Magnetic-control dynamic ciliary bionic photocatalytic array and preparation method thereof

A ciliated, photocatalytic technology, applied in the field of photocatalysis, can solve the problems of reducing the catalytic activity of photocatalytic films, the limitation of photocatalytic reaction mass transfer, and the inability to degrade pollutants, so as to improve the absorption and utilization efficiency, improve the photocatalytic efficiency, The effect of high photocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

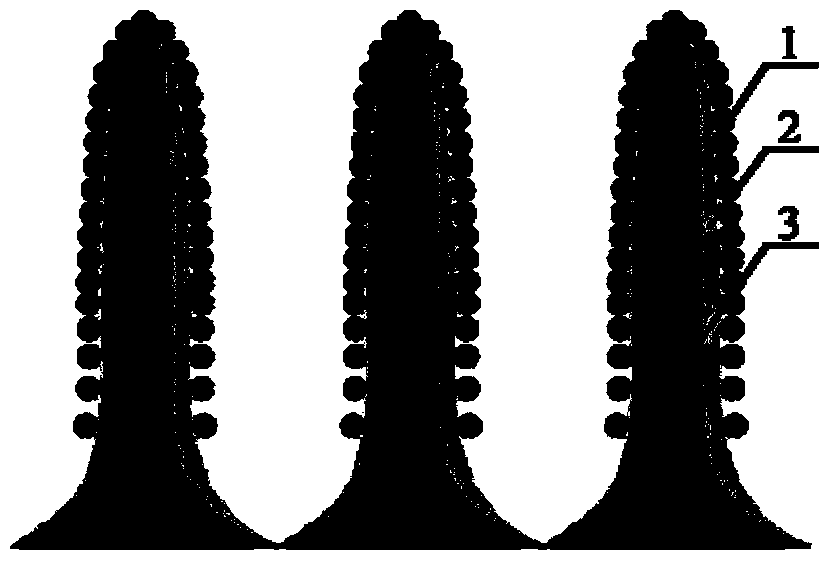

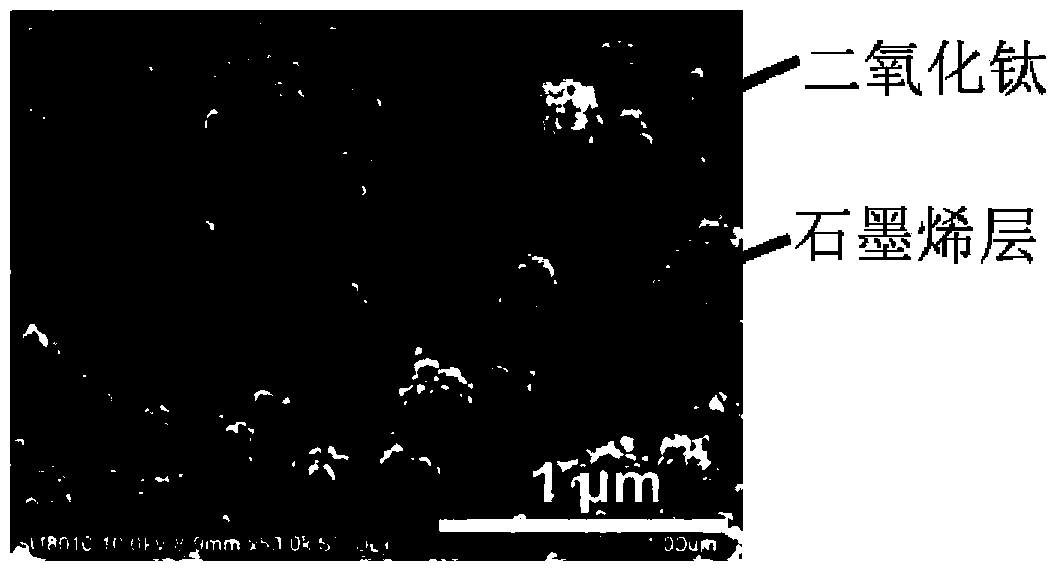

[0038] Add 0.15g of Co magnetic powder and 3g of silicone resin into 6.4g of solvent xylene, disperse with 180W ultrasonic for 5min, then disperse at 1500r / min for 60min, add 0.3g of hydroxyl hydrogen-containing silicone oil, and continue to disperse for 10min to obtain magnetic polymer suspension. The magnetic polymer suspension was injected into a 20×20×2mm polytetrafluoroethylene mold, and quickly placed in a uniform vertical magnetic field of 6000Gs, and cured at 60°C for 4 hours to obtain a 2mm cilia-like biomimetic array structure. Adjust the glow plasma voltage and current to 125V and 2A, respectively, to treat the sample for 5 minutes, and rinse it twice with absolute ethanol. Submerge the ciliated biomimetic array after plasma treatment in 0.02mg / mL carboxylated graphene aqueous solution, after soaking for 30s, pull out the array at a pulling speed of 6cm / min, place it in a vertical magnetic field of 15000Gs, and bake it at 70°C Dry, this process cycled 4 times to ob...

Embodiment 2

[0040] Add 0.12g of Fe magnetic powder and 3g of silicone resin into 6.4g of solvent xylene, and disperse with 150W ultrasonic for 5min. Then add, and then disperse at 1200r / min for 70min, then add 0.3g of hydroxyl hydrogen-containing silicone oil, and continue to disperse for 10min to obtain a magnetic polymer suspension. The magnetic polymer suspension was injected into a glass mold of 30×30×4mm, and quickly placed in a uniform vertical magnetic field of 10000Gs, and cured at 80°C for 4 hours to obtain a 4mm cilia-like biomimetic array structure. A 14W 180nm ultraviolet lamp was used to irradiate the biomimetic cilia-like array for 24h to carry out surface organic modification. The modified cilia-like biomimetic array was immersed in 0.04mg / mL carboxylated graphene aqueous solution. After soaking for 40s, the array was pulled out at a pulling speed of 3cm / min, placed in a vertical magnetic field of 17000Gs, and baked at 70°C. Dry, this process cycled 2 times to obtain the a...

Embodiment 3

[0042] Add 0.12g of Co magnetic powder and 3.5g of silicone resin into 7.0g of solvent xylene, and disperse with 200W ultrasonic for 8min. Then disperse at 1000r / min for 60min, add 0.3g of hydroxyl hydrogen-containing silicone oil, and continue to disperse for 10min to obtain a magnetic polymer suspension. The magnetic polymer suspension was injected into a 30×20×1mm polytetrafluoroethylene mold, and quickly placed in a uniform vertical magnetic field of 8000Gs, and cured at 70°C for 6 hours to obtain a cilia-like biomimetic array with a height of 1mm. Adjust the glow plasma voltage and current to 100V and 1.5A, respectively, to treat the sample for 10 minutes, and rinse it twice with absolute ethanol. Immerse the plasma-treated cilia-like biomimetic array in 0.01 mg / mL carboxylated graphene aqueous solution. After soaking for 20 s, the array was pulled out at a pulling speed of 2 cm / min, placed in a vertical magnetic field of 20000 Gs, and baked at 80 ° C. Dry, this process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com