Patents

Literature

48results about How to "Unique water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

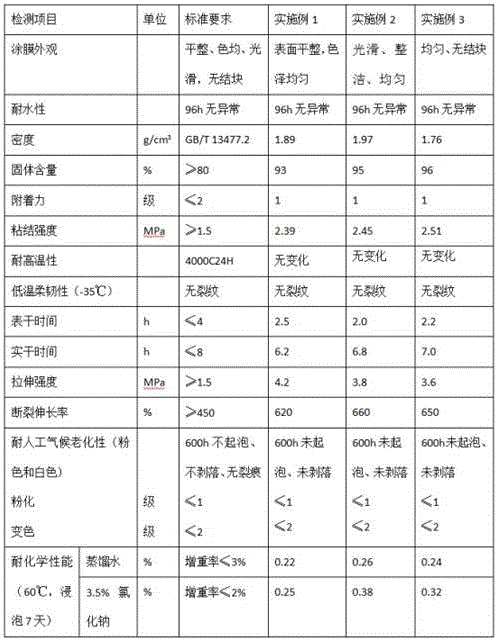

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

High polymer roof waterproof coating

InactiveCN1439683AOvercome limitationsOvercome the disadvantage of single colorAntifouling/underwater paintsPaints with biocidesHigh resistancePolymer science

A high-molecular water-proof paint for roof is prepared from acrylic emulsion, organosilicon emulsion, water as solvent and other assistants. Its advantages are no poison, ordour and environmental pollution, high resistance to water, ultraviolet radiation and ageing, rich colors and high adhesion.

Owner:翟广玉

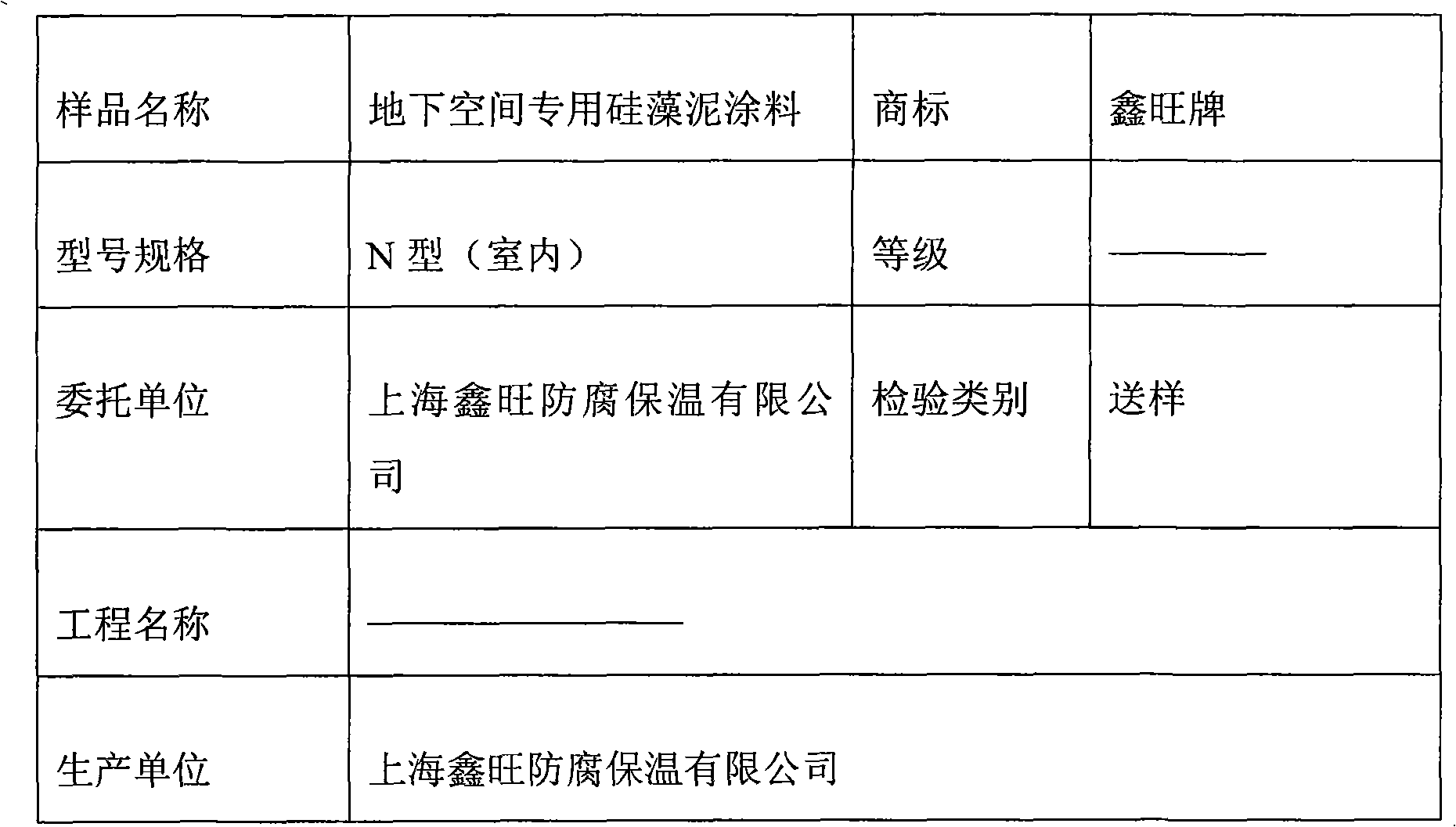

Diatom ooze coating special for underground space and preparation and application thereof

InactiveCN101570660AOvercome limitationsOvercome the disadvantage of single colorCoatingsOxygen ionsMoisture resistance

The invention relates to a diatom ooze coating special for underground space and preparation and application thereof. The coating is prepared by taking a polymer as a main film forming substance, water as a solvent, diatom ooze and the like as fillings and adding other addition agents. The coating takes the water as the solvent, so the coating has no toxicity and resistance to ultraviolet radiation, can generate negative oxygen ions, has high adhesive strength, good waterproof and quake-proof effects and moderate cost, and is widely used for decorating the inner walls of buildings such as office buildings, residential buildings, hospitals, schools, factory buildings, markets, and entertainment places; the coating has high adhesive strength, good effects of water resistance and permeability resistance, thermal resistance, frost resistance and good extensibility; the coating is performed cold construction, is directly painted, and is operated conveniently; and the coating is applicable to the water resistance, permeability resistance and moisture resistance of various buildings such as new and old roofs, basements, toilets, grain warehouse, dams, oil warehouses, pipelines, swimming pools, tunnels, construction gaps, expansion joints, roads and bridges and the like.

Owner:SHANGHAI XINWANG ANTICORROSION VACUUM FLASK

Green waterproof milk white polymer paint

InactiveCN1887990APromote environmental protectionHigh tensile strengthAntifouling/underwater paintsPaints with biocidesUltravioletSynthetic Polymeric Macromolecules

The present invention discloses one kind of waterproof milk white polymer paint. The green waterproof milk white polymer paint consists of 19 kinds of materials, including SEBS, SBS, coumarone resin, petroleum resin, terpene resin, etc. in certain weight proportion. It has good comprehensive mechanical performance, high waterproof performance, construction convenience and no environmental pollution.

