Thermoexpandable thermoplastic microspheres

A thermoplastic microsphere and thermal expansion technology, applied in the field of thermoplastic microspheres, can solve the problems of unsatisfactory performance, high price and complicated production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

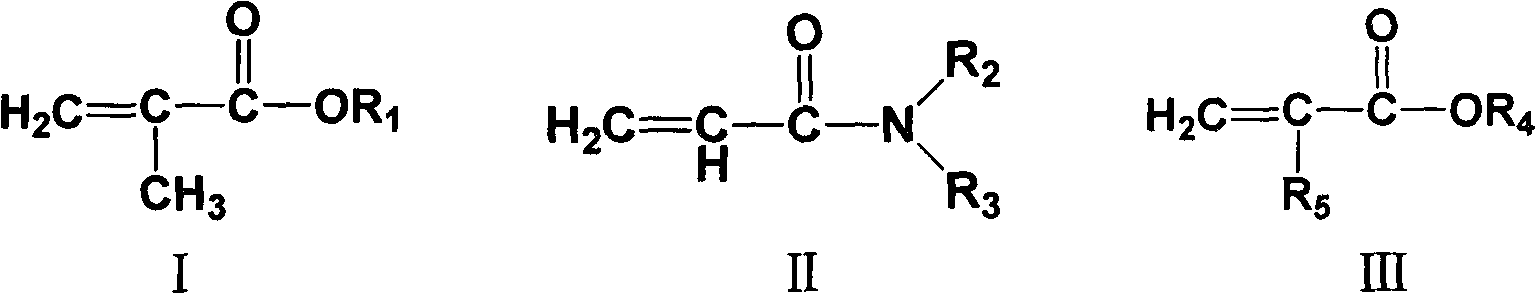

Method used

Image

Examples

Embodiment 1

[0050] By mixing 140 grams of acrylonitrile, 20 grams of N,N-dimethylacrylamide, 40 grams of methyl methacrylate, 0.1 grams of 2,2,2-trifluoroethyl methacrylate, 0.4 grams of trimethylol Propane trimethacrylate, 4 grams of benzoyl peroxide and 50 grams of isooctane resulted in a suspension polymerized oil phase.

[0051] Add 280 grams of deionized water, 30 grams of sodium hydroxide, 40 grams of sodium chloride and 0.2 grams of sodium lauryl sulfate into beaker No. 1 to fully dissolve; add 280 grams of deionized water, 85 grams of six Magnesium chloride hydrate, 30 grams of sodium chloride, and 0.01 grams of sodium nitrite are fully dissolved; the solution in the No. 1 beaker is first poured into a 2.5-liter three-necked flask with a stirring paddle, then stirred at 1200 rpm, and then poured into the three-necked flask Slowly add the solution in the No. 2 beaker to the flask. After the addition was complete, the mixture was fully stirred for 15 minutes to obtain a suspension-...

Embodiment 2

[0054] By mixing 40 g of acrylonitrile, 2 g of N,N-dimethylacrylamide, 3 g of methyl methacrylate, 4 g of methyl acrylate, 0.1 g of 2,2,2-trifluoroethyl methacrylate, 0.5 g of methacrylic acid, 0.1 g of acrylic acid, 0.4 g of trimethylolpropane trimethacrylate, 1 g of azobisisobutyronitrile, 12 g of isooctane and 3 g of isopentane yielded an oily phase for suspension polymerization.

[0055] In 200 parts by weight of ion-exchanged water, add 23 parts by weight of sodium chloride, 10 parts by weight (active ingredient amount: 20% by weight) of colloidal silicon dioxide, 0.1 parts by weight of polyvinylpyrrolidone and 0.01 parts by weight of sodium nitrite, then adjust the pH Adjust to 2.4, mix uniformly, and use it as an aqueous dispersion medium.

[0056] The oil phase and the water phase were dispersed by stirring at 6000 rpm for 3 minutes with a homomixer to prepare a suspension solution. Immediately inject the suspension solution into a 1-liter high-pressure reactor, repla...

