Modified polyurethane elastic curing agent and preparation method thereof

A polyurethane elasticity and curing agent technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of too little polyol, low effective NCO content, poor crosslinking density, etc., and achieve excellent use characteristics and application fields. Broad, high glass transition temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

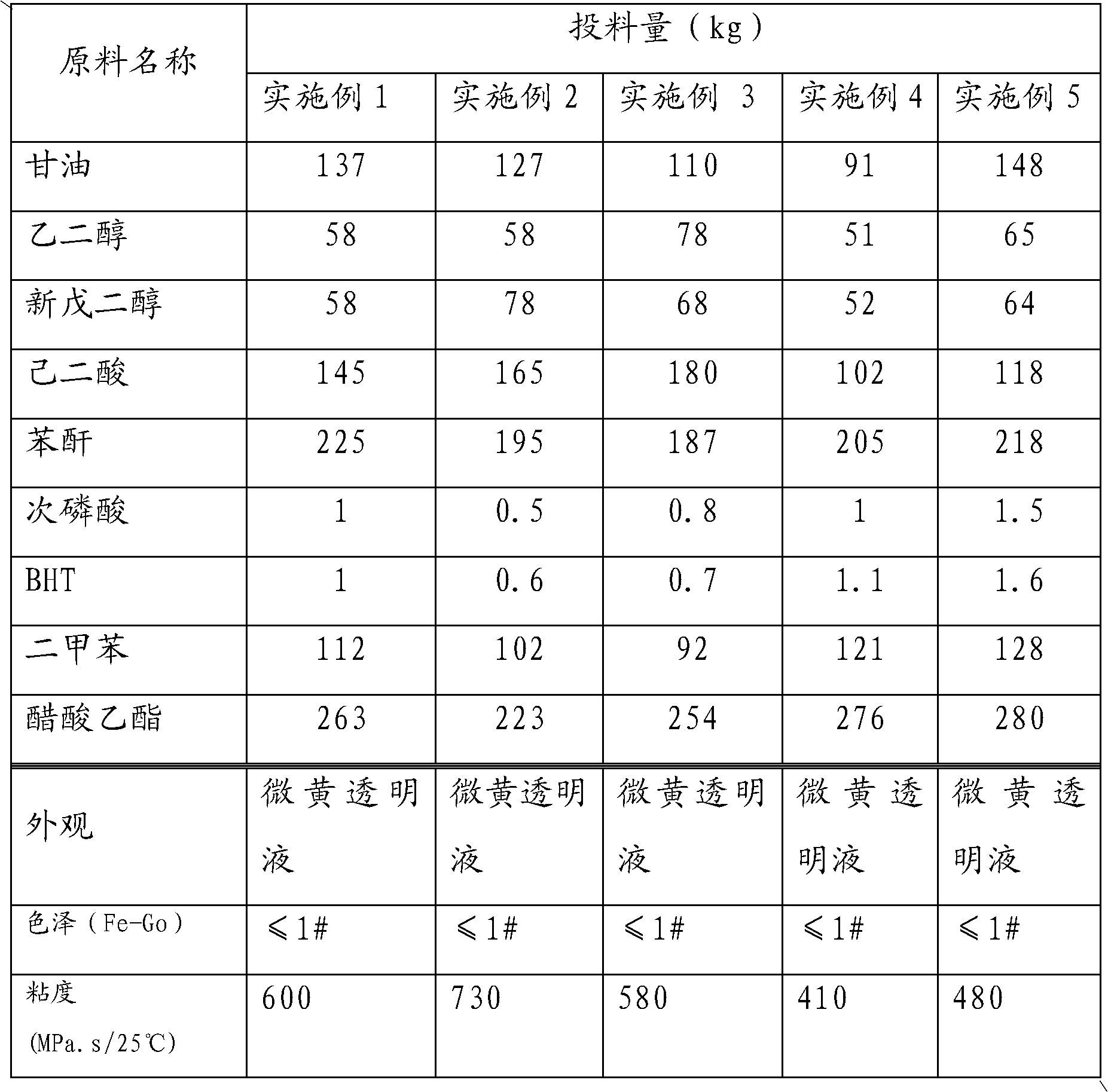

[0067] The present invention will be described in detail below in conjunction with specific embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