Owner:河南省治海建材有限公司

Waterproof building glue

The invention discloses waterproof building glue. The waterproof building glue comprises, by mass, 100 to 200 parts of main agent, 10 to 20 parts of compounding plasticizer, 10 to 20 parts of reinforcing agent and 10 to 20 parts of curing agent. The main agent is liquid polysulfide rubber. The compounding plasticizer is DEHP. The waterproof building glue provided by the invention has the advantages of unique waterproof performance, high elasticity and integrity, continuous film without any seam, high temperature resistance, low temperature resistance, aging resistance, great adhesion and permeability for cement mortar, a concrete matrix, wood, ceramic, glass and other building materials, great ductility, excellent ability to resist ultraviolet and sightly colors, is non-toxic, tasteless, pollution-free and environment-friendly, and beautifies the environment.

Owner:DALIAN SHUNFA CONSTR WATERPROOF TECH

Flame-retardant waterproof coating for interior wall of building and preparation method thereof

InactiveCN104650714AUnique water resistanceIncrease elasticityFireproof paintsAnti-corrosive paintsCelluloseGlycidyl methacrylate

The invention discloses a flame-retardant waterproof coating for an interior wall of a building. The flame-retardant waterproof coating is characterized by being prepared from the following raw materials in parts by weight: 20-45 parts of organic silicon rubber emulsion, 5-8 parts of an organic silicon waterproof agent, 3-6 parts of graphene prefabricated dispersion, 0.1-0.6 part of emulsion type defoaming agent, 0.1-0.6 part of sodium carboxymethylcellulose, 2-4 parts of ammonium polyphosphate, 3-5 parts of magnesium hydroxide, 4-6 parts of C5 resin emulsion, 5-8 parts of calcined kaolin, 1-2 parts of dicumyl peroxide, 6-9 parts of tourmaline powder, and 1-2 parts of glycidyl methacrylate. The flame-retardant waterproof coating disclosed by the invention has unique water resistance, high elasticity and integrality; coating is continuously carried out without any seam; the flame-retardant waterproof coating is leakage-resistant; the binding property to various substrates of buildings is good; by means of the added graphene, the water resistance, anti-ultraviolet capability and anti-corrosion property of the coating are improved; and the coating disclosed by the invention also has good flame-retardant property, and has the advantages of being poisonless, tasteless, environmentally friendly, good in decoration, high in covering power, convenient to coat and wide in application range when used as an interior wall coating.

Owner:安徽省东瑞装饰材料有限公司

Film-forming agent capable of preventing cow mastitis and preparation method thereof

InactiveCN105106177AGood compatibilityFacilitated DiffusionAntibacterial agentsPharmaceutical non-active ingredientsBiotechnologyMilk cow's

The invention relates to a film-forming agent capable of preventing cow mastitis, comprising by weight, 0.6 o 1.2 parts of povidone iodine, 1 to 2 parts of tween 80, 0.2 to 0.6 part of glycerine, 8 to 12 parts of PVA (polyvinyl acetate), and 100 parts of distilled water. The invention further relates to a preparation method of the film-forming agent. The preparation method includes the steps of sterilizing with distilled water, temperature adjusting, adding of the povidone iodine, glycerine, tween 80 and PVA, pH adjusting and the like. The components and production process are further simplified, thus the film forming speed is high and breathability is good, the film-forming agent is nonirritating to skin mucosa. Especially, the film-forming agent and the preparation method thereof have the advantages such as high antibacterial activity, short film-forming time, easiness of eluting or stripping, agent stability, convenience of use and the like.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Thermal insulation high-elasticity waterproof paint and preparation method thereof

InactiveCN104650726AUnique water resistanceIncrease elasticityAnti-corrosive paintsCelluloseThermal insulation

The invention discloses a thermal insulation high-elasticity waterproof paint which is characterized by being prepared from the following raw materials in parts by weight: 20-45 parts of organosilicon rubber emulsion, 6-8 parts of organosilicon waterproof agent, 2-5 parts of graphene prefabricated dispersion, 0.1-0.6 part of emulsion type antifoaming agent, 0.1-0.6 part of sodium carboxymethylcellulose, 2-4 parts of triphenyl phosphate, 6-9 parts of coumarone resin emulsion, 3-6 parts of attapulgite powder, 4-6 parts of perlite powder, 1-2 parts of ultraviolet absorber, 4-6 parts of fly ash, 7-9 parts of styrene-acrylic emulsion and 3-4 parts of linoleic acid. The waterproof paint disclosed by the invention has unique waterproof property, high elasticity and integrity; the film is continuous without any joint; the cured paint film has moderate hardness and good elasticity and is not broken easily; the added graphene has good performance in corrosion resistance, thermal insulation and salt mist resistance; the added perlite powder and fly ash are cheap and realize a good heat insulation effect; and the paint disclosed by the invention has the advantages of easiness in construction, short construction time, safety and environmental protection, no toxicity or odor, low cost and good application prospect.

Owner:安徽枞阳县渡江充气设备制造有限公司

Anti-flaking waterproof coating material for buildings and preparation method thereof

InactiveCN104673087AUnique water resistanceEasy to prepareCoatingsSodium carboxymethylcelluloseEmulsion

The invention discloses an anti-flaking waterproof coating material for buildings, which is characterized by comprising the following raw materials in parts by weight: 20-45 parts of organic silicone rubber emulsion, 3-8 parts of organic silicone waterproof agent, 2-7 parts of a graphene prefabricated dispersion, 0.1-0.6 part of an emulsion-type defoaming agent, 0.1-0.6 part of sodium carboxymethylcellulose, 0.2-0.4 part of hydrophobic aerosol, 2-3 parts of a water reducing agent, 5-7 parts of quartz powder, 10-15 parts of cement, 2-3 parts of dipropylene glycol methyl ether and 3-5 parts of sodium tripolyphosphate. The waterproof coating material provided by the invention has unique waterproofness, high elasticity and integrality, is spread continuously without any seam, prevents seepage, is simple in preparation method, low in manufacturing cost, energy-saving, environment-friendly, high in application property and bonding force, hard to flake and good in decorating property and anti-aging property, and has the advantages of no cracking at low temperature and no swelling at high temperature.

Owner:安徽省东瑞装饰材料有限公司

High-strength fire-resistant thermal insulation material

The invention discloses a high-strength fire-resistant thermal insulation material. A preparation method of the high-strength fire-resistant thermal insulation material comprises the following steps: preparing a shaped product with the required size by using expanded vermiculite, clay, refractory cement and dextrin as initial materials and adding a waterproof agent and a binding agent in a mechanical pressing forming manner, wherein a nano-modification organic silicon rubber solution is used as the waterproof agent, and the binding agent is an inorganic binding agent, drying, carrying out heat preservation, and baking at a high temperature, thus obtaining the high-strength fire-resistant thermal insulation material. The high-strength fire-resistant thermal insulation material has the advantages of good structure and volume stability, high strength, low cost, simple process, convenience for construction and baking, environmental protection, safety and the like.

