Low-odor scratch-resistant high-rigidity polypropylene composition and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of polymer material processing, can solve the problems of high scratch resistance, high price, and poor comprehensive mechanical properties of automobile dashboards, and achieve excellent surface scratch resistance and low price. Low, good impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

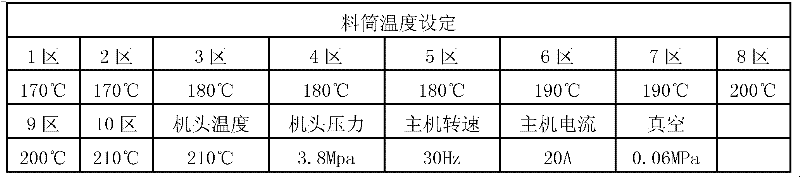

[0035] Table 1

[0036] raw material

parts by mass

PP

80

20

[0037] Nano anti-scratch agent

0.1

Antioxidant 1010

1

Antioxidant 168

1

PTFE

2

1

[0038] In this case, the nano-scratch-resistant agent was compounded as nano-alumina: nano-silicon oxide: nano-zinc oxide = 50:30:20;

[0039] After weighing the materials according to the ratio in Table 1, follow the steps below to make the materials

[0040] (1) Add talcum powder and stir and mix for 4 minutes at a speed of 480 rpm;

[0041] (2) Add the nano anti-scratch agent and stir and mix for 9 minutes at a speed of 450 rpm;

[0042] (3) Stir and mix the polypropylene material with lubricant and antioxidant at a speed of 500 rpm for 5 minutes;

[0043] (4) Stir and mix for 10 minutes at a rotating speed of 1800 rpm;

[0044] (5). Stir for 10 minutes at a rotating speed of 350...

Embodiment 2

[0053] Table 4

[0054] raw material

[0055] In this case, the nano-scratch-resistant agent is compounded as nano-alumina: nano-silicon oxide: nano-zinc oxide = 40:40:20;

[0056] After weighing the materials according to the ratio in Table 4, follow the steps below to make the materials

[0057] (1) Add talcum powder and stir and mix for 4 minutes at a speed of 480 rpm;

[0058] (2) Add the nano anti-scratch agent and stir and mix for 9 minutes at a speed of 450 rpm;

[0059] (3) Stir and mix the polypropylene material with lubricant and antioxidant at a speed of 500 rpm for 5 minutes;

[0060] (4) Stir and mix for 10 minutes at a rotating speed of 1800 rpm;

[0061] (5) Stir for 10 minutes at a rotating speed of 350 rpm to obtain the initial mixture;

[0062] (6) Extruding and granulating the primary mixture through an extruder to obtain the final product.

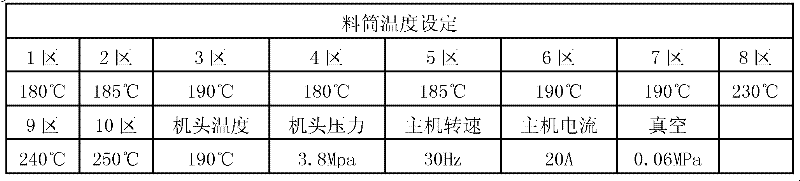

[0063] Concrete process conditions are as shown in table 5:

[0064] table 5

[0065]

[0066] Th...

Embodiment 3

[0071] Table 7

[0072] raw material

parts by mass

PP

70

Talc powder

20

Nano anti-scratch agent

10

Antioxidant 1010

1

Antioxidant 168

1

PTFE

2

2

[0073] In this case, the nano-scratch-resistant agent is compounded as nano-alumina: nano-silicon oxide: nano-zinc oxide = 25:70:5;

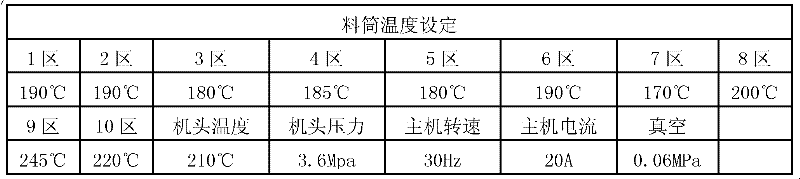

[0074] After weighing the above-mentioned materials according to the ratio in Table 7, make the materials according to the following steps

[0075] (1) Add talcum powder and stir and mix for 4 minutes at a speed of 480 rpm;

[0076] (2) Add the nano anti-scratch agent and stir and mix for 9 minutes at a speed of 450 rpm;

[0077] (3) Stir and mix the polypropylene material with lubricant and antioxidant at a speed of 500 rpm for 5 minutes;

[0078] (4) Stir and mix for 10 minutes at a rotating speed of 1800 rpm;

[0079] (5) Stir for 10 minutes at a rotating speed of 350 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com