Spiral fluid dynamic pressure polishing pad and polishing method thereof

A fluid dynamic pressure, polishing pad technology, applied in grinding/polishing equipment, surface polishing machine tools, abrasives, etc., can solve the problems of difficulty in meeting the surface processing requirements of large-diameter aspherical optical components, and the limited working area of tools. The effect of improving polishing efficiency and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

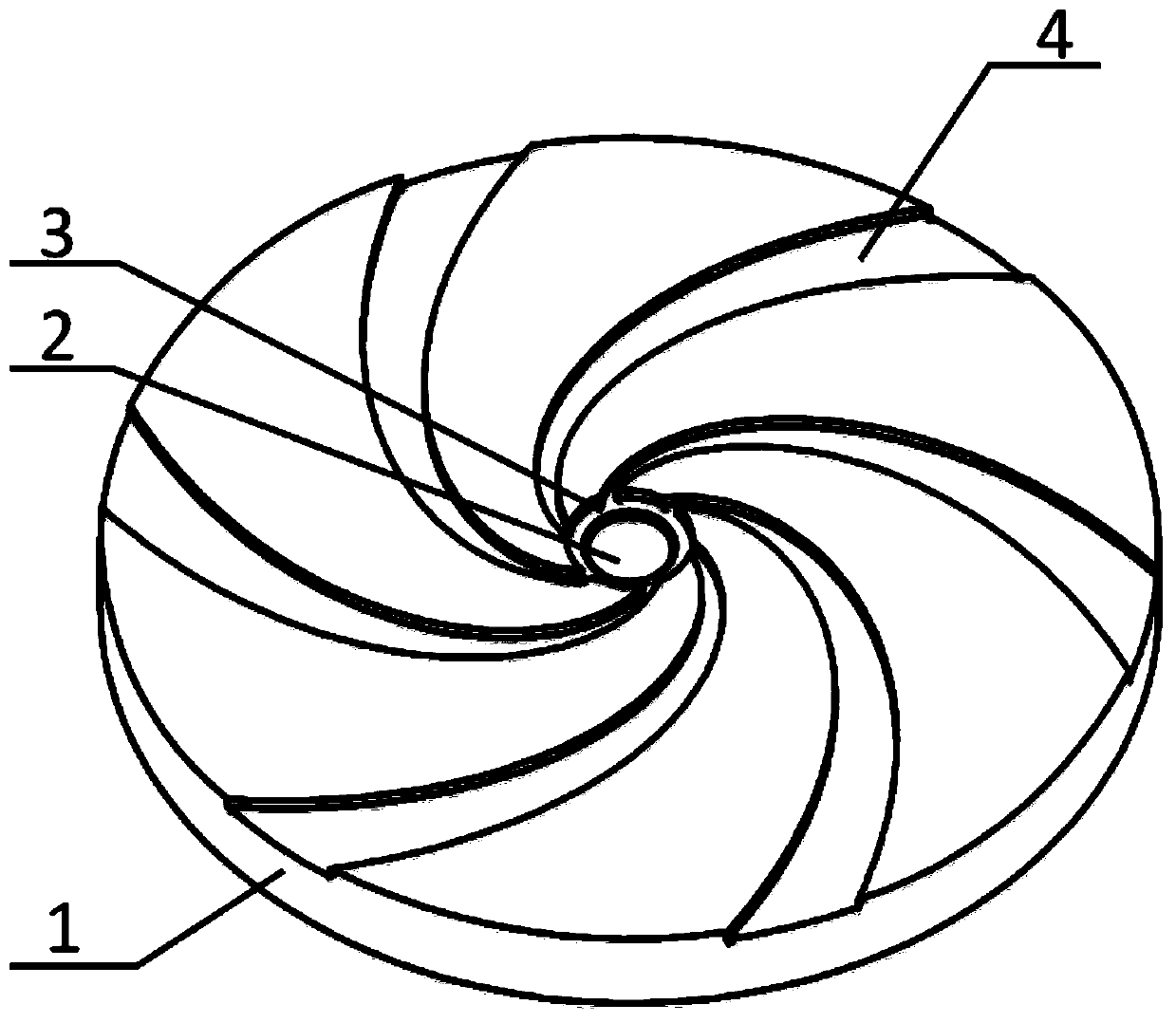

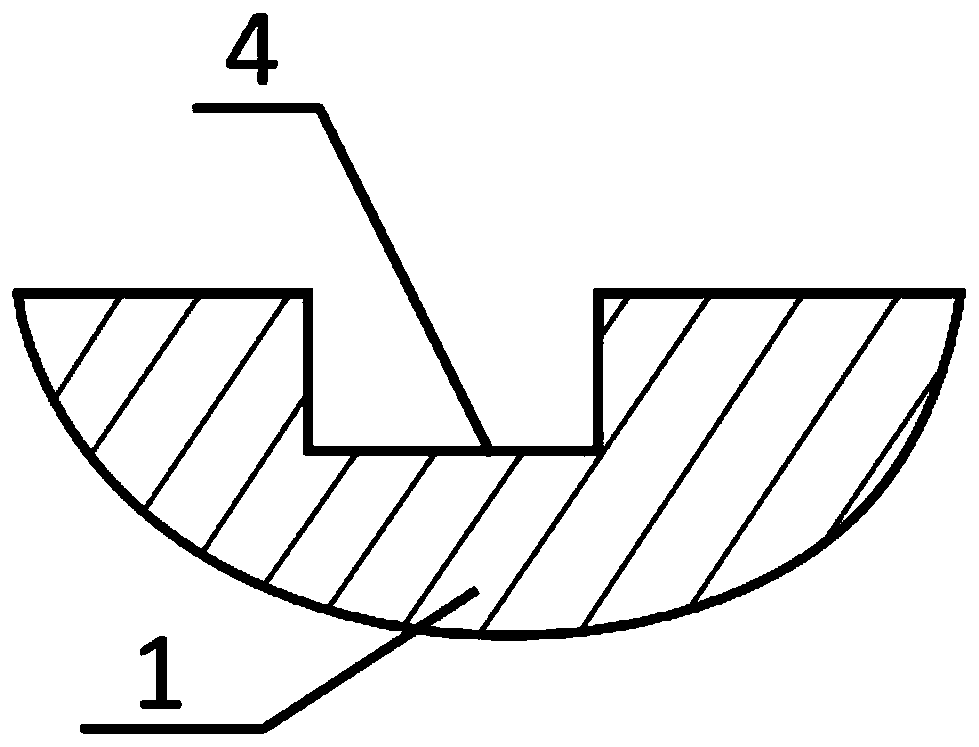

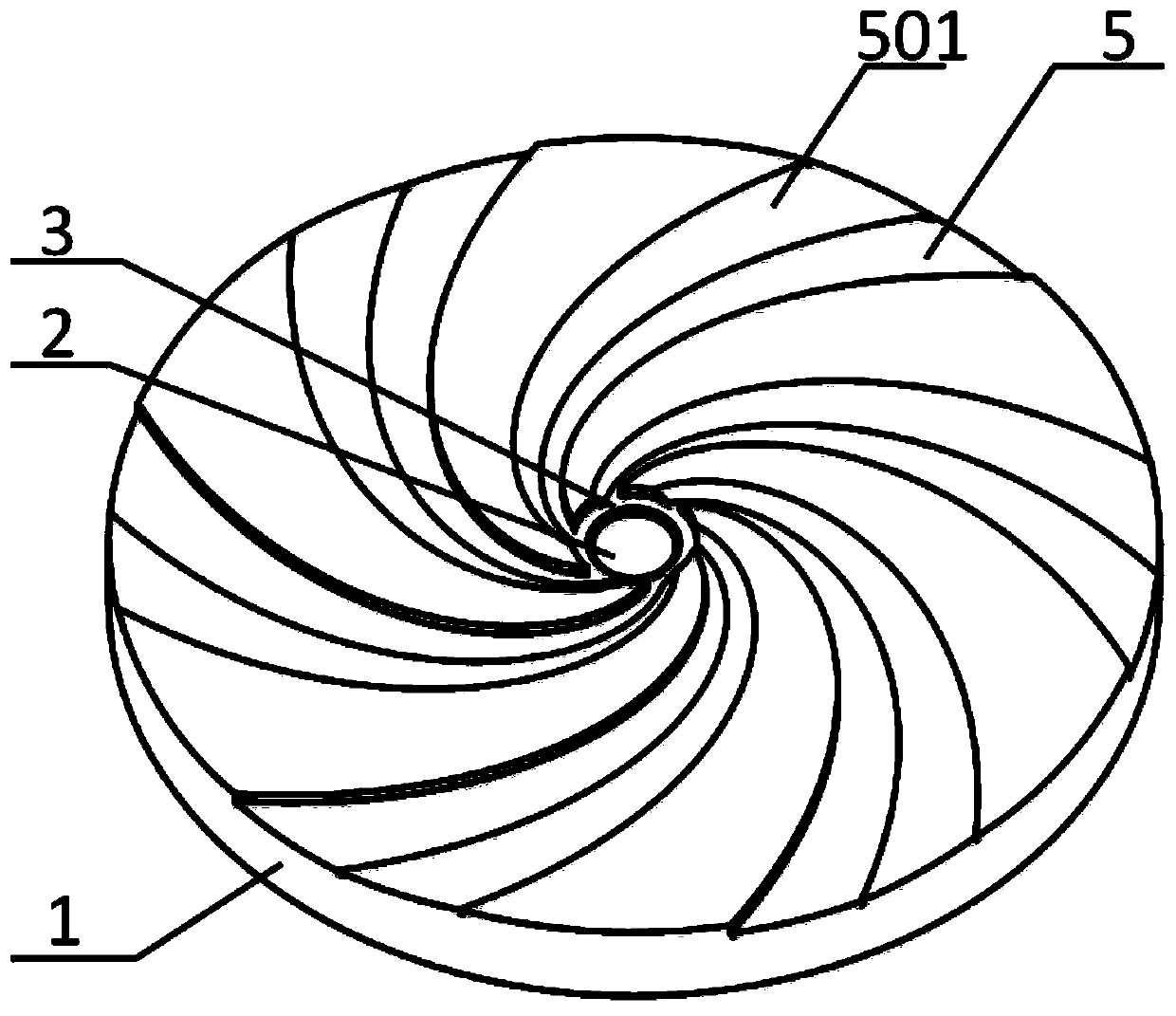

[0034] as attached Figure 1 to Figure 4As shown, a spiral hydrodynamic polishing pad includes a polishing pad base 1, and the polishing pad base 1 can be fixed on a polishing disc with a central liquid supply function by a clamp or a direct bonding method, and can be placed on the Driven by the above-mentioned polishing disc to perform high-speed rotation. The center of the polishing pad base 1 is provided with a central liquid supply hole 2 and a central liquid storage area 3, and the central liquid storage area 3 is arranged at the edge of the central liquid supply hole 2; the surface of the polishing pad base 1 Spiral dynamic pressure grooves are evenly arranged on the top, the inner end of the spiral dynamic pressure groove communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com