Owner:内蒙古包钢利尔高温材料有限公司

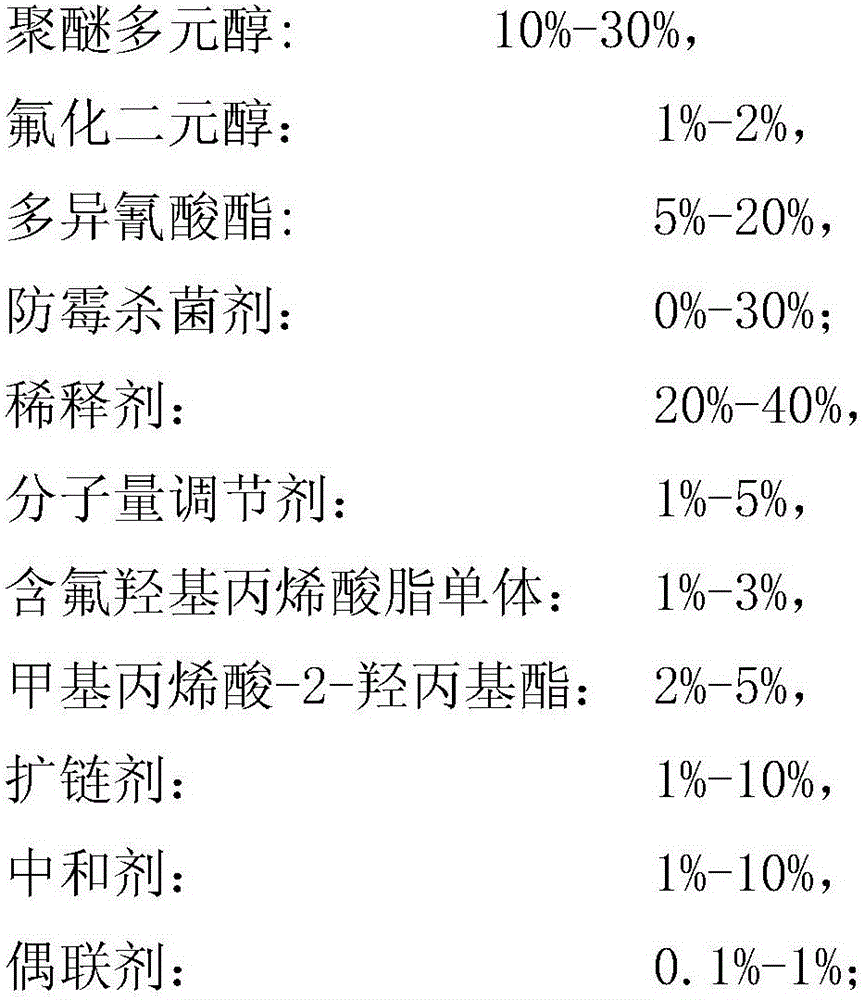

Normal-temperature cured water-based polyurethane and preparation method and application thereof

InactiveCN106188474AHigh water resistance and stain resistanceStrong adhesionAntifouling/underwater paintsPaints with biocidesDouble bondChemistry

The invention discloses normal-temperature cured water-based polyurethane and a preparation method and application thereof. The polyurethane is prepared from polyether polyol, fluoride glycol, polyisocyanate, anti-mildew bactericide dimethyl fumarate, diluent, molecular weight modifier, fluorine-containing hydroxyl acrylate monomer, methacrylic acid-2-hydroxypropyl ester, chain extender, neutralizer and coupling agent. By means of the addition polymerization mode of unsaturated double bond containing polyether polyol, polyalkoxy silicon base and fluorine-containing hydroxyl acrylate are chemically bonded into polyurethane chains, novel water-soluble polyurethane resin of a polyalkoxy silicon base fluoro modified acrylic resin-polyurethane interpenetrating polymer networks (IPN) structure is synthesized and is made to have the common advantages of water-based polyurethane paint and polyacrylate emulsion, and the polyurethane is cured at normal temperature, has oil resistance and stain resistance, is suitable for waterproof and anti-foul coating on surface layers of leather, plastic, wood, metal, external walls and the like, and is environmentally friendly, high in industrial practicability and high in economic benefit.

Owner:CHENGDU KAITE ORGANOSILICON NEW MATERIALS TECH

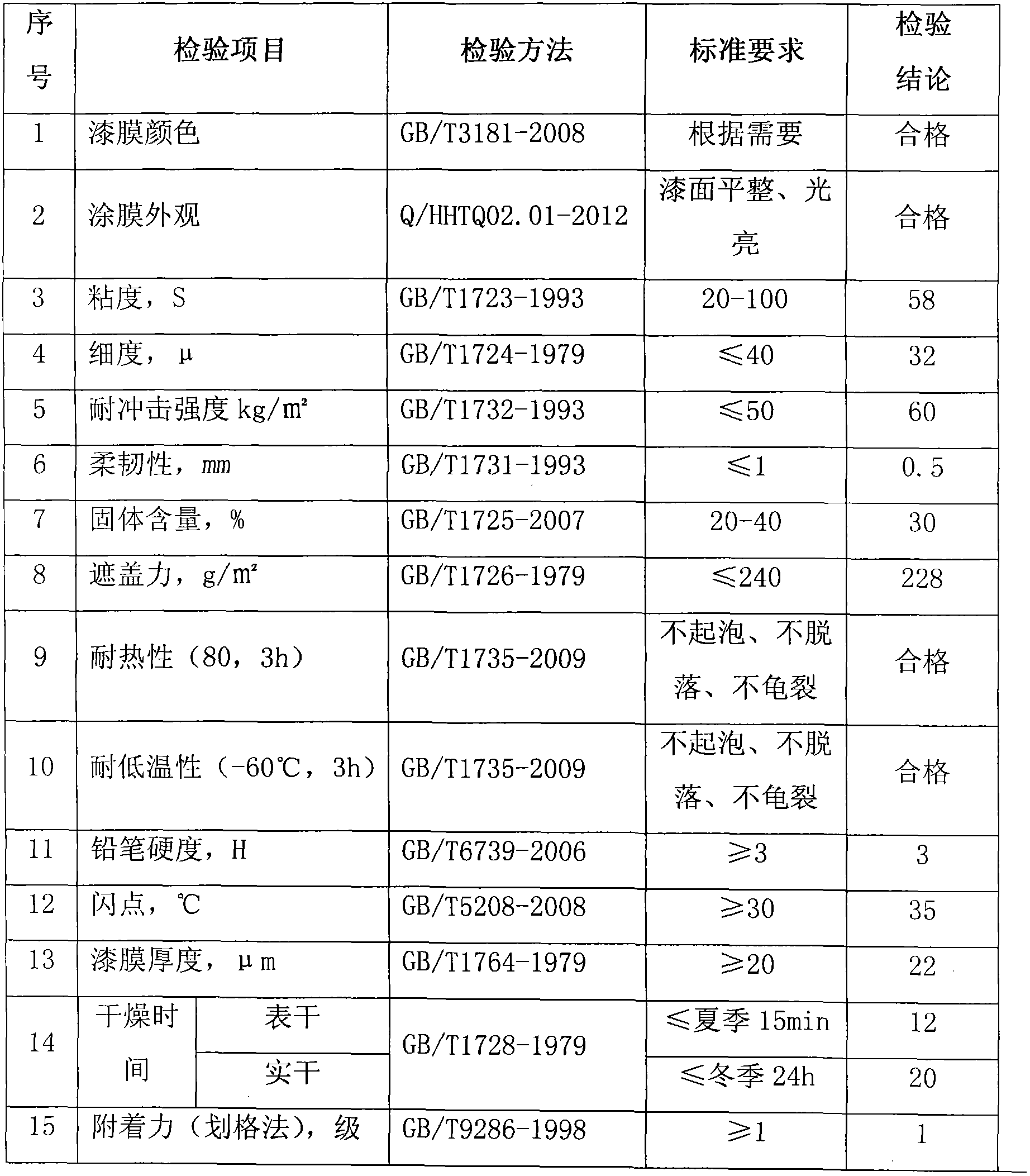

Specific anticorrosion paint for chemical equipment and production method thereof

