Preparation method of drilling fluid shearing enhancer

A cutting agent and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased drilling fluid workload, unstable drilling fluid performance, damage to oil and gas layers, etc., and achieve formation inhibition Effects of collapse and fracture, improvement of biodegradability, and balance of formation water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

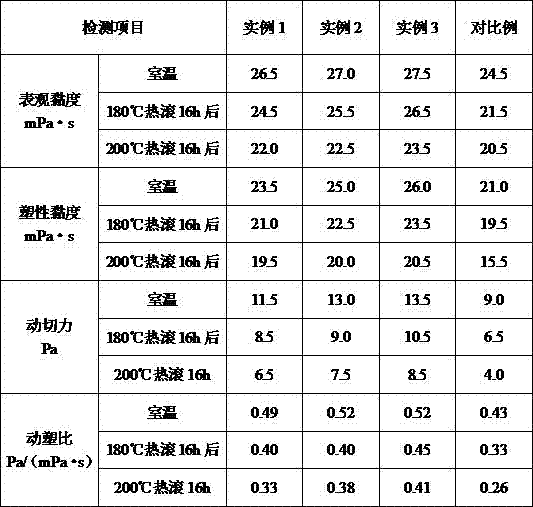

Examples

preparation example Construction

[0021] Catalyst preparation: mix platinum and Raney nickel at a mass ratio of 1:1.

[0022] Preparation of crosslinking agent: Mix glutaraldehyde and diethylenetriamine at a mass ratio of 3:1.

[0023] Choice of emulsifier: any one of fatty acid polyoxyethylene ester and alkylphenol polyoxyethylene ether.

[0024] The initiator is selected as dicumyl peroxide.

[0025] The auxiliary agent is sodium dodecylsulfonate.

[0026] The preparation method of drilling fluid cutting agent of the present invention comprises the following steps:

[0027] (1) According to the mass ratio of 4~6:8~10:3~5:7~9, put methyl methacrylate, ethylene glycol, butyl acrylate and propylene oxide into the reactor, and use hydrogen oxidation Adjust the pH to 8.5-9.0 with sodium solution, then add zinc stearate with 0.6-0.9% ethylene glycol mass, use nitrogen protection, and react at 95-105°C for 4-9 hours;

[0028] (2) After the reaction, cool to room temperature, add chitosan and vinyltrimethoxysila...

example 1

[0032] Catalyst preparation: mix platinum and Raney nickel at a mass ratio of 1:1.

[0033] Preparation of crosslinking agent: Mix glutaraldehyde and diethylenetriamine at a mass ratio of 3:1.

[0034] Choice of emulsifier: any one of fatty acid polyoxyethylene ester and alkylphenol polyoxyethylene ether.

[0035] The preparation method of drilling fluid cutting agent of the present invention comprises the following steps:

[0036] (1) According to the mass ratio of 4:8:3:7, put methyl methacrylate, ethylene glycol, butyl acrylate and propylene oxide into the reactor, use sodium hydroxide solution to adjust the pH to 8.5, and then Add zinc stearate with 0.6% ethylene glycol mass, use nitrogen protection, and react at 95°C for 4 hours;

[0037] (2) After the reaction, cool to room temperature, add chitosan and vinyltrimethoxysilane, the mass ratio of chitosan and vinyltrimethoxysilane is 3:2, and the mass of chitosan is ethylene di 35% of the mass of alcohol, mix well, let s...

example 2

[0041] Catalyst preparation: mix platinum and Raney nickel at a mass ratio of 1:1.

[0042] Preparation of crosslinking agent: Mix glutaraldehyde and diethylenetriamine at a mass ratio of 3:1.

[0043] Choice of emulsifier: any one of fatty acid polyoxyethylene ester and alkylphenol polyoxyethylene ether.

[0044] The initiator is selected as dicumyl peroxide.

[0045] The preparation method of drilling fluid cutting agent of the present invention comprises the following steps:

[0046] (1) According to the mass ratio of 5:9:4:8, put methyl methacrylate, ethylene glycol, butyl acrylate and propylene oxide into the reactor, use sodium hydroxide solution to adjust the pH to 8.8, and then Add zinc stearate with 0.8% ethylene glycol mass, use nitrogen protection, and react at 100°C for 7 hours;

[0047](2) After the reaction, cool to room temperature, add chitosan and vinyltrimethoxysilane, the mass ratio of chitosan and vinyltrimethoxysilane is 3:2, and the mass of chitosan is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com