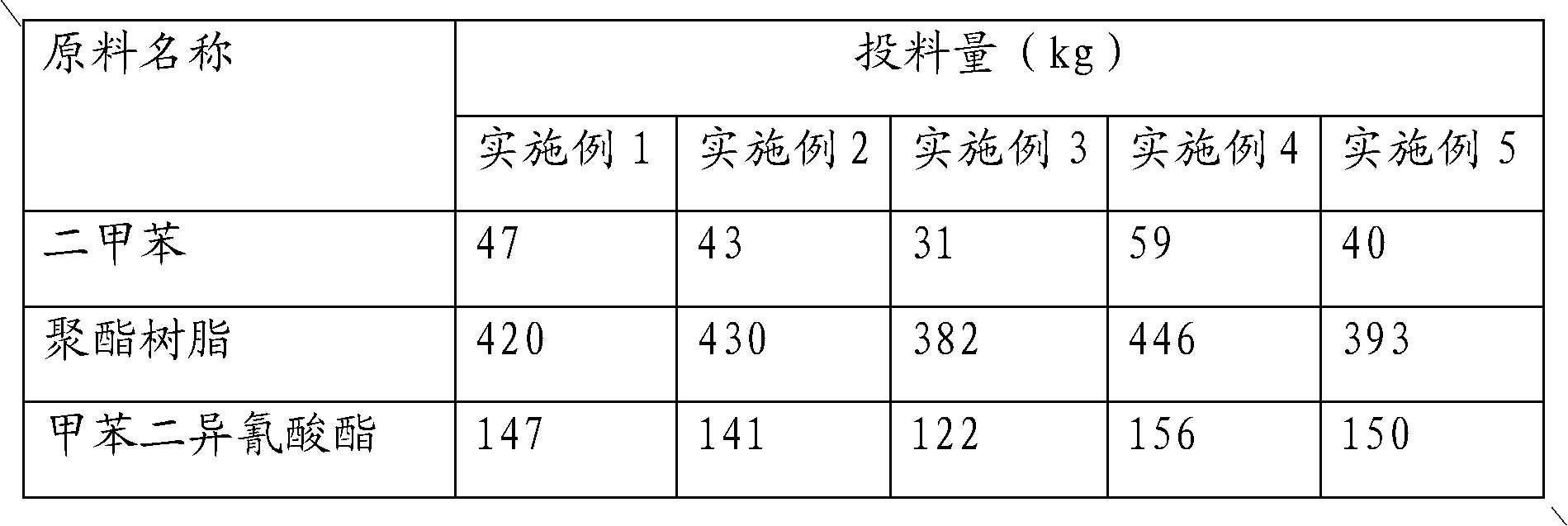

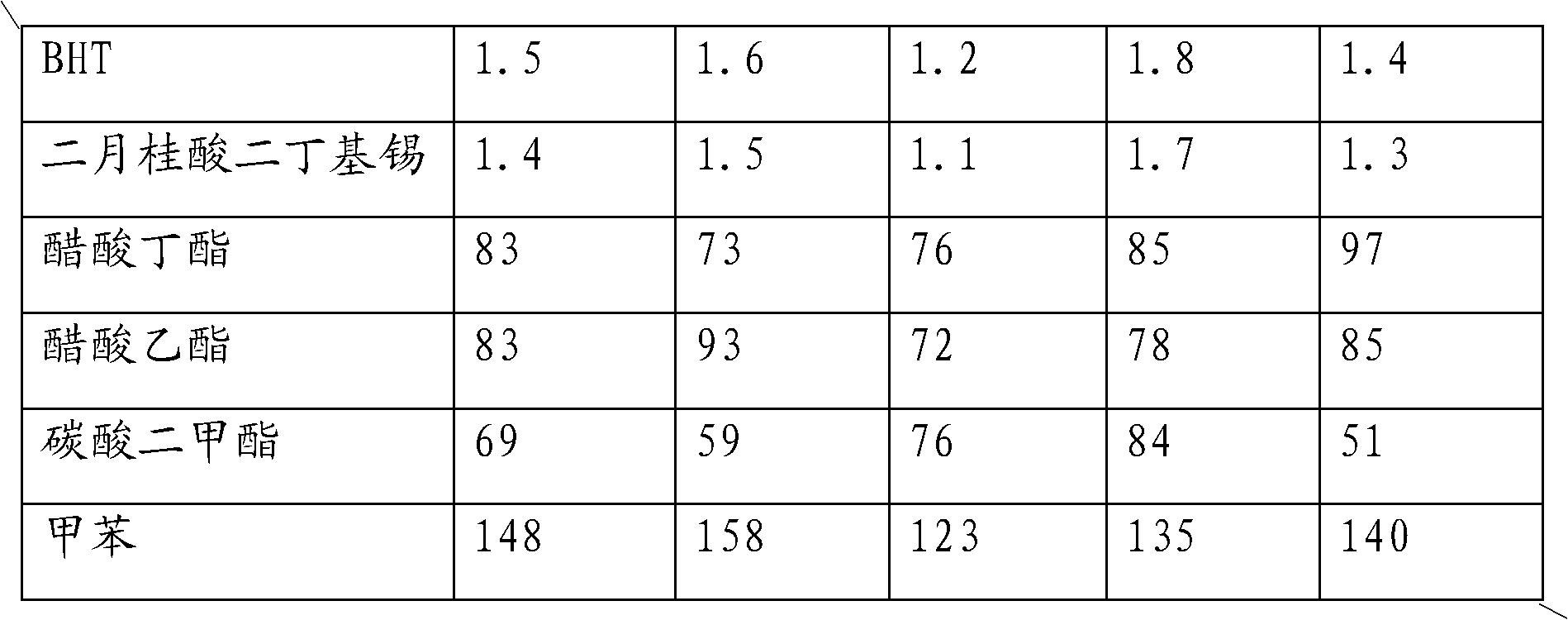

[0068] It should be noted that: toluene diisocyanate, 2,6-di-tert-butyl-4-methylphenol (BHT), dibutyltin dilaurate, xylene, butyl acetate, ethyl acetate used in the following examples , dimethyl carbonate, and toluene are domestic industrial-grade raw materials; polyester resin is an industrial-grade semi-finished raw material produced by Guangdong Carpoly Chemical Group Co., Ltd.

[0069] The following examples prepare the method for above-mentioned modified polyurethane elastic curing agent, all adopt following steps:

[0070] 1. Prepare a four-neck flask equipped with a thermometer, condenser, and stirring paddle;

[0071] 2. Add xylene, polyester resin, toluene diisocyanate, and BHT in sequence according to the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com