Micro-fluidic chip and method for studying effect of fluid shearing force on cell with the micro-fluidic chip

A microfluidic chip, fluid shear force technology, applied in the field of biomedical research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

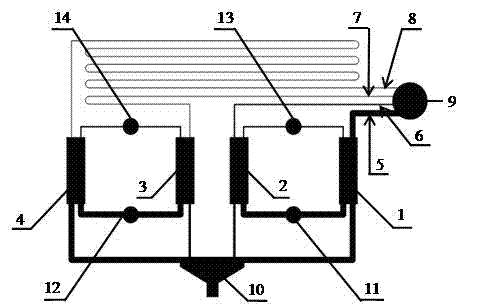

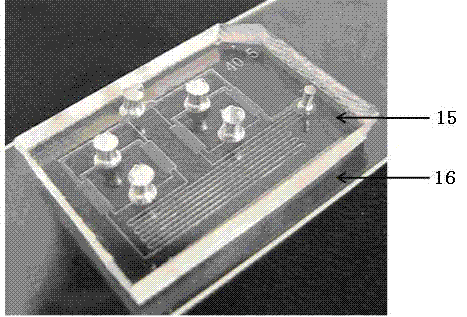

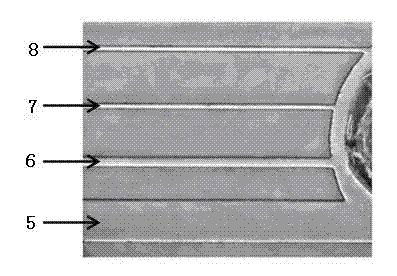

[0025] A microfluidic chip, the specific structure is as figure 1 As shown, its actual figure is shown in figure 2 As shown, the upper material of the chip is PDMS polymer, which is sealed to the lower glass surface by irreversible sealing technology, mainly composed of cell culture pool a 1, cell culture pool b 2, cell culture pool c 3, cell culture pool d 4 and The fluid channel a 5, the fluid channel b 6, the fluid channel c 7, the fluid channel d 8, the culture fluid sampling port 9 and the waste liquid pool 10; the fluid channel a 5, the fluid channel b 6, the fluid channel c 7 and The fluid channel d 8 starts from the culture solution inlet 9 together, and the ends of the above four fluid channels are respectively connected to the cell culture pool a 1, the cell culture pool b 2, the cell culture pool c 3, and the cell culture pool d 4 in sequence , and cell culture pool a 1, cell culture pool b 2, cell culture pool c 3 and cell culture pool d 4 are connected to the s...

Embodiment 2

[0027] Using the microfluidic chip in Example 1, connect the microsyringe pump to the culture solution inlet, perform perfusion of the culture solution at a flow rate of 0.08 μl / min, and measure the flow field distribution in the cell culture pool of the above-mentioned microfluidic chip , the flow fields in the four cell culture pools (1) cell culture pool a, (2) cell culture pool b, (3) cell culture pool c, and (4) cell culture pool d are evenly distributed, see Figure 4 .

Embodiment 3

[0029] Using the microfluidic chip in Example 1, connect the microsyringe pump to the culture solution inlet, and perfuse the culture solution at a flow rate of 0.08 μl / min, and measure the fluid shear in different cell culture pools of the above microfluidic chip The size of the force, in which (1) cell culture pool a, (2) cell culture pool b, (3) cell culture pool c, (4) cell culture pool d, the fluid shear force in cell culture pool a is far greater than The ratio of fluid shear force in cell culture pools b, c, and d is about 1:5:25:125, see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com