InactiveCN104212258AEasy constructionLong storage periodAnti-corrosive paintsChemistryTritolyl Phosphates

The invention discloses specific anticorrosion paint for chemical equipment and a production method thereof. The specific anticorrosion paint comprises chlorosulfonated polyethylene, acrylic copolymeric resin, tritolyl phosphate, melamine-formaldehyde resin, titanium dioxide, n-butanol, ethyl acetate, butyl acetate, xylene and dibutyl phthalate. The production method comprises the following steps of adding chlorosulfonated polyethylene, acrylic copolymeric resin, tritolyl phosphate, melamine-formaldehyde resin and titanium dioxide into a dispenser, carrying out mixing stirring, taking the mixture, grinding the mixture until fineness is 20 microns, putting the ground mixture into the dispenser, adding ethyl acetate, butyl acetate, xylene, dibutyl phthalate and the n-butanol into the dispenser with stirring, carrying out full homogenization, putting the uniform mixture into a filter, carrying out filtration and carrying out packaging by a barrel. The production method has simple processes. The specific anticorrosion paint can be fast dried and has good electrochemical corrosion resistance and chemical corrosion resistance, good adhesion and a long service life. The specific anticorrosion paint can be widely used for modern petroleum chemical engineering and can be used for anti-corrosion coating of harshly corroded equipment such as devices for preparing alkali, acid and salt from natural gas.

Owner:HULUDAO HENGTONG SPECIAL PAINT

Waterproof paint with high corrosion resistance and adhesive property and preparation method of waterproof paint

InactiveCN104650721AUnique water resistanceIncrease elasticityAnti-corrosive paintsPolyvinyl alcoholPyrrolidinones

The invention discloses waterproof paint with high corrosion resistance and adhesive property. The waterproof paint is characterized in that the waterproof paint is prepared by the following raw material in parts by weight: 20-45 parts of organosilicon rubber emulsion, 3-5 parts of organosilicon waterproof agent, 4-7 parts of graphene prefabricated dispersoid, 0.1-0.6 part of emulsion-type defoaming agent, 4-6 parts of quartz powder, 3-6 parts of vinyl acetate, 2-3 parts of oxidized polyethlene wax, 1-2 parts of N-methyl-pyrrolidone, 0.3-0.6 part of polyvinyl alcohol, 6-9 parts of potash feldspar powder and 1-2 parts of ethylparaben. The waterproof paint has the advantages of unique water resistance, high elasticity and integrality, continuity in a paint film without any seam, leaking resistance, good cohesiveness to various construction base materials, low possibility of peeling, outstanding anticorrosion effect, good anti-ageing effect, high decoration property, good durability, etc.

Owner:安徽枞阳县渡江充气设备制造有限公司

Color modified waterproof coating

InactiveCN106433458AShorten drying timeGood extensibilityProtein coatingsMulticolor effect coatingsWeather resistanceThermal insulation

The invention discloses a color modified waterproof coating which is prepared by the following steps: grinding pigment and filler into powder by a ball milling way; sequentially adding the powder together with a film forming agent, a solvent and an auxiliary into a plastic tank; stirring for 8-10min till uniform mixing; stirring for 25-28min at a speed of 1,500rpm for full dispersion; adding a film forming agent and dispersing at a high speed for 3-5min to obtain a disperse system; adding a sodium hydroxide solution and adjusting the pH value to 7.5-8.5; and mixing uniformly to obtain the waterproof coating. In the invention, the film forming agent is modified to serve as an important raw material for preparing the coating disclosed by the invention, the tensile strength and film hardness are remarkably improved, and the prepared coating has good weather resistance and waterproof property under an indoor condition and has the effects of high-temperature resistance, thermal insulation and decoration; and the preparation process is simple.

Owner:南宁马瑞娜装饰工程有限公司

Wear-resistant scrub-resistant waterproof paint and preparation method thereof

InactiveCN104650728AUnique water resistanceIncrease elasticityCoatingsParaffin waxSodium carboxymethylcellulose

The invention discloses a wear-resistant scrub-resistant waterproof paint. The invention is characterized in that the waterproof paint is prepared from the following raw materials in parts by weight: 20-45 parts of organic silicon rubber emulsion, 3-8 parts of organosilicon waterproofing agent, 2-7 parts of graphene pre-dispersion, 0.1-0.6 part of emulsion-type defoaming agent, 0.1-0.6 part of sodium carboxymethyl cellulose, 5-8 parts of ceramic powder, 2-3 parts of hydrophobic paraffin, 3-4 parts of cellaburate solution, 6-8 parts of styrene-acrylic emulsion, 7-9 parts of quartz sand, 3-4 parts of aluminum nitride and 6-8 parts of magnesium silicate. The waterproof paint has the advantages of unique waterproof quality, high elasticity and high integrity. The coated film has the advantages of no seam, leakage resistance, favorable waterproof quality, high hardness, favorable wear resistance, stable chemical properties, high safety, environment friendliness, high aging resistance, high binding property, low shedding tendency and scrub resistance. The waterproof paint can be directly brushed, and is convenient to operate, thereby shortening the construction period and enhancing the work efficiency.

Owner:安徽枞阳县渡江充气设备制造有限公司

Waterproof coating with good flexible permeability and preparation method thereof

The invention discloses a waterproof coating with good flexible permeability. The waterproof coating is characterized by being prepared from the following raw materials in parts by weight: 20-45 parts of organic silicon rubber emulsions, 3-8 parts of organic silicon waterproof agents, 2-7 parts of graphene prefabricating dispersoid, 0.1-0.6 part of emulsion type deforming agents, 0.1-0.3 part of sodium carboxymethyl cellulose, 4-6 parts of C9 resin emulsion, 5-7 parts of glass microballoons, 2-4 parts of barium metaborate, 5-8 parts of precipitated barium sulfate, 1-2 parts of zinc stearate, 2-3 parts of sodium borate and 5-8 parts of silicon micropowder. The waterproof coating disclosed by the invention has the advantages of unique water resistance, high elasticity and integrity, good elongation percentage, low possibility in breakage generation, continuity in film coating without any joint, leakage resistance, and good adhesivity on various building base materials. The preparation method disclosed by the invention is simple, easy to operate and relatively low in production cost, and the adopted raw materials are easy to obtain; in addition, a produced coating has a good waterproof effect.

