Polymer composite material for laptop computer outer shell and preparation method of polymer composite material

A notebook computer and composite material technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as insufficient hardness and poor thermal conductivity, improve hardness and scratch resistance, repair lattice defects, improve Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

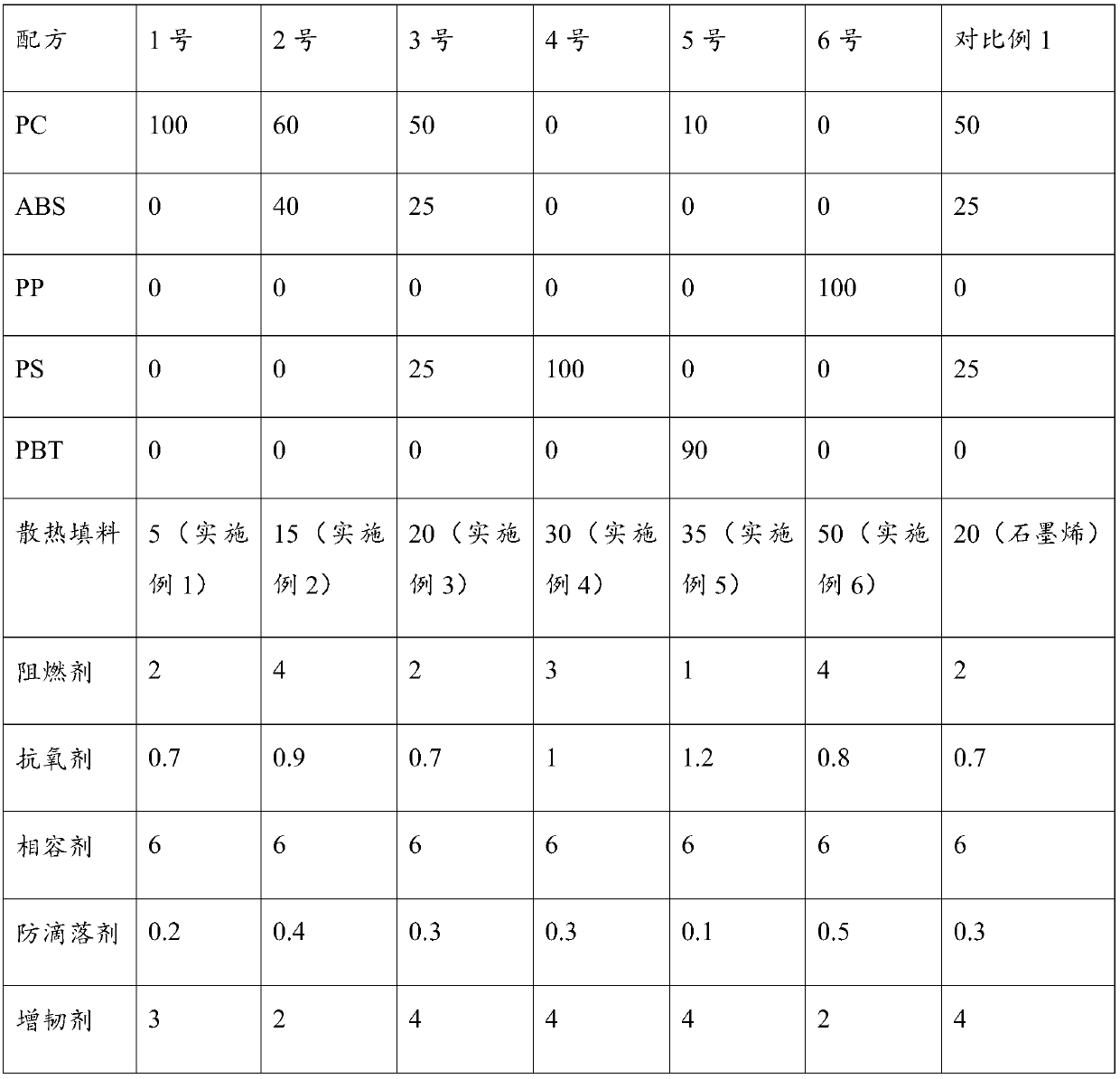

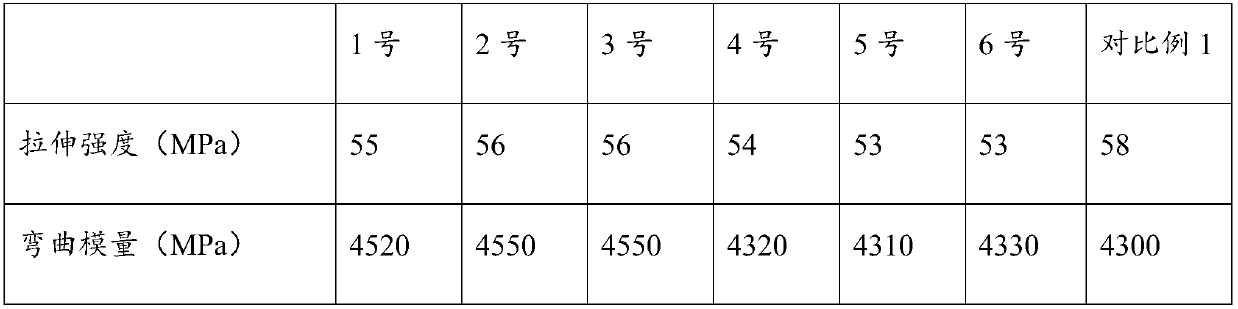

Embodiment 1

[0025] The preparation of embodiment 1 heat-dissipating filler

[0026] (3.1) Weigh 0.1 parts by weight of graphene and add it to the CMC dispersion, fully stir at 300r / min for 10 minutes until completely soaked to obtain the mixed solution A, and ultrasonicate for 1 hour;

[0027] (3.2) Weigh 1 part by weight of nano-alumina powder, grind it through a 100-mesh sieve, add it to the mixed solution A, stir at 300 r / min for 1 min, and obtain the mixed solution B;

[0028] (3.3) Weigh 0.5 parts by weight of carbon nanotubes and add them to the mixed solution B, first stir at 300r / min for 30min, then circulate and grind for 2 hours through a horizontal sand mill to obtain the mixed solution C, and filter the mixed solution C , crushing and drying to obtain graphene / nano powder composite;

[0029] (3.4) Put the graphene / nano-powder composite into a high-temperature device with an inert gas protection atmosphere, and treat it at 200°C for 0.5 hours to obtain a graphene / nano-powder c...

Embodiment 2

[0031] The preparation of embodiment 2 heat-dissipating fillers

[0032] (3.1) Weigh 10 parts by weight of graphene oxide and add it to the BYK-163 dispersion, and stir it at 800r / min for 60 minutes until it is completely soaked to obtain the mixed solution A, and ultrasonicate for 12 hours;

