Printing color management (PCM) composite steel plate

A technology of composite steel plate and steel plate, applied in the direction of decorative art, special decorative structure, etc., can solve the problem of single product, achieve the effect of good gloss, convenient operation, and good scratch resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

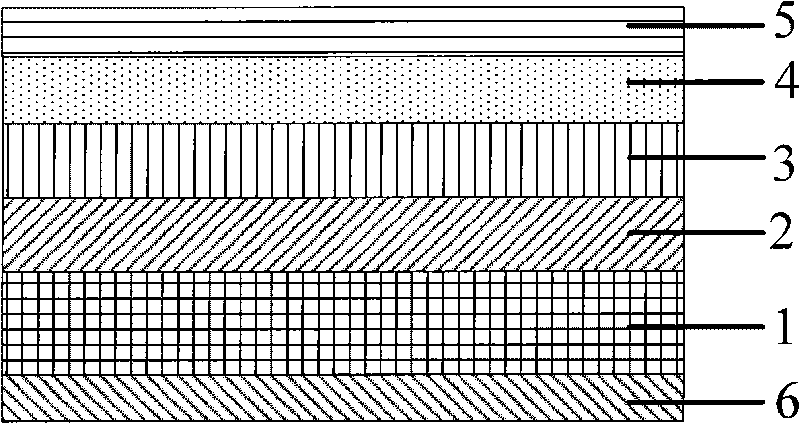

[0017] Such as figure 1 As shown, the PCM composite steel plate is printed, the base material is a steel plate, a primer layer 2 is coated on the front of the steel plate 1, a top coat layer 3 is rolled on the primer layer 2, and a pattern printing layer is rolled on the top coat layer 3 4. A finish paint layer 5 is rolled on the pattern printing layer 4 , and a back paint layer 6 is provided on the back of the steel plate 1 .

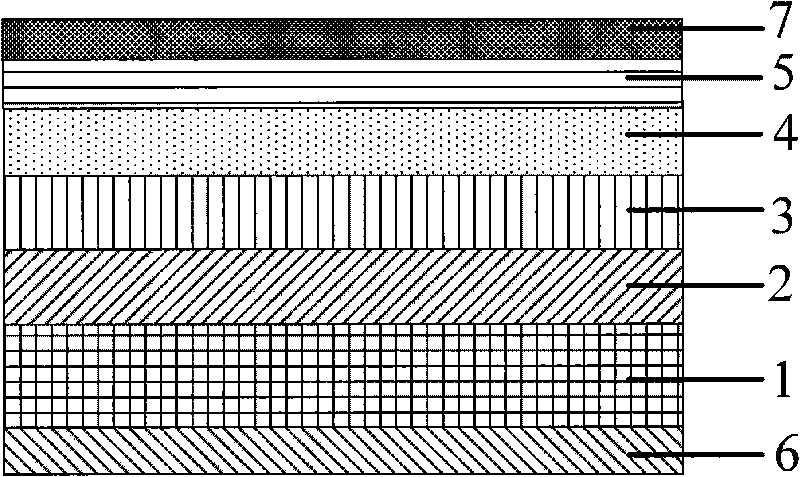

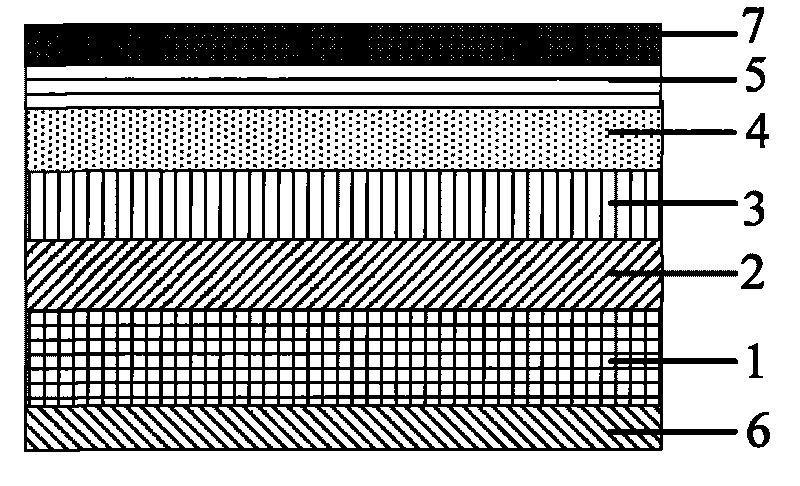

[0018] Such as figure 2 , on the basis of the above structure, a protective film layer 7 is also covered and bonded on the finish paint layer 5 .

[0019] Using cold-rolled steel plate as the substrate, the adhesion between the paint and the steel plate is enhanced by applying primer; the primer is coated with a top coat, and the top paint layer 3 is coated with a pattern printing layer 4, and the pattern printing layer 4 realizes various colors and patterns The visual effect plays a decorative and aesthetic role; in addition, the surface of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com