Magneto-rheological torsion damper

A torsional vibration damper and magnetorheological technology, applied in non-rotation vibration suppression, vibration suppression adjustment and other directions, can solve the problems of complex processing and limited damping force, and achieve improved adjustable damping force, large damping force, and extended design. Effects of theory and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with accompanying drawing:

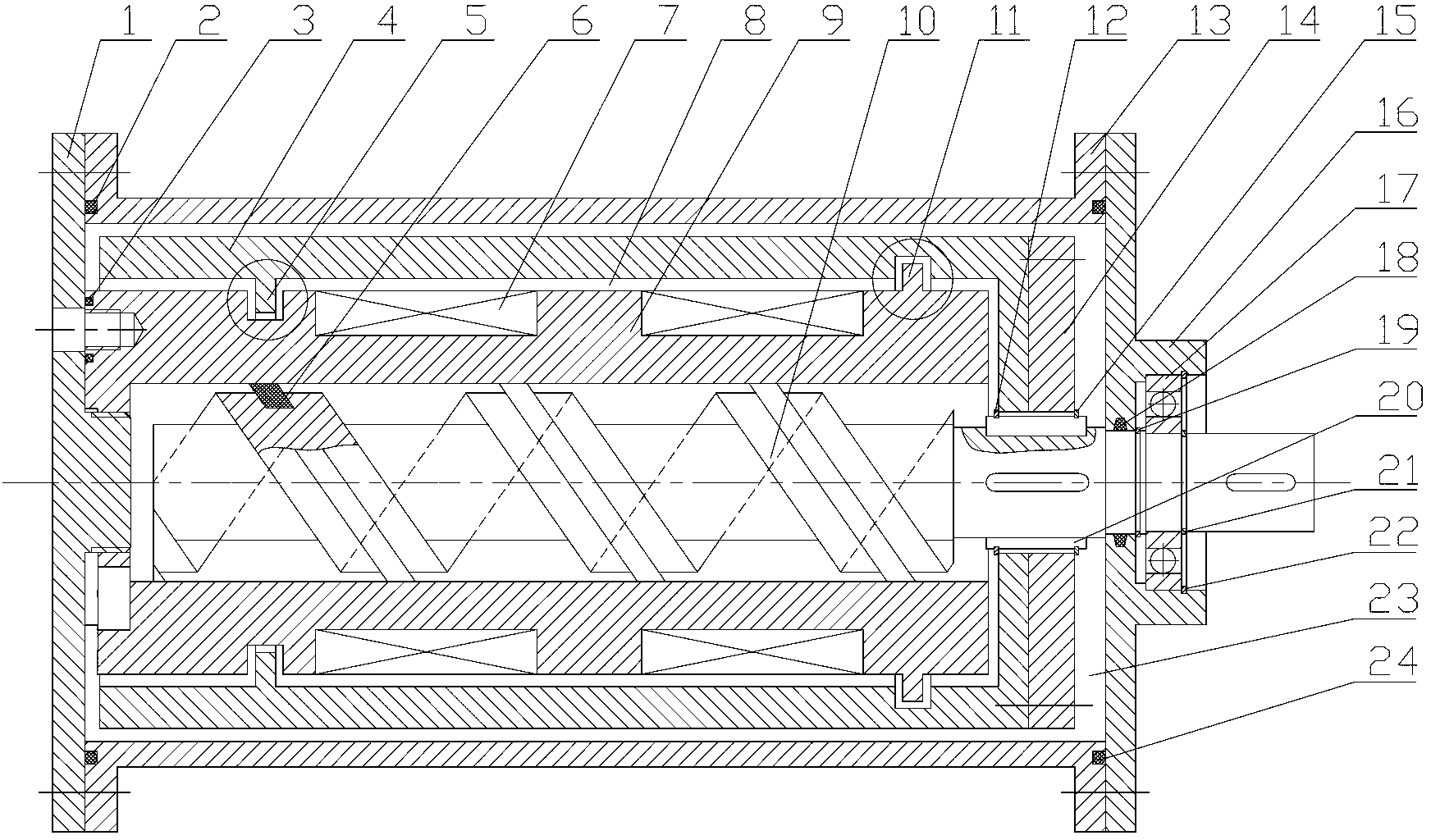

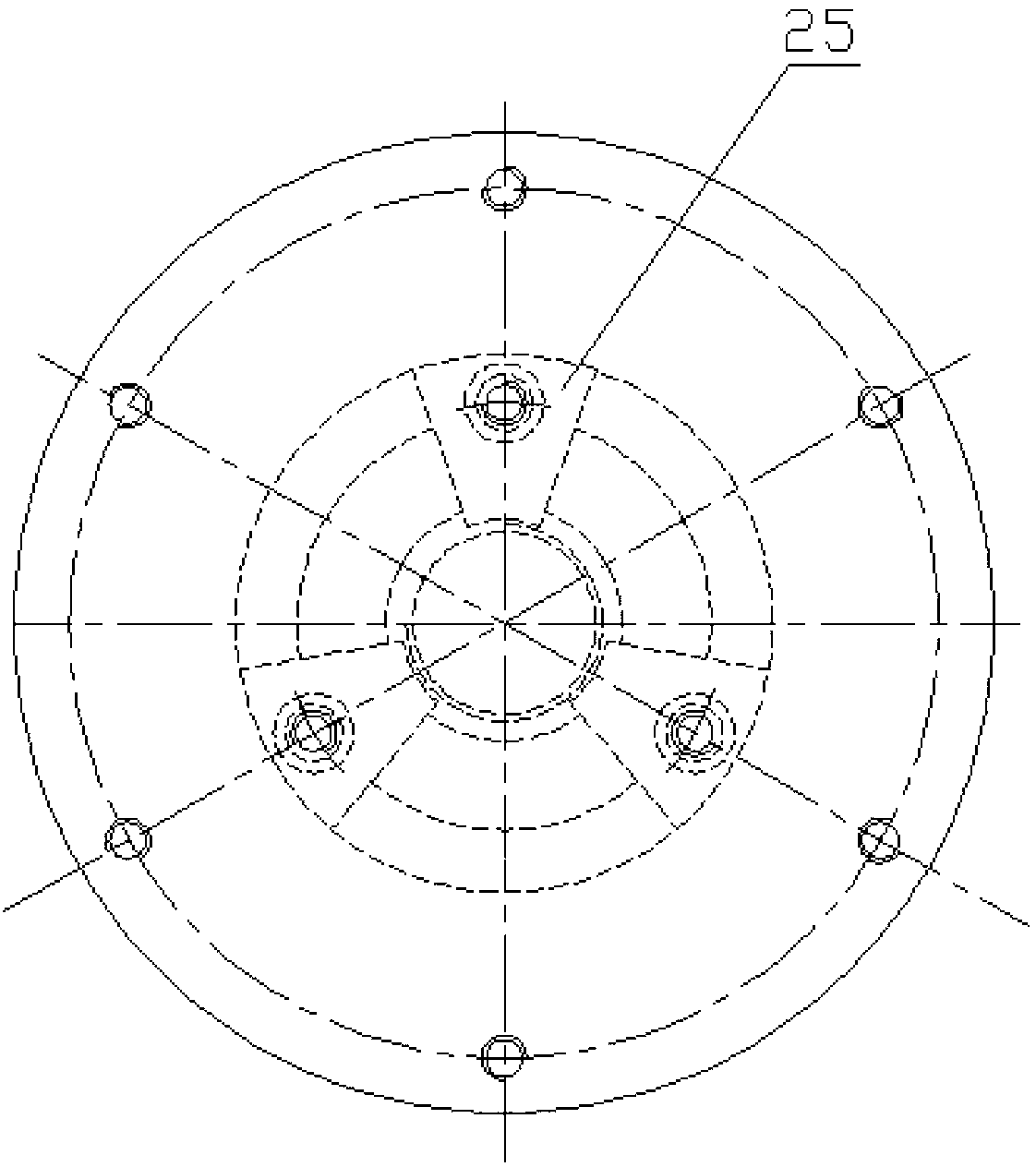

[0025] see figure 1 and figure 2 , The magnetorheological torsional shock absorber proposed by the present invention includes a rotor assembly, a stator 9 wound with an electromagnetic coil, a magnetorheological fluid 23, a sealed bearing 17 and a shock absorber cylinder. The rotor assembly is composed of a propulsion rod 10 with a helical propulsion structure, an inner sleeve 4 fixedly connected with the propulsion rod and a connecting disc 14, and the input end of the rotor assembly is connected with the load equipment through a coupling. The shock absorber cylinder is formed by connecting the outer sleeve 13 and the left and right end covers 1 and 16.

[0026] The stator 9 is firmly connected with the shock absorber cylinder, and the outer circle is wound with multi-level electromagnetic coils 7 . A propulsion rod 10 with a helical propulsion structure performs rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com