Heat-conducting thermosetting molding composite material and application thereof

A composite material and thermosetting technology, which is applied in the field of thermally conductive thermosetting molding composite materials, can solve the problems of high limitations, long molding cycle, and insufficient design flexibility, and achieve effective isolation and temperature control, and good molding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of thermally conductive thermosetting composite material includes:

[0031] 1) Resin ingredients: Weigh each component of the thermosetting resin and stir evenly;

[0032] 2) Weigh relevant fillers according to the required percentage by weight, and place them in an airtight container for pre-mixing;

[0033] 3) Fully mix resin and filler in internal mixer, kneader or screw extruder to make raw material mixture. The mixing processing temperature is within the respective processing temperature according to different resin systems. It can be 20-100 degrees in the epoxy vinyl / silicone-filler system for the following examples. In the example shown, the mixing system is an internal mixer kneader. The obtained lump plastic is packed for use.

Embodiment 1

[0040] Table 1. Formulation and properties of epoxy vinyl resin composite materials

[0041]

[0042]

[0043] As shown in Table 1, this embodiment can effectively improve the thermal conductivity of the premix by blending a certain amount of low-cost thermally conductive fillers in the epoxy vinyl resin, in this embodiment, aluminum oxide and graphite. Its thermal conductivity can reach more than 2.1, which is 10 times that of the matrix resin, while maintaining electrical insulation properties.

[0044] The heat sink made of the heat-conducting thermosetting molding composite material prepared in this embodiment can keep the soldering point temperature of the LED chip below 85° C., which can fully meet the actual use requirements of the LED lamp.

