Wave-shaped helical groove heat exchange tube and heat exchanger thereof

A technology of spiral grooves and heat exchange tubes, applied in the direction of heat exchangers, indirect heat exchangers, tubular elements, etc., can solve the problems of different diameters, achieve the effects of enhanced heat transfer, increased length, and enhanced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

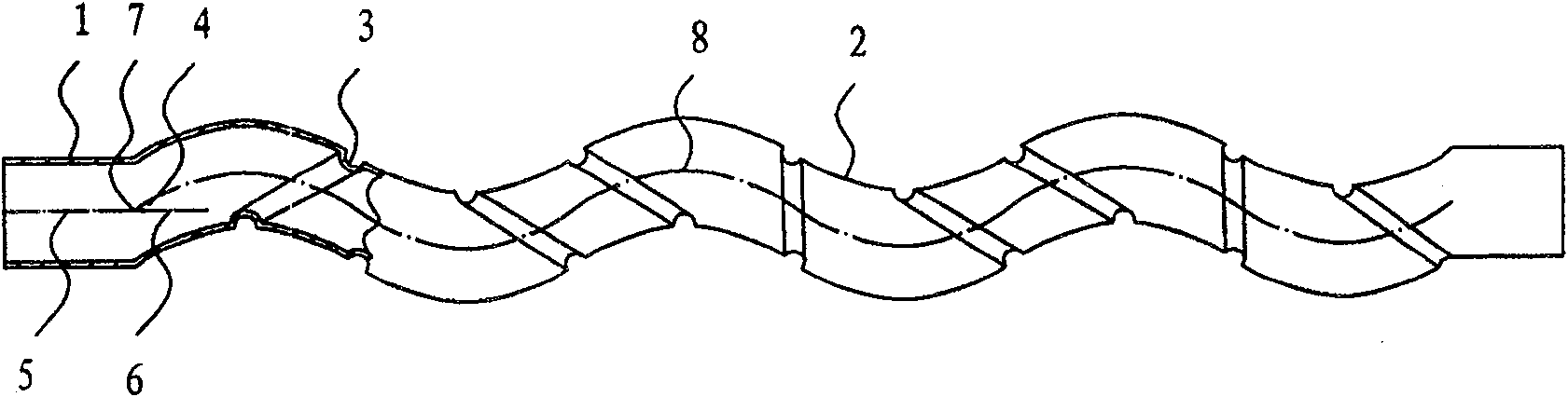

[0040] see figure 1 A wave-shaped spiral groove heat exchange tube, the two ends of the heat exchange tube body along the length direction are straight tube sections 1, the middle is a wave-shaped curved tube section 2, and the surface of the heat exchange tube is provided with a groove 3 protruding into the tube , the wave shape is that the center 7 of the section of the heat exchange tube bends up and down along the horizontal axis 6 that coincides with the axis 5 of the straight pipe section, and the maximum bending amplitude is the same; the curved arc of the wave-shaped curved pipe section 2 is straight The angle 4 of the axis 5 of the pipe section is less than 60 degrees; the test proves that when the angle 4 between the curved arc of the curved pipe section 2 and the axis 5 of the straight pipe section is greater than 60 degrees, although the heat exchange efficiency of the heat exchange tube increases, the The corresponding resistance characteristics increase faster, a...

Embodiment 2

[0046] Referring to the wave-shaped spiral groove heat exchange tube in Example 1, this embodiment is a wave-shaped spiral groove heat exchange tube in which the angle 4 between the curved arc of the wave-shaped curved pipe section 2 and the axis 5 of the straight pipe section is 30 degrees. Heat pipe.

Embodiment 3

[0048] Referring to a wave-shaped spiral groove heat exchange tube in Example 1, this embodiment is a wave-shaped spiral groove heat exchange tube in which the angle 4 between the curved arc of the wave-shaped curved pipe section 2 and the axis 5 of the straight pipe section is 45 degrees. Heat pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com