[0033](3.2) Weigh 30 parts by weight of nano-boron nitride and nano-calcium carbonate powder, grind through a 100-mesh sieve, add to mixed solution A, and stir at 800r / min for 120min to obtain mixed solution B;

[0034] (3.3) Weigh 30 parts by weight of carbon nanotubes and add them to the mixed solution B, first stir at 800r / min for 120min, then circulate and grind for 2 hours through a horizontal sand mill to obtain the mixed solution C, and filter the mixed solution C , crushing and drying to obtain graphene / nano powder composite;

[0035] (3.4) Put the graphene / nano-powder composite into a high-temperature device with an inert gas protection atmosphere, and treat it at 1500°C for 12...

Embodiment 3

[0037] The preparation of embodiment 3 heat-dissipating fillers

[0038] (3.1) Weigh 5 parts by weight of graphene and add it to the SDS dispersion liquid, fully stir at 550r / min for 30min until fully soaked to obtain the mixed solution A, and ultrasonicate for 6 hours;

[0039] (3.2) Weigh 15 parts by weight of nano-calcium carbonate powder, grind through a 100-mesh sieve and add to mixed solution A, stir at 600r / min for 60min to obtain mixed solution B;

[0040] (3.3) Weigh 15 parts by weight of carbon nanotubes and add them to the mixed solution B, first stir at 600r / min for 80min, then circulate and grind for 2 hours through a horizontal sand mill to obtain the mixed solution C, and filter the mixed solution C , crushing and drying to obtain graphene / nano powder composite;

[0041] (3.4) Put the graphene / nano-powder composite into a high-temperature device with an inert gas protection atmosphere, and treat it at 600°C for 6 hours to obtain a graphene / nano-powder composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com