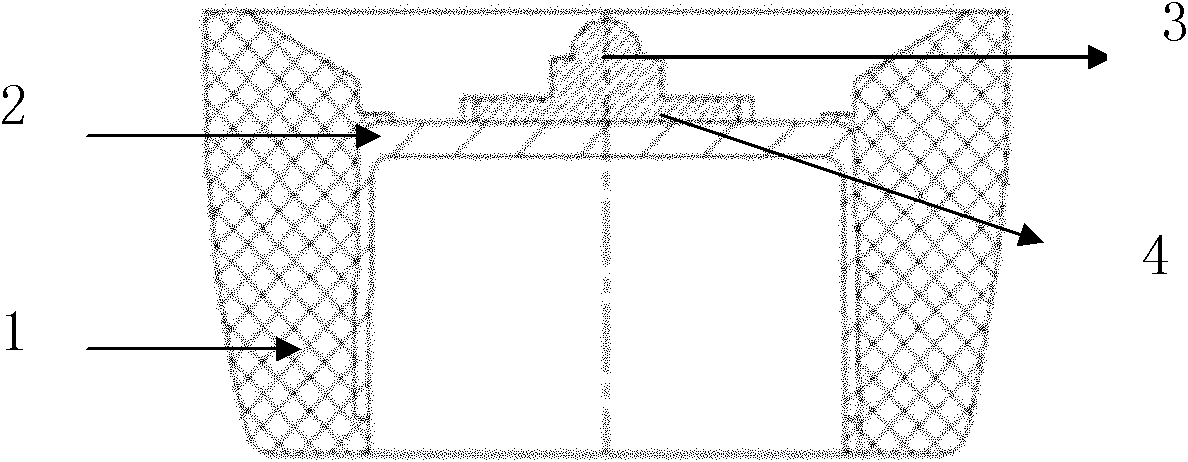

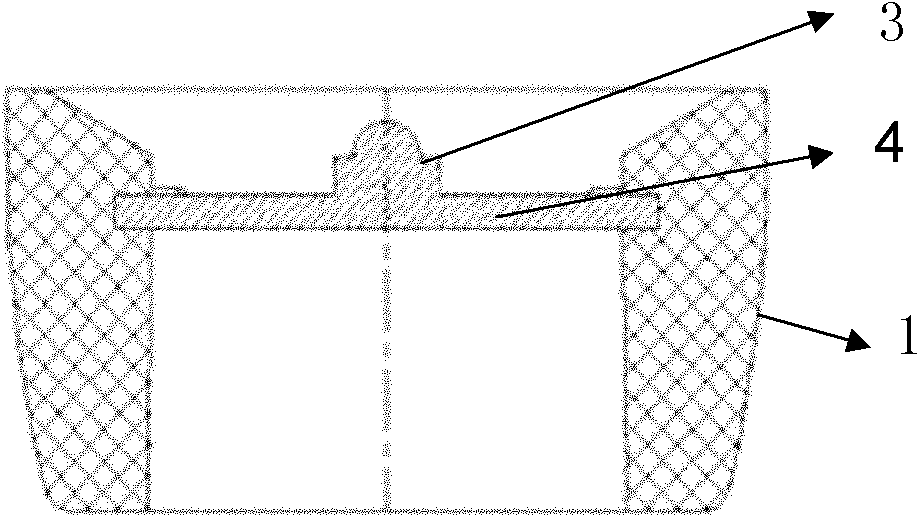

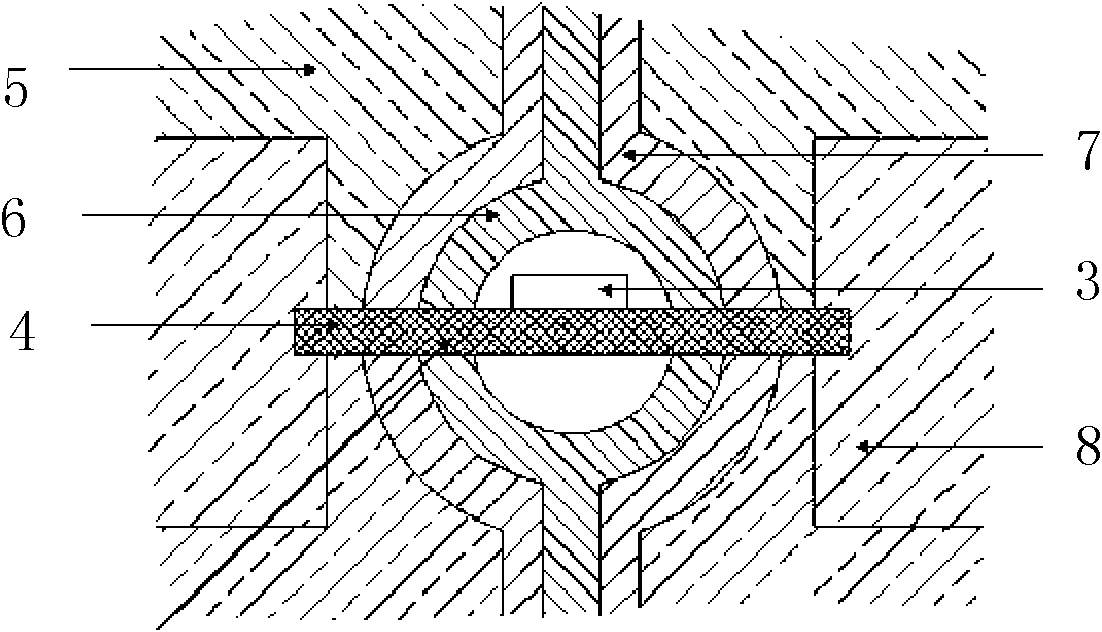

[0045] Using the thermally conductive thermosetting molding composite material prepared in this example to prepare LED lighting heat dissipation parts requires the following molding process:

[0046] 1. Mold pre-treatment, ...

Embodiment 2

[0056] Table 2. Formulations and Properties of Epoxy Vinyl Composite Materials

[0057]

[0058]

[0059] As shown in Table 4, this example can effectively improve the thermal conductivity of the premix by blending another type of low-cost thermally conductive filler, in this example, magnesium hydroxide and graphite, into the epoxy vinyl resin , its thermal conductivity can reach more than 1.9, which is more than 8 times that of the matrix resin, while maintaining electrical insulation properties.

[0060] The heat sink made of the heat-conducting thermosetting molding composite material prepared in this embodiment can keep the soldering point temperature of the LED chip below 85° C., which can fully meet the actual use requirements of the LED lamp.

[0061] The use and design of the mold is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com