Environment-friendly scattering cooling macromolecular water-proof coating and preparation method thereof

A polymer waterproof and environment-friendly technology, applied in the field of architectural coatings, can solve the problems of high construction requirements, thick coating, poor stain resistance, etc., achieve high bonding strength, overcome single color, waterproof and anti- good penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

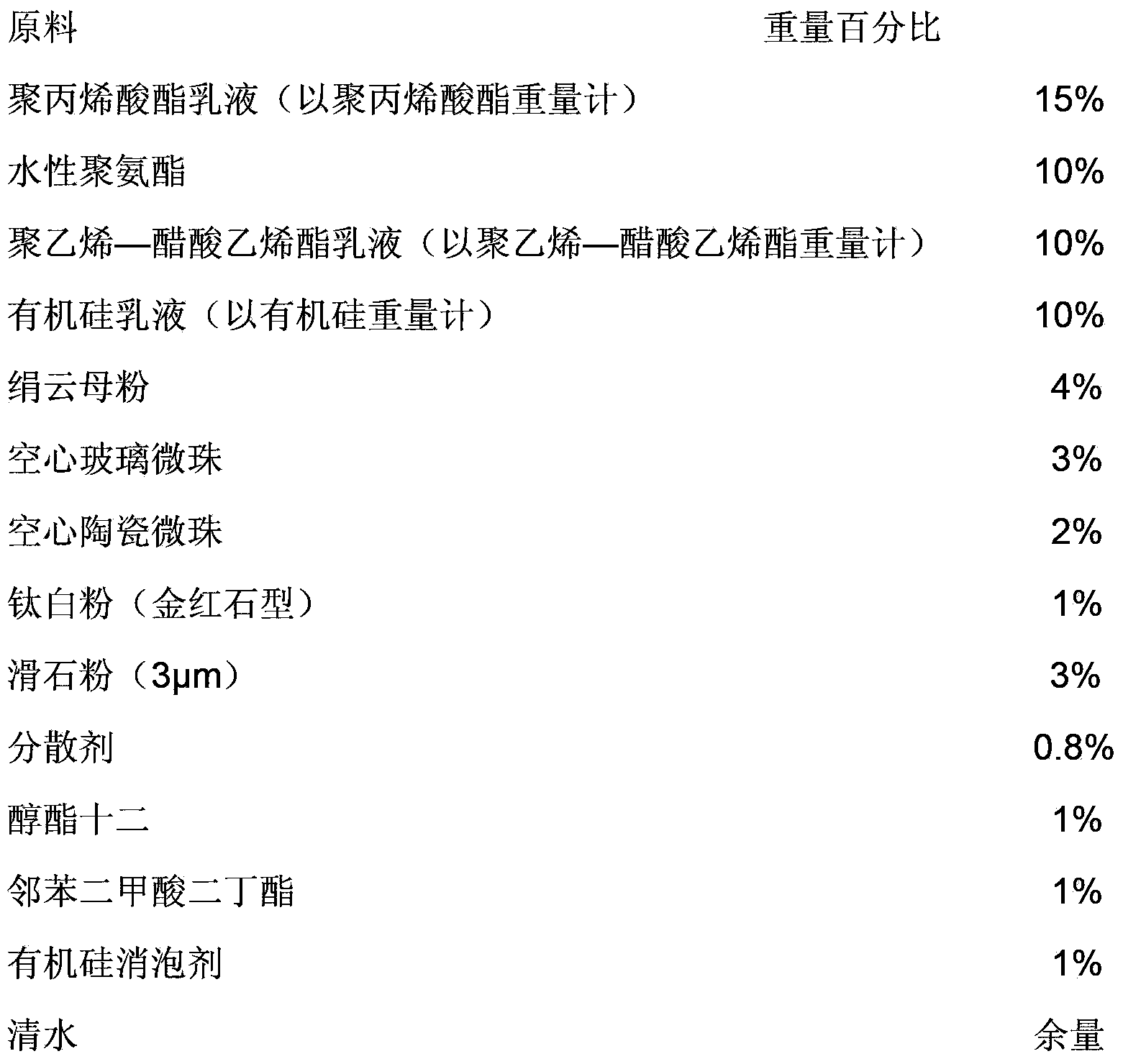

Embodiment 1

[0026]

[0027] Production steps:

[0028] Step 1, add polymer emulsion polyacrylate emulsion, water-based polyurethane, polyethylene-vinyl acetate emulsion and silicone emulsion into a high-speed stirring disperser and stir for 10 minutes;

[0029] Step 2, add dispersant, one-third of defoamer and two-thirds of water and stir for about 30 minutes;

[0030] Step 3, add titanium dioxide, talcum powder, sericite powder and one-third of the defoamer, and stir at high speed for 25 minutes;

[0031] Step 4, adding hollow glass microspheres, hollow ceramic microspheres, film-forming aids and remaining defoamer, stirring at low speed for 50 minutes;

[0032] Step 5, add the remaining water and plasticizer to a high-speed disperser to disperse evenly, and finally go through a colloid mill until the particle size is less than 20 microns.

