Method for synthesizing NANO hydroxyapatite

A technology of nano-hydroxyapatite and synthesis method, which is applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., and can solve the problem that the shape, size and agglomeration degree of nano-hydroxyapatite cannot be strictly and effectively controlled, and nano-hydroxyphosphorus Limestone application limitations, high reaction temperature and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as figure 1 , measure 35mL of 1.0mol / L Ca(NO 3 ) 2 4H 2 O, added to a three-necked flask placed in a constant temperature water bath at 40°C, and then added 1.76 grams of trisodium citrate; stirred and added dropwise 35 mL of 0.6 mol / L H 3 PO 4 . use NH 3 ·H 2 O adjusted the pH of the reaction solution to 10, and stirred at constant temperature for 4 hours. Afterwards, the solution was added into a stainless steel hydrothermal synthesis kettle lined with polytetrafluoroethylene and reacted at 200° C. for 8 hours. After the reaction, a milky white precipitate was obtained. The white precipitate was suction filtered and washed to obtain rod-shaped hydroxyapatite with an average diameter and length of 14 and 34 nm, respectively.

Embodiment 2

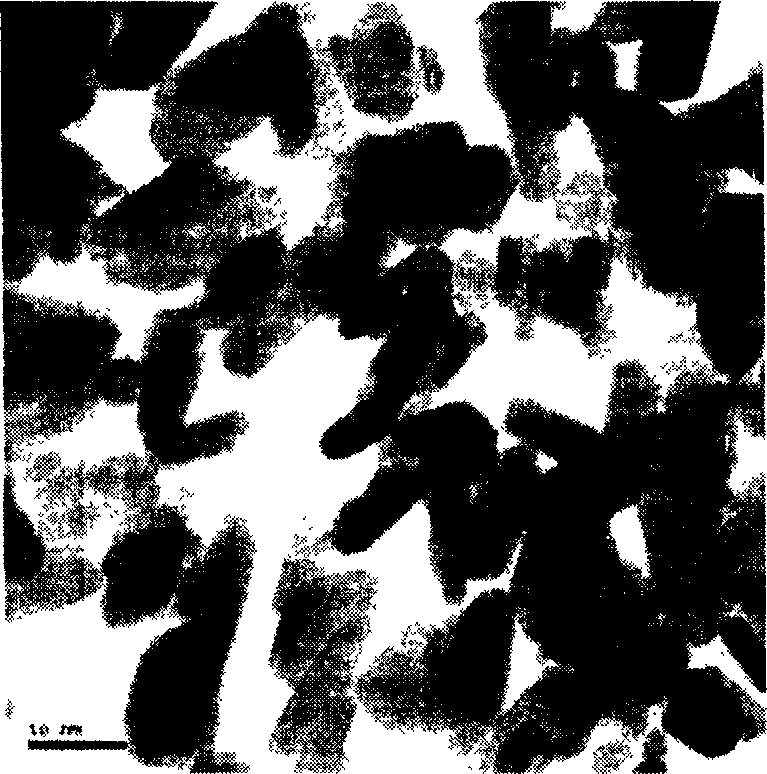

[0031] Such as figure 2 , measure 35mL of 1.0mol / L Ca(NO 3 ) 2 4H 2 O, put it into a three-neck flask placed in a constant temperature water pot at 60°C, and then add 5.27 grams of sodium dodecylsulfonate; stir and add 35 mL of 0.6mol / L H 3 PO 4 . use NH 3 ·H 2 O adjusted the pH of the reaction solution to 11, and stirred at constant temperature for 6 hours. Afterwards, the solution was added into a stainless steel hydrothermal synthesis kettle lined with polytetrafluoroethylene and reacted at 200° C. for 10 hours. After the reaction, a milky white precipitate was obtained. The white precipitate was suction filtered and washed to obtain rod-shaped hydroxyapatite with an average diameter and length of 22 and 51 nm, respectively.

Embodiment 3

[0033] Such as image 3 , measure 35mL of 1.0mol / L Ca(NO 3 ) 2 4H 2 O, add 10.54 grams of sodium dodecylbenzenesulfonate to a three-necked flask placed in a constant temperature water pot at 100°C; stir and add 35m of 0.6mol / L H 3 PO 4 . use NH 3 ·H 2 O adjusted the pH of the reaction solution to 13, stirred at constant temperature for 8 hours, and then added the solution into a stainless steel hydrothermal synthesis kettle lined with polytetrafluoroethylene and reacted at 200°C for 12 hours. After the reaction, a milky white precipitate was obtained. The white precipitate was suction-filtered and washed to obtain rod-shaped hydroxyapatite with an average diameter and length of 19 and 47 nm, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com