High-thermal-conductivity polymer composite material and preparation method and application thereof

A technology of composite materials and polymers, applied in the direction of nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of limited use, low thermal conductivity, and formation of thermal conductivity networks, etc., to achieve wide application, high thermal conductivity, The effect of stable thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

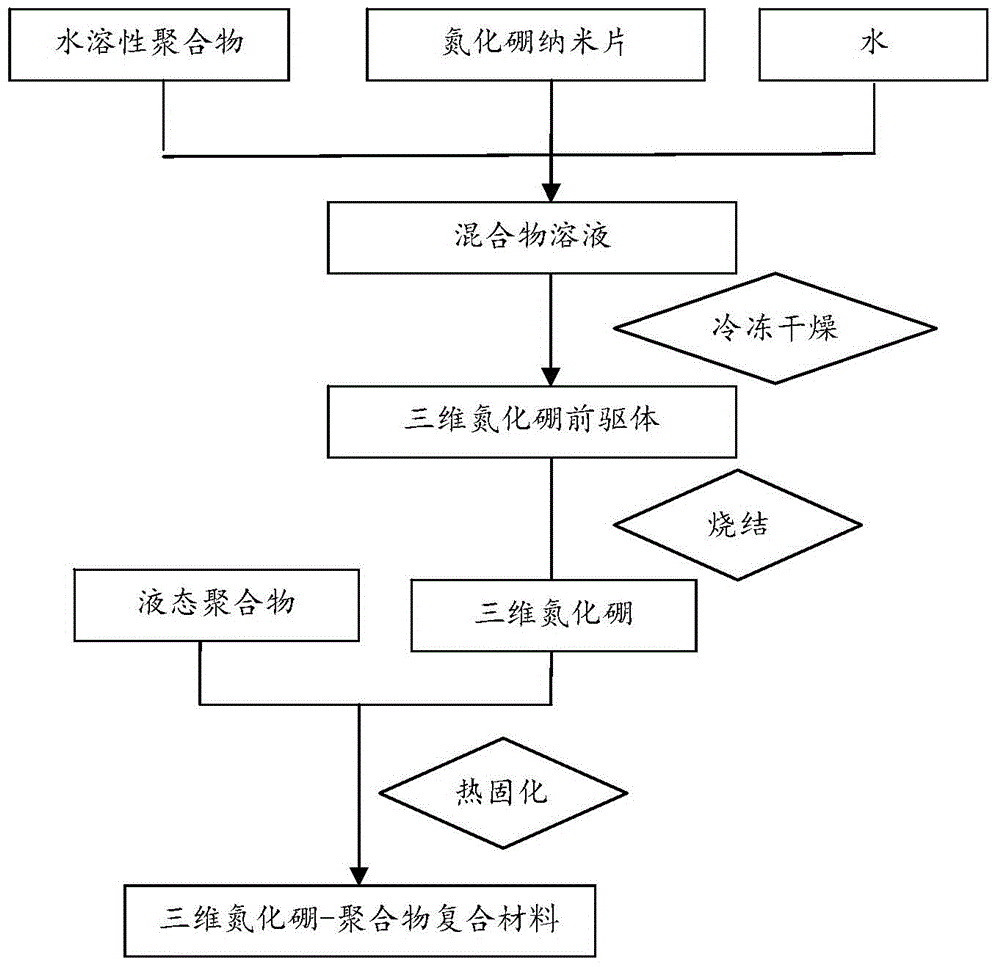

[0031] Correspondingly, an embodiment of the present invention provides a preparation method of the above-mentioned high thermal conductivity polymer composite material. The process steps of the preparation method of the high thermal conductivity polymer composite material of the embodiment of the present invention are as follows: figure 1 As shown, it includes the following steps:

[0032]Step S01: mixing boron nitride nanosheets, water and water-soluble polymer according to the mass ratio of 1:(1-50):100 to obtain a mixture solution;

[0033] Step S02: Freeze the mixture solution prepared in step S01 to form a frozen mixture, and freeze-dry the frozen mixture to obtain a three-dimensional boron nitride precursor;

[0034] Step S03: Sintering and heat-treating the three-dimensional boron nitride precursor prepared in step S02 to obtain three-dimensional boron nitride;

[0035] Step S04: impregnating the three-dimensional boron nitride prepared in step S03 into the liquid pr...

