Slowly-recoverable polyurethane foam material

A foam material, slow rebound technology, applied in the field of polymer composite materials, can solve the problems of unhealthy consumers, production operators and environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

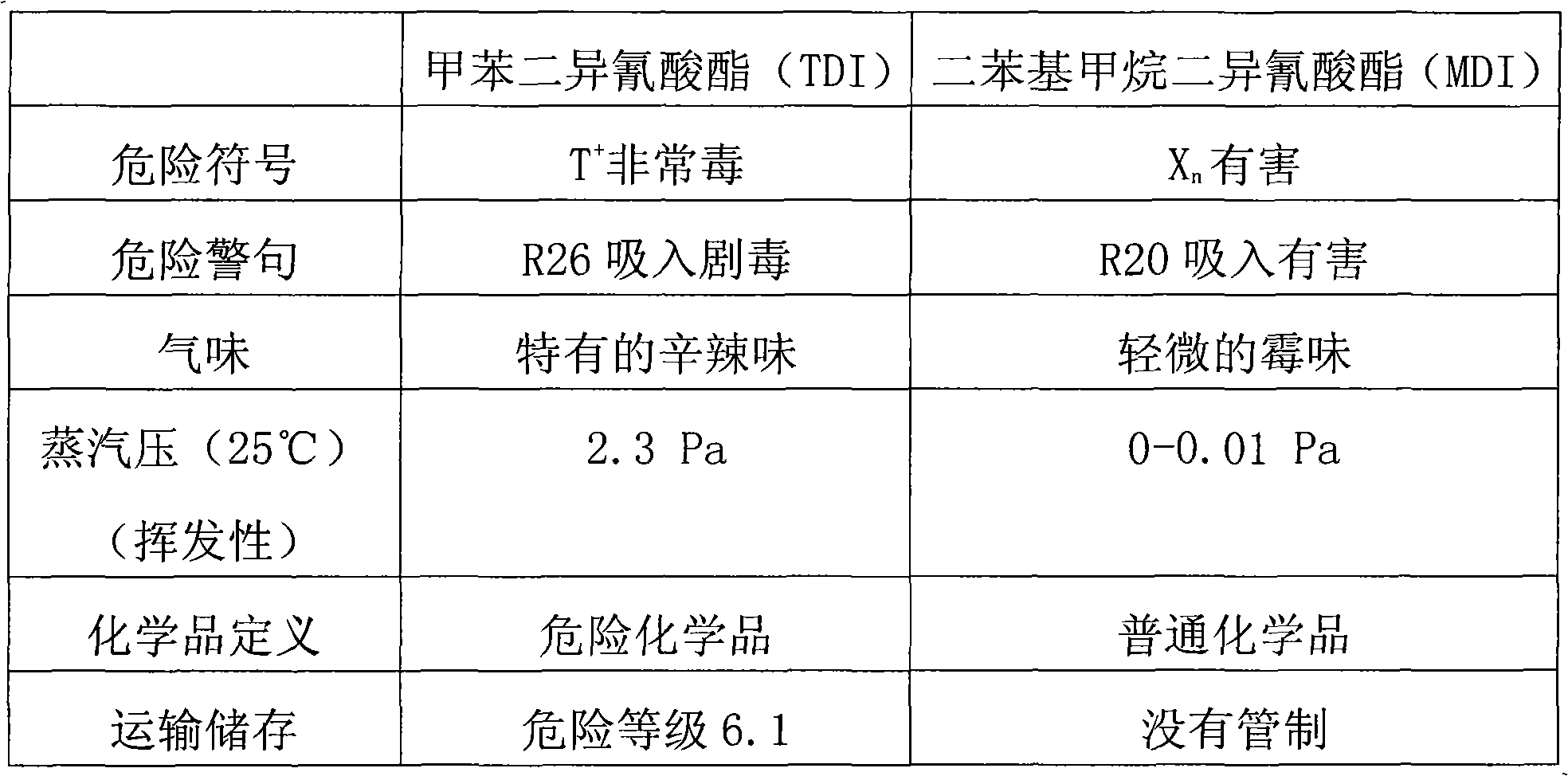

[0008]

[0009]

[0010] (

[0011]

[0012]

