A kind of pressure-sensitive adhesive for PET protective film and preparation method thereof

A pressure-sensitive adhesive and protective film technology, applied in the direction of film/sheet adhesive, adhesive, adhesive type, etc., can solve the problem of static electricity and poor heat resistance caused by the use, lamination or tearing of pressure-sensitive adhesives problem, to achieve a strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

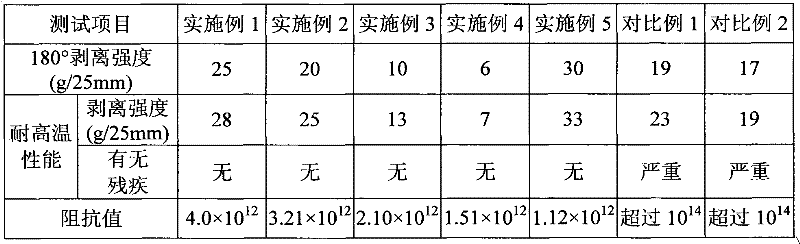

Examples

Embodiment 1

[0032] This embodiment provides a pressure-sensitive adhesive used for a PET protective film and a preparation method thereof, wherein the raw material composition of the pressure-sensitive adhesive is shown in Table 1.

[0033] Table 1

[0034] Raw material components

Weight (kg)

2-Ethylhexyl Acrylate

9

12

6

2-Hydroxyethyl Acrylate

1.2

0.6

2

0.03

28

0.005

Acetyl tributyl citrate

0.005

Cresyl diisocyanate

0.7

Potassium alkyl diphenyl ether sulfonate

0.1

[0035] The preparation method of the pressure-sensitive adhesive provided in this embodiment is as follows:

[0036]1), 3 kilograms of 2-ethylhexyl acrylate, 4 kilograms of butyl acrylate, 2 kilograms of methyl methacrylate, 7 kilogr...

Embodiment 2

[0042] This embodiment provides a pressure-sensitive adhesive used for a PET protective film and a preparation method thereof, wherein the raw material composition of the pressure-sensitive adhesive is shown in Table 2.

[0043] Table 2

[0044] Raw material components

Weight (kg)

2-Ethylhexyl Acrylate

12

9

6

3

acrylic

1

1

0.08

21

0.004

Acetyl tributyl citrate

0.006

Cresyl diisocyanate

0.5

Potassium alkyl diphenyl ether sulfonate

0.5

[0045] The preparation method of the pressure-sensitive adhesive provided in this embodiment is as follows:

[0046] 1) Add 4 kg of 2-ethylhexyl acrylate, 3 kg of butyl acrylate, 2 kg of methyl acrylate, 7 kg of ethyl acetate and 0.03 kg of...

Embodiment 3

[0052] This embodiment provides a pressure-sensitive adhesive used for a PET protective film and a preparation method thereof, wherein the raw material composition of the pressure-sensitive adhesive is shown in Table 3.

[0053] table 3

[0054] Raw material components

Weight (kg)

2-Ethylhexyl Acrylate

12

9

6

2-Hydroxyethyl Acrylate

3

acrylic

1.5

3

0.08

ethyl acetate

21

0.004

Acetyl tributyl citrate

0.006

Dicresyl diisocyanate

1

Potassium alkyl diphenyl ether sulfonate

0.8

[0055] The preparation method of the pressure-sensitive adhesive provided in this embodiment is as follows:

[0056] 1) Add 4 kg of 2-ethylhexyl acrylate, 3 kg of butyl acrylate, 2 kg of methyl acrylate, 7 kg of ethyl acetate and 0.03 kg of dib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com