Composite material of poly lactic acid / natural faric, and production method

A natural fiber and composite material technology, applied in natural fiber reinforced modified polylactic acid composite materials and its production field, can solve the problems of high mechanical equipment requirements, low production efficiency, and difficulty in industrialization, and achieve high production efficiency and good molding processing Sexuality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

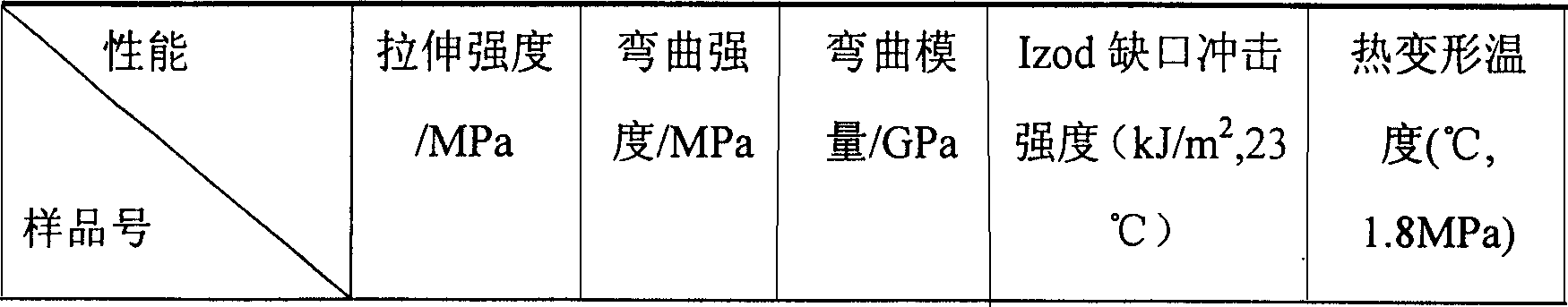

[0015] Accurately weigh 70 parts of polylactic acid and 0.3 part of antioxidant tetrakis{β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid}pentaerythritol and mix them uniformly and then add them into the extruder from the main hopper. At the same time, 30 parts of short ramie fibers are fed into an extruder through a side feeding device to carry out extrusion granulation, and the product is obtained after drying. Its mechanical properties are listed in Table 1. # As shown, for comparison, 0 in Table 1 # The mechanical properties of pure polylactic acid are listed.