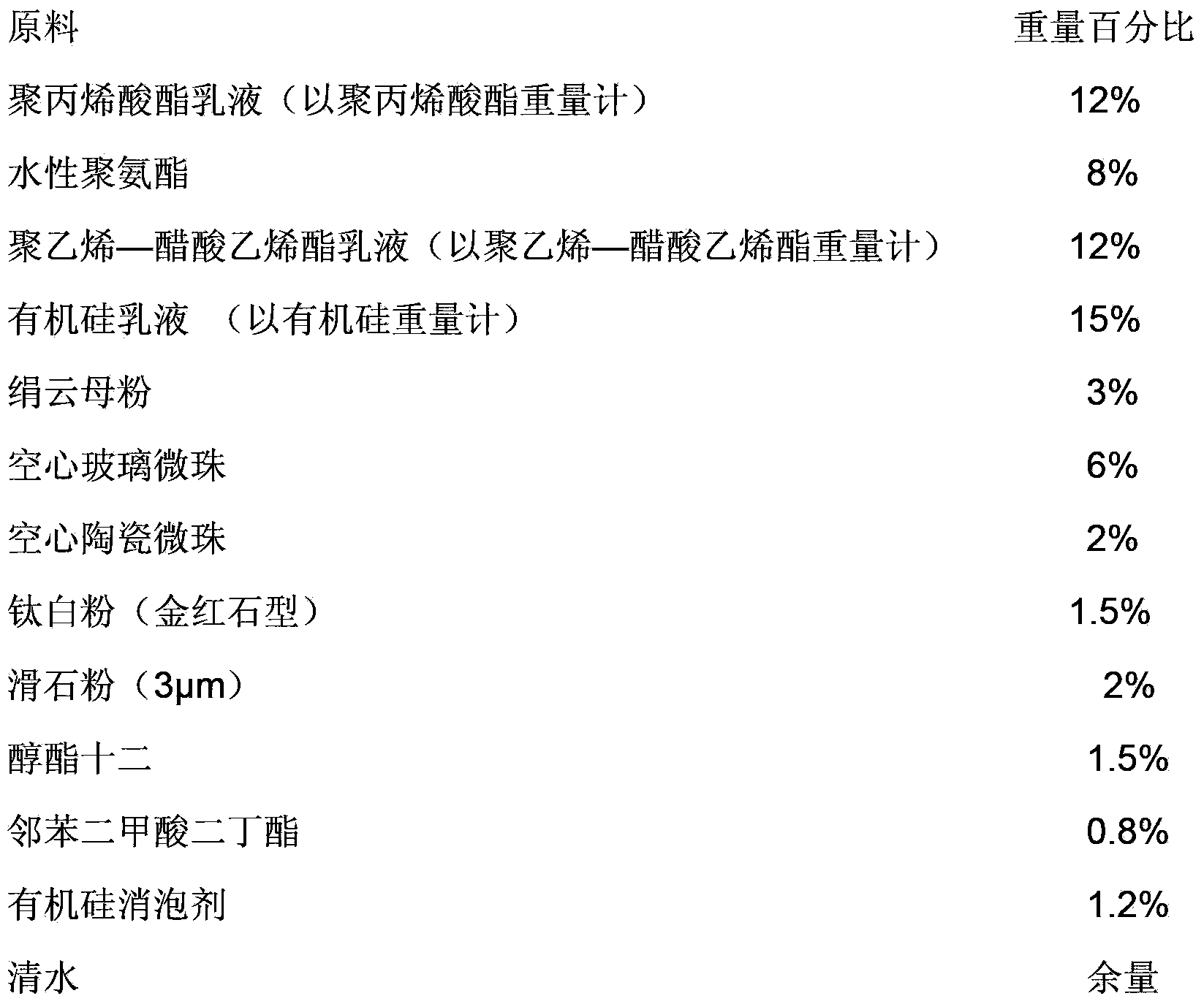

Embodiment 2

[0034]

[0035] Production steps:

[0036] Step 1, adding polymer emulsion polyacrylate emulsion, water-based polyurethane, polyethylene-vinyl acetate emulsion and silicone emulsion into a high-speed stirring disperser and stirring for 8 minutes;

[0037] Step 2, add dispersant, one-third of defoamer and two-thirds of water and stir for about 25 minutes;

[0038] Step 3, add titanium dioxide, talcum powder, sericite powder and one-third of the defoamer, and stir at high speed for 30 minutes;

[0039] Step 4, adding hollow glass microspheres, hollow ceramic microspheres, film-forming aids and remaining defoamer, stirring at low speed for 55 minutes;

[0040] Step 5, add the remaining water and plasticizer to a high-speed disperser to disperse evenly, and finally go through a colloid mill until the particle size is less than 20 microns.

Embodiment 3

[0042]

[0043]

[0044] Production steps:

[0045] Step 1, add polymer emulsion polyacrylate emulsion, water-based polyurethane, polyethylene-vinyl acetate emulsion and silicone emulsion into a high-speed stirring disperser and stir for 12 minutes;

[0046] Step 2, add dispersant, one-third of defoamer and two-thirds of water and stir for about 35 minutes;

[0047] Step 3, add titanium dioxide, talcum powder, sericite powder and one-third of the defoamer, and stir at high speed for 20 minutes;

[0048] Step 4, adding hollow glass microspheres, hollow ceramic microspheres, film-forming aids and remaining defoamer, stirring at low speed for 45 minutes;

[0049] Step 5, add the remaining water and plasticizer to a high-speed disperser to disperse evenly, and finally go through a colloid mill until the particle size is less than 20 microns.

[0050]The invention has unique heat dissipation and cooling performance, waterproof performance, resistance to ultraviolet radiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com