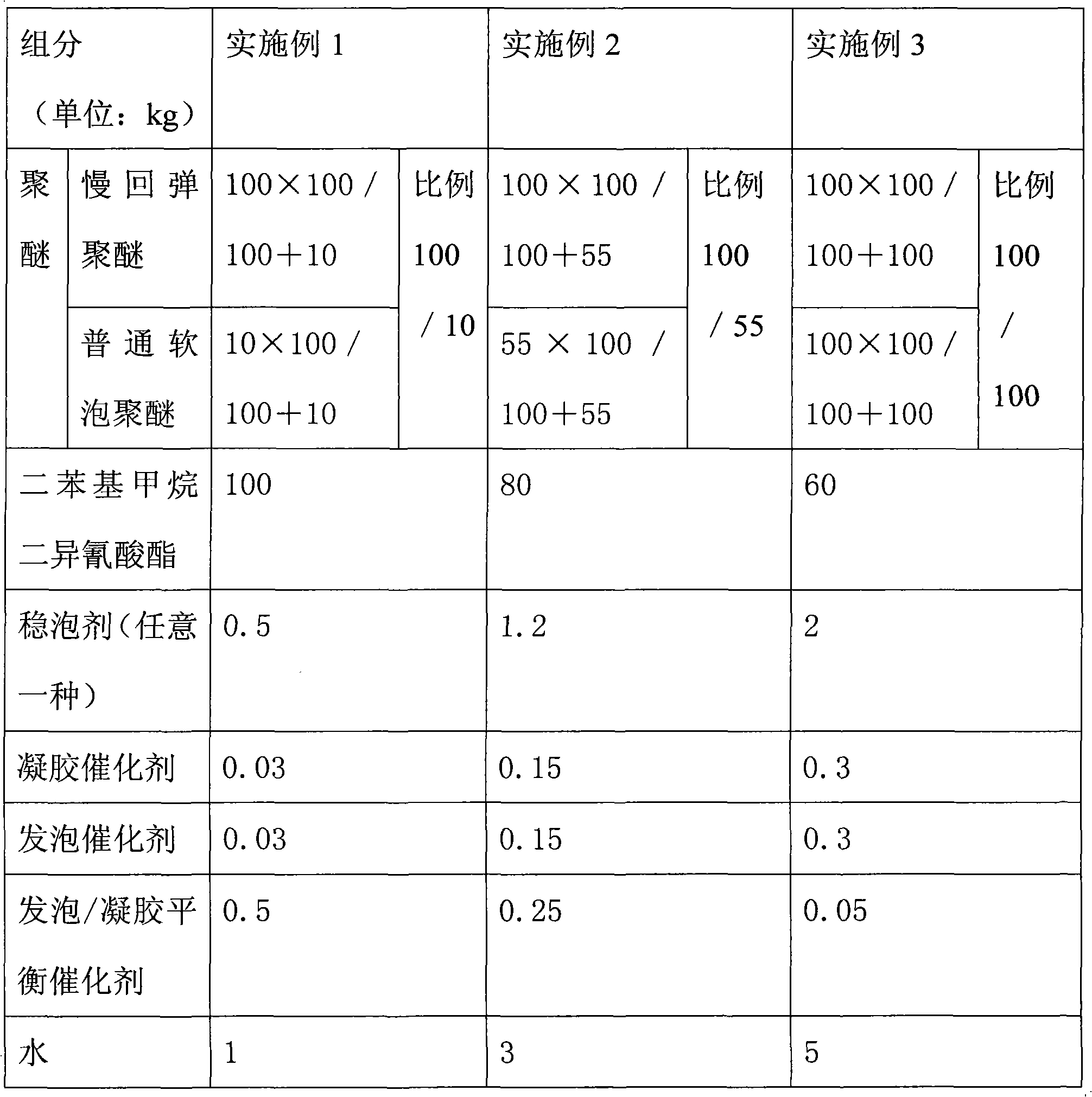

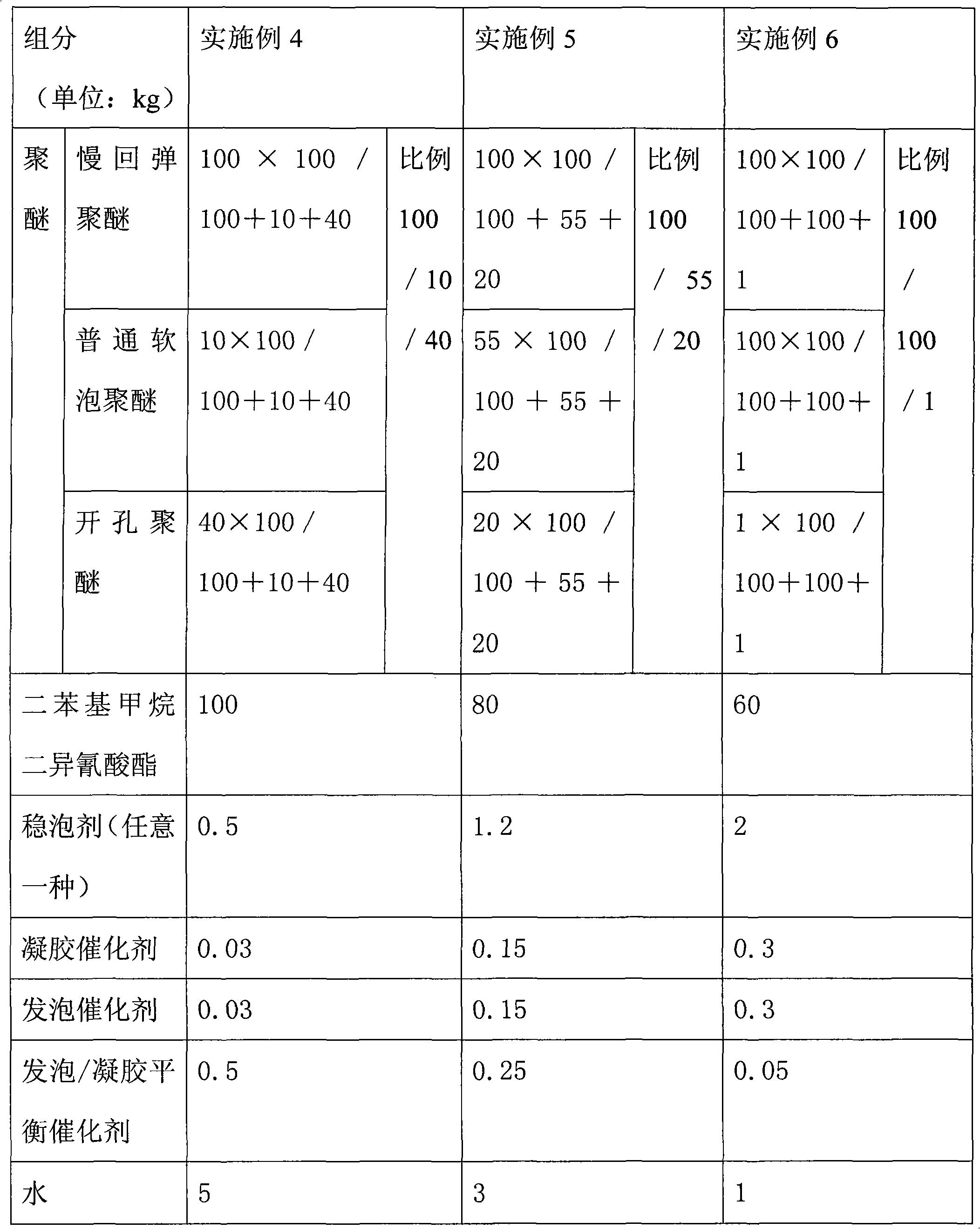

[0013] The foam stabilizer in the following examples 13 to 24 is selected from the NIAX silicone product produced by Momentive High-tech Materials Group of the United States, and the model is any two of L568, L590, L598, L618, L635, L638, L650, L682, L626, and L627. The foam stabilizer produced by American Air Products Company, the model is any two of DC2525, DC198, DC5188, DC5810, DC5906, DC5950, DC5986; the surfactant produced by German Gosmit company, the model is BF2370, BF2470 , B4900, B8002, B8040, B8050, and B8080, the ratio of any two parts by weight is 100:10-80, and the parts by weight of any two of the above-mentioned specified ones (components of the model) The combined sequence of ratios can be interchanged.

[0014]

[0015]

[0016]

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com