Embodiment 1

[0058] A high thermal conductivity polymer composite material and a preparation method thereof. The high thermal conductivity polymer composite material provided in this embodiment 1 is prepared according to the following method:

[0059] S11: Mixing boron nitride nanosheets, deionized water and polyethylene glycol according to the mass ratio of 1:50:100;

[0060] S12: Freeze the mixed solution in step S11 in a refrigerator at -20°C for 12 hours to obtain a frozen mixture, and use a freeze-vacuum drying process for the frozen mixed solution with a vacuum degree of -40Pa and a freezing temperature of -50°C to obtain Three-dimensional boron nitride precursor;

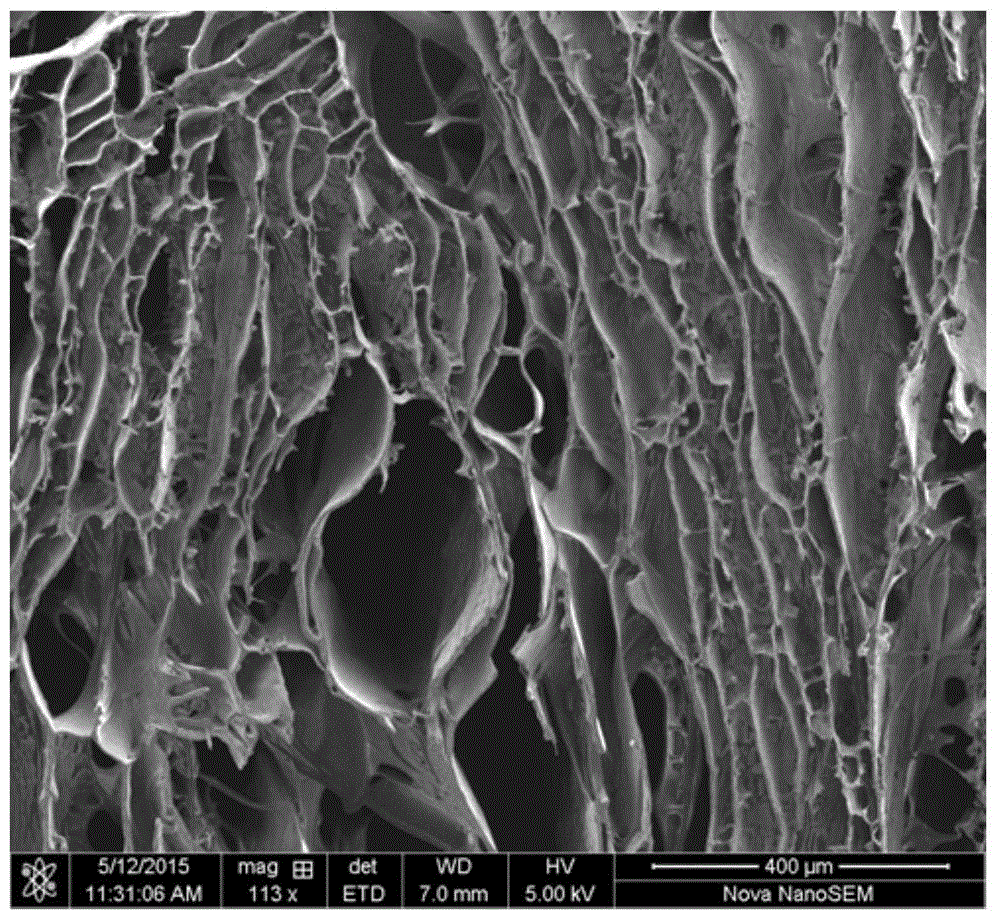

[0061] S13: The high-temperature sintering operation process of the three-dimensional boron nitride precursor, the sintering temperature is 1000°C, and the sintering time is 4h, to obtain three-dimensional boron nitride;

[0062] S14: Immerse the three-dimensional boron nitride in the liquid epoxy resin system, remove a...

Embodiment 2

[0066] A high thermal conductivity polymer composite material and a preparation method thereof. The high thermal conductivity polymer composite material provided in this embodiment 2 is prepared according to the following method:

[0067] S21: Mixing boron nitride nanosheets, deionized water and polyvinyl alcohol according to the mass ratio of 1:30:100;

[0068] S22: Freeze the mixed solution in step S21 in a refrigerator at -20°C for 12 hours to obtain a frozen mixture, and use a freeze-vacuum drying process for the frozen mixed solution with a vacuum degree of -40Pa and a freezing temperature of -50°C to obtain Three-dimensional boron nitride precursor;

[0069] S23: the high-temperature sintering process of the three-dimensional boron nitride precursor, the sintering temperature is 1000°C, and the sintering time is 4h, to obtain three-dimensional boron nitride;

[0070]S24: Immerse three-dimensional boron nitride in liquid cyanate, remove air bubbles under vacuum, and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com