Double-cone dynamic mixer

A dynamic mixer and double-cone technology, applied in the field of mechanical mixing device design, can solve the problems of limited number of mixing sheets, small number of divisions, fluid shearing, unsatisfactory mixing effect, etc., so as to achieve no flow dead angle, Improve the mixing of fluids, improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

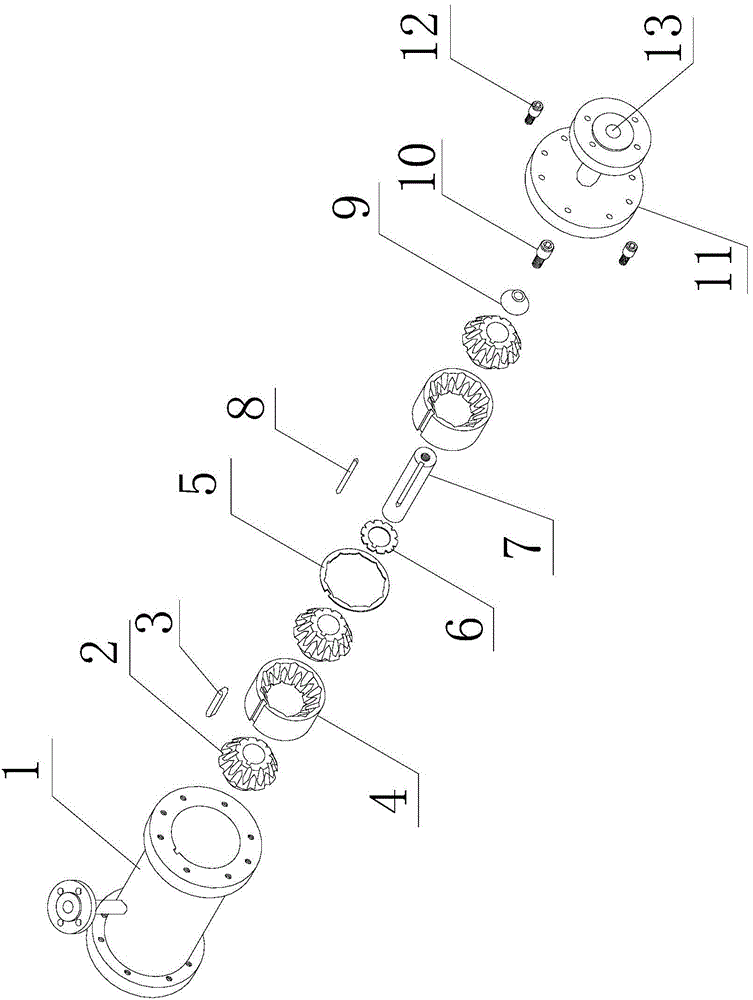

[0045] The present invention will be further described below in conjunction with accompanying drawing:

