Release film for leather and preparation method thereof

A release film and leather technology, applied in the field of release film for leather and its preparation, can solve the problems of complex hierarchical structure of the release paper, affecting the smoothness of the texture, complicated production process, etc. Good, good surface scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

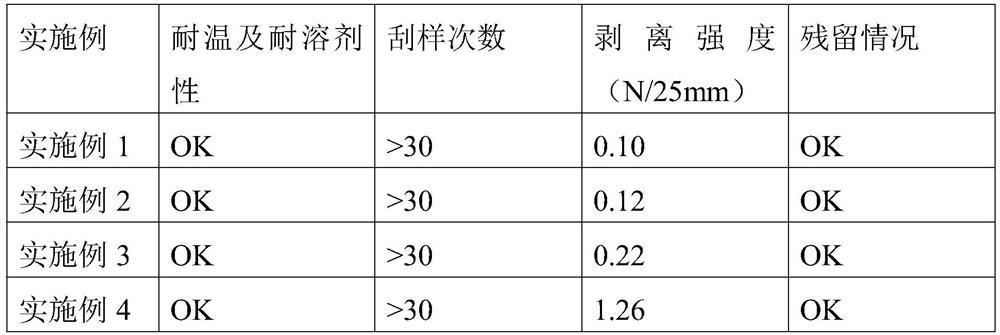

Examples

preparation example Construction

[0028] A kind of preparation method of release film for leather provided by the invention, its preparation method comprises the following steps:

[0029] Step 1, prepare pre-coat paint;

[0030] Step 2, preparing a release layer coating;

[0031] Step 3, utilizing corona treatment to prepare the base material;

[0032] Step 4, coating the pre-coating paint on the base material, forming a pre-coating layer after curing, and obtaining a pre-coating base material;

[0033] In step 5, the release layer coating is embossed and cured on the pre-coated substrate to form a release layer by means of slit coating with the aid of electron beams, and the release film for leather is obtained.

[0034] It should be noted that the steps 1 to 3 do not have a strict preparation sequence, and the preparation sequence of the release layer material, precoat material and substrate can be set according to actual production needs.

[0035] Preferably, in the step 1, the pre-coat paint consists of...

Embodiment 1

[0058] Embodiment 1: a kind of release film for leather provided in this embodiment and preparation method thereof, its preparation method comprises the following steps:

[0059] Step 1, prepare the pre-coat paint: 45 parts of deionized water, 30 parts of water-based acrylic emulsion, 2 parts of surfactant, and 2 parts of defoamer are put into the container in order to mix and stir to obtain a uniform pre-coat coating;

[0060] Step 2, prepare the release layer coating: by weight, 30 parts of urethane acrylate, 70 parts of modified epoxy acrylate, 10 parts of tripropylene glycol diacrylate, 10 parts of ethoxylated Trimethylolpropane triacrylate, 2 parts perfluoromethacrylate, 2 parts γ-methacryloxypropyl trimethylsilane, 1 part light curing silicone release agent, 5 parts lightweight Calcium carbonate is put into the container successively and mixes, stirs, to impel the solid component to fully dissolve, obtains the uniform described release layer coating, and adopts vacuum p...

Embodiment 2

[0064] Embodiment 2: A kind of release film for leather provided in this embodiment and its preparation method, its preparation method comprises the following steps:

[0065] Step 1, prepare the pre-coat paint: 50 parts of deionized water, 35 parts of water-based acrylic emulsion, 2 parts of surfactant, and 2 parts of defoamer are put into the container in order to mix and stir to obtain a uniform pre-coat coating;

[0066] Step 2, prepare the release layer coating: by weight, 50 parts of urethane acrylate, 50 parts of modified epoxy acrylate, 10 parts of tripropylene glycol diacrylate, 10 parts of ethoxylated Trimethylolpropane triacrylate, 2 parts perfluoromethacrylate, 2 parts gamma-methacryloxypropyltrimethylsilane, 3 parts photocurable silicone release agent, 5 parts lightweight Calcium carbonate is put into the container successively and mixes, stirs, to impel the solid component to fully dissolve, obtains the uniform described release layer coating, and adopts vacuum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com