Owner:安徽枞阳县渡江充气设备制造有限公司

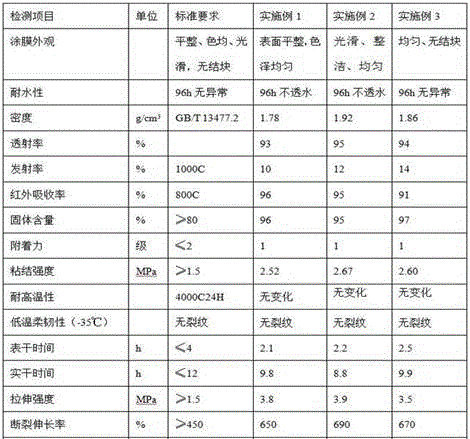

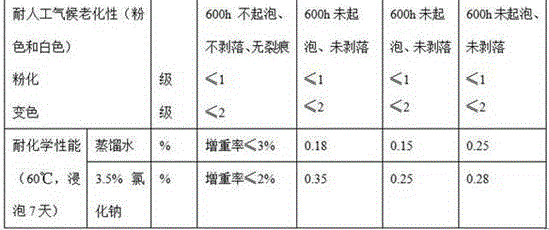

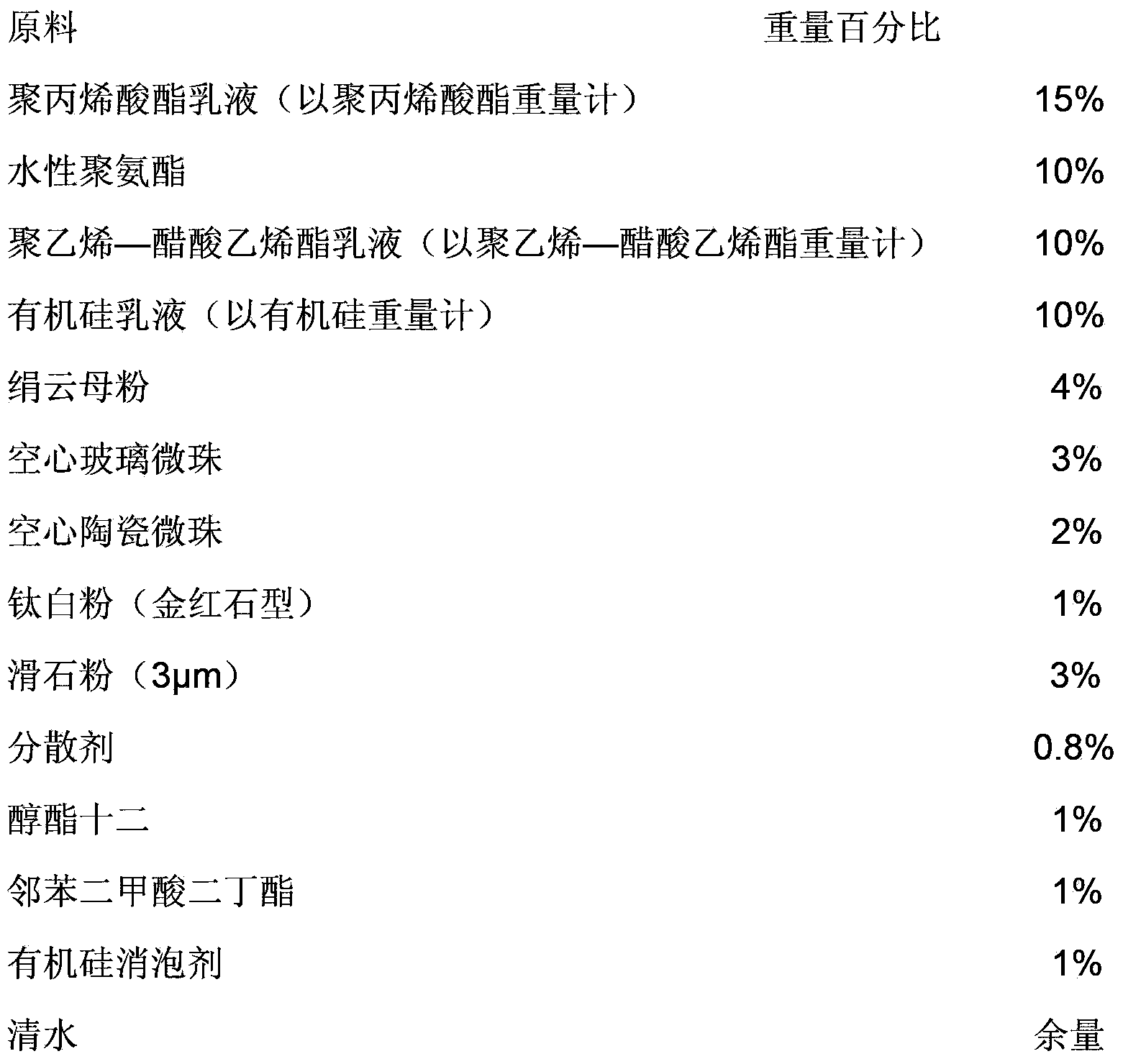

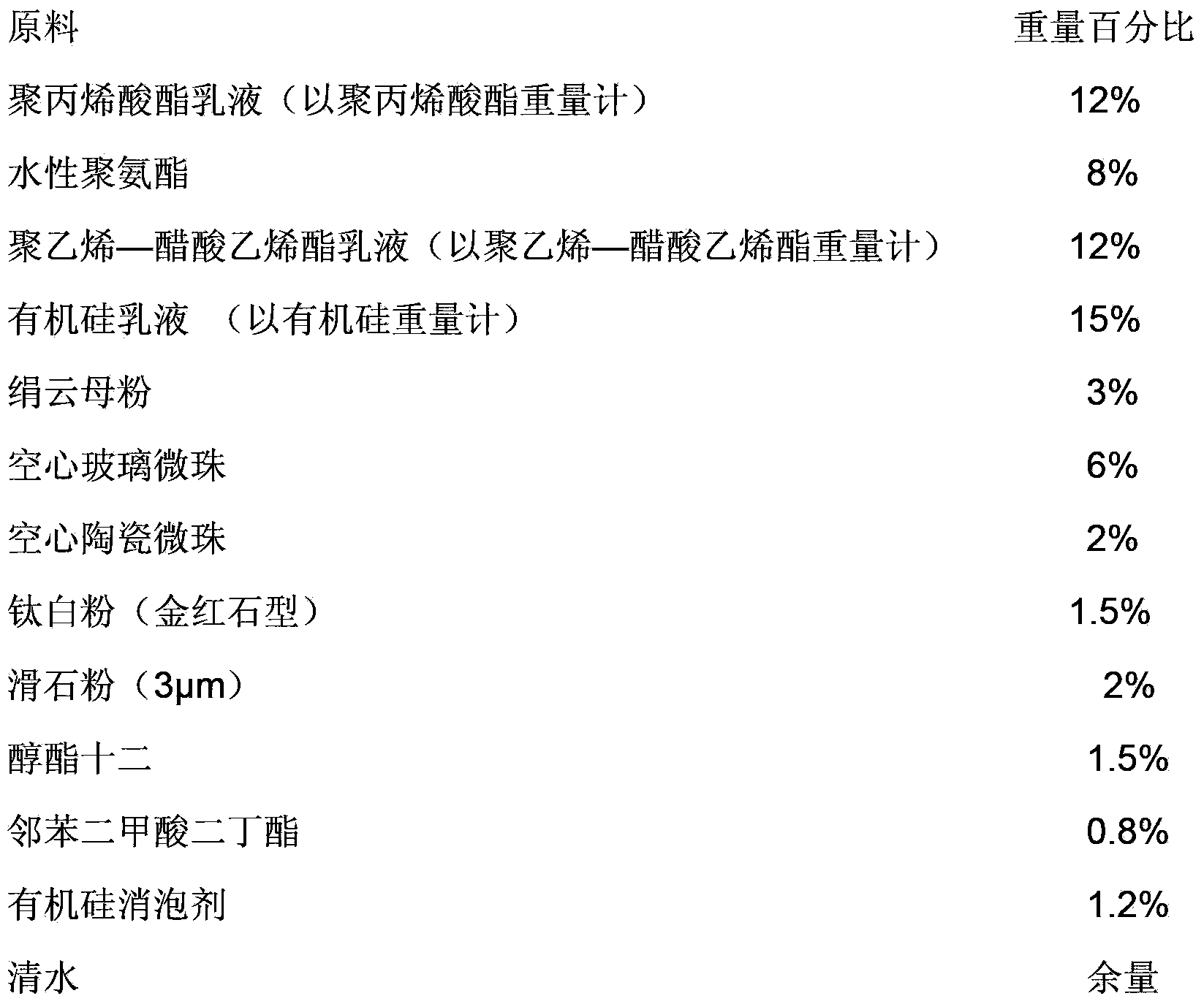

Environment-friendly scattering cooling macromolecular water-proof coating and preparation method thereof

InactiveCN104341935AUnique heat dissipation and cooling performanceUnique water resistancePolyurea/polyurethane coatingsPolyethylene vinyl acetatePolymer science

The invention provides an environment-friendly scattering cooling macromolecular water-proof coating and a preparation method thereof. The environment-friendly scattering cooling macromolecular water-proof coating comprises polyacrylic ester, waterborne polyurethane, an organic silicone emulsion and polyethylene-vinyl acetate serving as main film forming matters; water is taken as a solvent; and a filler, a dispersing agent and a plasticizer are added. The environment-friendly scattering cooling macromolecular water-proof coating has unique heat dissipation and cooling performance and water-proofing performance, is resistant to ultraviolet radiation and aging, and can be made into various colors as required; and the defect of single colors of other water-proof coatings are overcome. The environment-friendly scattering cooling macromolecular water-proof coating has high bonding strength, good water-proofing and anti-leakage effects, heat resistance, freezing resistance and high extension performance, is applied to cold construction, brushed directly, easy to operate, and suitable for water proofing and cooling of new and old roofs of various buildings, basements, bathrooms, grain depots, water conservation dams, oil depots, swinging pools, tunnels, roads and bridges, courses, construction joints, expansion joints and the like.

Owner:SHANGHAI LUJUN MATERIAL TECH CO LTD

Mildew-proof anti-static waterproof paint and preparation method thereof

InactiveCN104650723AUnique water resistanceGood lookingAntifouling/underwater paintsPaints with biocidesSodium carboxymethylcelluloseEmulsion

The invention discloses mildew-proof anti-static waterproof paint. The mildew-proof anti-static waterproof paint is characterized by being prepared from the following raw materials in parts by weight: 20-45 parts of organic silicone rubber emulsion, 3-5 parts of an organic silicon waterproof agent, 4-7 parts of graphene prefabricated dispersoid, 0.1-0.3 part of an emulsion type defoaming agent, 0.2-0.4 part of sodium carboxymethyl cellulose, 2-4 parts of carbon black, 5-7 parts of montmorillonite, 2-4 parts of dipropylene glycol, 2-3 parts of citrate, 10-14 parts of silica sol and 1-2 parts of sodium pentachlorophenate. The waterproof paint disclosed by the invention has the characteristics of unique water resistance, high elasticity and integrity, and a coating film is continuous and free of any joint and anti-leakage. The paint provided by the invention is good in appearance, good in caking property for various base materials of a building, stable in storage, good in heat resistance, freezing resistance and waterproof function, excellent in mildew-proof anti-static effect, and good in protection to an interior wall.