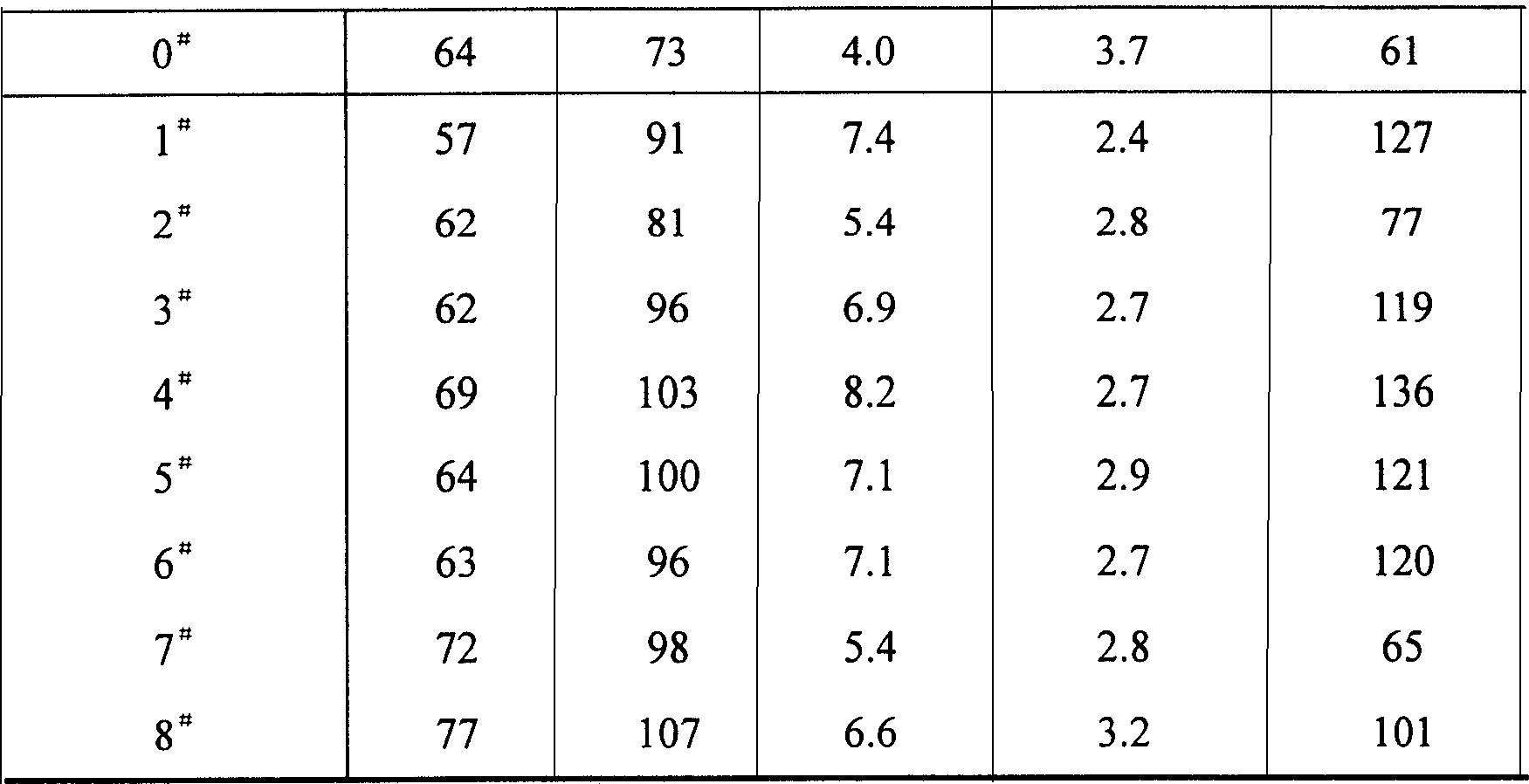

[0016] The crystallization properties of the composite material were measured by differential scanning calorimetry (DSC). The first cooling and second heating curves were taken, and the crystallization rate was characterized by the peak value (crystallization temperature) and half-peak width of the crystallization peak. The higher the temperature, the narrower the half-width, the greater the crystallization ra...

Embodiment 2

[0020] Cotton short fibers are surface treated with coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, the specific method is as follows: prepare a 1wt% coupling agent aqueous solution, add a certain amount of concentrated hydrochloric acid dropwise to adjust the pH of the solution to 3-4, and The cotton fiber is soaked in the solution, and after soaking for two hours, it is taken out and placed in a blast oven for drying at 80°C.

[0021] Accurately weigh 90 parts of polylactic acid and 0.3 parts of antioxidant tetrakis{β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid}pentaerythritol and mix them uniformly and then add them to the extruder from the main hopper. Simultaneously, 10 parts of processed cotton staple fibers are added into the extruder through a side feeding device to extrude and granulate, and the product is obtained after drying. The rest are the same as in Example 1, and its mechanical properties are shown in Table 1. 2 # As shown, the crystallization...

Embodiment 3

[0025] The ramie short fiber was surface-treated with coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, and the soaking time was 0.5 hour. Concrete processing method is with the processing of cotton fiber in embodiment 2.

[0026] Accurately weigh 80 parts of polylactic acid and 0.2 part of antioxidant tetrakis{β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid}pentaerythritol and mix them uniformly and then add them into the extruder from the main hopper. Simultaneously, 20 parts of processed ramie short fibers are added to the extruder through a side feeding device to extrude and granulate. After drying, the product is obtained. All the other are the same as in Example 1, and its mechanical properties are shown in Table 1. # As shown, the crystallization properties are shown in Table 2 3 * shown.

[0027] It can be seen from Table 1 that the mechanical properties of the composite material of the present invention, such as flexural strength, flexural modulus and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com