Degradable and anti-scratching microporous ink-jet printing photo paper and preparation method thereof

An inkjet printing and anti-scratch technology, which is applied in the direction of copying/marking methods, printing, coating, etc., can solve the problems of RC paper that is difficult to degrade and the environment of RC paper is damaged, so as to improve the fastness of the coating and improve the Coating water retention capacity, good rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the degradable and scratch-resistant microporous inkjet photo paper of the present invention specifically comprises the following steps:

[0035] (1) Preparation of degradable RC photo paper base paper

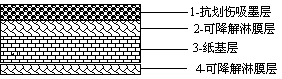

[0036] The base paper base (3) is made of base paper made of all wood pulp or mixed wood pulp, and then double-sided coated with degradable coated layers (2) and (4), the gloss is higher than 50% (60° , GB / 8941-2007).

[0037] (2) Preparation of anti-scratch ink-absorbing layer coating

[0038] Preparation of the dispersion: slowly add 100 parts of nano-alumina, 5-10 parts of nano-cellulose, 0.5-1 part of pH regulator and 0.5-1 part of silane coupling agent to the In deionized water, then increase the stirring speed to 2000-2300 r / min, and spread at high speed for 30-45 minutes to obtain a dispersion with a solid content of 20-25%;

[0039] Aging of the dispersion: put the above-prepared dispersion in a water bath at 60±5°C for more than 12 ...

Embodiment 1

[0046] Preparation of degradable RC photo paper base paper, the paper base (3) is made of base paper base paper made of whole wood pulp or mixed wood pulp, and then double-sided coated with degradable coated layers (2), (4), The gloss is higher than 50% (60°, GB / 8941-2007);

[0047] The degradable coating layers (2), (4) are polylactic acid films;

[0048]The anti-scratch ink-absorbing layer (1) includes the following components in parts by weight: 100 parts of nano-alumina, 10 parts of adhesive, 5 parts of nano-cellulose, 1.0 part of pH regulator, 1.0 part of silane coupling agent, 2 parts of defoamer, 0.2 part of leveling agent, 0.5 part of crosslinking agent. The binder is polyvinyl alcohol; the pH regulator is 10% acetic acid; the defoamer is a mixture of isopropanol and n-butanol in a weight ratio of 3:1; the The leveling agent is a fluorine-modified acrylic copolymer; the crosslinking agent is a mixture of glyoxal and borax in a weight ratio of 2:1;

[0049] Coating ...

Embodiment 2

[0051] This example is the same as Example 1, except that the anti-scratch ink-absorbing layer (1) includes the following components in parts by weight, 10 parts of nanocellulose, to obtain the anti-scratch ink-absorbing layer of Example 2 (1), the evaluation results are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com