Owner:安徽枞阳县渡江充气设备制造有限公司

Anti-corrosion weather-proof waterproof paint

InactiveCN106497417AShorten drying timeGood extensibilityFireproof paintsAnti-corrosive paintsWeather resistanceFilm-forming agent

The invention discloses anti-corrosion weather-proof waterproof paint which is prepared from the following raw materials in parts by weight: 70 to 90 parts of film forming agent, 30 to 50 parts of solvent, 15 to 25 parts of coalescing agent, 10 to 20 parts of pigment filler and 10 to 30 parts of auxiliaries. A preparation method of the anti-corrosion weather-proof waterproof paint comprises the steps: grinding the pigment filler into powder in a ball milling mode; sequentially adding the pigment filler powder, the film forming agent, the solvent and the auxiliaries into a plastic tank; stirring for 8 to 10min until the materials are evenly mixed; stirring for 25 to 28min in a rotation speed of 1500r / min to fully disperse the materials; then adding the coalescing agent to disperse for 3 to 5min in a high speed to obtain a dispersion system; adding sodium hydroxide solution to adjust the pH value to 7.0 to 8.0; evenly mixing to obtain the anti-corrosion weather-proof waterproof paint. The tensile strength and the film hardness of the modified film forming agent are obviously improved, the paint which is prepared from the film forming agent matched with other ingredients has good weather resistance and waterproofness in the outdoor condition, also has the obvious effects of corrosion resistance and high temperature resistance and is simple in preparation process.

Owner:南宁马瑞娜装饰工程有限公司

Fluororubber-containing modified waterproof coating

InactiveCN107118629APrevent precipitationGood film forming effectCoatingsEnvironmental resistanceEnvironmentally friendly

The invention discloses a fluororubber-containing modified waterproof coating which is prepared from the following components in percentage by weight: 35-45 percent of fluororubber, 25-35 percent of a film forming agent, 2-5 percent of a natural surfactant, 10-15 percent of a high temperature improving agent, 10-15 percent of a filler, 6-9 percent of a flame retardant and 1-4 percent of a pH regulator. The invention also discloses a preparation method of the waterproof coating. The preparation method comprises the following steps: adding the fluororubber, the film forming agent, the natural surfactant and the flame retardant in a sealed reaction kettle, continuously adding the filler for reaction for 1-3h under the condition with the temperature being 80-100 DEG C, cooling to 40-50 DEG C, adding the pH regulator, and carrying out continuous reaction to obtain the fluororubber-containing modified waterproof coating. As for the fluororubber-containing modified waterproof coating, by using the fluororubber, the formation of the waterproof coating is promoted, the adhesion performance of the waterproof coating to an interface is improved, the waterproof effect is better, and the waterproof coating is safe and environmentally friendly to use and cannot bring negative effects.