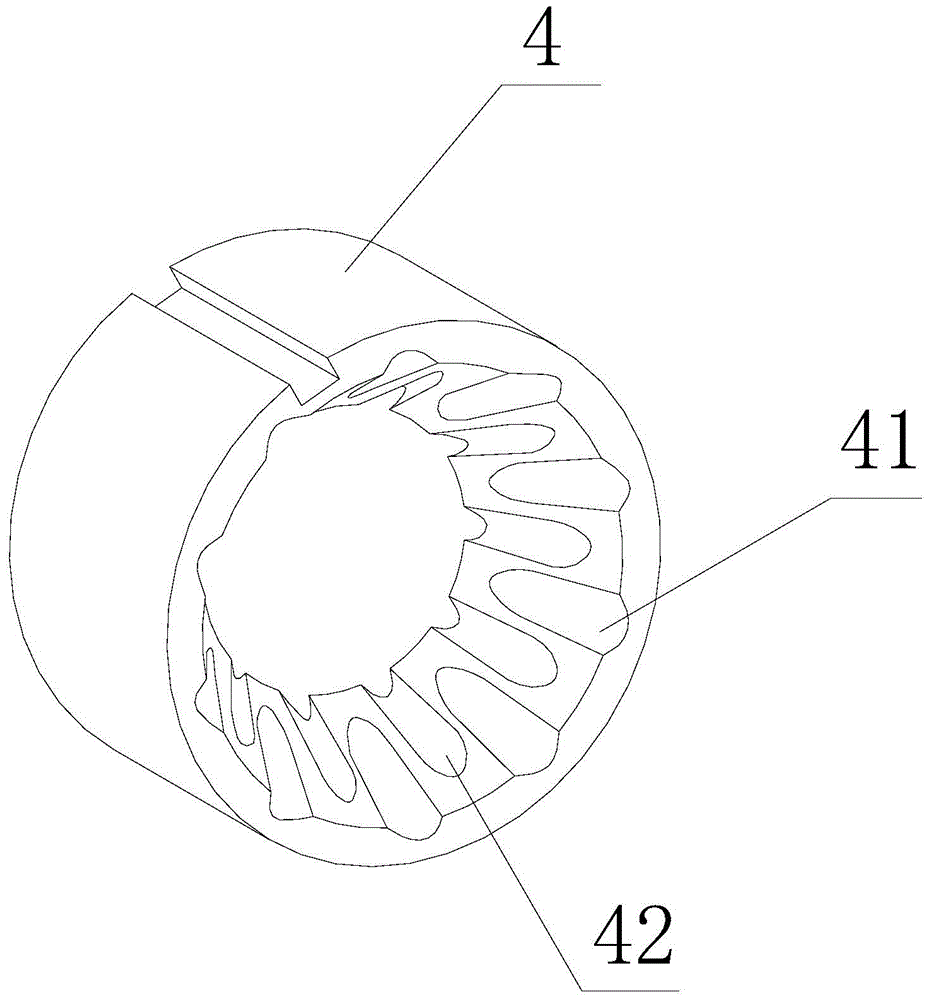

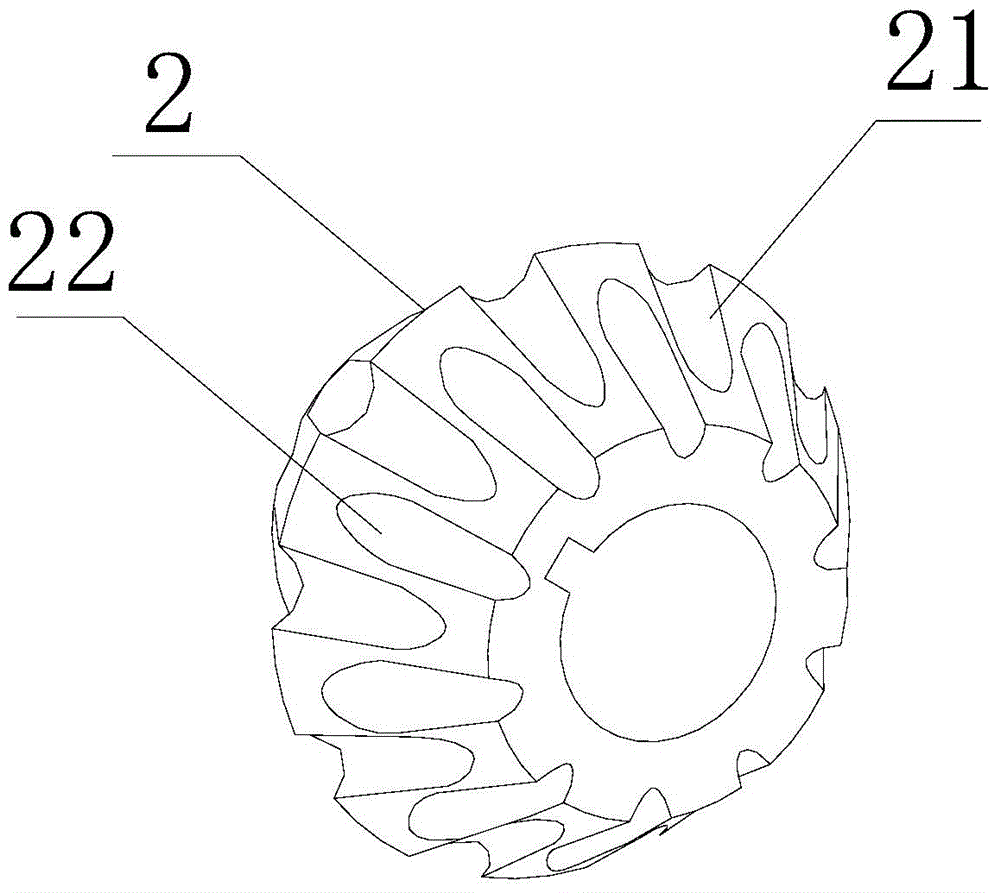

[0046] Such as Figure 1-3 Shown: a double-cone dynamic mixer, including a mixing chamber 1 with a feed inlet and a discharge outlet, the mixing chamber 1 is provided with a rotating shaft 7, coaxial with the rotating shaft 7 is provided with a static piece 4 and A moving piece 2; a static piece adjusting piece 5 is provided between two adjacent static pieces 4, and a moving piece adjusting piece 6 is arranged between two adjacent moving pieces 2. The rotary shaft 7 in the mixer is driven by a geared motor, and the rotational speed of the rotary shaft 7 is controlled at 5-150 rpm.

[0047] Both ends of the mixing chamber 1 are provided with flange surface structures for mounting and fixing with the end covers 11 on both sides. The end caps 11 on both sides of the mixing chamber 1 are provided with feed inlets and discharge ports as required, one end feeds and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com