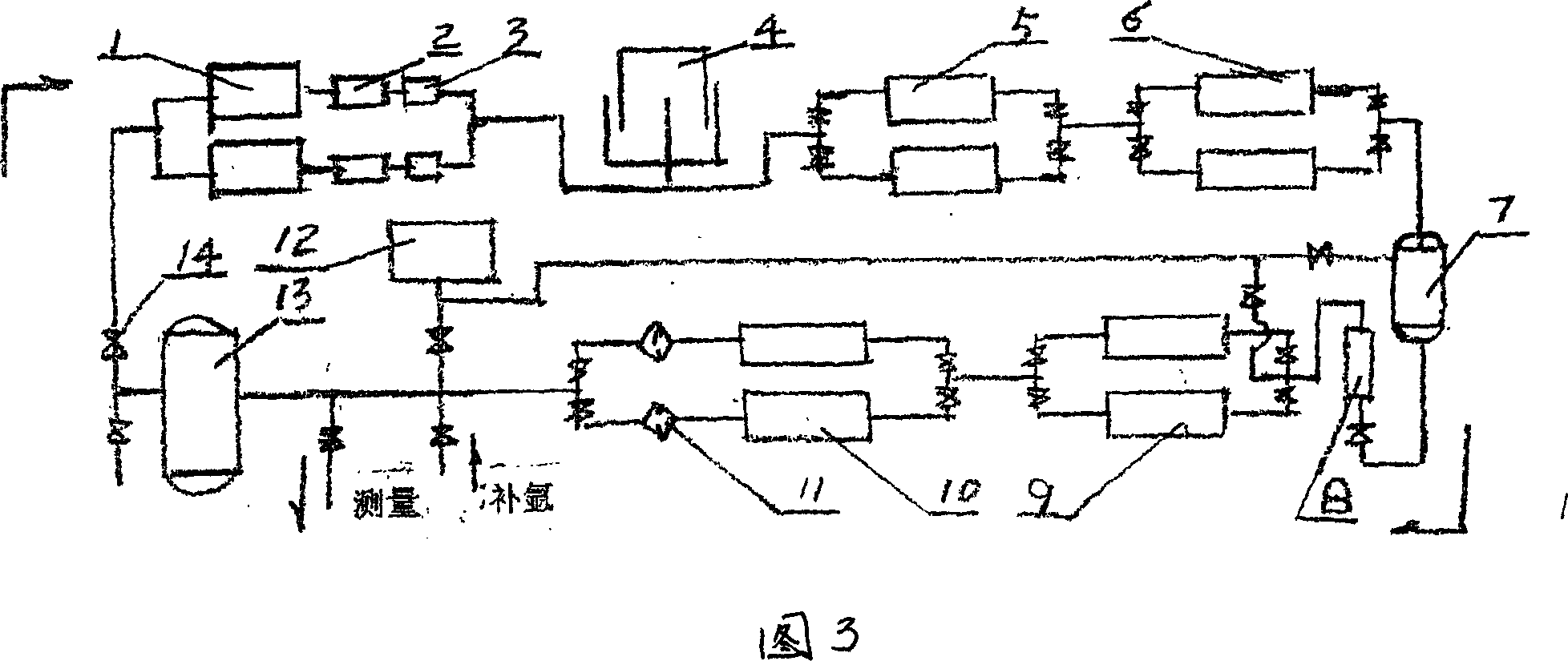

[0037] The method of using rare earth lanthanide-based alloy getters to purify and recycle argon gas in Czochralski single crystal silicon. The combined process flow is shown in Figure 3. Almost all Czochralski single crystal silicon adopts a negative pressure process. The single crystal furnace (1) system The argon gas discharged from the medium vacuum pump (2) contains a large amount of oil mist. After removing most of the oil mist through the small oil-gas separator (3), it enters the gas cabinet (4) sealed with low-volatile special oil. The function of the gas cabinet is Store argon and ensure that the outlet of the vacuum pump is at normal pressure. The oil-free film compressor (5) injects the argon gas in the gas tank into the medium-pressure tank (7), and the pressure of the argon gas has risen to 0.2-0.3 MPa at this time, so as to ensure that the argon gas can pass through the purification system at all levels. After passing through the dry oil absorber (9) and the CF0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com