Owner:阎玉珍

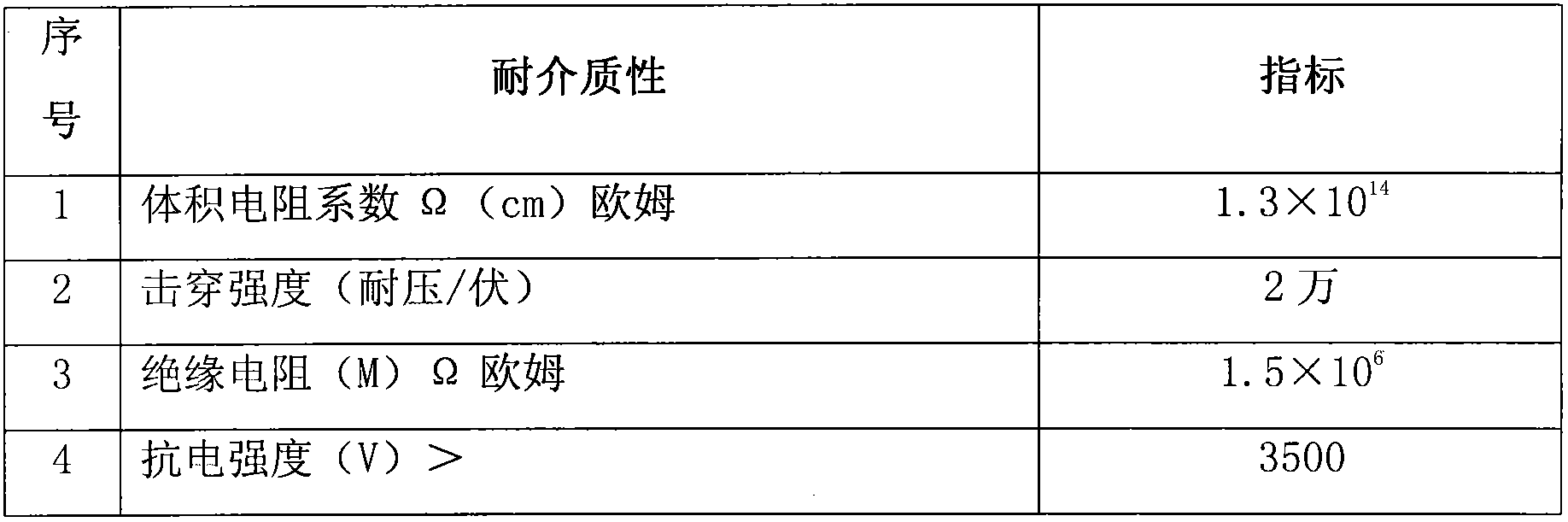

Chlorosulfonated polyethylene voltage-resistance and high-performance special anticorrosive paint and production method thereof

ActiveCN103013235ASimple production methodEasy constructionAnti-corrosive paintsPolyurea/polyurethane coatingsMicaTitanium

The invention discloses chlorosulfonated polyethylene voltage-resistance and high-performance special anticorrosive paint. The paint comprises chlorosulfonated polyethylene, acrylic polyurethane, high chlorinated potyethlene, dimethylbenzene, titanium white chloridization, phthalo blue, phthalo green, ironoxidered, ultramarine, o-xylene, mica sheet, zinc powder and the like. The production method comprises the following steps: ingredients are stirred, rolled and mixed; produced copolymerized grease adhesive tapes are prepared to copolymerized grease adhesive sheets by a slicer; and after being totally added in a reaction kettle to react for a certain time, all raw materials are filtered and packaged to obtain finished products after the inspection thereof is qualified. The product has the characteristics of easy production method, long anticorrosive protection period, unique performances of resisting ultraviolet rays, water, oil, cold, acid, alkali and salt, resistance to low temperature of -60 DEG C, resistance to voltage of 20,000 V, excellent insulation performance, excellent wear and impact resistance, good flexibility, strong adhesion and long service life. The paint is suitable for protective coating of facilities and equipment in various power industries.

Owner:HULUDAO HENGTONG SPECIAL PAINT

Stable waterproof coating material

The present invention discloses a stable waterproof coating material, which is prepared from the following raw materials by weight: 3.5-7.6 parts of a styrene-acrylate emulsion, 1.3-2.8 parts of mica titanium pearl powder, 1.5-2.6 parts of triethanolamine, 2.1-3.5 parts of tripropylene glycol diacrylate, 5-10 parts of deionized water, 2.3-3.5 parts of octylphenol polyoxyethylene ether, 1.5-2.8 parts of rosin-polythylene oxide ester, and 1.5-3.7 parts of sodium dodecyl benzene sulfonate. Compared with the existing waterproof coating material, the stable waterproof coating material of the present invention has characteristics of unique waterproof performance, stable chemical property, safety, environmental protection, corrosion resistance, direct coating and easy operation.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Diatom mud paint with self-repairing function and preparation method thereof

InactiveCN108587257AEasy self-repair operationWith self-healing functionCoatingsMicroballoon preparationStearic acidMaterials science

The invention relates to diatom mud paint with a self-repairing function and a preparation method thereof and belongs to the field of preparation of diatom mud paint. The preparation method comprises(1) encapsulating dispersible latex powder as a core material through stearic acid as a capsule wall to obtain microcapsules, and (2) uniformly mixing the microcapsules and diatom mud powder accordingto a weight ratio of 1: 7 to 10 to obtain the diatom mud paint having a self-repairing function. After use of the diatom mud paint with a self-repairing function, when the diatom mud is cracked or damaged, the damaged position is heated so that the diatom mud is self-repaired and the repaired diatom mud paint has high bonding ability and unique water resistance. The diatom mud paint can repair cracks or breakage of diatom mud during use and can increase the waterproofness and scrub resistance of diatom mud.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Waterproof coating prepared from pure acrylic emulsion

The invention provides a waterproof coating prepared from a pure acrylic emulsion. The waterproof coating is characterized by comprising the following components in parts by weight: 31-39 parts of pure acrylic emulsion, 9-13 parts of ethylene-vinyl acetate copolymer emulsion, 9-18 parts of ethylene glycol butyl ether, 7-13 parts of xylene and 4-12 parts of ethyl acetate. The waterproof coating has unique waterproof property, stable chemical properties and certain corrosion resistance, is safe and environment-friendly, is directly applied and is convenient to operate.

Owner:南通优尼科化工有限公司

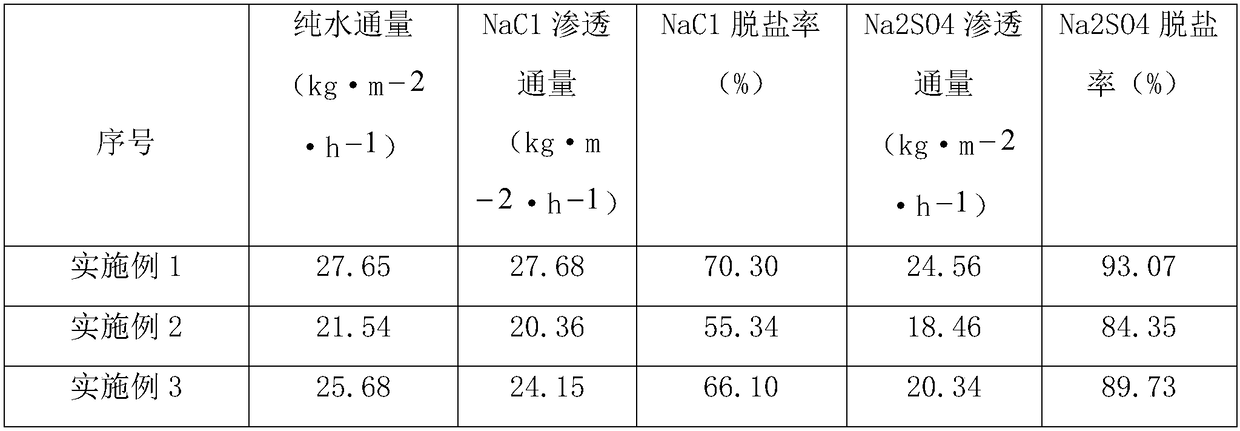

Preparation method of graphene macromoleclar polymer composite nanofiltration membrane