Embodiment 3-6

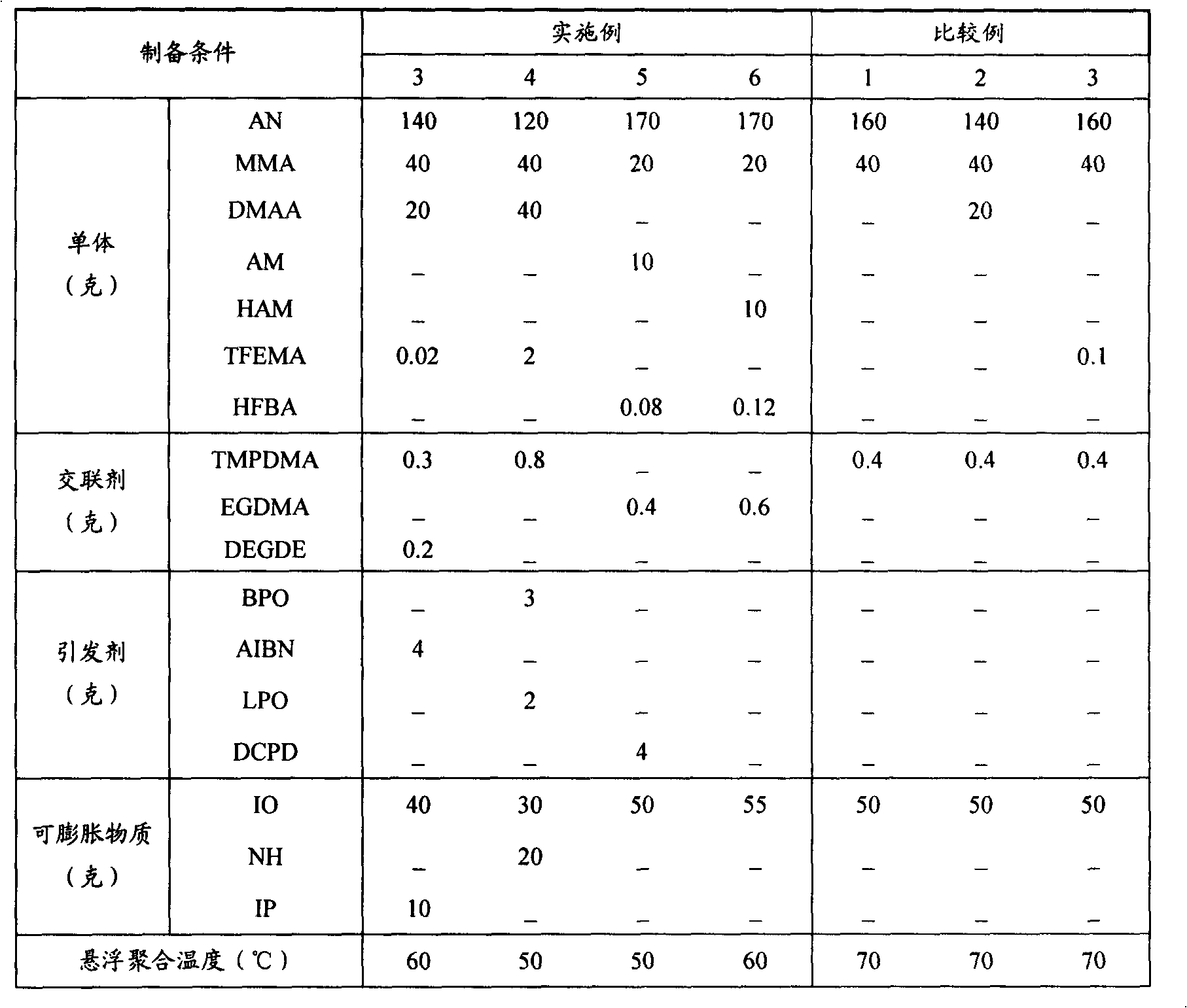

[0058] Except changing the type and amount of monomers used, crosslinking agent, initiator and expandable substance and polymer temperature (see Table 1 for details), other conditions are the same as in Example 1 to prepare different heat-expandable microspheres, Its performance is shown in Table 2.

[0059] Table 1

[0060]

[0061] In Table 1, AN: acrylonitrile, MMA: methyl methacrylate, DMAA: N,N-dimethylacrylamide, AM: acrylamide, HMAA: N-methylolacrylamide, TFEMA: trimethacrylate Fluoroethyl ester, HFBA: Hexafluorobutyl acrylate, TMPDMA: Trimethylolpropane trimethacrylate, EGDMA: Ethylene glycol dimethacrylate, DEGDE: Diethylene glycol divinyl ether, BPO: Over Benzoyl oxide, AIBN: azobisisobutyronitrile, LPO: lauroyl peroxide, DCPD: dicyclohexyl peroxycarbonate, IO: isooctane, NH: n-hexane, IP: isopentane.

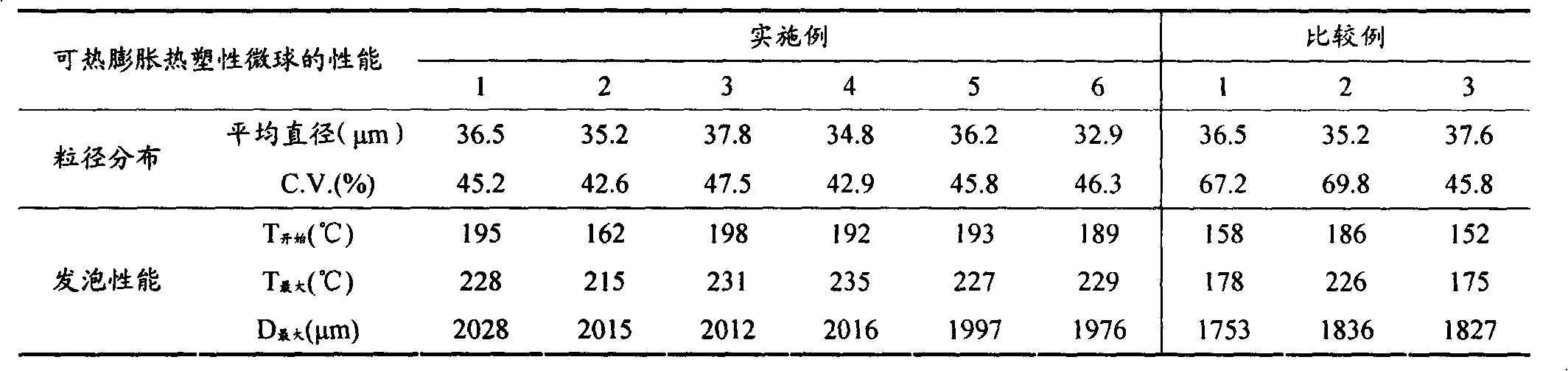

[0062] Table 2

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com