InactiveCN108525533AImprove adsorption capacityImprove purification effectSemi-permeable membranesMembranesUltrafiltrationFiltration

The invention discloses a preparation method of a graphene macromoleclar polymer composite nanofiltration membrane. The method includes: taking an ultrafiltration membrane as the base membrane, coating the base membrane with a layer of 0.3-0.5mm thick cationic polyacrylamide and graphene solution mixed liquid by solution coating method, and putting the product in a 60-80DEG C oven for crosslinkingfor 0.5-3h, thus obtaining the graphene macromoleclar polymer composite nanofiltration membrane. The graphene macromoleclar polymer composite nanofiltration membrane has excellent adsorbability, low temperature far infrared, bacteriostasis, ultraviolet resistance and other functions, the macromoleclar polymer cationic polyacrylamide has filtration promoting, clarification and settling promoting effects, and can promote the purification and filtration ability of the nanofiltration membrane, by adding the cationic polyacrylamide, a quaternary ammonium salt cationic group is introduced to the nanofiltration membrane surface, thus increasing the hydrophilicity and selectivity of the membrane, by adding graphene and the macromoleclar polymer, the prepared graphene macromoleclar polymer composite nanofiltration membrane ha significantly improved performance, good selective separation ability, and significantly improved Na2SO4 rejection rate and NaCl rejection rate.

Owner:JIMEI UNIV

A high-strength refractory insulation material

The invention discloses a high-strength fire-resistant thermal insulation material. A preparation method of the high-strength fire-resistant thermal insulation material comprises the following steps: preparing a shaped product with the required size by using expanded vermiculite, clay, refractory cement and dextrin as initial materials and adding a waterproof agent and a binding agent in a mechanical pressing forming manner, wherein a nano-modification organic silicon rubber solution is used as the waterproof agent, and the binding agent is an inorganic binding agent, drying, carrying out heat preservation, and baking at a high temperature, thus obtaining the high-strength fire-resistant thermal insulation material. The high-strength fire-resistant thermal insulation material has the advantages of good structure and volume stability, high strength, low cost, simple process, convenience for construction and baking, environmental protection, safety and the like.

Owner:内蒙古包钢利尔高温材料有限公司

Waterproof paint for architectural roofing waterproof layer

InactiveCN104119749AUnique water resistanceStable chemical propertiesCoatingsSodium PyrithioneGlycol methacrylate

The invention discloses a waterproof paint for an architectural roofing waterproof layer, which is prepared from the following raw materials in parts by weight: 62-70 parts of pure acrylic emulsion, 0.8-2 parts of sodium disulfhydrylpropylsulfonate, 0.1-0.3 part of butylated hydroxyanisole, 1-2 parts of ethylene glycol dimethacrylate, 0.2-0.4 part of zinc pyrithione, 0.6-1 part of zirconium silicate, 1-3 parts of polyethyleneglycol 1000, 3-5 parts of graphite powder, 6-10 parts of titanium white, 1-2 parts of diisopropyl ethanolamine, 1-2 parts of 1,4-cyclohexanedimethanol, 5-8 parts of film formation assistant and 10-20 parts of deionized water. The waterproof paint has the advantages of unique waterproof property, stable chemical properties, high safety, environment friendliness and favorable abrasion resistance, can prevent puncture destroy to some extent, has certain corrosion resistance, can be directly brushed, and is convenient to operate.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

High-viscosity environment-friendly waterproof coating

InactiveCN106497180AImproves water resistance and wet rub resistanceImproves elongation and flex resistanceFireproof paintsSolventAmmonium hydroxide

The invention discloses a high-viscosity environment-friendly waterproof coating. The high-viscosity environment-friendly waterproof coating is prepared from the following raw materials in parts by weight: 80 to 100 parts of film-forming agent, 40 to 50 parts of solvent, 10 to 15 parts of film-forming additives, 15 to 25 parts of pigment filler, and 15 to 30 parts of additives. A preparation method comprises the following steps: successively adding the film-forming agent, the solvent and the additives into a plastic tank, stirring for 8 to 10 minutes until all materials are uniformly mixed, stirring for 25 to 28 minutes at a rotation speed of 1500 r / min, sufficiently dispersing the materials, then adding the film-forming additives, dispersing for 3 to 5 minutes at high speed to obtain a dispersion system, adding a mixed solvent of acetone and ethyl acetate in a mass ratio of 1 to 1 to adjust the viscosity, finally adding an ammonium hydroxide solution to adjust a pH value to be 7.5 to 8.5, and uniformly mixing, thus obtaining the high-viscosity environment-friendly waterproof coating. The film-forming agent is modified to be used as an important raw material of the coating provided by the invention, so that the tensile strength, the coating film hardness and the viscosity are remarkably improved, and the prepared coating is not only good in weather and water resistance in outdoor conditions, but also remarkable in anticorrosion and high-temperature-resistant effects, and is non-toxic and pollution-free.

Owner:南宁马瑞娜装饰工程有限公司

Novel waterproof coating

ActiveCN103602237AUnique waterproof performanceStable chemical propertiesPolyether coatingsPolycarbonate coatingsChemistryTriethanolamine

The invention discloses a novel waterproof coating prepared from the following raw materials in parts by weight: 3.5-7.6 parts of sodium hypochlorite, 1.3-2.8 parts of mica titanium pearl powder, 1.5-2.6 parts of triethanolamine, 2.1-3.5 parts of tripropylene glycol diacrylate, 5-10 parts of deionized water, 2.3-3.5 parts of octylphenol polyoxyethylene ether, 1.5-2.8 parts of rosin-polythylene oxide ester and 1.5-3.7 parts of aliphatic polycarbonate polyol. Compared with the traditional waterproof coating, the novel waterproof coating has unique water resistance, stable chemical performance and certain corrosion resistance and is safe, environment-friendly and convenient to operate because of being directly coated.

Owner:中山爱因新材料有限公司

Water-based resin for waterproof oil paint and its preparation method and application

ActiveCN110028847BUnique water resistanceImprove water resistanceArtist's paintsAlkylphenolMethacrylate methyl

The invention relates to a water-based resin for waterproof oil paint and a preparation method thereof. The water-based resin of the present invention is made of water, alkylphenol polyoxyethylene ether, sodium lauryl sulfate, polyacrylamide, styrene, butyl acrylate, methyl methacrylate, acrylic acid, ammonium persulfate, and ammonia solution . The preparation method of the resin is as follows: adding alkylphenol polyoxyethylene ether, sodium lauryl sulfate, polyacrylamide, ammonium persulfate and water in sequence to the reaction vessel, stirring and dissolving, and then adding styrene and butyl acrylate in sequence Ester, methyl methacrylate and acrylic acid are synthesized after being stirred and emulsified for 20-40 minutes. The emulsion back-drop method is adopted in the synthesis process. After the reaction is completed, ammonia water is added to adjust the pH value to obtain the water-based resin. When the resin is used in oil paints, oil paints with good water resistance and scrub resistance can be obtained. Because the chemical heat energy generated by the reaction is fully utilized, it belongs to the energy-saving and environment-friendly oil paint waterproof resin.

Owner:北京勇搏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com